调节输出电压至精确水平,并为各种应用提供稳定的电源。

A

A

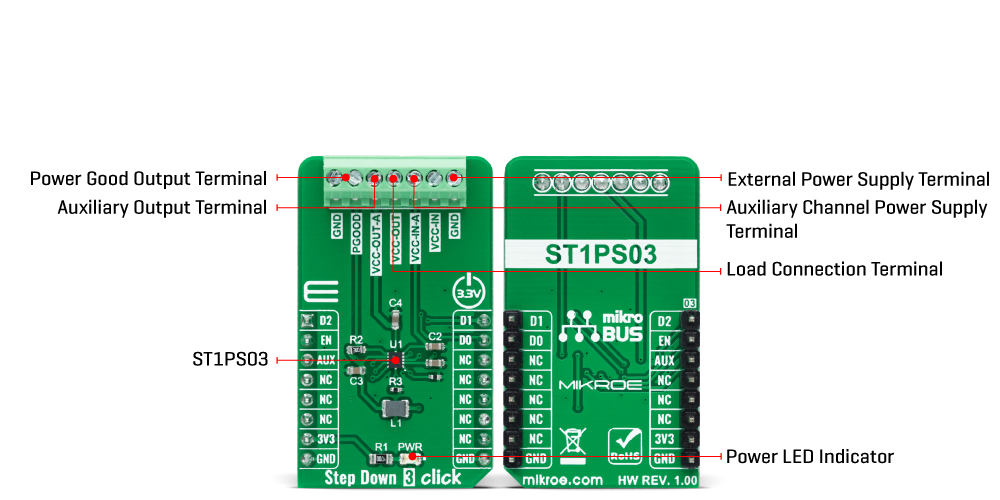

硬件概览

它是如何工作的?

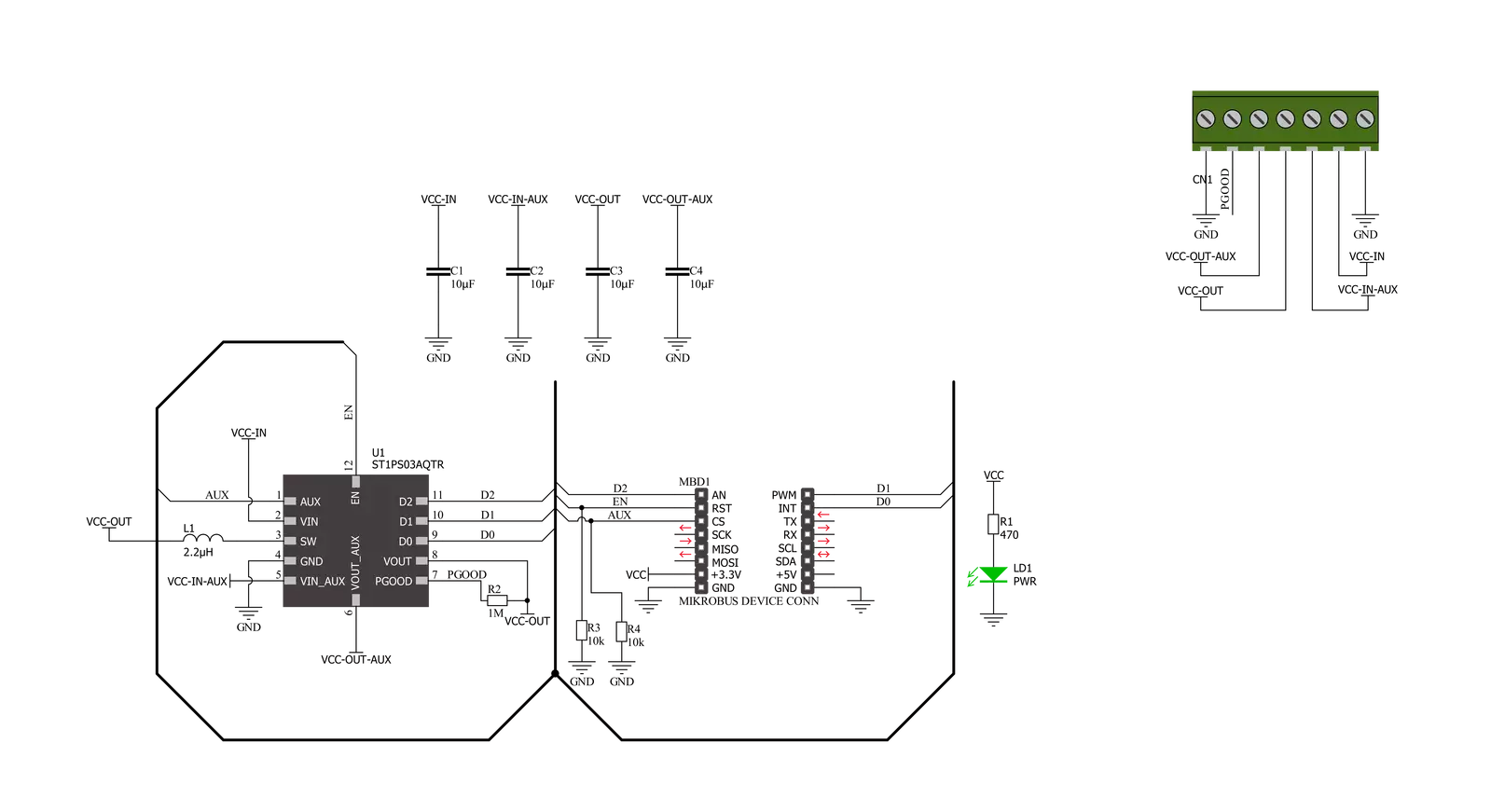

Step Down 3 Click 基于 STMicroelectronics 的 ST1PS03,这是一款超低静态电流的新一代降压转换器。ST1PS03 旨在实现小静态电流消耗,并保证即使在几微安负载下也能高效运行。它可以提供高达 400mA 的输出电流,输出电压范围为 1.6V 至 3.3V,可通过连接到 mikroBUS™ 插座的 INT、PWM 和 AN 引脚的三个数字控制引脚选择,输入电压范围为 1.8V 至 5.5V,可在 VCC-IN 端子上应用。ST1PS03 基于一个滞后比较器,感应线圈的纹波电流,在所有操作模式下保持恒定。ST1PS03 根据输入电源电压变化开关频率,以在所选线圈上保持连续纹波电流。它在 PFM(脉冲频率调制)和 PWM(脉冲宽

度调制)模式之间无缝切换,具有低纹波和良好的负载瞬态响应。在 PWM 模式(重负载)下,设备在连续导通模式下工作,最高可达 400mA 和 2MHz 的开关频率。如果输入电压接近所选的输出电压,设备进入 100% 占空比操作。在此模式下,调节器关闭,输出引脚通过内部高侧 MOSFET 直接连接到输入引脚。一旦输入电压超过 100% 占空比,设备重新开始开关并再次调节输出电压。此 Click board™ 还具有电源良好比较器,可监控所选输出电压并在适当的 PGOOD 端子上提供信息。Step Down 3 Click 使用多个 GPIO 引脚与 MCU 通信。连接到 mikroBUS™ 插座的 CS 引脚的 AUX 引

脚控制标记为 VCC-OUT-A 的辅助输出端子。当 AUX 引脚和连接到 mikroBUS™ 插座 RST 引脚的 EN 引脚都为高电平时,它提供与 VCC-IN-a 输入电压相同的调节电压水平,负载开关电路上的压降更小。VCC-OUT-A 端子允许将其他系统负载连接/断开到 ST1PS03 的输出。此 Click board™ 只能在 3.3V 逻辑电压水平下运行。在使用不同逻辑电平的 MCU 之前,板必须执行适当的逻辑电压电平转换。然而,该 Click board™ 配备了包含函数和示例代码的库,可作为进一步开发的参考。

功能概述

开发板

Flip&Click PIC32MZ 是一款紧凑型开发板,设计为一套完整的解决方案,它将 Click 板™的灵活性带给您喜爱的微控制器,使其成为实现您想法的完美入门套件。它配备了一款板载 32 位 PIC32MZ 微控制器,Microchip 的 PIC32MZ2048EFH100,四个 mikroBUS™ 插槽用于 Click 板™连接,两个 USB 连接器,LED 指示灯,按钮,调试器/程序员连接器,以及两个与 Arduino-UNO 引脚兼容的头部。得益于创

新的制造技术,它允许您快速构建具有独特功能和特性的小工具。Flip&Click PIC32MZ 开发套件的每个部分都包含了使同一板块运行最高效的必要组件。此外,还可以选择 Flip&Click PIC32MZ 的编程方式,使用 chipKIT 引导程序(Arduino 风格的开发环境)或我们的 USB HID 引导程序,使用 mikroC、mikroBasic 和 mikroPascal for PIC32。该套件包括一个通过 USB 类型-C(USB-C)连接器的干净且调

节过的电源供应模块。所有 mikroBUS™ 本身支持的 通信方法都在这块板上,包括已经建立良好的 mikroBUS™ 插槽、用户可配置的按钮和 LED 指示灯。Flip&Click PIC32MZ 开发套件允许您在几分钟内创建新的应用程序。它由 Mikroe 软件工具原生支持,得益于大量不同的 Click 板™(超过一千块板),其数量每天都在增长,它涵盖了原型制作的许多方面。

微控制器概述

MCU卡片 / MCU

建筑

PIC32

MCU 内存 (KB)

2048

硅供应商

Microchip

引脚数

100

RAM (字节)

524288

使用的MCU引脚

mikroBUS™映射器

“仔细看看!”

Click board™ 原理图

一步一步来

项目组装

实时跟踪您的结果

应用程序输出

1. 应用程序输出 - 在调试模式下,“应用程序输出”窗口支持实时数据监控,直接提供执行结果的可视化。请按照提供的教程正确配置环境,以确保数据正确显示。

2. UART 终端 - 使用UART Terminal通过USB to UART converter监视数据传输,实现Click board™与开发系统之间的直接通信。请根据项目需求配置波特率和其他串行设置,以确保正常运行。有关分步设置说明,请参考提供的教程。

3. Plot 输出 - Plot功能提供了一种强大的方式来可视化实时传感器数据,使趋势分析、调试和多个数据点的对比变得更加直观。要正确设置,请按照提供的教程,其中包含使用Plot功能显示Click board™读数的分步示例。在代码中使用Plot功能时,请使用以下函数:plot(insert_graph_name, variable_name);。这是一个通用格式,用户需要将“insert_graph_name”替换为实际图表名称,并将“variable_name”替换为要显示的参数。

软件支持

库描述

该库包含 Step Down 3 Click 驱动程序的 API。

关键功能:

stepdown3_enable_device- 此函数通过将 AUX 引脚设置为高逻辑状态来启用辅助输出(VOUT_AUX)。stepdown3_enable_aux_output- 此函数通过将 AUX 引脚设置为低逻辑状态来禁用辅助输出(VOUT_AUX)。stepdown3_set_output_voltage- 此函数通过将 D2、D1 和 D0 引脚设置为所需状态来设置输出电压。

开源

代码示例

完整的应用程序代码和一个现成的项目可以通过NECTO Studio包管理器直接安装到NECTO Studio。 应用程序代码也可以在MIKROE的GitHub账户中找到。

/*!

* @file main.c

* @brief Step Down 3 Click Example.

*

* # Description

* This example demonstrates the use of Step Down 3 click board by

* iterating through the entire output voltage range.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and logger, then enables the click board and disables

* the auxiliary output.

*

* ## Application Task

* Changes the output voltage every 3 seconds and displays the set voltage output value

* on the USB UART.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "stepdown3.h"

static stepdown3_t stepdown3; /**< Step Down 3 Click driver object. */

static log_t logger; /**< Logger object. */

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

stepdown3_cfg_t stepdown3_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

stepdown3_cfg_setup( &stepdown3_cfg );

STEPDOWN3_MAP_MIKROBUS( stepdown3_cfg, MIKROBUS_1 );

if ( DIGITAL_OUT_UNSUPPORTED_PIN == stepdown3_init( &stepdown3, &stepdown3_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

stepdown3_enable_device ( &stepdown3 );

stepdown3_disable_aux_output ( &stepdown3 );

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

static uint8_t vout = STEPDOWN3_OUT_VOLTAGE_1V6;

stepdown3_set_output_voltage ( &stepdown3, vout );

switch ( vout )

{

case STEPDOWN3_OUT_VOLTAGE_1V6:

{

log_printf( &logger, " Output voltage: 1.6 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_1V8:

{

log_printf( &logger, " Output voltage: 1.8 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_2V1:

{

log_printf( &logger, " Output voltage: 2.1 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_2V5:

{

log_printf( &logger, " Output voltage: 2.5 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_2V7:

{

log_printf( &logger, " Output voltage: 2.7 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_2V8:

{

log_printf( &logger, " Output voltage: 2.8 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_3V0:

{

log_printf( &logger, " Output voltage: 3.0 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_3V3:

{

log_printf( &logger, " Output voltage: 3.3 V\r\n\n" );

break;

}

}

if ( ++vout > STEPDOWN3_OUT_VOLTAGE_3V3 )

{

vout = STEPDOWN3_OUT_VOLTAGE_1V6;

}

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

/*!

* @file main.c

* @brief Step Down 3 Click Example.

*

* # Description

* This example demonstrates the use of Step Down 3 click board by

* iterating through the entire output voltage range.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and logger, then enables the click board and disables

* the auxiliary output.

*

* ## Application Task

* Changes the output voltage every 3 seconds and displays the set voltage output value

* on the USB UART.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "stepdown3.h"

static stepdown3_t stepdown3; /**< Step Down 3 Click driver object. */

static log_t logger; /**< Logger object. */

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

stepdown3_cfg_t stepdown3_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

stepdown3_cfg_setup( &stepdown3_cfg );

STEPDOWN3_MAP_MIKROBUS( stepdown3_cfg, MIKROBUS_1 );

if ( DIGITAL_OUT_UNSUPPORTED_PIN == stepdown3_init( &stepdown3, &stepdown3_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

stepdown3_enable_device ( &stepdown3 );

stepdown3_disable_aux_output ( &stepdown3 );

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

static uint8_t vout = STEPDOWN3_OUT_VOLTAGE_1V6;

stepdown3_set_output_voltage ( &stepdown3, vout );

switch ( vout )

{

case STEPDOWN3_OUT_VOLTAGE_1V6:

{

log_printf( &logger, " Output voltage: 1.6 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_1V8:

{

log_printf( &logger, " Output voltage: 1.8 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_2V1:

{

log_printf( &logger, " Output voltage: 2.1 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_2V5:

{

log_printf( &logger, " Output voltage: 2.5 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_2V7:

{

log_printf( &logger, " Output voltage: 2.7 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_2V8:

{

log_printf( &logger, " Output voltage: 2.8 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_3V0:

{

log_printf( &logger, " Output voltage: 3.0 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_3V3:

{

log_printf( &logger, " Output voltage: 3.3 V\r\n\n" );

break;

}

}

if ( ++vout > STEPDOWN3_OUT_VOLTAGE_3V3 )

{

vout = STEPDOWN3_OUT_VOLTAGE_1V6;

}

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

/*!

* @file main.c

* @brief Step Down 3 Click Example.

*

* # Description

* This example demonstrates the use of Step Down 3 click board by

* iterating through the entire output voltage range.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and logger, then enables the click board and disables

* the auxiliary output.

*

* ## Application Task

* Changes the output voltage every 3 seconds and displays the set voltage output value

* on the USB UART.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "stepdown3.h"

static stepdown3_t stepdown3; /**< Step Down 3 Click driver object. */

static log_t logger; /**< Logger object. */

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

stepdown3_cfg_t stepdown3_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

stepdown3_cfg_setup( &stepdown3_cfg );

STEPDOWN3_MAP_MIKROBUS( stepdown3_cfg, MIKROBUS_1 );

if ( DIGITAL_OUT_UNSUPPORTED_PIN == stepdown3_init( &stepdown3, &stepdown3_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

stepdown3_enable_device ( &stepdown3 );

stepdown3_disable_aux_output ( &stepdown3 );

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

static uint8_t vout = STEPDOWN3_OUT_VOLTAGE_1V6;

stepdown3_set_output_voltage ( &stepdown3, vout );

switch ( vout )

{

case STEPDOWN3_OUT_VOLTAGE_1V6:

{

log_printf( &logger, " Output voltage: 1.6 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_1V8:

{

log_printf( &logger, " Output voltage: 1.8 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_2V1:

{

log_printf( &logger, " Output voltage: 2.1 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_2V5:

{

log_printf( &logger, " Output voltage: 2.5 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_2V7:

{

log_printf( &logger, " Output voltage: 2.7 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_2V8:

{

log_printf( &logger, " Output voltage: 2.8 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_3V0:

{

log_printf( &logger, " Output voltage: 3.0 V\r\n\n" );

break;

}

case STEPDOWN3_OUT_VOLTAGE_3V3:

{

log_printf( &logger, " Output voltage: 3.3 V\r\n\n" );

break;

}

}

if ( ++vout > STEPDOWN3_OUT_VOLTAGE_3V3 )

{

vout = STEPDOWN3_OUT_VOLTAGE_1V6;

}

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END