监测室内湿度水平和空气质量,以确保更健康的生活和工作环境,降低呼吸问题和过敏的风险。

A

A

硬件概览

它是如何工作的?

Environment 4 Click 基于 SHT41A-AD1B,这是第4代高精度 SHT 相对湿度和温度传感器,结合了 Sensirion 的 SGP41 基于 MOx 的气体传感器。基于 Sensirion 的成熟 CMOSens® 技术和在湿度传感方面的长期经验,SHT41A-AD1B 确保了最高的精度。它覆盖了从 0 到 100%RH 和 -40°C 到 125°C 的扩展工作湿度和温度范围,精度分别为 ±2%RH 和 ±0.3°C。SHT41A-AD1B 还专门用于汽车应用,满足诸如 85°C/85%RH 加速寿命测试和 AEC Q100 资格认证等可靠性要求。SHT41A-AD1B 在推荐的平均温度和湿度范围 5-60°C 和 20-80%RH 内工作效果最佳。长时间暴露在推荐正常范围之外的条件

下,尤其是在高相对湿度下,可能会暂时偏移 RH 信号。回到推荐的平均温度和湿度范围后,传感器将恢复到规格范围内。此组合解决方案的补充部分是 SGP41,这是 Sensirion 新的基于 MOx 的气体传感器,可提供一个 VOC 和一个基于 NOx 的室内空气质量信号。正如所述,SGP41 提供两个对室内环境中常见的 VOC 以及氧化气体(如 NOx 或 O3)敏感的原始数字信号。这意味着该板可以持续监测 VOC 和 NOx 情况,包括人类无法感知的潜在有害事件。原始信号与感应材料电阻的对数成正比,并由 Sensirion 强大的气体指数算法处理。该算法可自动触发空气处理设备清除室内气体污染物,而无需手动用户干

预。Environment 4 Click 使用标准 I2C 2 线接口与 MCU 通信。由于这两个传感器都只需要 3.3V 的逻辑电压水平运行,因此该 Click board™ 还配备了德州仪器的 PCA9306 电压电平转换器。I2C 接口总线线路被路由到双向电压电平转换器,使得该 Click board™ 能够与 3.3V 和 5V 的 MCU 正常工作。该 Click board™ 可以在 3.3V 或 5V 逻辑电压水平下运行,通过 VCC SEL 跳线选择。这样,3.3V 和 5V 的 MCU 都可以正确使用通信线路。此外,该 Click board™ 配备了包含易于使用的函数和示例代码的库,可作为进一步开发的参考。

功能概述

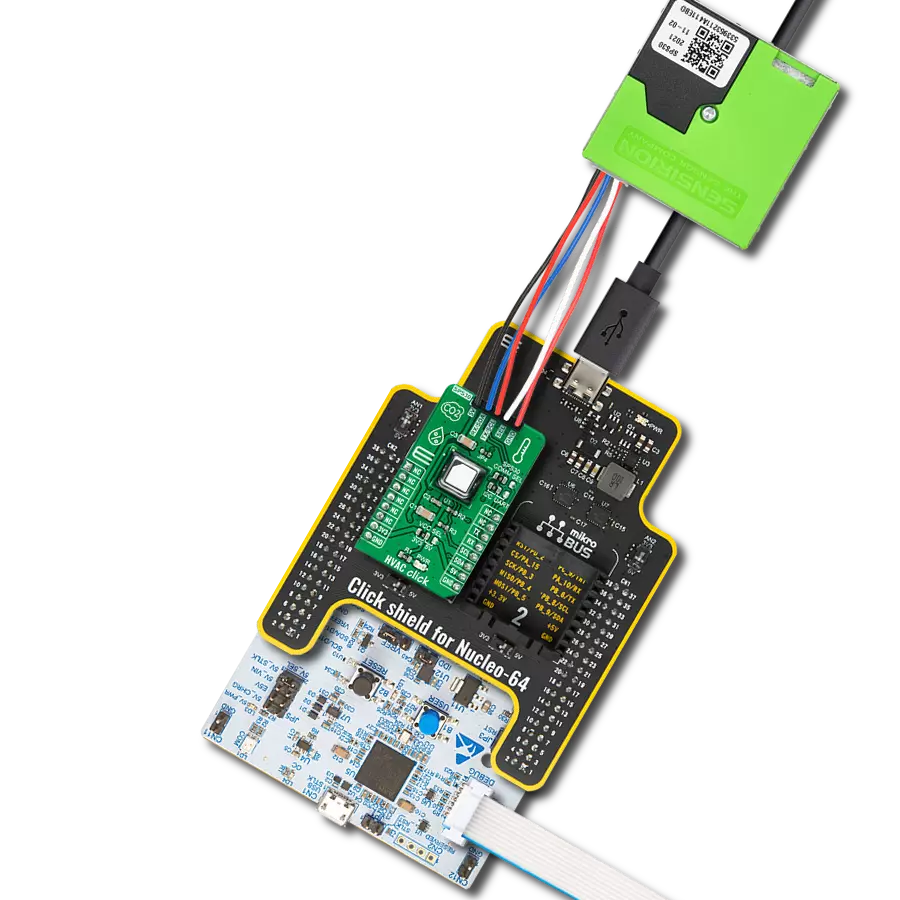

开发板

Nucleo 32开发板搭载STM32F031K6 MCU,提供了一种经济且灵活的平台,适用于使用32引脚封装的STM32微控制器进行实验。该开发板具有Arduino™ Nano连接性,便于通过专用扩展板进行功能扩展,并且支持mbed,使其能够无缝集成在线资源。板载集成

ST-LINK/V2-1调试器/编程器,支持通过USB重新枚举,提供三种接口:虚拟串口(Virtual Com port)、大容量存储和调试端口。该开发板的电源供应灵活,可通过USB VBUS或外部电源供电。此外,还配备了三个LED指示灯(LD1用于USB通信,LD2用于电源

指示,LD3为用户可控LED)和一个复位按钮。STM32 Nucleo-32开发板支持多种集成开发环境(IDEs),如IAR™、Keil®和基于GCC的IDE(如AC6 SW4STM32),使其成为开发人员的多功能工具。

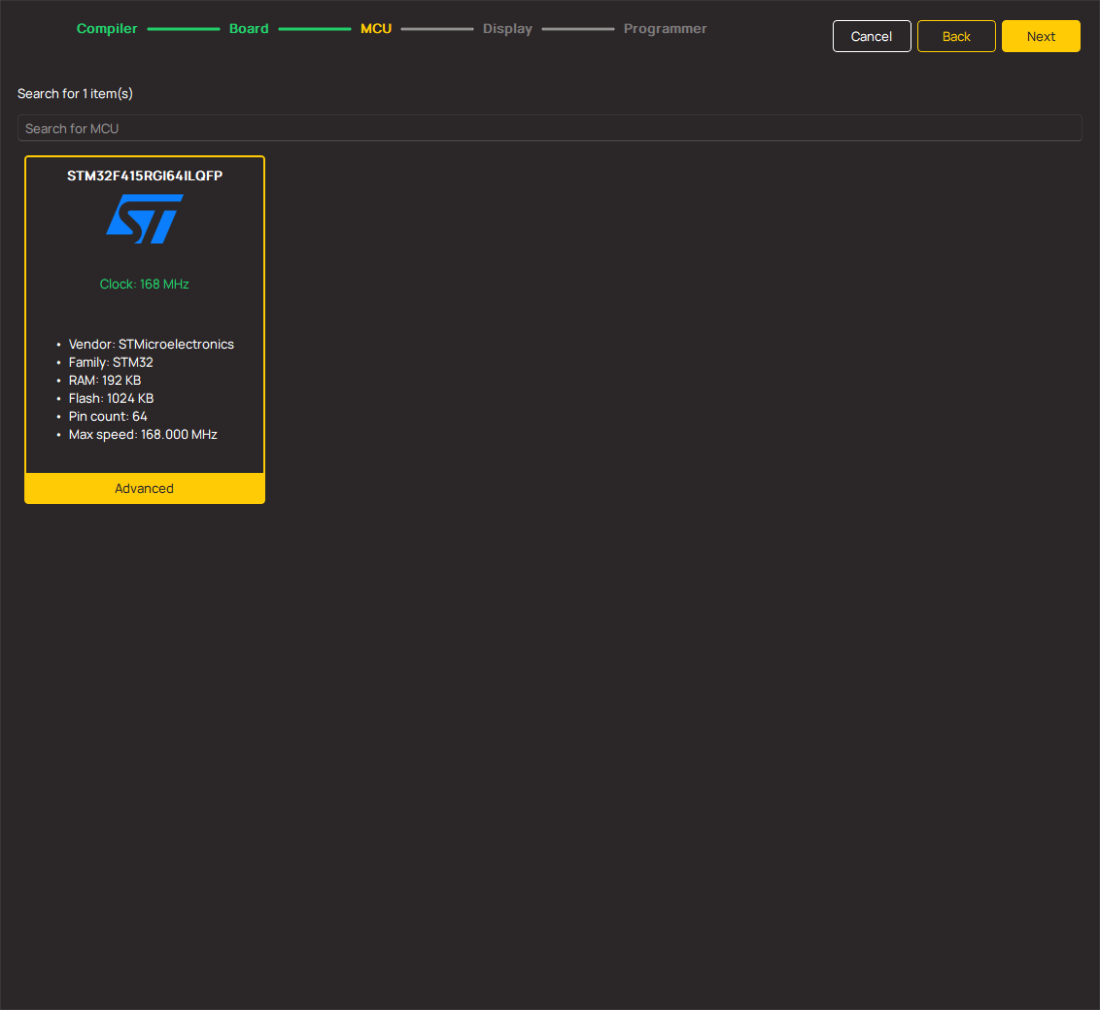

微控制器概述

MCU卡片 / MCU

建筑

ARM Cortex-M0

MCU 内存 (KB)

32

硅供应商

STMicroelectronics

引脚数

32

RAM (字节)

4096

你完善了我!

配件

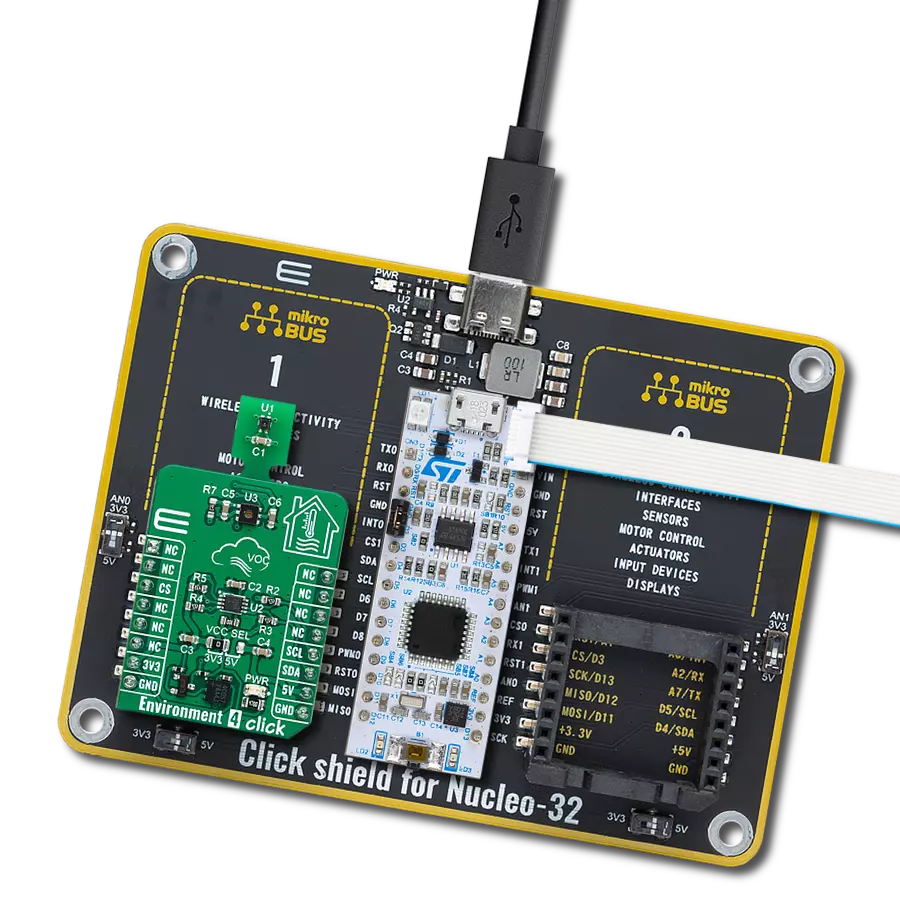

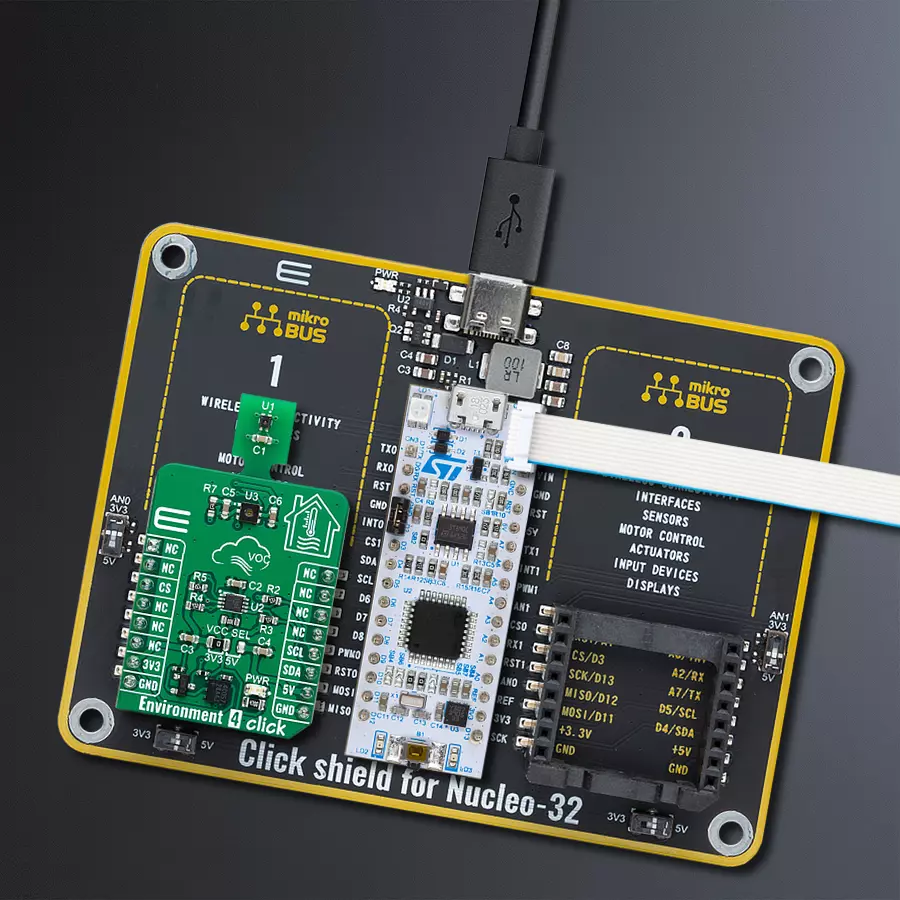

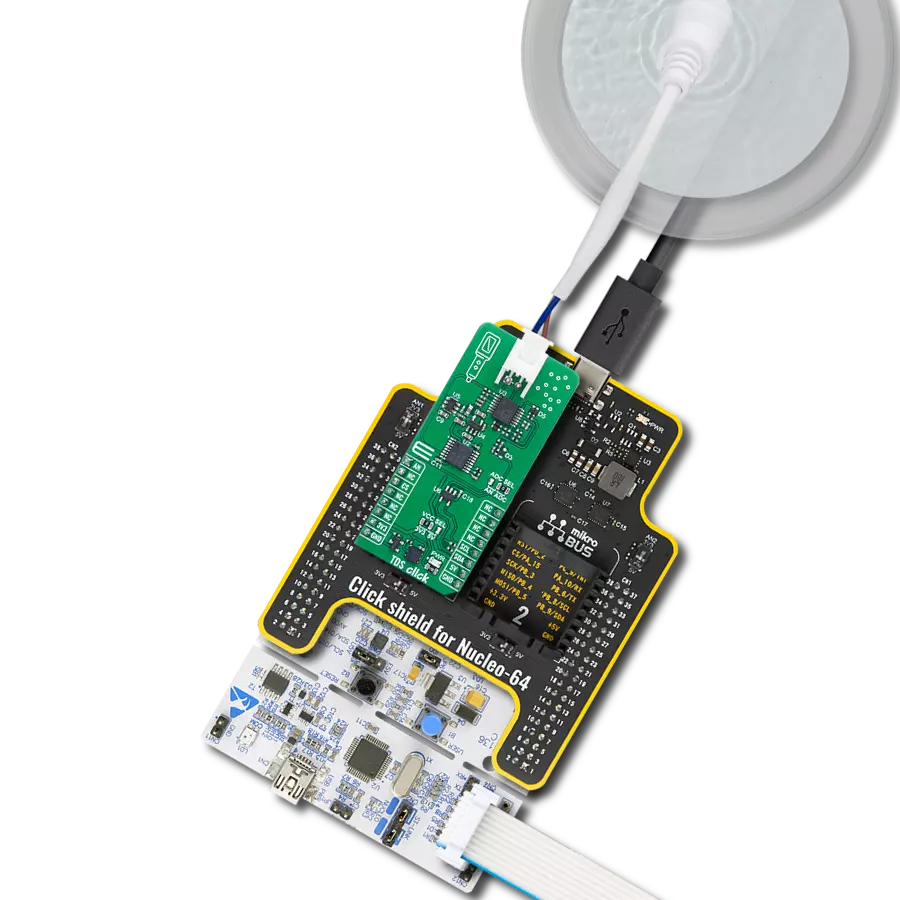

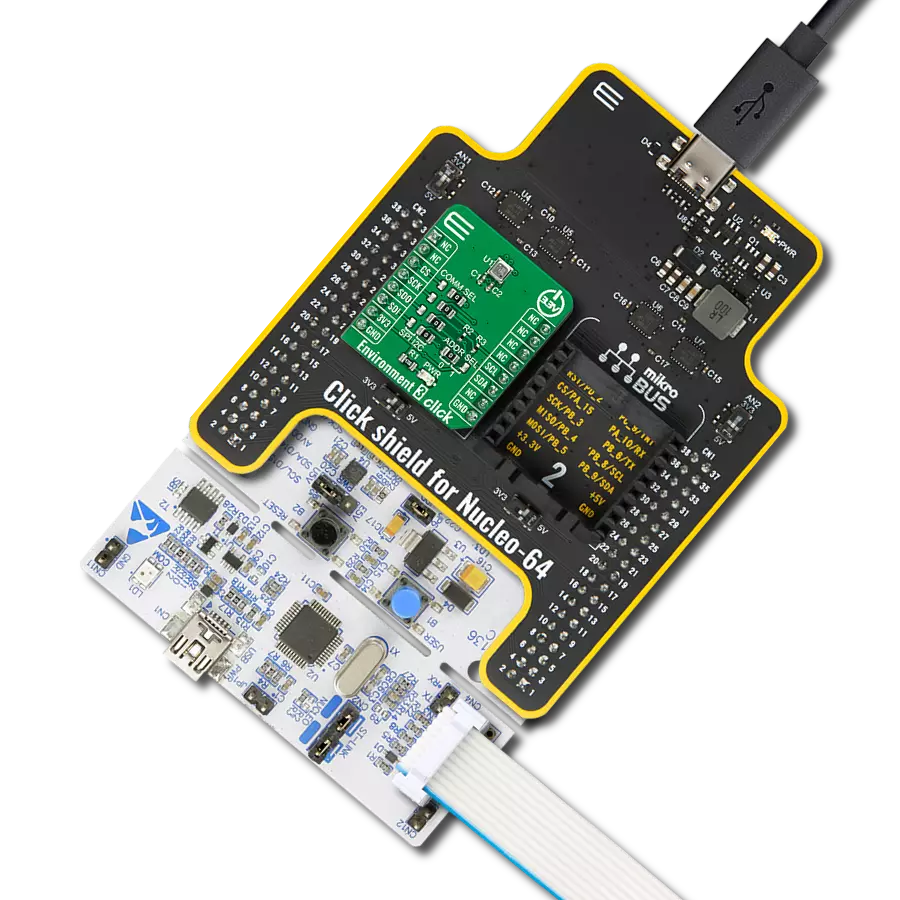

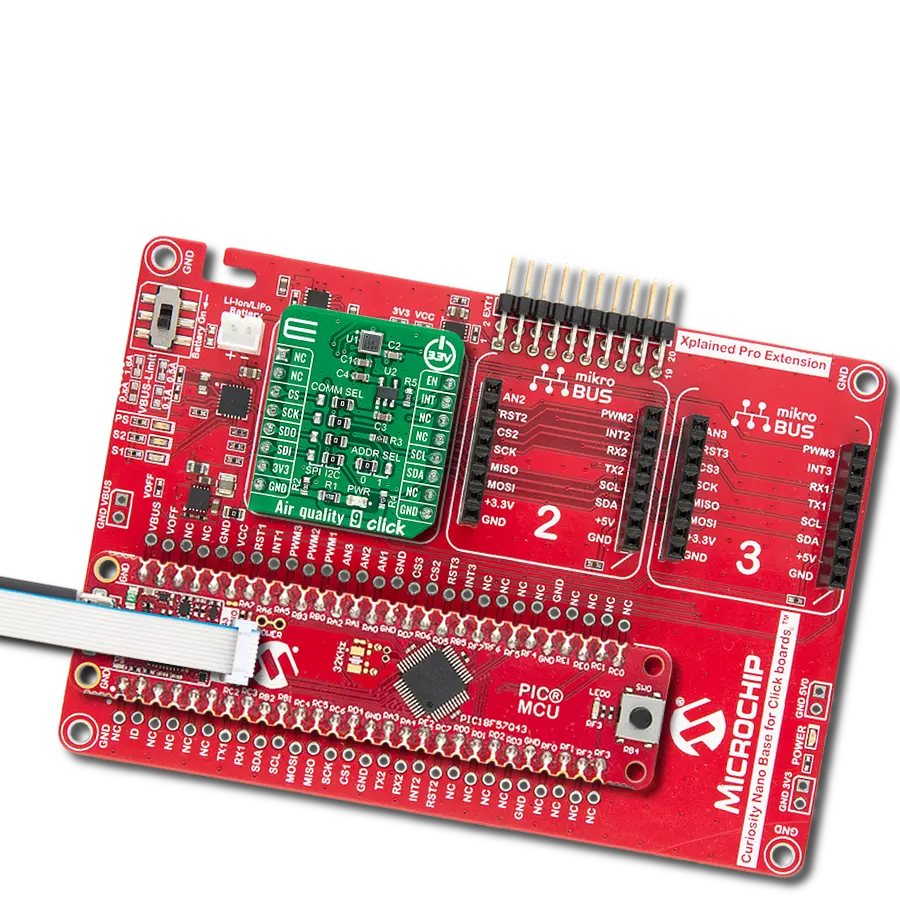

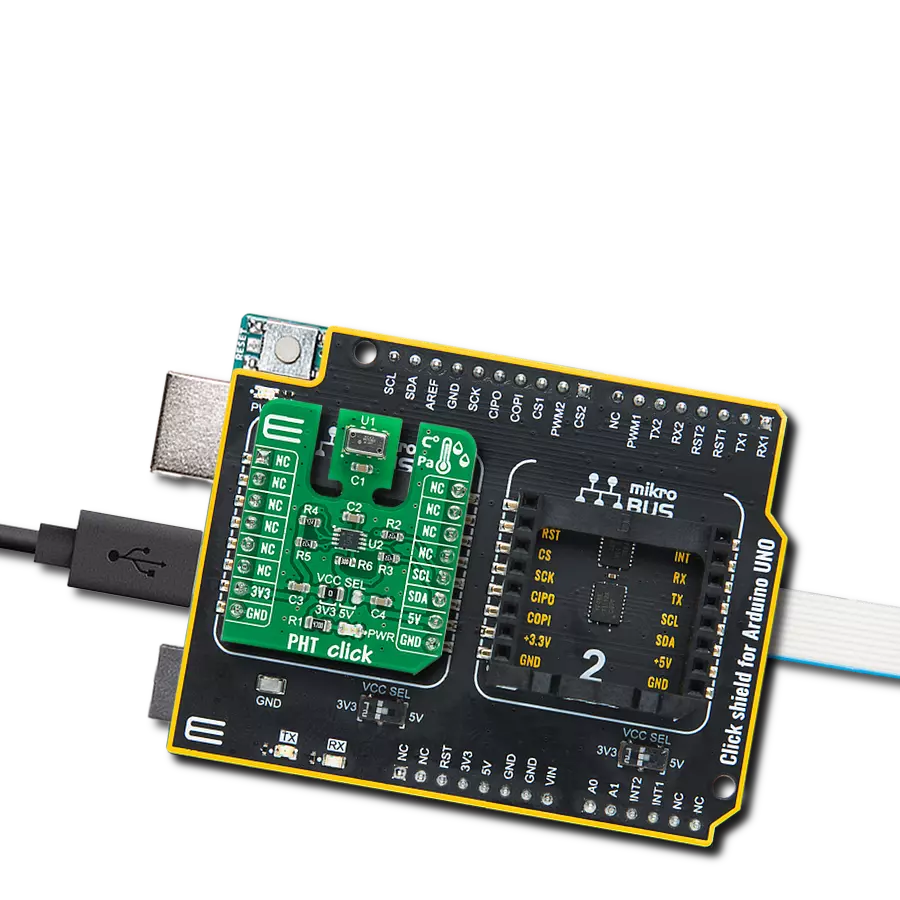

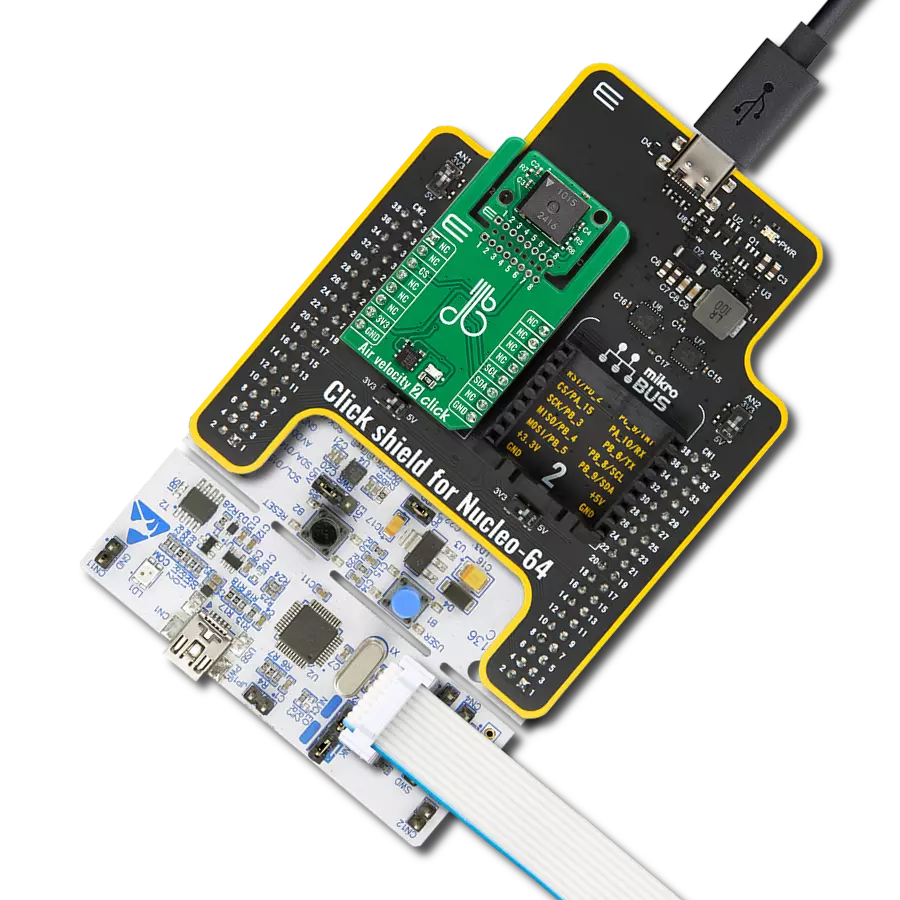

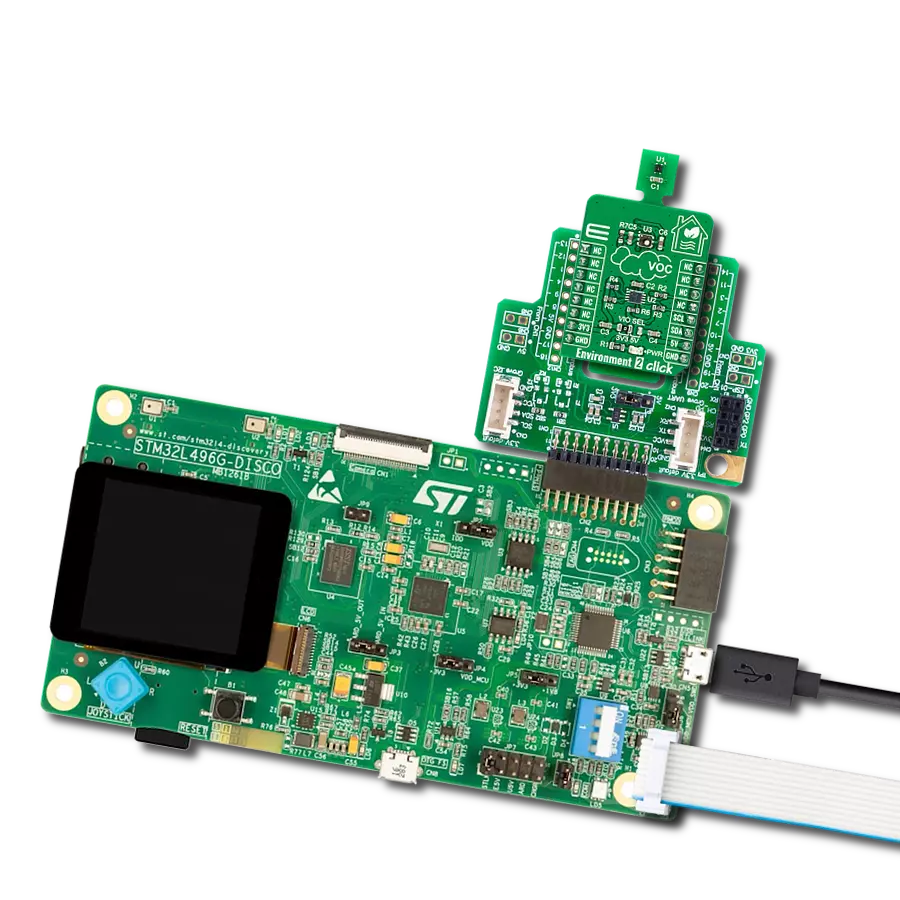

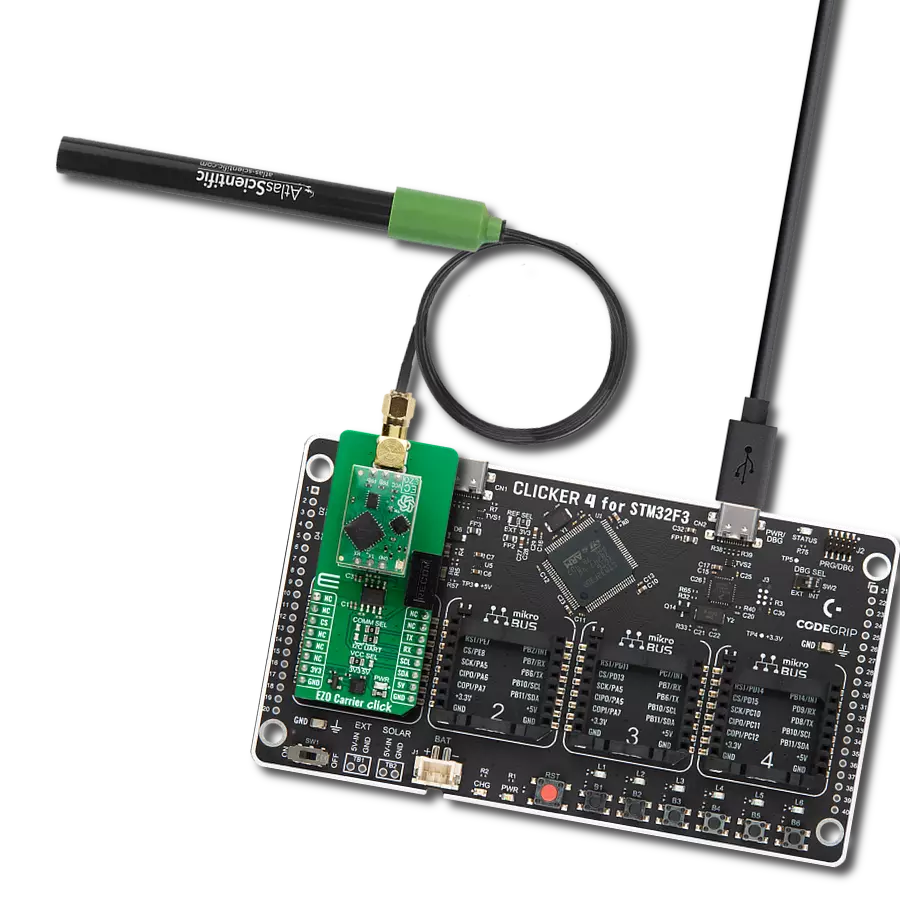

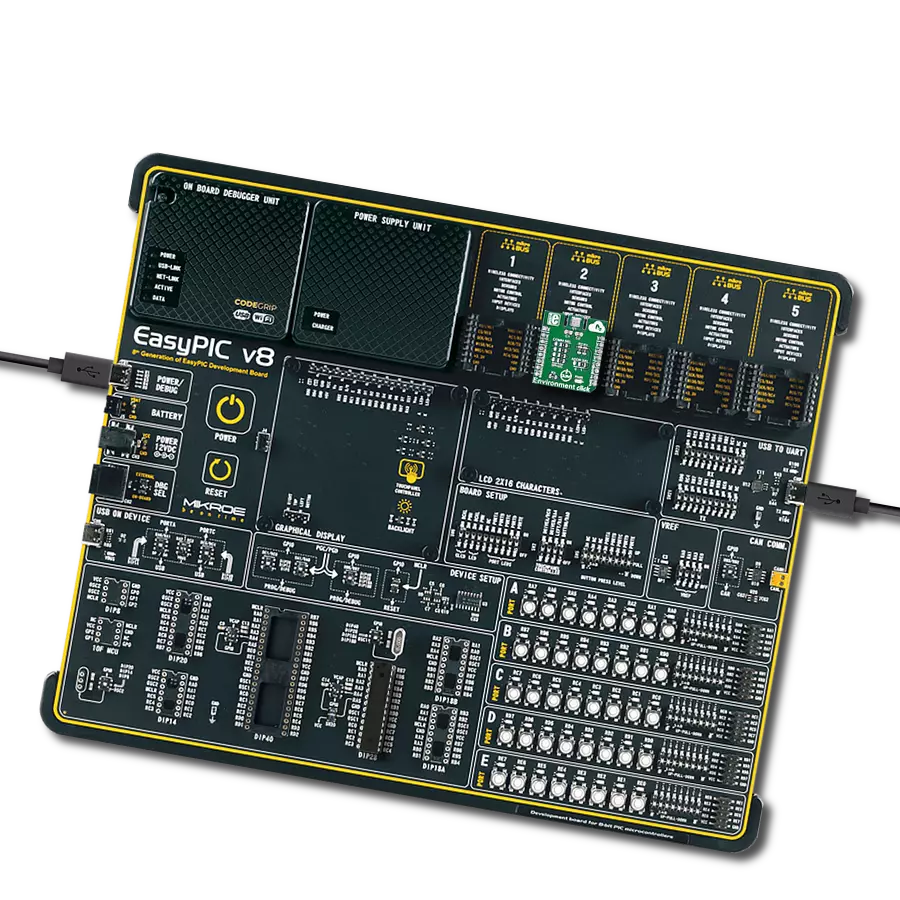

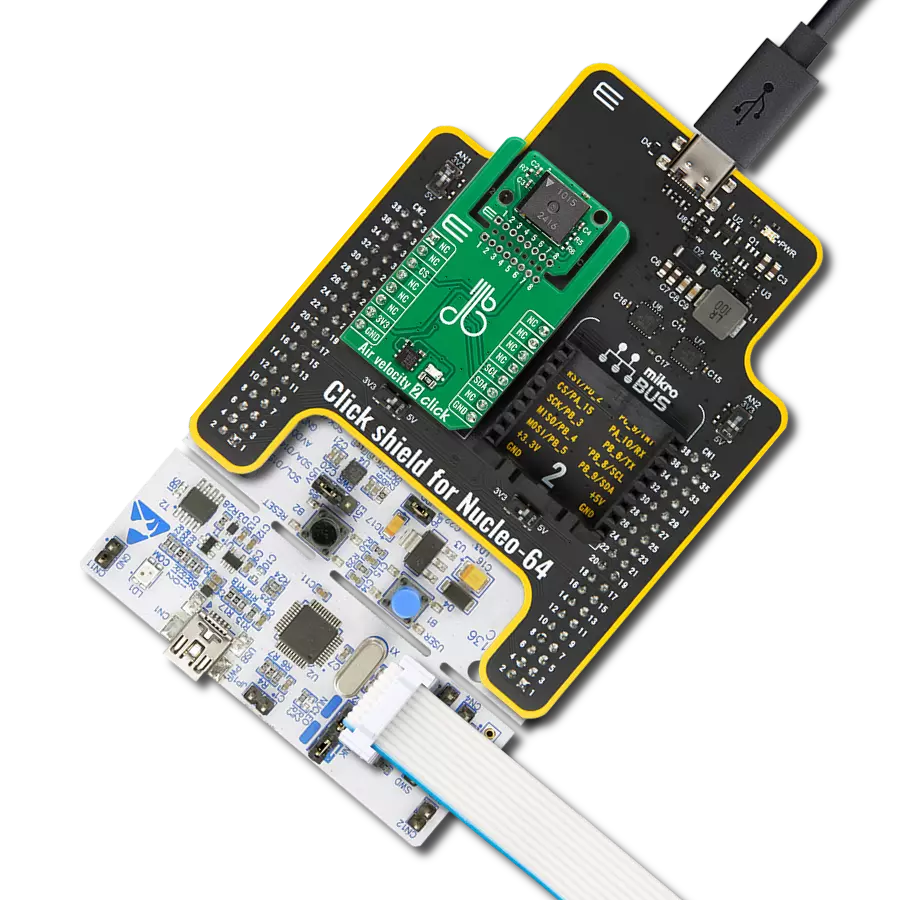

Click Shield for Nucleo-32是扩展您的开发板功能的理想选择,专为STM32 Nucleo-32引脚布局设计。Click Shield for Nucleo-32提供了两个mikroBUS™插座,可以添加来自我们不断增长的Click板™系列中的任何功能。从传感器和WiFi收发器到电机控制和音频放大器,我们应有尽有。Click Shield for Nucleo-32与STM32 Nucleo-32开发板兼容,为用户提供了一种经济且灵活的方式,使用任何STM32微控制器快速创建原型,并尝试各种性能、功耗和功能的组合。STM32 Nucleo-32开发板无需任何独立的探针,因为它集成了ST-LINK/V2-1调试器/编程器,并随附STM32全面的软件HAL库和各种打包的软件示例。这个开发平台为用户提供了一种简便且通用的方式,将STM32 Nucleo-32兼容开发板与他们喜欢的Click板™结合,应用于即将开展的项目中。

使用的MCU引脚

mikroBUS™映射器

“仔细看看!”

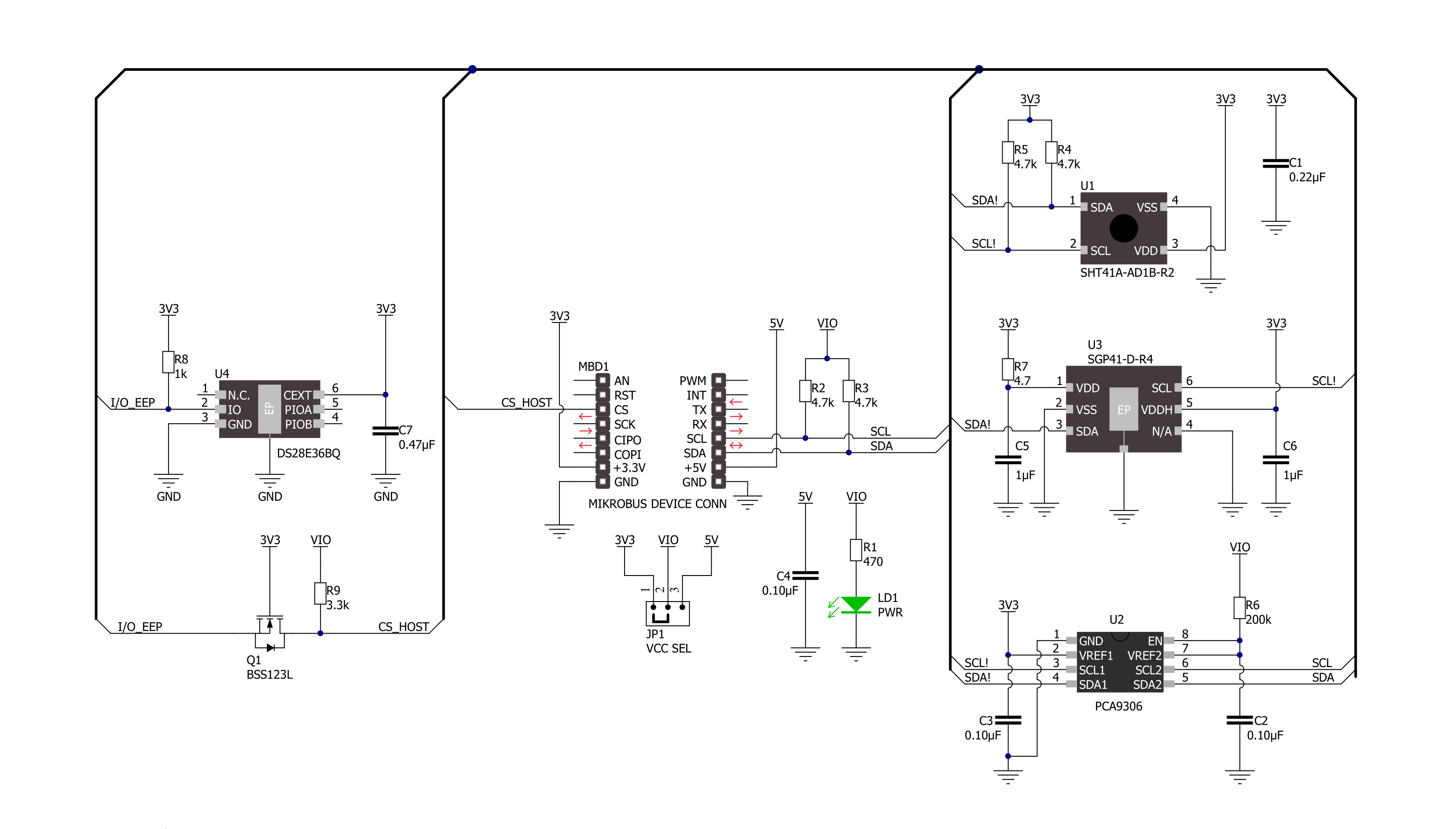

Click board™ 原理图

一步一步来

项目组装

软件支持

库描述

该库包含 Environment 4 Click 驱动程序的 API。

关键功能:

environment4_sht_read_meas_hp- 此功能以高精度从 SHT41A 设备读取温度和湿度测量值environment4_sgp_exe_conditioning- 此功能通过使用 I2C 串行接口执行 SGP41 设备的调节命令environment4_sgp_meas_raw_signals- 此功能通过使用 I2C 串行接口测量 SGP41 设备的原始信号

开源

代码示例

完整的应用程序代码和一个现成的项目可以通过NECTO Studio包管理器直接安装到NECTO Studio。 应用程序代码也可以在MIKROE的GitHub账户中找到。

/*!

* @file main.c

* @brief Environment 4 Click example

*

* # Description

* This example demonstrates the use of Environment 4 Click board by reading

* the temperature and humidity data and calculating VOC and NOx indexes.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver, and reads and displays the SGP41 sensor unique serial number

* and performs its build-in self-test. After that performs the SHT41 sensor software reset

* and reads its unique serial number. Finally, it initializes the sensirion gas index algorithm

* for VOC and NOx index calculation.

*

* ## Application Task

* Reads the temperature (degC) and the relative humidity (%RH) data from SHT41 sensor with high precision.

* For the first 10 seconds it executes NOx conditioning and after that it reads the raw signals for VOC and NOx

* data and processes them with sensirion's gas index algorithm for calculating VOC and NOx indexes.

* All data will be displayed on the USB UART approximately once per second.

*

* @note

* Time required for reliably detecting VOC and NOx events on switching ON is typically less than 60 seconds.

* Refer to the SGP41 sensor datasheet for more timing specifications.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "environment4.h"

#include "sensirion_gas_index_algorithm.h"

static environment4_t environment4;

static log_t logger;

static GasIndexAlgorithmParams voc_params;

static GasIndexAlgorithmParams nox_params;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

environment4_cfg_t environment4_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

environment4_cfg_setup( &environment4_cfg );

ENVIRONMENT4_MAP_MIKROBUS( environment4_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == environment4_init( &environment4, &environment4_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

uint16_t serial_num_sgp[ 3 ];

if ( ENVIRONMENT4_OK == environment4_sgp_get_serial_num ( &environment4, serial_num_sgp ) )

{

log_printf ( &logger, " SGP Serial number: 0x%.4X%.4X%.4X\r\n",

serial_num_sgp[ 0 ], serial_num_sgp[ 1 ], serial_num_sgp[ 2 ] );

}

uint8_t test_result_sgp;

if ( ENVIRONMENT4_OK == environment4_sgp_exe_self_test ( &environment4, &test_result_sgp ) )

{

log_printf ( &logger, " SGP Self test result: " );

if ( ENVIRONMENT4_SGP_SELF_TEST_OK == test_result_sgp )

{

log_printf ( &logger, "OK\r\n" );

}

else

{

if ( ENVIRONMENT4_SGP_SELF_TEST_VOC_PIXEL == test_result_sgp )

{

log_printf ( &logger, "VOC pixel fail; " );

}

if ( ENVIRONMENT4_SGP_SELF_TEST_NOX_PIXEL == test_result_sgp )

{

log_printf ( &logger, "NOx pixel fail; " );

}

log_printf ( &logger, "\r\n" );

}

}

if ( ENVIRONMENT4_OK == environment4_sht_soft_reset ( &environment4 ) )

{

log_printf ( &logger, " SHT Software reset\r\n" );

Delay_1sec ( );

}

uint32_t serial_num_sht;

if ( ENVIRONMENT4_OK == environment4_sht_read_serial_num ( &environment4, &serial_num_sht ) )

{

log_printf ( &logger, " SHT Serial number: 0x%.8LX\r\n", serial_num_sht );

}

log_printf ( &logger, " Initialize Gas Index algorithm for VOC and NOx\r\n" );

GasIndexAlgorithm_init ( &voc_params, GasIndexAlgorithm_ALGORITHM_TYPE_VOC );

GasIndexAlgorithm_init ( &nox_params, GasIndexAlgorithm_ALGORITHM_TYPE_NOX );

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

float temperature, humidity;

uint16_t comp_rh, comp_t, sraw_voc, sraw_nox;

int32_t voc_index, nox_index;

static uint8_t conditioning_num = 10;

Delay_ms ( 1000 );

if ( ENVIRONMENT4_OK == environment4_sht_read_meas_hp ( &environment4, &temperature, &humidity ) )

{

log_printf ( &logger, "\r\n Temperature: %.2f degC\r\n", temperature );

log_printf ( &logger, " Humidity: %.2f %%RH\r\n", humidity );

comp_rh = ( uint16_t ) ( humidity * ENVIRONMENT4_SHT_DATA_RESOLUTION /

( ENVIRONMENT4_SHT_ABS_MAX_HUM - ENVIRONMENT4_SHT_ABS_MIN_HUM ) );

comp_t = ( uint16_t ) ( ( temperature - ENVIRONMENT4_SHT_ABS_MIN_TEMP ) * ENVIRONMENT4_SHT_DATA_RESOLUTION /

( ENVIRONMENT4_SHT_ABS_MAX_TEMP - ENVIRONMENT4_SHT_ABS_MIN_TEMP ) );

if ( conditioning_num )

{

if ( ENVIRONMENT4_OK == environment4_sgp_exe_conditioning ( &environment4, comp_rh, comp_t, &sraw_voc ) )

{

conditioning_num--;

}

}

else

{

if ( ENVIRONMENT4_OK == environment4_sgp_meas_raw_signals ( &environment4, comp_rh, comp_t, &sraw_voc, &sraw_nox ) )

{

GasIndexAlgorithm_process( &voc_params, ( int32_t ) sraw_voc, &voc_index );

GasIndexAlgorithm_process( &nox_params, ( int32_t ) sraw_nox, &nox_index );

log_printf ( &logger, " VOC Index: %ld\r\n", voc_index );

log_printf ( &logger, " NOx Index: %ld\r\n", nox_index );

}

}

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

额外支持

资源

类别:环境