实现卓越的负载调节,确保在不同负载条件下输出电压稳定,适用于精密驱动应用。

A

A

硬件概览

它是如何工作的?

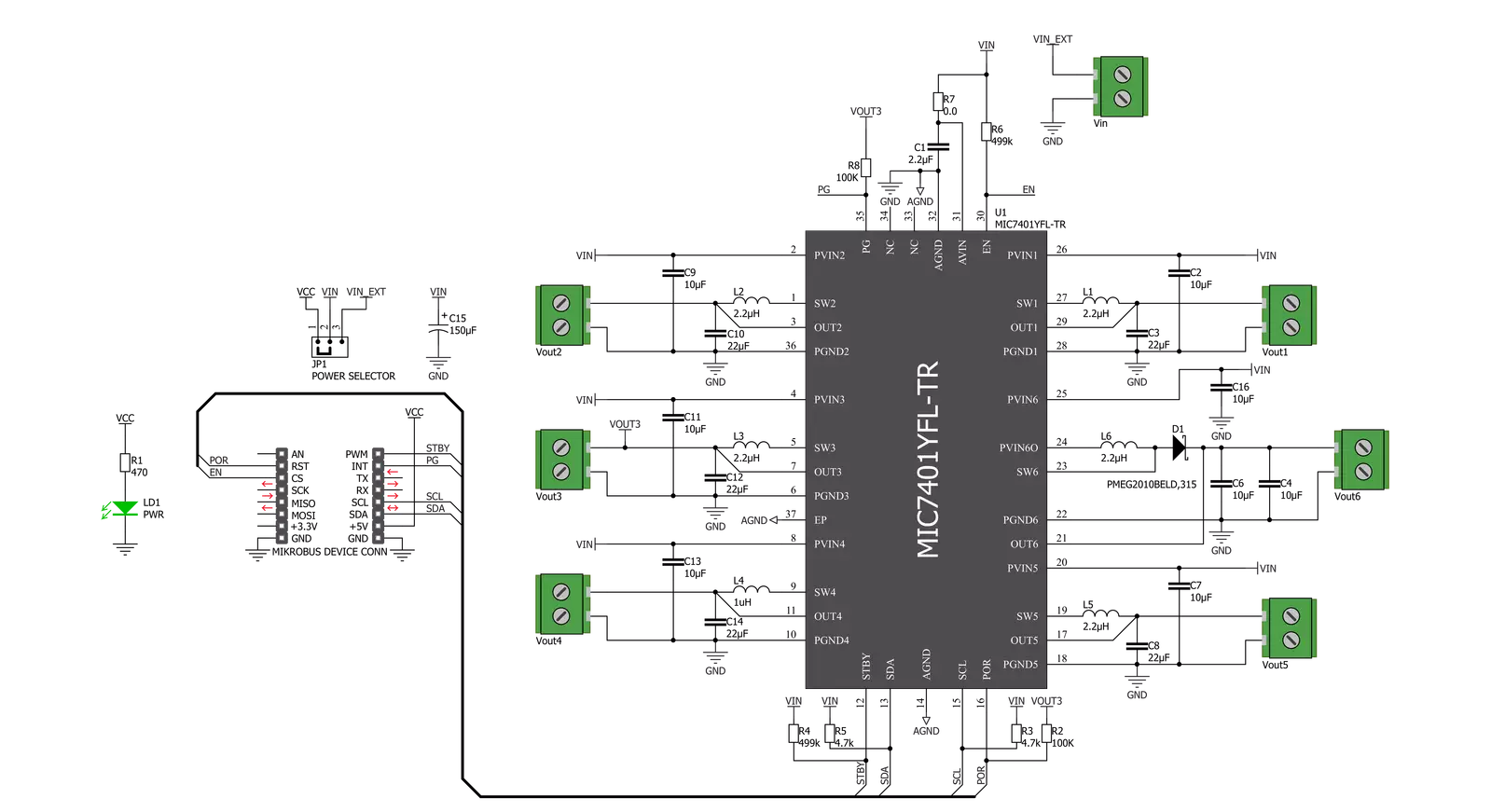

Buck & Boost Click 基于 Microchip 的 MIC7401,这是一款强大的高度集成可配置电源管理集成电路 (PMIC),具有降压和升压调节器、高速 I2C 接口、内部 EEPROM 存储器和微功耗关断功能。该 Click 板™ 具有五个 3A 同步降压调节器,采用高速自适应导通时间控制,以及一个升压调节器,提供高达 200mA 输出电流的闪存编程电源。升压调节器具有输出断开开关,如果检测到对地短路故障,该开关将打开。MIC7401 提供两种不同的工作模式,待机模式和正常模式,旨在提供适用于便携手持设备和信息娱乐应用的节能解决方案。在正常模式下,可编程的开关转换器可以配置

支持多种启动排序、时间、软启动斜坡、输出电压水平、电流限制水平和每个通道的输出放电。在待机模式下,可以通过关闭输出或将输出电压更改为较低水平来将此 PMIC 配置为低功耗状态。通过 I2C 通信或 mikroBUS™ 插座的 STB 引脚,可以实现独立退出待机模式。Buck & Boost Click 使用标准 I2C 双线接口与 MCU 通信,标准模式下频率最高为 100kHz,快速模式下最高为 400kHz,高速模式下最高为 3.4MHz。该 Click 板™ 还包含路由到 mikroBUS™ 插座上的 CS、AN、PWM 和 INT 引脚的附加功能。标记为 EN 的 CS 引脚表示一个使能引脚,可关闭设备以实现额外的节

能。标记为 STB 的 PWM 引脚表示待机复位功能,通过降低电源电压或关闭电源来减少总功耗。除了这些功能外,该 Click 板™ 具有电源开启复位,在 POR 延迟时间过去后变高,以及当所有调节器的电源良好标志都变高时被拉高的全局电源良好输出。该 Click 板™ 设计为可在 mikroBUS™ 提供的 5V 逻辑电压水平下运行,或从外部输入端子选择 2.4V 至 5.5V 范围内的电压,通过 VIN SEL 跳线选择。通过使用 mikroBUS™ 插座的逻辑电压水平或外部电压电源,使 3.3V 和 5V 兼容的 MCU 都能正确使用 I2C 通信线路。

功能概述

开发板

EasyPIC v8 是一款专为快速开发嵌入式应用的需求而特别设计的开发板。它支持许多高引脚计数的8位PIC微控制器,来自Microchip,无论它们的引脚数量如何,并且具有一系列独特功能,例如首次集成的调试器/程序员。开发板布局合理,设计周到,使得最终用户可以在一个地方找到所有必要的元素,如开关、按钮、指示灯、连接器等。得益于创新的制造技术,EasyPIC v8 提供了流畅而沉浸式的工作体验,允许在任何情况下、任何地方、任何时候都能访问。

EasyPIC v8 开发板的每个部分都包含了使同一板块运行最高效的必要组件。除了先进的集成CODEGRIP程 序/调试模块,该模块提供许多有价值的编程/调试选项和与Mikroe软件环境的无缝集成外,该板还包括一个干净且调节过的开发板电源供应模块。它可以使用广泛的外部电源,包括电池、外部12V电源供应和通过USB Type-C(USB-C)连接器的电源。通信选项如USB-UART、USB DEVICE和CAN也包括在内,包括 广受好评的mikroBUS™标准、两种显示选项(图形和

基于字符的LCD)和几种不同的DIP插座。这些插座覆盖了从最小的只有八个至四十个引脚的8位PIC MCU的广泛范围。EasyPIC v8 是Mikroe快速开发生态系统的一个组成部分。它由Mikroe软件工具原生支持,得益于大量不同的Click板™(超过一千块板),其数量每天都在增长,它涵盖了原型制作和开发的许多方面。

微控制器概述

MCU卡片 / MCU

建筑

PIC

MCU 内存 (KB)

48

硅供应商

Microchip

引脚数

28

RAM (字节)

3328

使用的MCU引脚

mikroBUS™映射器

“仔细看看!”

Click board™ 原理图

一步一步来

项目组装

实时跟踪您的结果

应用程序输出

1. 应用程序输出 - 在调试模式下,“应用程序输出”窗口支持实时数据监控,直接提供执行结果的可视化。请按照提供的教程正确配置环境,以确保数据正确显示。

2. UART 终端 - 使用UART Terminal通过USB to UART converter监视数据传输,实现Click board™与开发系统之间的直接通信。请根据项目需求配置波特率和其他串行设置,以确保正常运行。有关分步设置说明,请参考提供的教程。

3. Plot 输出 - Plot功能提供了一种强大的方式来可视化实时传感器数据,使趋势分析、调试和多个数据点的对比变得更加直观。要正确设置,请按照提供的教程,其中包含使用Plot功能显示Click board™读数的分步示例。在代码中使用Plot功能时,请使用以下函数:plot(insert_graph_name, variable_name);。这是一个通用格式,用户需要将“insert_graph_name”替换为实际图表名称,并将“variable_name”替换为要显示的参数。

软件支持

库描述

该库包含 Buck & Boost Click 驱动程序的 API。

关键功能:

bucknboost_set_buck_out_voltage- 此功能设置所需降压通道的输出电压bucknboost_set_boost_out_voltage- 此功能设置升压通道 (CH6) 的输出电压bucknboost_get_status- 此功能读取电源良好、EEPROM 和过流状态寄存器

开源

代码示例

完整的应用程序代码和一个现成的项目可以通过NECTO Studio包管理器直接安装到NECTO Studio。 应用程序代码也可以在MIKROE的GitHub账户中找到。

/*!

* @file main.c

* @brief BucknBoost Click example

*

* # Description

* This application demonstrates the use of Buck n Boost click board.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and sets the click default configuration.

* The default config enables the click board and limits the current of all outputs to 1100mA.

* It also sets the default voltages of all channels which are the following:

* OUT1 - 1.8V, OUT2 - 1.1V, OUT3 - 1.8V, OUT4 - 1.05V, OUT5 - 1.25V, OUT6 - 12V

*

* ## Application Task

* Iterates through the entire range of Buck voltages for Buck 1 output starting from the maximal output.

* It also checks the Power Good and Overcurrent status.

* All data is being displayed on the USB UART where you can track the program flow.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "bucknboost.h"

static bucknboost_t bucknboost;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

bucknboost_cfg_t bucknboost_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

bucknboost_cfg_setup( &bucknboost_cfg );

BUCKNBOOST_MAP_MIKROBUS( bucknboost_cfg, MIKROBUS_1 );

err_t init_flag = bucknboost_init( &bucknboost, &bucknboost_cfg );

if ( init_flag == I2C_MASTER_ERROR )

{

log_error( &logger, " Application Init Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

init_flag = bucknboost_default_cfg ( &bucknboost );

if ( init_flag == BUCKNBOOST_ERROR )

{

log_error( &logger, " Default Config Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

bucknboost_status_t status_data;

for ( uint8_t cnt = BUCKNBOOST_BUCK_OUTPUT_VOLTAGE_3300mV;

cnt <= BUCKNBOOST_BUCK_OUTPUT_VOLTAGE_800mV; cnt++ )

{

err_t error_check = bucknboost_set_buck_out_voltage( &bucknboost,

BUCKNBOOST_OUTPUT_CH_1,

cnt );

if ( error_check == BUCKNBOOST_ERROR )

{

log_error( &logger, " Setting Buck 1 Output Voltage." );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

else

{

log_printf( &logger, " Buck 1 Output Voltage set to %u mV.\r\n", 3300 - cnt * 50 );

bucknboost_get_status( &bucknboost, &status_data );

log_printf( &logger, " Power Good status -" );

if ( status_data.power_good == BUCKNBOOST_PGOOD_ALL_MASK )

{

log_printf( &logger, " Valid!\r\n" );

}

else

{

log_printf( &logger, " Not Valid! - Mask: 0x%.2X\r\n", ( uint16_t ) status_data.power_good );

}

log_printf( &logger, " Overcurrent status -" );

if ( status_data.power_good == BUCKNBOOST_PGOOD_ALL_MASK )

{

log_printf( &logger, " No Fault!\r\n" );

}

else

{

log_printf( &logger, " Fault! - Mask: 0x%.2X\r\n", ( uint16_t ) status_data.overcurrent_fault );

}

log_printf( &logger, "-----------------------------------\r\n" );

}

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

/*!

* @file main.c

* @brief BucknBoost Click example

*

* # Description

* This application demonstrates the use of Buck n Boost click board.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and sets the click default configuration.

* The default config enables the click board and limits the current of all outputs to 1100mA.

* It also sets the default voltages of all channels which are the following:

* OUT1 - 1.8V, OUT2 - 1.1V, OUT3 - 1.8V, OUT4 - 1.05V, OUT5 - 1.25V, OUT6 - 12V

*

* ## Application Task

* Iterates through the entire range of Buck voltages for Buck 1 output starting from the maximal output.

* It also checks the Power Good and Overcurrent status.

* All data is being displayed on the USB UART where you can track the program flow.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "bucknboost.h"

static bucknboost_t bucknboost;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

bucknboost_cfg_t bucknboost_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

bucknboost_cfg_setup( &bucknboost_cfg );

BUCKNBOOST_MAP_MIKROBUS( bucknboost_cfg, MIKROBUS_1 );

err_t init_flag = bucknboost_init( &bucknboost, &bucknboost_cfg );

if ( init_flag == I2C_MASTER_ERROR )

{

log_error( &logger, " Application Init Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

init_flag = bucknboost_default_cfg ( &bucknboost );

if ( init_flag == BUCKNBOOST_ERROR )

{

log_error( &logger, " Default Config Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

bucknboost_status_t status_data;

for ( uint8_t cnt = BUCKNBOOST_BUCK_OUTPUT_VOLTAGE_3300mV;

cnt <= BUCKNBOOST_BUCK_OUTPUT_VOLTAGE_800mV; cnt++ )

{

err_t error_check = bucknboost_set_buck_out_voltage( &bucknboost,

BUCKNBOOST_OUTPUT_CH_1,

cnt );

if ( error_check == BUCKNBOOST_ERROR )

{

log_error( &logger, " Setting Buck 1 Output Voltage." );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

else

{

log_printf( &logger, " Buck 1 Output Voltage set to %u mV.\r\n", 3300 - cnt * 50 );

bucknboost_get_status( &bucknboost, &status_data );

log_printf( &logger, " Power Good status -" );

if ( status_data.power_good == BUCKNBOOST_PGOOD_ALL_MASK )

{

log_printf( &logger, " Valid!\r\n" );

}

else

{

log_printf( &logger, " Not Valid! - Mask: 0x%.2X\r\n", ( uint16_t ) status_data.power_good );

}

log_printf( &logger, " Overcurrent status -" );

if ( status_data.power_good == BUCKNBOOST_PGOOD_ALL_MASK )

{

log_printf( &logger, " No Fault!\r\n" );

}

else

{

log_printf( &logger, " Fault! - Mask: 0x%.2X\r\n", ( uint16_t ) status_data.overcurrent_fault );

}

log_printf( &logger, "-----------------------------------\r\n" );

}

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

/*!

* @file main.c

* @brief BucknBoost Click example

*

* # Description

* This application demonstrates the use of Buck n Boost click board.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and sets the click default configuration.

* The default config enables the click board and limits the current of all outputs to 1100mA.

* It also sets the default voltages of all channels which are the following:

* OUT1 - 1.8V, OUT2 - 1.1V, OUT3 - 1.8V, OUT4 - 1.05V, OUT5 - 1.25V, OUT6 - 12V

*

* ## Application Task

* Iterates through the entire range of Buck voltages for Buck 1 output starting from the maximal output.

* It also checks the Power Good and Overcurrent status.

* All data is being displayed on the USB UART where you can track the program flow.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "bucknboost.h"

static bucknboost_t bucknboost;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

bucknboost_cfg_t bucknboost_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

bucknboost_cfg_setup( &bucknboost_cfg );

BUCKNBOOST_MAP_MIKROBUS( bucknboost_cfg, MIKROBUS_1 );

err_t init_flag = bucknboost_init( &bucknboost, &bucknboost_cfg );

if ( init_flag == I2C_MASTER_ERROR )

{

log_error( &logger, " Application Init Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

init_flag = bucknboost_default_cfg ( &bucknboost );

if ( init_flag == BUCKNBOOST_ERROR )

{

log_error( &logger, " Default Config Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

bucknboost_status_t status_data;

for ( uint8_t cnt = BUCKNBOOST_BUCK_OUTPUT_VOLTAGE_3300mV;

cnt <= BUCKNBOOST_BUCK_OUTPUT_VOLTAGE_800mV; cnt++ )

{

err_t error_check = bucknboost_set_buck_out_voltage( &bucknboost,

BUCKNBOOST_OUTPUT_CH_1,

cnt );

if ( error_check == BUCKNBOOST_ERROR )

{

log_error( &logger, " Setting Buck 1 Output Voltage." );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

else

{

log_printf( &logger, " Buck 1 Output Voltage set to %u mV.\r\n", 3300 - cnt * 50 );

bucknboost_get_status( &bucknboost, &status_data );

log_printf( &logger, " Power Good status -" );

if ( status_data.power_good == BUCKNBOOST_PGOOD_ALL_MASK )

{

log_printf( &logger, " Valid!\r\n" );

}

else

{

log_printf( &logger, " Not Valid! - Mask: 0x%.2X\r\n", ( uint16_t ) status_data.power_good );

}

log_printf( &logger, " Overcurrent status -" );

if ( status_data.power_good == BUCKNBOOST_PGOOD_ALL_MASK )

{

log_printf( &logger, " No Fault!\r\n" );

}

else

{

log_printf( &logger, " Fault! - Mask: 0x%.2X\r\n", ( uint16_t ) status_data.overcurrent_fault );

}

log_printf( &logger, "-----------------------------------\r\n" );

}

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END