我们的数字差压传感器经过精心设计,能够为从工业自动化到环境监测的广泛应用提供精确和可靠的读数。

A

A

硬件概览

它是如何工作的?

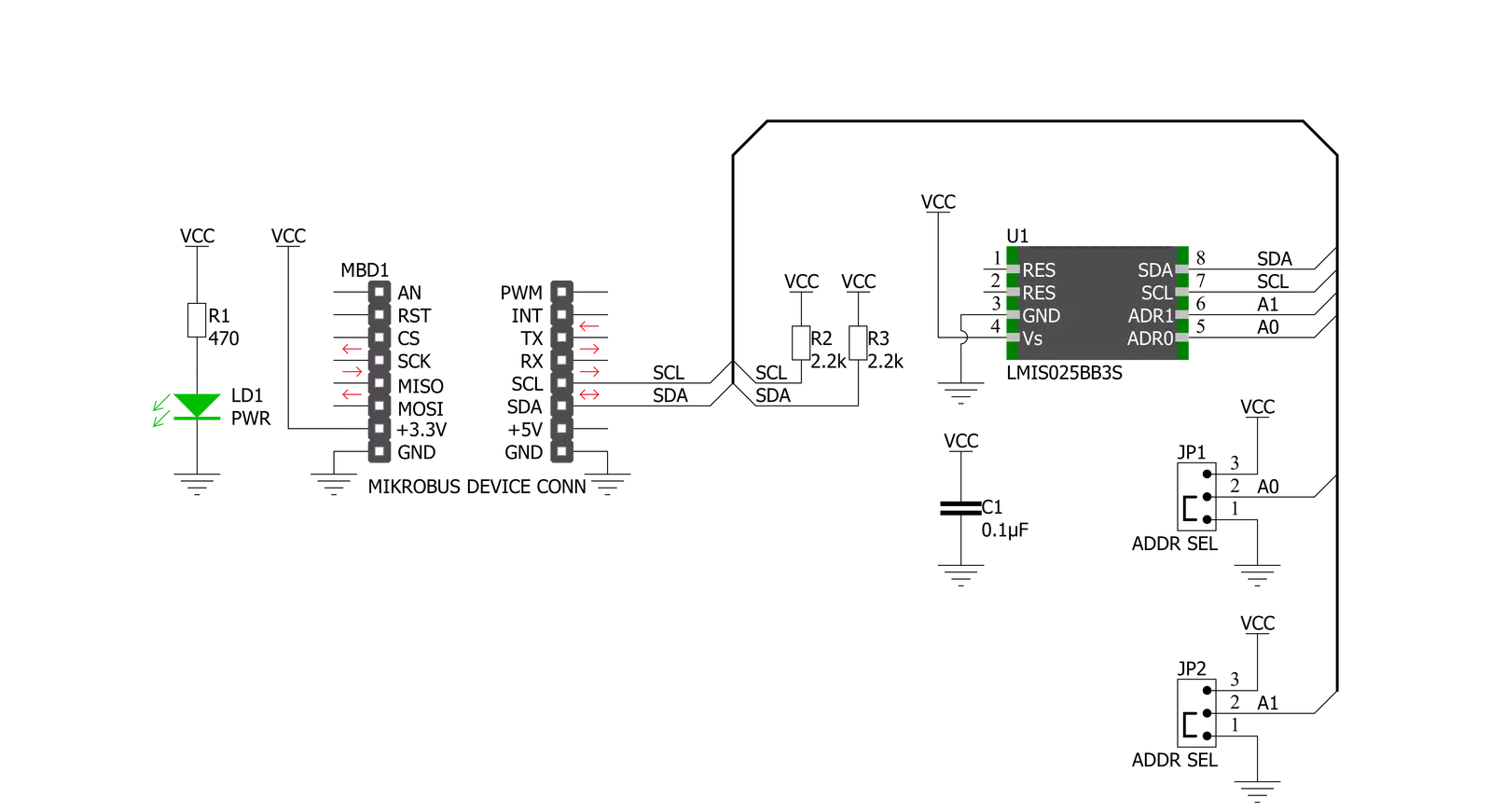

VAV Press Click 基于TE Connectivity的低差压传感器LMIS025B,该传感器提供数字输出,用于读取指定压力范围内的压力。创新的LMI技术具有卓越的灵敏度,尤其适用于0至25Pa / 0至0.25mbar(0.1英寸H2O)的超低压力。它基于通过传感器芯片内集成的微流通道进行气体的热流量测量。与其他基于流量的压力传感器相比,传感器内的极低气流确保了对灰尘污染、湿度和长管道的高免疫力,以及卓越的长期稳定性,

精度和专利的实时偏移补偿和线性化技术。LMIS025B提供两种操作模式:连续模式下的5ms采样时间,可提供近乎连续的压力数据流;低功耗模式下的400μA待机电流,可使设备从睡眠状态唤醒以“按需”提供压力数据。在任一模式下的第一次测量将在大约25 ms的预热和转换序列后可用。VAV Press Click通过标准I2C两线接口与MCU通信,通过16位sigma-delta A/D转换提供线性化的数字输出。此外,还可以通过将标记为

ADDR SEL的SMD跳线设置到标记为0和1的适当位置,选择其I2C从设备地址的最低有效位。此Click板™只能在3.3V逻辑电压水平下操作。在使用具有不同逻辑电平的MCU之前,必须进行适当的逻辑电压电平转换。此外,该Click板™配备了包含函数和示例代码的库,可作为进一步开发的参考。

功能概述

开发板

Nucleo 32开发板搭载STM32F031K6 MCU,提供了一种经济且灵活的平台,适用于使用32引脚封装的STM32微控制器进行实验。该开发板具有Arduino™ Nano连接性,便于通过专用扩展板进行功能扩展,并且支持mbed,使其能够无缝集成在线资源。板载集成

ST-LINK/V2-1调试器/编程器,支持通过USB重新枚举,提供三种接口:虚拟串口(Virtual Com port)、大容量存储和调试端口。该开发板的电源供应灵活,可通过USB VBUS或外部电源供电。此外,还配备了三个LED指示灯(LD1用于USB通信,LD2用于电源

指示,LD3为用户可控LED)和一个复位按钮。STM32 Nucleo-32开发板支持多种集成开发环境(IDEs),如IAR™、Keil®和基于GCC的IDE(如AC6 SW4STM32),使其成为开发人员的多功能工具。

微控制器概述

MCU卡片 / MCU

建筑

ARM Cortex-M0

MCU 内存 (KB)

32

硅供应商

STMicroelectronics

引脚数

32

RAM (字节)

4096

你完善了我!

配件

Click Shield for Nucleo-32是扩展您的开发板功能的理想选择,专为STM32 Nucleo-32引脚布局设计。Click Shield for Nucleo-32提供了两个mikroBUS™插座,可以添加来自我们不断增长的Click板™系列中的任何功能。从传感器和WiFi收发器到电机控制和音频放大器,我们应有尽有。Click Shield for Nucleo-32与STM32 Nucleo-32开发板兼容,为用户提供了一种经济且灵活的方式,使用任何STM32微控制器快速创建原型,并尝试各种性能、功耗和功能的组合。STM32 Nucleo-32开发板无需任何独立的探针,因为它集成了ST-LINK/V2-1调试器/编程器,并随附STM32全面的软件HAL库和各种打包的软件示例。这个开发平台为用户提供了一种简便且通用的方式,将STM32 Nucleo-32兼容开发板与他们喜欢的Click板™结合,应用于即将开展的项目中。

使用的MCU引脚

mikroBUS™映射器

“仔细看看!”

Click board™ 原理图

一步一步来

项目组装

实时跟踪您的结果

应用程序输出

1. 应用程序输出 - 在调试模式下,“应用程序输出”窗口支持实时数据监控,直接提供执行结果的可视化。请按照提供的教程正确配置环境,以确保数据正确显示。

2. UART 终端 - 使用UART Terminal通过USB to UART converter监视数据传输,实现Click board™与开发系统之间的直接通信。请根据项目需求配置波特率和其他串行设置,以确保正常运行。有关分步设置说明,请参考提供的教程。

3. Plot 输出 - Plot功能提供了一种强大的方式来可视化实时传感器数据,使趋势分析、调试和多个数据点的对比变得更加直观。要正确设置,请按照提供的教程,其中包含使用Plot功能显示Click board™读数的分步示例。在代码中使用Plot功能时,请使用以下函数:plot(insert_graph_name, variable_name);。这是一个通用格式,用户需要将“insert_graph_name”替换为实际图表名称,并将“variable_name”替换为要显示的参数。

软件支持

库描述

该库包含 VAV Press Click 驱动程序的 API。

关键功能:

vavpress_set_default_sensor_param- VAV Press 设置默认传感器参数功能vavpress_get_dif_press_and_temp- VAV Press 获取差压和温度功能vavpress_retrieve_electronic_signature- VAV Press 获取电子签名功能

开源

代码示例

完整的应用程序代码和一个现成的项目可以通过NECTO Studio包管理器直接安装到NECTO Studio。 应用程序代码也可以在MIKROE的GitHub账户中找到。

/*!

* @file main.c

* @brief VavPress Click example

*

* # Description

* This library contains API for the Vav Press click driver.

* This demo application shows an example of

* differential pressure and temperature measurement.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization of I2C module and log UART.

* After driver initialization and default settings,

* the app display retrieve the electronic signature

* and set the sensor parameters data.

*

* ## Application Task

* This is an example that shows the use of a Vav Press click board™.

* Logs pressure difference value [ Pa ] and temperature [ degree Celsius ] value.

* Results are being sent to the Usart Terminal where you can track their changes.

*

*

* @author Nenad Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "vavpress.h"

static vavpress_t vavpress;

static log_t logger;

static float diff_press;

static float temperature;

vavpress_el_signature_data_t el_signature_data;

vavpress_sensor_param_data_t param_data;

void application_init ( void ) {

log_cfg_t log_cfg; /**< Logger config object. */

vavpress_cfg_t vavpress_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_printf( &logger, "\r\n" );

log_info( &logger, " Application Init " );

// Click initialization.

vavpress_cfg_setup( &vavpress_cfg );

VAVPRESS_MAP_MIKROBUS( vavpress_cfg, MIKROBUS_1 );

err_t init_flag = vavpress_init( &vavpress, &vavpress_cfg );

if ( init_flag == I2C_MASTER_ERROR ) {

log_error( &logger, " Application Init Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

vavpress_default_cfg ( &vavpress );

log_info( &logger, " Application Task " );

Delay_ms ( 100 );

vavpress_retrieve_electronic_signature( &vavpress, &el_signature_data );

Delay_ms ( 100 );

log_printf( &logger, "--------------------------------\r\n" );

log_printf( &logger, " Firmware Version : %.3f \r\n", el_signature_data.firmware_version );

log_printf( &logger, " Pressure Range : %d Pa \r\n", el_signature_data.pressure_range );

log_printf( &logger, " Part # : %.11s \r\n", el_signature_data.part_number );

log_printf( &logger, " Lot # : %.7s \r\n", el_signature_data.lot_number );

log_printf( &logger, " Output Type : %c \r\n", el_signature_data.output_type );

log_printf( &logger, " Scale Factor : %d \r\n", el_signature_data.scale_factor );

log_printf( &logger, " Calibration ID : %.2s \r\n", el_signature_data.calibration_id );

log_printf( &logger, " Week number : %d \r\n", el_signature_data.week_number );

log_printf( &logger, " Year number : %d \r\n", el_signature_data.year_number );

log_printf( &logger, " Sequence number : %d \r\n", el_signature_data.sequence_number );

log_printf( &logger, "--------------------------------\r\n" );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

param_data.scale_factor_temp = 72;

param_data.scale_factor_press = el_signature_data.scale_factor;

param_data.readout_at_known_temperature = 50;

param_data.known_temperature_c = 24.0;

Delay_ms ( 100 );

}

void application_task ( void ) {

err_t error_flag = vavpress_get_dif_press_and_temp( &vavpress, ¶m_data, &diff_press, &temperature );

if ( error_flag == VAVPRESS_OK ) {

log_printf( &logger, " Diff. Pressure : %.4f Pa\r\n", diff_press );

log_printf( &logger, " Temperature : %.4f C\r\n", temperature );

log_printf( &logger, "--------------------------------\r\n" );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

} else {

log_error( &logger, " Communcation Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

/*!

* @file main.c

* @brief VavPress Click example

*

* # Description

* This library contains API for the Vav Press click driver.

* This demo application shows an example of

* differential pressure and temperature measurement.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization of I2C module and log UART.

* After driver initialization and default settings,

* the app display retrieve the electronic signature

* and set the sensor parameters data.

*

* ## Application Task

* This is an example that shows the use of a Vav Press click board™.

* Logs pressure difference value [ Pa ] and temperature [ degree Celsius ] value.

* Results are being sent to the Usart Terminal where you can track their changes.

*

*

* @author Nenad Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "vavpress.h"

static vavpress_t vavpress;

static log_t logger;

static float diff_press;

static float temperature;

vavpress_el_signature_data_t el_signature_data;

vavpress_sensor_param_data_t param_data;

void application_init ( void ) {

log_cfg_t log_cfg; /**< Logger config object. */

vavpress_cfg_t vavpress_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_printf( &logger, "\r\n" );

log_info( &logger, " Application Init " );

// Click initialization.

vavpress_cfg_setup( &vavpress_cfg );

VAVPRESS_MAP_MIKROBUS( vavpress_cfg, MIKROBUS_1 );

err_t init_flag = vavpress_init( &vavpress, &vavpress_cfg );

if ( init_flag == I2C_MASTER_ERROR ) {

log_error( &logger, " Application Init Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

vavpress_default_cfg ( &vavpress );

log_info( &logger, " Application Task " );

Delay_ms ( 100 );

vavpress_retrieve_electronic_signature( &vavpress, &el_signature_data );

Delay_ms ( 100 );

log_printf( &logger, "--------------------------------\r\n" );

log_printf( &logger, " Firmware Version : %.3f \r\n", el_signature_data.firmware_version );

log_printf( &logger, " Pressure Range : %d Pa \r\n", el_signature_data.pressure_range );

log_printf( &logger, " Part # : %.11s \r\n", el_signature_data.part_number );

log_printf( &logger, " Lot # : %.7s \r\n", el_signature_data.lot_number );

log_printf( &logger, " Output Type : %c \r\n", el_signature_data.output_type );

log_printf( &logger, " Scale Factor : %d \r\n", el_signature_data.scale_factor );

log_printf( &logger, " Calibration ID : %.2s \r\n", el_signature_data.calibration_id );

log_printf( &logger, " Week number : %d \r\n", el_signature_data.week_number );

log_printf( &logger, " Year number : %d \r\n", el_signature_data.year_number );

log_printf( &logger, " Sequence number : %d \r\n", el_signature_data.sequence_number );

log_printf( &logger, "--------------------------------\r\n" );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

param_data.scale_factor_temp = 72;

param_data.scale_factor_press = el_signature_data.scale_factor;

param_data.readout_at_known_temperature = 50;

param_data.known_temperature_c = 24.0;

Delay_ms ( 100 );

}

void application_task ( void ) {

err_t error_flag = vavpress_get_dif_press_and_temp( &vavpress, ¶m_data, &diff_press, &temperature );

if ( error_flag == VAVPRESS_OK ) {

log_printf( &logger, " Diff. Pressure : %.4f Pa\r\n", diff_press );

log_printf( &logger, " Temperature : %.4f C\r\n", temperature );

log_printf( &logger, "--------------------------------\r\n" );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

} else {

log_error( &logger, " Communcation Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END