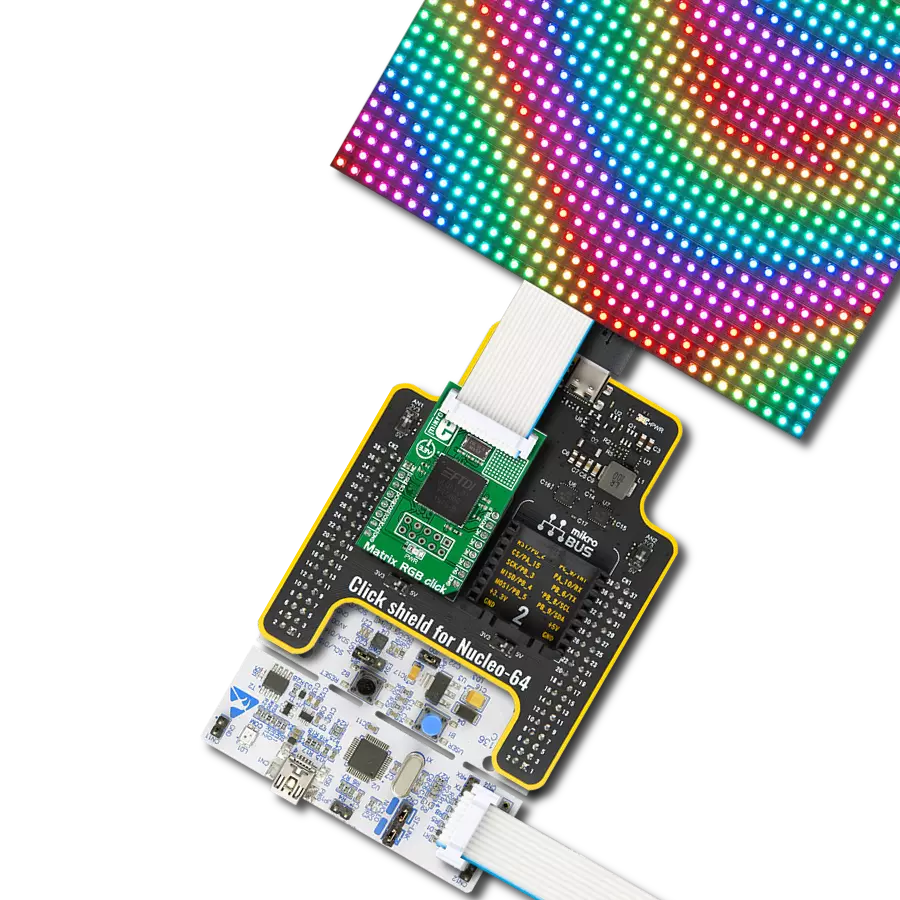

Our solution, featuring a 10x10 display matrix of 100 'intelligent' RGB elements, transforms your creative ideas into mesmerizing visuals, making it the ultimate choice for dynamic displays, animations, and interactive presentations

A

A

Hardware Overview

How does it work?

10x10 RGB Click is based on the WS2812, an intelligent control LED light source from Worldsemi. Its exterior adopts the latest MOLDING packaging technology, and the control circuit and RGB chips are integrated into a package of 2020 components. It's internal includes an intelligent digital port data latch and signal reshaping amplification drive circuit. It also includes a precision internal oscillator and a voltage-programmable constant current control part, ensuring consistent pixel point light color height. The data transfer protocol use single NZR communication mode. After the pixel power-on reset, the DIN port receive data from controller, the first pixel collect initial 24bit data then sent to the internal data latch, the other data which reshaping by the internal signal reshaping amplification circuit sent to the next cascade pixel through the DO port. After transmission for each

pixel, the signal to reduce 24bit. pixel adopt auto reshaping transmit technology, making the pixel cascade number is not limited the signal transmission, only depend on the speed of signal transmission. RESET time >280μs , it won't cause wrong reset while interruption, it supports the lower frequency and inexpensive MCU. Refresh Frequency updates to 2KHz, Low Frame Frequency and No Flicker appear in HD Video Camera, it improve excellent display effect. LED with low driving voltage, environmental protection and energy saving, high brightness, large scattering angle, good consistency, low power, long life and other advantages. The control chip integrated in LED above becoming more simple circuit, small volume, convenient installation. 10x10 RGB Click can be used in many applications, like full-color module, full color soft lights a lamp strip, LED decorative lighting, indoor/outdoor LED

irregular screen, game machine and amusement equipment, and more. The INT pin of the mikroBUS™, which is labeled as DO on this Click board™, allows cascading of multiple 10x10 RGB click devices. It simply routes the data line back to the mikroBUS™, allowing it to be re-used for the next 10x10 RGB click, and so on. The length of the whole chain is limited only by the communication speed, required to scan through all the LED devices, in order to maintain a reasonable refresh speed. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, it comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

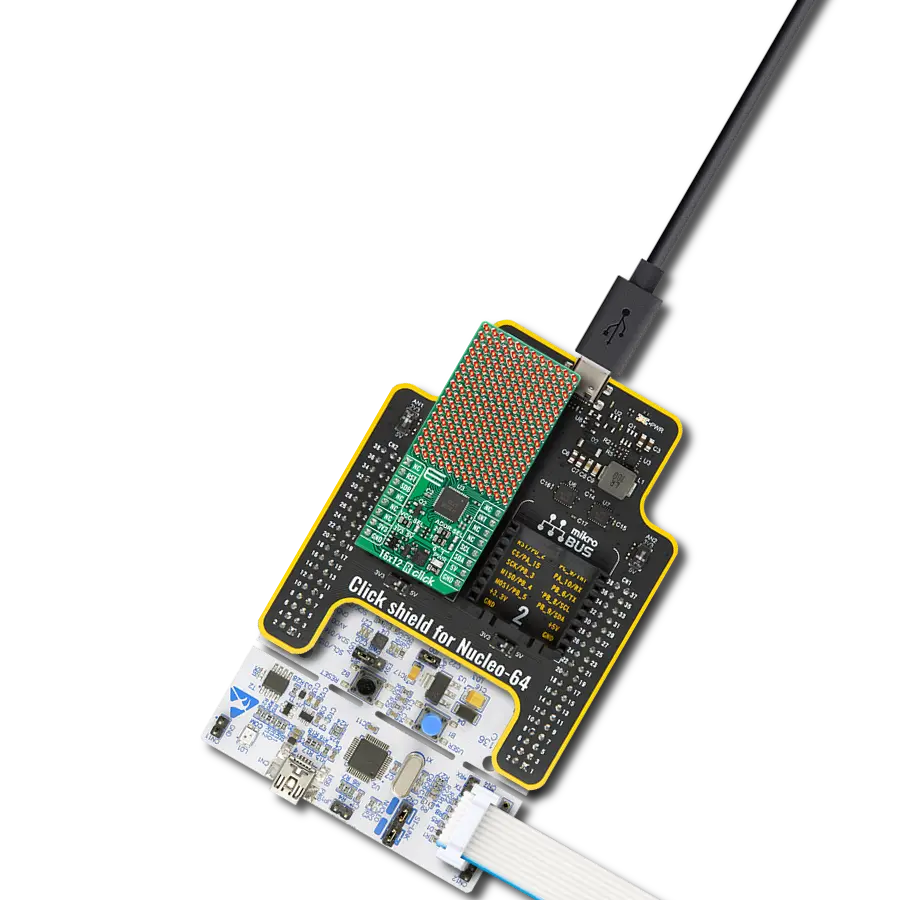

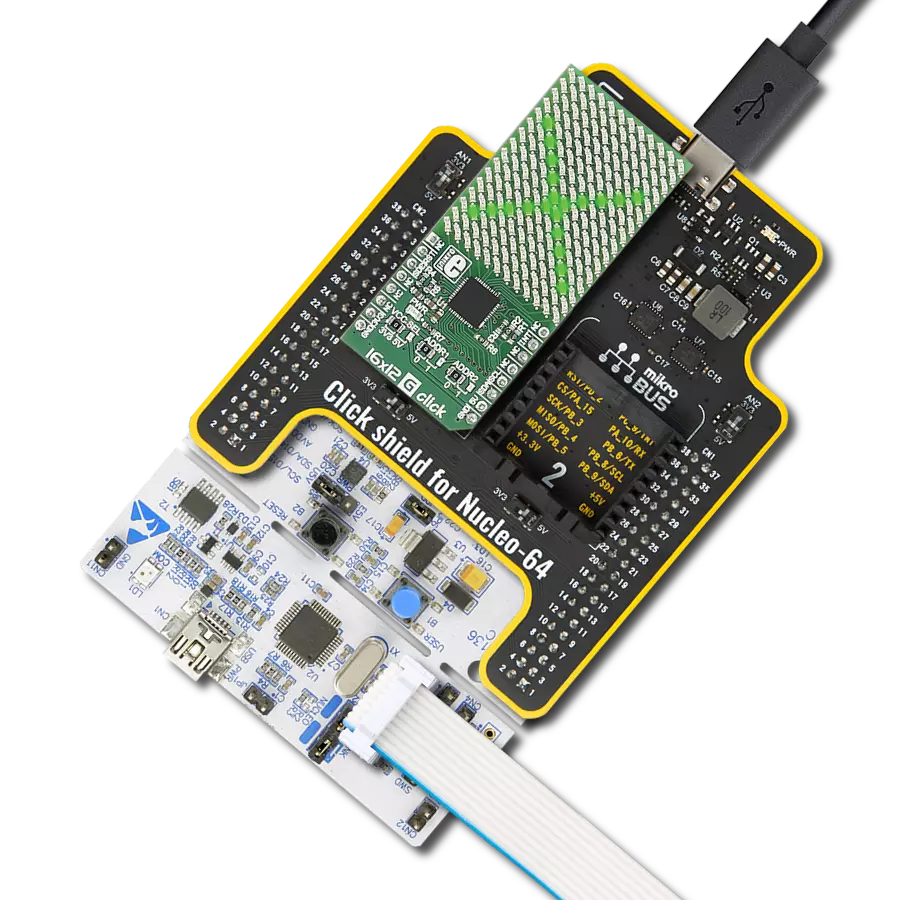

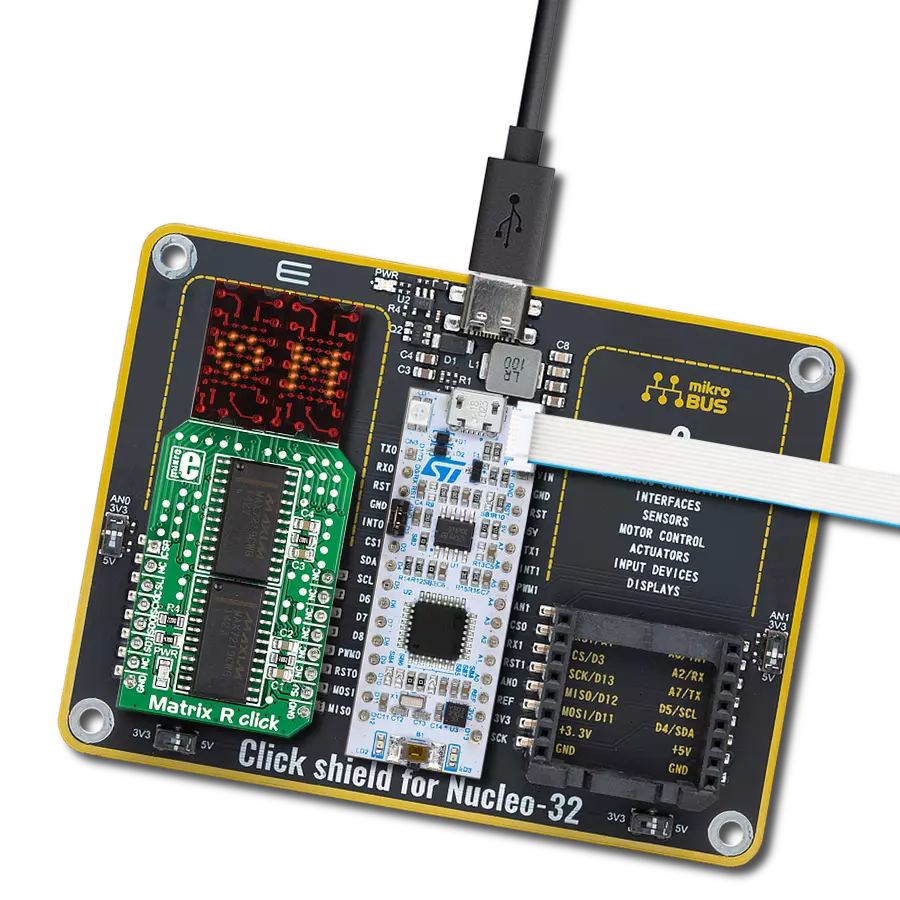

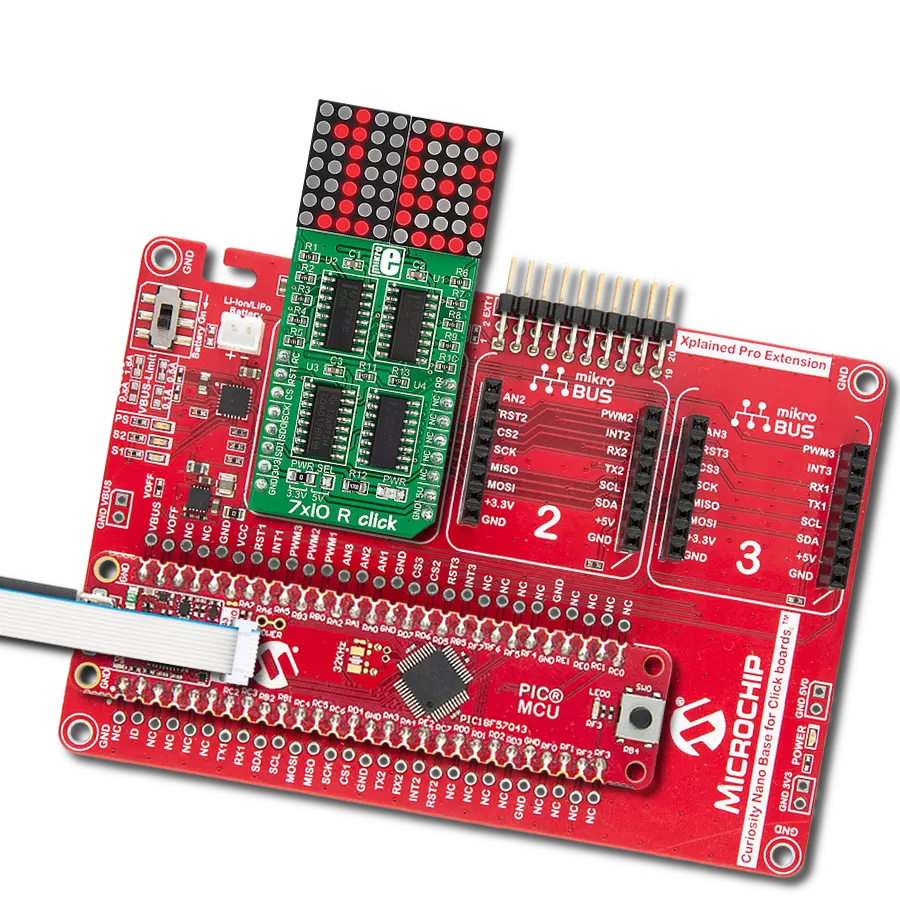

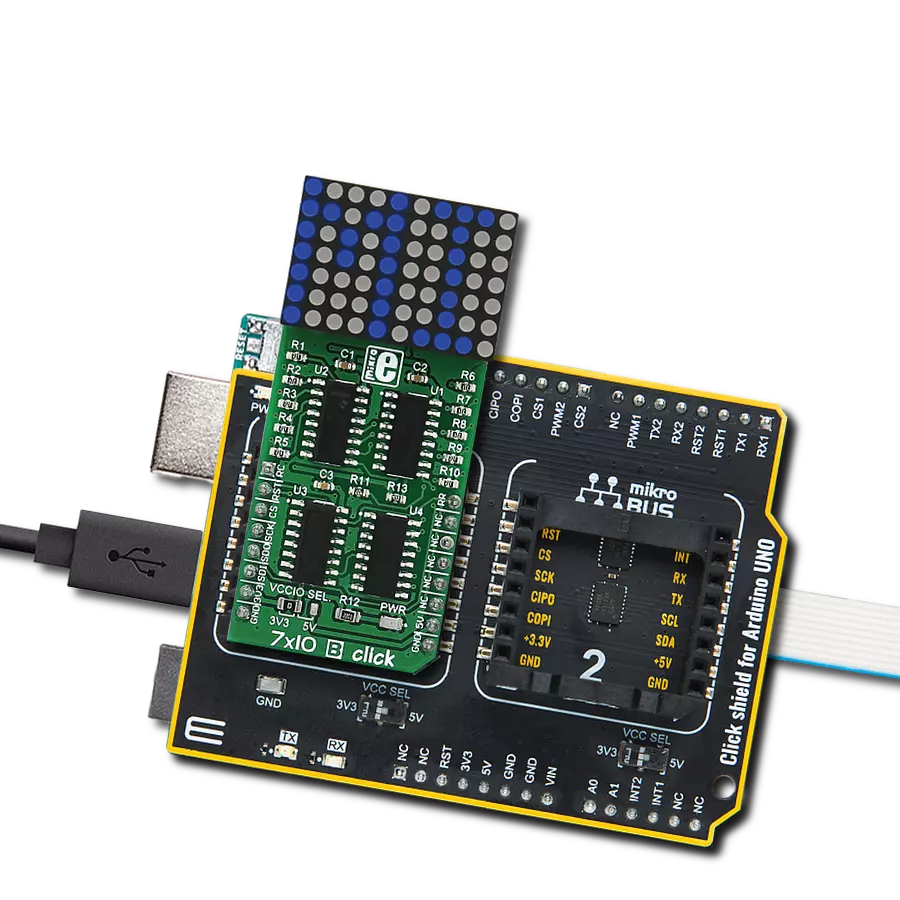

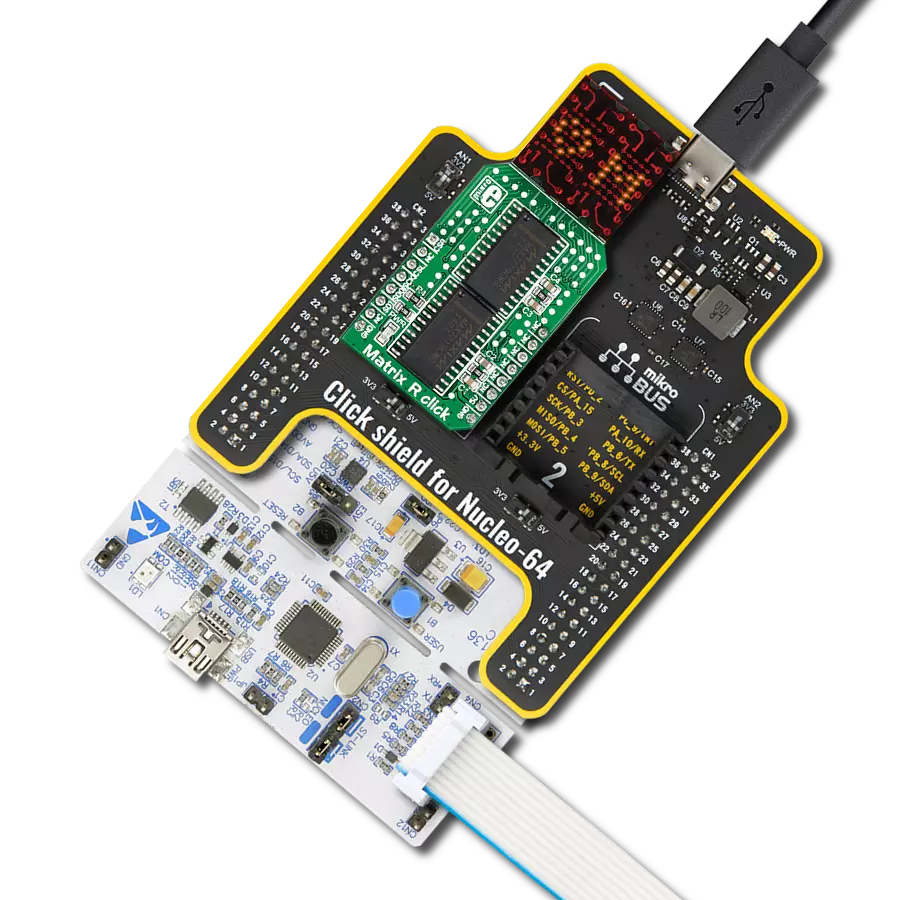

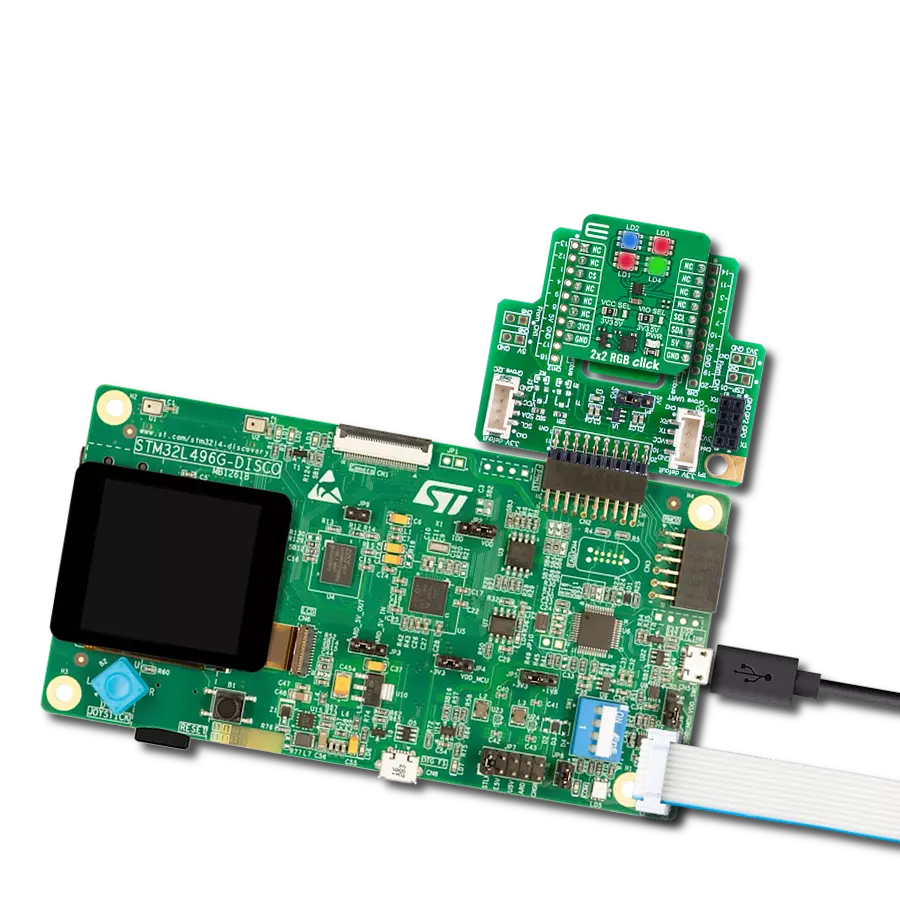

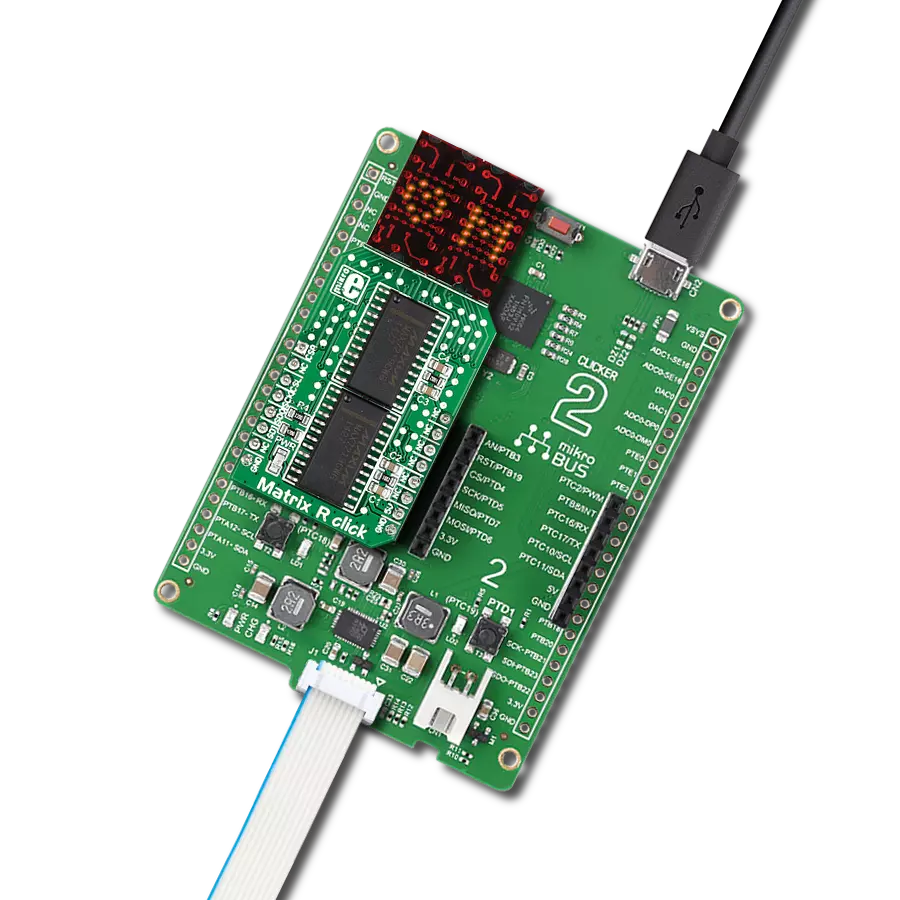

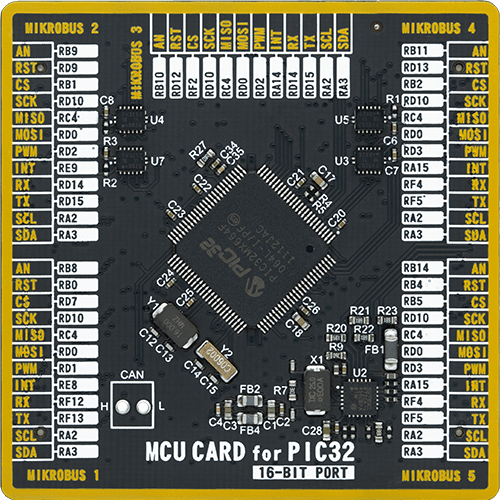

Development board

UNI Clicker is a compact development board designed as a complete solution that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It supports a wide range of microcontrollers, such as different ARM, PIC32, dsPIC, PIC, and AVR from various vendors like Microchip, ST, NXP, and TI (regardless of their number of pins), four mikroBUS™ sockets for Click board™ connectivity, a USB connector, LED indicators, buttons, a debugger/programmer connector, and two 26-pin headers for interfacing with external electronics. Thanks to innovative manufacturing technology, it allows you to build

gadgets with unique functionalities and features quickly. Each part of the UNI Clicker development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the UNI Clicker programming method, using a third-party programmer or CODEGRIP/mikroProg connected to onboard JTAG/SWD header, the UNI Clicker board also includes a clean and regulated power supply module for the development kit. It provides two ways of board-powering; through the USB Type-C (USB-C) connector, where onboard voltage regulators provide the appropriate voltage levels to each component on the board, or using a Li-Po/Li

Ion battery via an onboard battery connector. All communication methods that mikroBUS™ itself supports are on this board (plus USB HOST/DEVICE), including the well-established mikroBUS™ socket, a standardized socket for the MCU card (SiBRAIN standard), and several user-configurable buttons and LED indicators. UNI Clicker is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

PIC32

MCU Memory (KB)

64

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

32768

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for 10x10 RGB Click driver.

Key functions:

c10x10rgb_display_image- This function displays an image from the specified demo_image addressc10x10rgb_display_byte- This function displays the specified bytec10x10rgb_display_string- This function displays the specified string.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief 10x10 RGB Click example

*

* # Description

* This example showcases how to initialize, configure and use the 10x10 RGB Click module. The

* Click has a 10 by 10 RGB LED matrix which can be programmed to show different colors or even

* images. LED elements that form the matrix communicate by a single line with the host MCU.

*

* The demo application is composed of two sections :

*

* ## Application Init

* This function initializes and configures the Click board.

*

* ## Application Task

* This function first displays 3 chars { R, G, B }, the string "MIKROE", the company logo and

* a rainbow in the end.

*

* @note

* Make sure the logic delays are defined for your system in the c10x10rgb_delays.h file.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "c10x10rgb.h"

#include "c10x10rgb_delays.h"

// ------------------------------------------------------------------ VARIABLES

static c10x10rgb_t c10x10rgb;

const uint32_t MIKROE_IMAGE[ 100 ] =

{

0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,

0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,

0x000000,0x000000,0x181800,0x181800,0x181800,0x181800,0x181800,0x181800,0x181800,0x000000,

0x000000,0x181800,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,

0x000000,0x181800,0x181800,0x181800,0x181800,0x181800,0x181800,0x181800,0x181800,0x000000,

0x000000,0x181800,0x181800,0x181800,0x181800,0x181800,0x181800,0x181800,0x181800,0x000000,

0x000000,0x181800,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,

0x000000,0x000000,0x181800,0x181800,0x181800,0x181800,0x181800,0x181800,0x181800,0x000000,

0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,

0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000,0x000000

};

static c10x10rgb_byte_t scroll_data_obj[ 6 ] =

{

{ 'M', C10X10RGB_COLOR_OFF, C10X10RGB_COLOR_YELLOW_25, C10X10RGB_SCROLL_ROTATE_V },

{ 'I', C10X10RGB_COLOR_OFF, C10X10RGB_COLOR_YELLOW_25, C10X10RGB_SCROLL_ROTATE_V },

{ 'K', C10X10RGB_COLOR_OFF, C10X10RGB_COLOR_YELLOW_25, C10X10RGB_SCROLL_ROTATE_V },

{ 'R', C10X10RGB_COLOR_OFF, C10X10RGB_COLOR_YELLOW_25, C10X10RGB_SCROLL_ROTATE_V },

{ 'O', C10X10RGB_COLOR_OFF, C10X10RGB_COLOR_YELLOW_25, C10X10RGB_SCROLL_ROTATE_V },

{ 'E', C10X10RGB_COLOR_YELLOW_25, C10X10RGB_COLOR_OFF, C10X10RGB_SCROLL_ROTATE_V }

};

static uint16_t scroll_speed_ms = 100;

static uint8_t scroll_data_len = 6;

static c10x10rgb_byte_t rgb_data_byte[ 3 ] =

{

{ 'R', C10X10RGB_COLOR_RED_25, C10X10RGB_COLOR_OFF, C10X10RGB_BYTE_ROTATE_H_UP },

{ 'G', C10X10RGB_COLOR_OFF, C10X10RGB_COLOR_GREEN_25, C10X10RGB_BYTE_ROTATE_H_UP },

{ 'B', C10X10RGB_COLOR_BLUE_25, C10X10RGB_COLOR_OFF, C10X10RGB_BYTE_ROTATE_H_UP }

};

static uint8_t rainbow_brightness = 10;

static uint16_t rainbow_speed_ms = 20;

// ------------------------------------------------------- ADDITIONAL FUNCTIONS

static void logic_zero ( void )

{

hal_ll_gpio_set_pin_output( &c10x10rgb.di_pin.pin );

DELAY_TOH;

hal_ll_gpio_clear_pin_output( &c10x10rgb.di_pin.pin );

DELAY_TOL;

}

static void logic_one ( void )

{

hal_ll_gpio_set_pin_output( &c10x10rgb.di_pin.pin );

DELAY_T1H;

hal_ll_gpio_clear_pin_output( &c10x10rgb.di_pin.pin );

DELAY_T1L;

}

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

c10x10rgb_cfg_t cfg;

// Click initialization.

c10x10rgb_cfg_setup( &cfg, &logic_zero, &logic_one );

C10X10RGB_MAP_MIKROBUS( cfg, MIKROBUS_1 );

c10x10rgb_init( &c10x10rgb, &cfg );

c10x10rgb_fill_screen( &c10x10rgb, C10X10RGB_COLOR_OFF );

Delay_ms ( 1000 );

}

void application_task ( void )

{

c10x10rgb_display_byte ( &c10x10rgb, &rgb_data_byte[ 0 ] );

Delay_ms ( 1000 );

c10x10rgb_display_byte ( &c10x10rgb, &rgb_data_byte[ 1 ] );

Delay_ms ( 1000 );

c10x10rgb_display_byte ( &c10x10rgb, &rgb_data_byte[ 2 ] );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

c10x10rgb_display_string( &c10x10rgb, &scroll_data_obj, scroll_data_len, scroll_speed_ms );

Delay_ms ( 1000 );

c10x10rgb_display_image( &c10x10rgb, &MIKROE_IMAGE[ 0 ] );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

c10x10rgb_demo_rainbow( &c10x10rgb, rainbow_brightness, rainbow_speed_ms );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:LED Matrix