Create crystal-clear audio recordings with your own custom-built microphone system

A

A

Hardware Overview

How does it work?

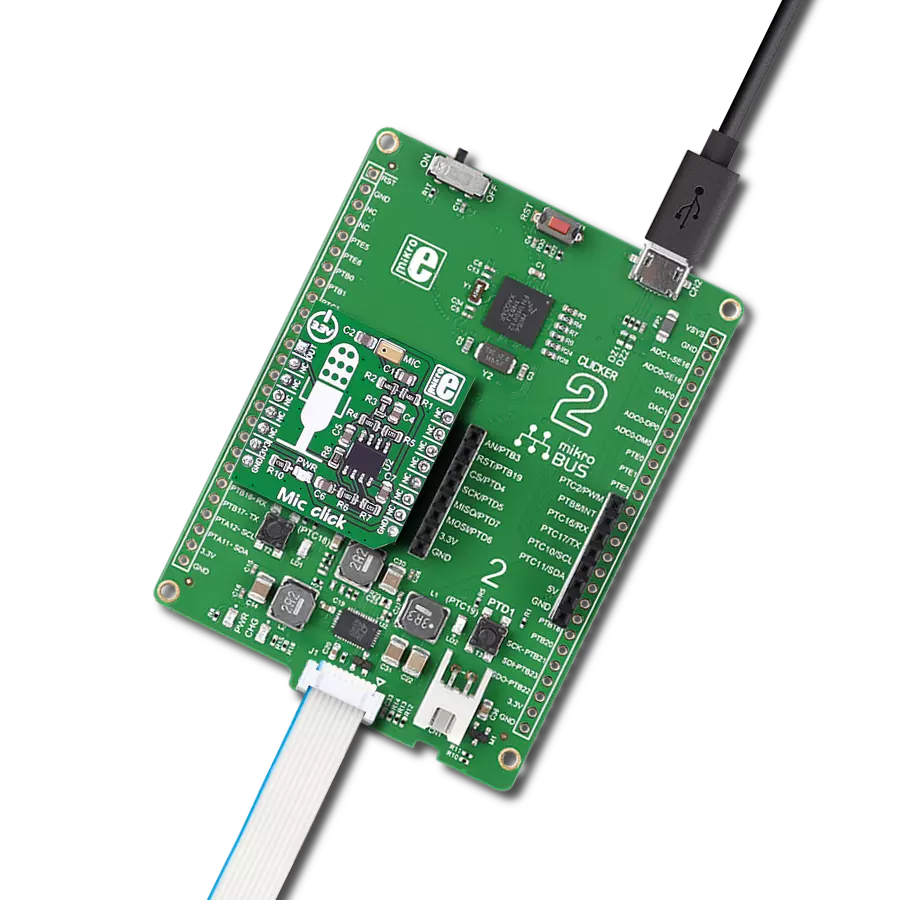

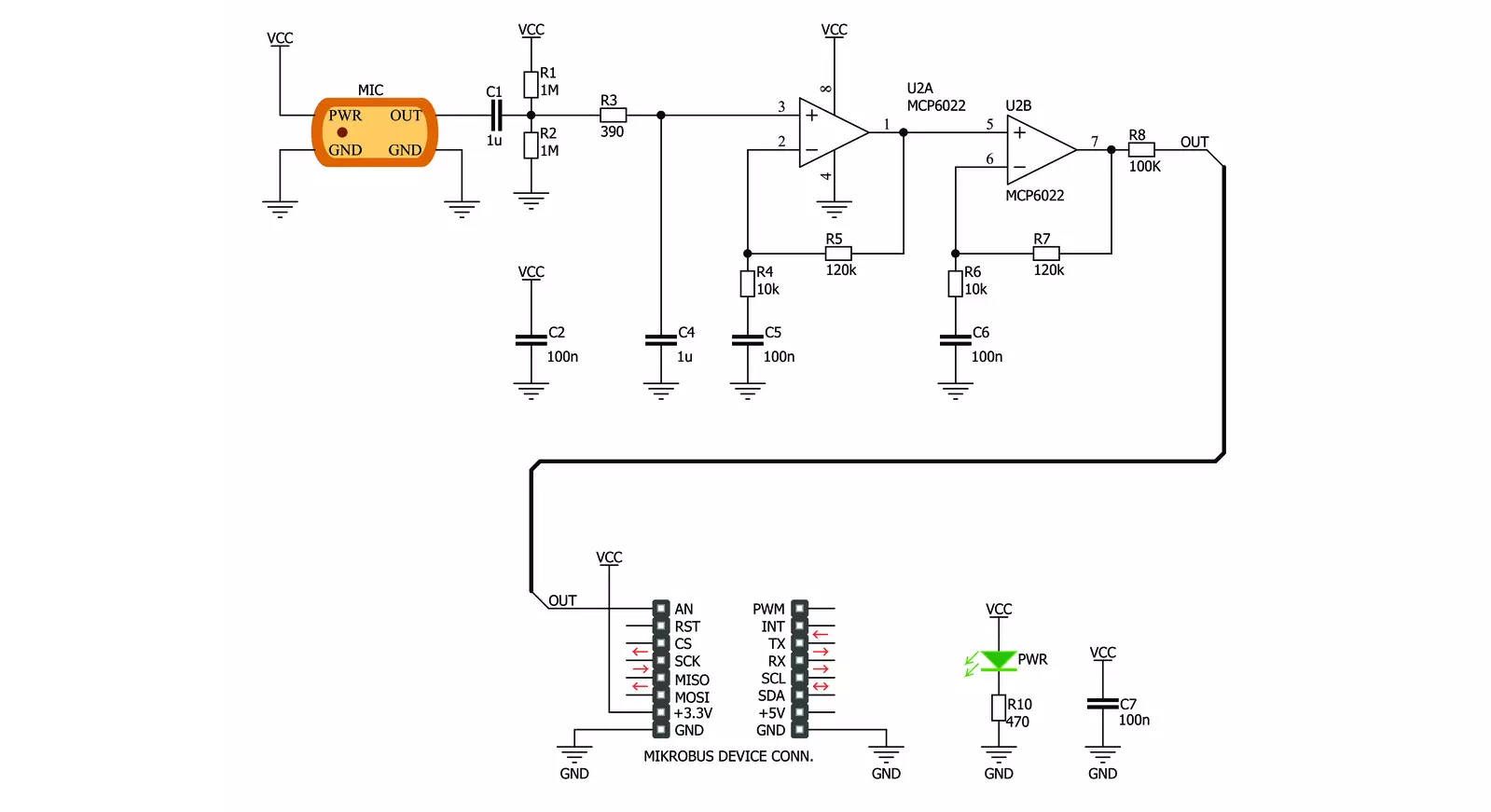

Mic Click is based on the SPQ0410HRSH-B, a slim ultra-mini SiSonic™ microphone specification with maximum RF protection and ultra-narrow design from Knowles. It is a MEMS microphone and consists of an acoustic sensor, a low noise input buffer, and an output amplifier. It is a very reliable microphone, resistant to mechanical shocks, vibrations, thermal shocks, low and high temperatures, ESD-HBM, and more. It is not resistant to high pressure and vacuum. The

microphone is top-port oriented and has a typical sensitivity of -42dB at 94dB SPL, with a 59dB signal-to-noise ratio. Mic Click uses an analog OUT pin of the mikroBUS™ socket to communicate with the host MCU. The analog output from the microphone to the OUT pin goes through the MCP6022, a rail-to-rail input/output 10MHz Op Amp from Microchip. This operational amplifier has a wide bandwidth, low noise, low input offset voltage, and low distortion and amplifies the

microphone's output with high performance. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, it comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

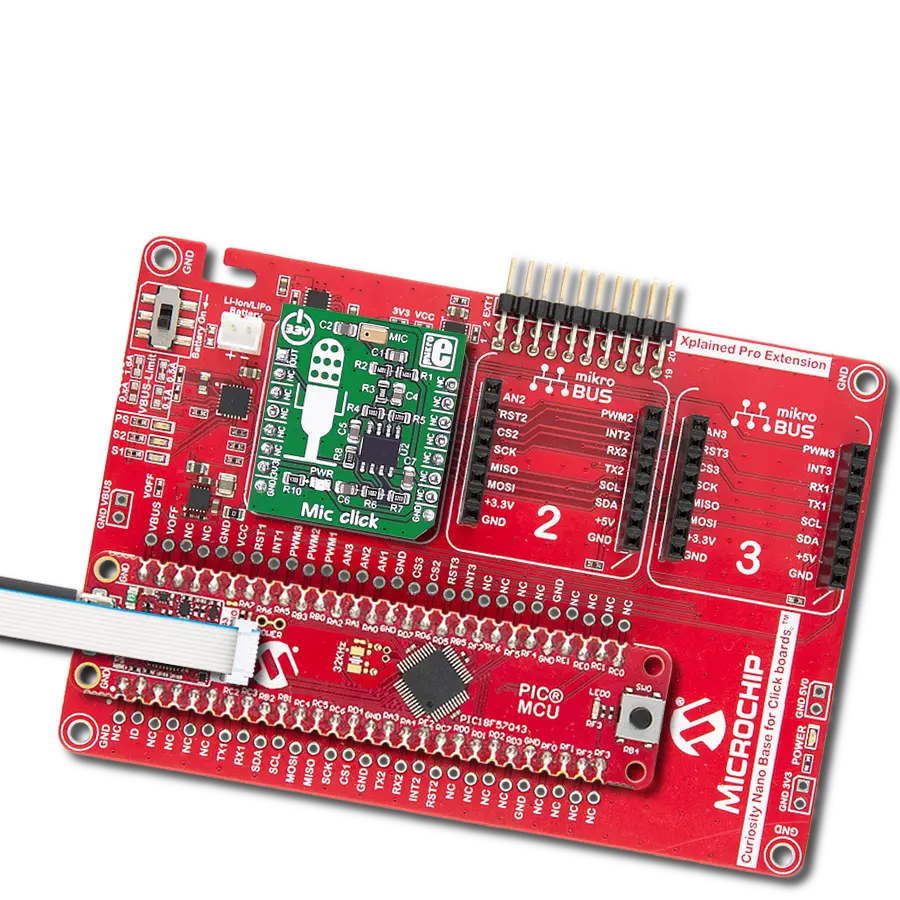

Development board

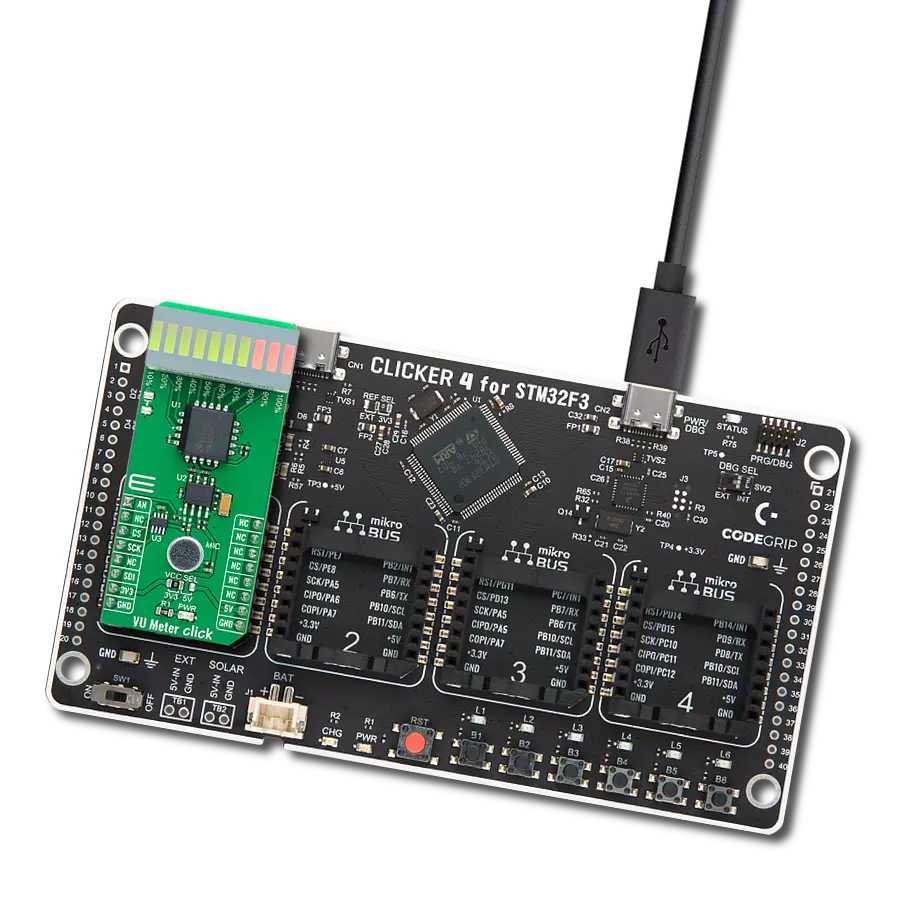

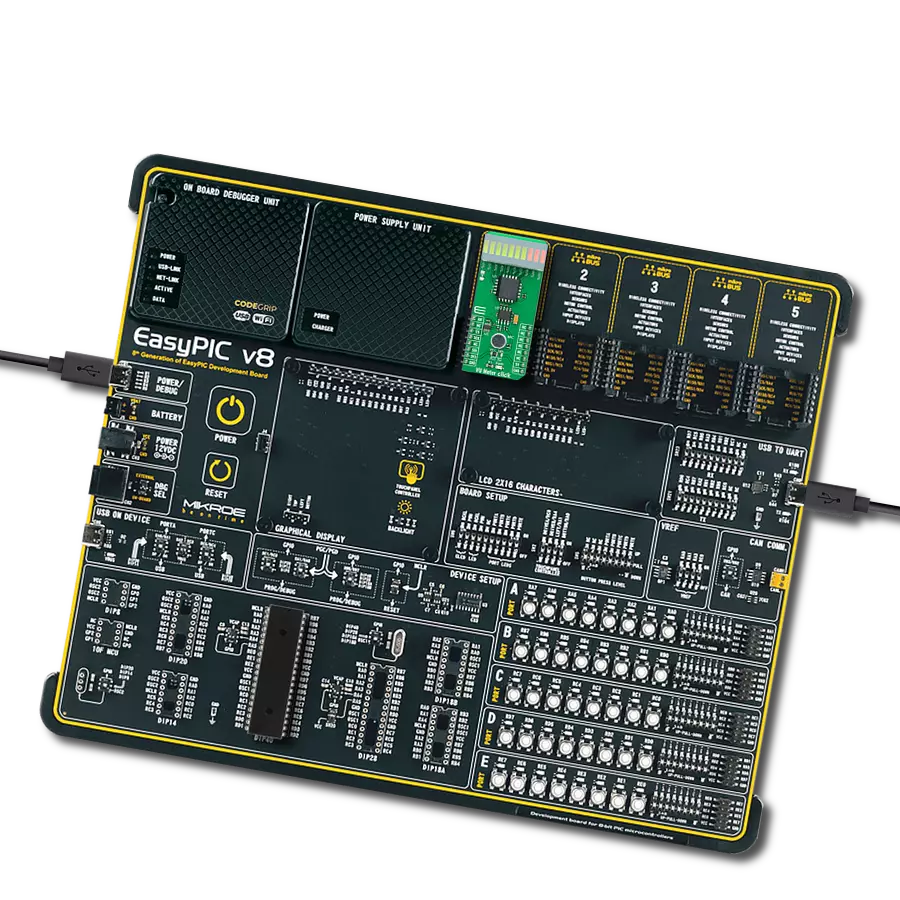

Flip&Click PIC32MZ is a compact development board designed as a complete solution that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit PIC32MZ microcontroller, the PIC32MZ2048EFH100 from Microchip, four mikroBUS™ sockets for Click board™ connectivity, two USB connectors, LED indicators, buttons, debugger/programmer connectors, and two headers compatible with Arduino-UNO pinout. Thanks to innovative manufacturing technology,

it allows you to build gadgets with unique functionalities and features quickly. Each part of the Flip&Click PIC32MZ development kit contains the components necessary for the most efficient operation of the same board. In addition, there is the possibility of choosing the Flip&Click PIC32MZ programming method, using the chipKIT bootloader (Arduino-style development environment) or our USB HID bootloader using mikroC, mikroBasic, and mikroPascal for PIC32. This kit includes a clean and regulated power supply block through the USB Type-C (USB-C) connector. All communication

methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, user-configurable buttons, and LED indicators. Flip&Click PIC32MZ development kit allows you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

2048

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for MIC Click driver.

Key functions:

mic_generic_read- This function read ADC data

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Mic Click example

*

* # Description

* This example showcases the initialization and configuration of the Click and logger

* modules and later on reads and displays data recorded by the mic.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes LOG communication, ADC and configures AN pin as input on MIKROBUS1.

*

* ## Application Task

* Reads 12 bit ADC data from AN pin and displays it using the logger module.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "mic.h"

// ------------------------------------------------------------------ VARIABLES

static mic_t mic;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

mic_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

mic_cfg_setup( &cfg );

MIC_MAP_MIKROBUS( cfg, MIKROBUS_1 );

mic_init( &mic, &cfg );

}

void application_task ( void )

{

mic_data_t tmp;

// Task implementation.

tmp = mic_generic_read ( &mic );

log_printf( &logger, "** ADC value : [DEC]- %d, [HEX]- 0x%x \r\n", tmp, tmp );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Microphone