Experience the precision of an advanced quadrature counter, designed to elevate your design with accurate motion measurements

A

A

Hardware Overview

How does it work?

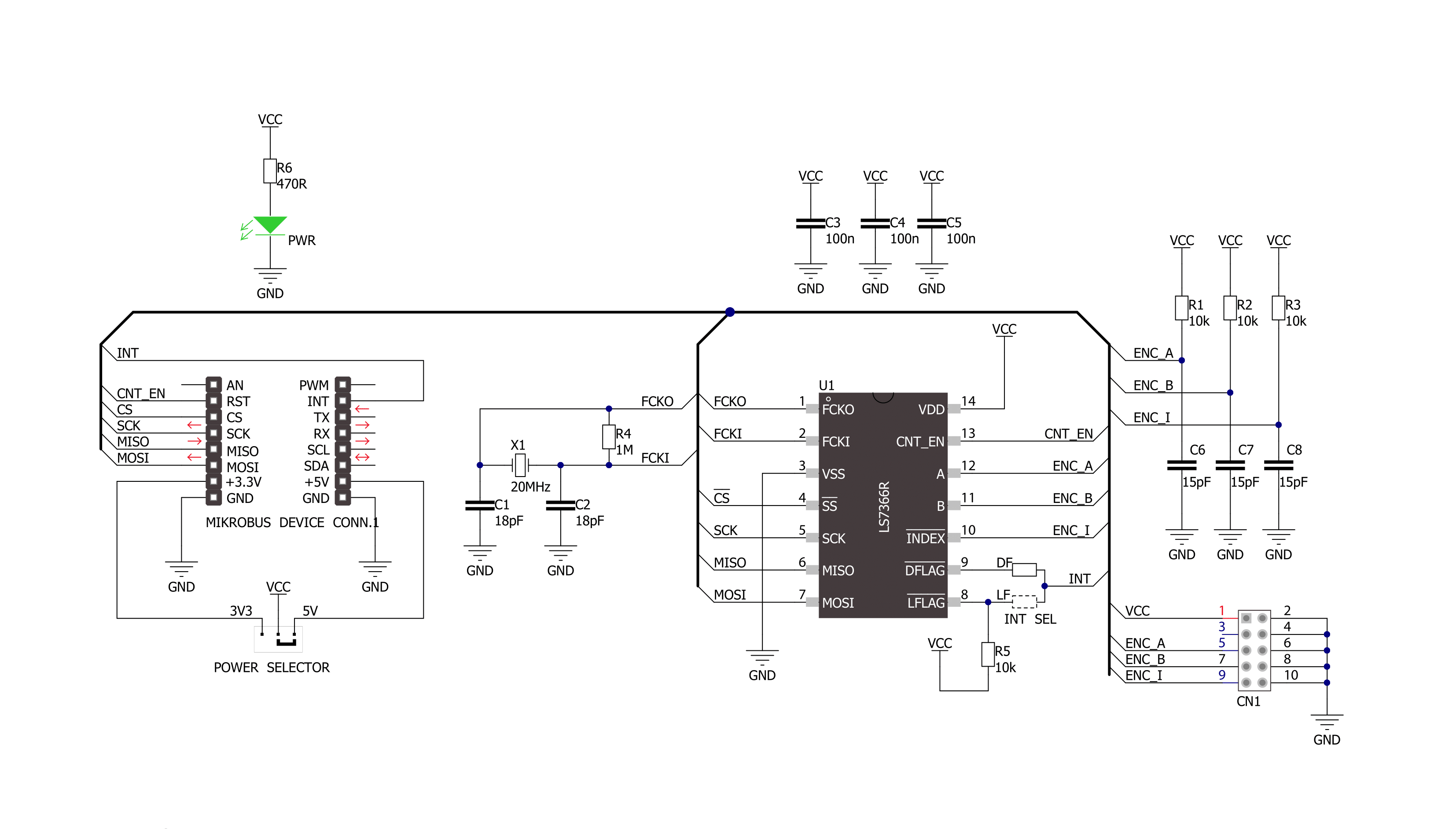

Counter Click is based on the LS7366R, a 32-bit quadrature counter with a serial interface from LSI Computer Systems. It is a CMOS counter with a direct interface for quadrature clocks from incremental encoders. It also interfaces with the index signals from incremental encoders to perform various marker functions. This counter can be configured to operate as a 1, 2, 3, or 4-byte counter. It can also be programmed to work in several counting modes such as Modulo-N, Non-recycle, Range-limit, or Free-running mode. This Click board™ features a 2x5 header (2.54mm pitch) with pins to interface the LS7366R inputs, VCC, and a few GNDs, basically the power supply

pins of the Click board™ itself. The VCC and GND pins can power the quadrature incremental encoder. This header also includes ENCA and ENCB, the input A and B pins of the LS7366R, to directly apply the quadrature clock outputs from incremental encoders on them, and Index (ENCI) pin, a programmable input driven directly by an incremental encoder's index output. The LS7366R uses a standard 4-wire SPI serial interface to communicate with the host MCU over the mikroBUS™ socket. The counter is enabled when EN input is in a high logic state; otherwise, it is disabled with a LOW logic level. In addition, this Click board™ features interrupt over INT pin that

can be configured to use LFLAG or DFLAG over the LF and DF solder jumpers with DFLAG set by default. This way, users can choose LFLAG, an open drain latched output, or DFLAG, an instantaneous push-pull output, thus using these outputs to flag Carry, Borrow, Compare, and Index occurrences. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the PWR SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

Development board

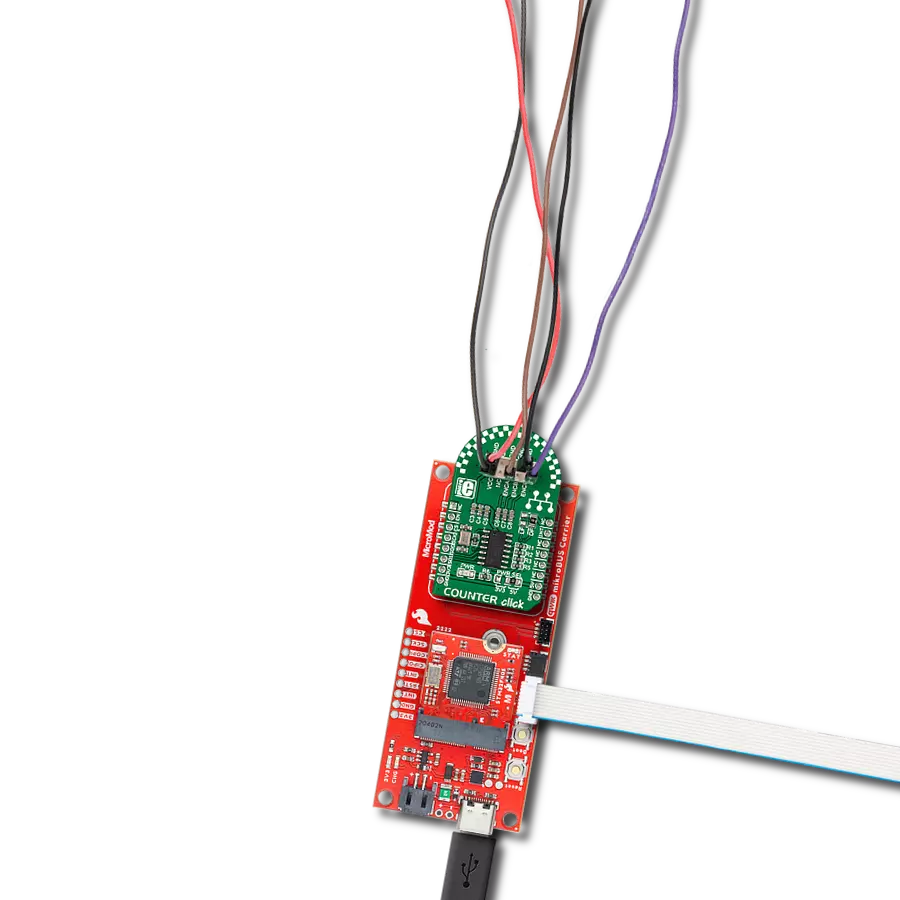

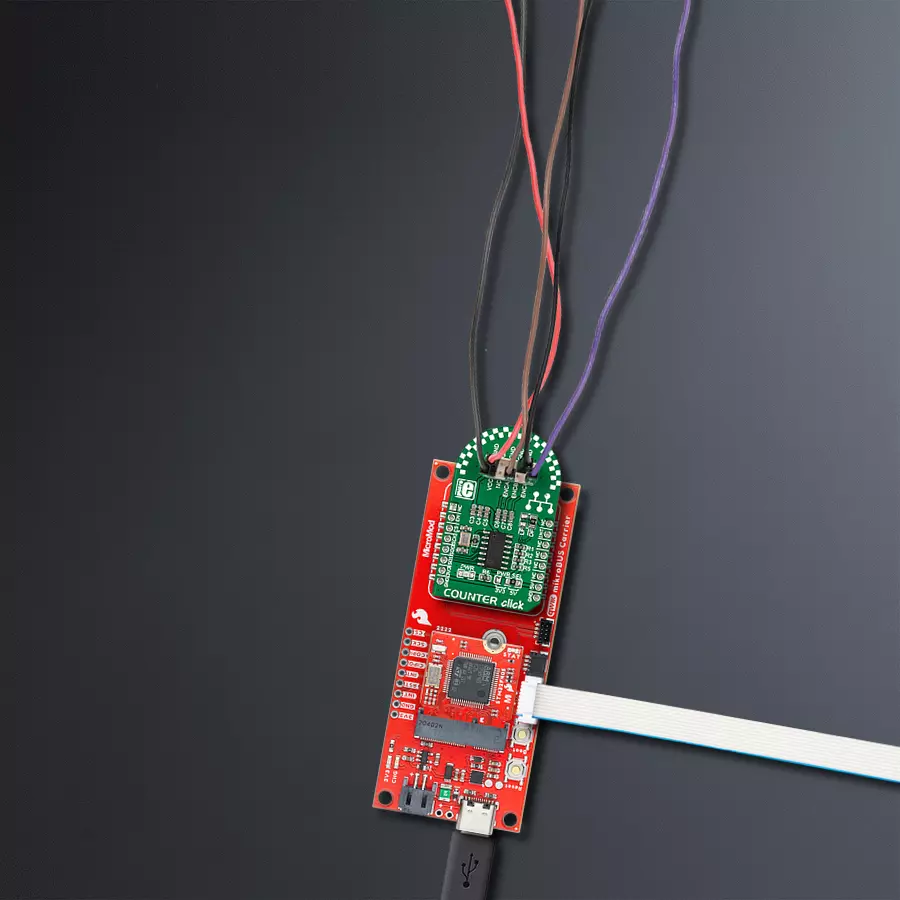

SparkFun MicroMod mikroBUS Carrier board takes advantage of the MicroMod, Qwiic, and mikroBUS™ ecosystems making it easy to prototype with each combined rapidly. The MicroMod M.2 socket and mikroBUS™ 8-pin header allow users to experiment with any processor board in the MicroMod ecosystem and any Click board™ in the mikroBUS™ ecosystem,

respectively. This board also features two Qwiic connectors to seamlessly integrate hundreds of Qwiic sensors and accessories into your project. The mikroBUS™ socket comprises a pair of 8-pin female headers with a standardized pin configuration. The pins consist of three groups of communications pins (SPI, UART, and I2C), six additional pins (PWM, Interrupt, Analog input,

Reset, and Chip select), and two power groups (3.3V and 5V). While a modern USB-C connector makes programming easy, the Carrier Board is also equipped with an MCP73831 single-cell Lithium-Ion/Lithium-Polymer charge IC so you can charge an attached single-cell Li-Po battery. The charge IC receives power from the USB connection and can source up to 450mA to charge an attached battery.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

STMicroelectronics

Pin count

64

RAM (Bytes)

196608

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

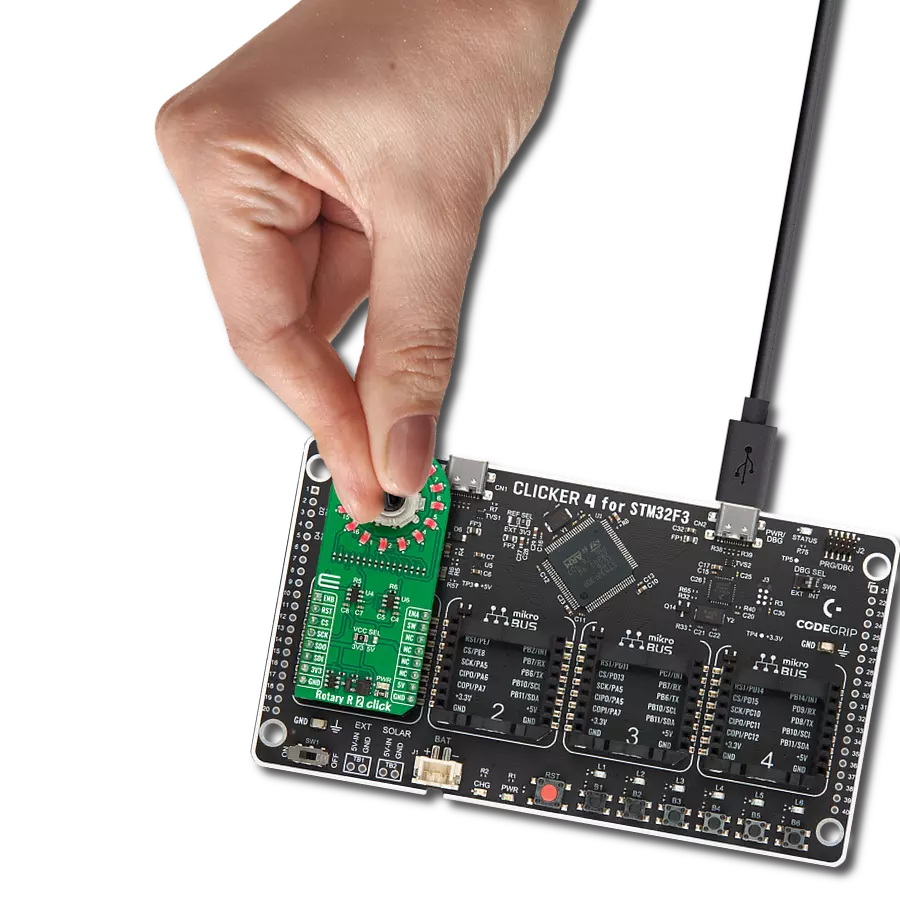

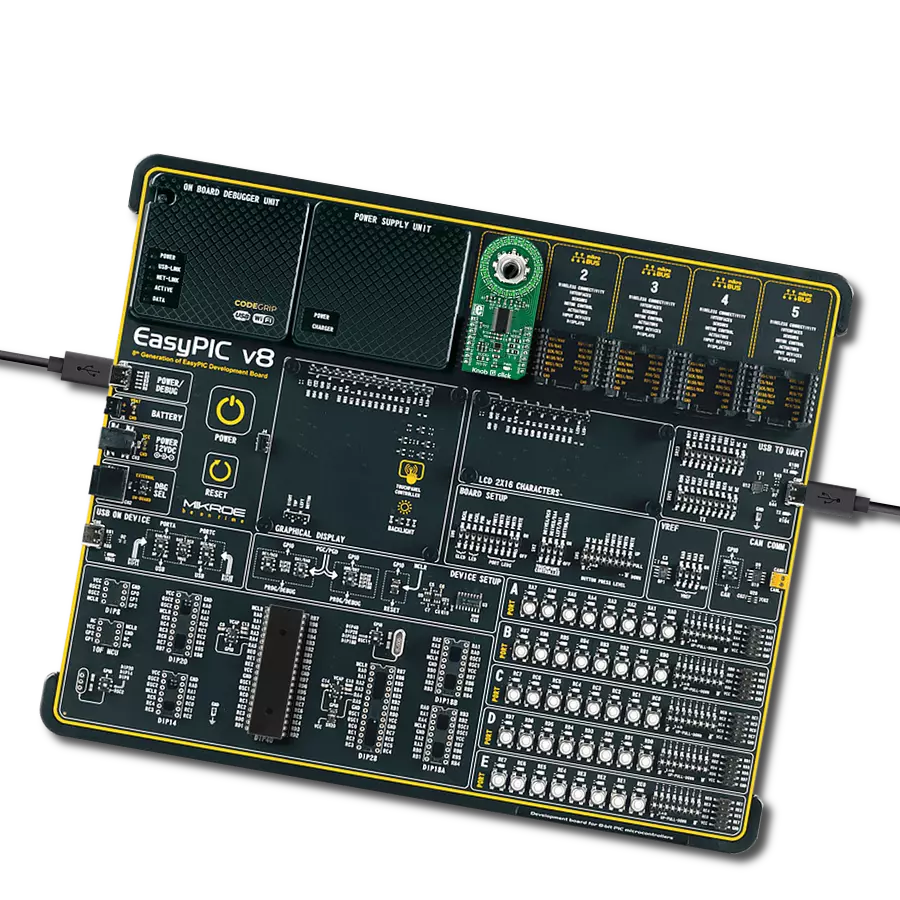

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Counter Click driver.

Key functions:

counter_read_cntr- This function reads CNTR, using click object.counter_read_str- This function reads STR, using click object.counter_read_otr- This function reads OTR, using click object.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Counter Click example

*

* # Description

* This application measures the speed and the position of the DC motor shafts.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes driver and configures the Click board.

*

* ## Application Task

* Reads data from the CNTR register and calculates the speed of the motor in Rad/s.

* All data is being displayed on the USB UART terminal where you can track their changes.

* The CNTR is a software configurable 8, 16, 24 or 32-bit up/down counter which

* counts the up/down pulses resulting from the quadrature clocks applied at the

* A and B inputs, or alternatively, in non-quadrature mode, pulses applied at the A input.

*

* ## NOTE

* An appropriate motor with optical encoder needs to be connected to the Click board.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "counter.h"

// ------------------------------------------------------------------ VARIABLES

static counter_t counter;

static log_t logger;

static int32_t count;

static int32_t count_old;

static float speed;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

counter_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

counter_cfg_setup( &cfg );

COUNTER_MAP_MIKROBUS( cfg, MIKROBUS_1 );

counter_init( &counter, &cfg );

counter_default_cfg( &counter );

Delay_ms ( 300 );

}

void application_task ( void )

{

count = counter_read_cntr( &counter );

log_printf( &logger, "Counter: %ld\r\n", count );

speed = ( float ) ( count - count_old ) / 3600.0;

speed *= 6.283185;

log_printf( &logger, "Speed: %.4f Rad/s\r\n", speed );

count_old = count;

log_printf( &logger, "-------------------------\r\n" );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Rotary encoder