Implement biometric fingerprint recognition and enable accurate and unique identification of individuals for secure access to digital systems and physical spaces

A

A

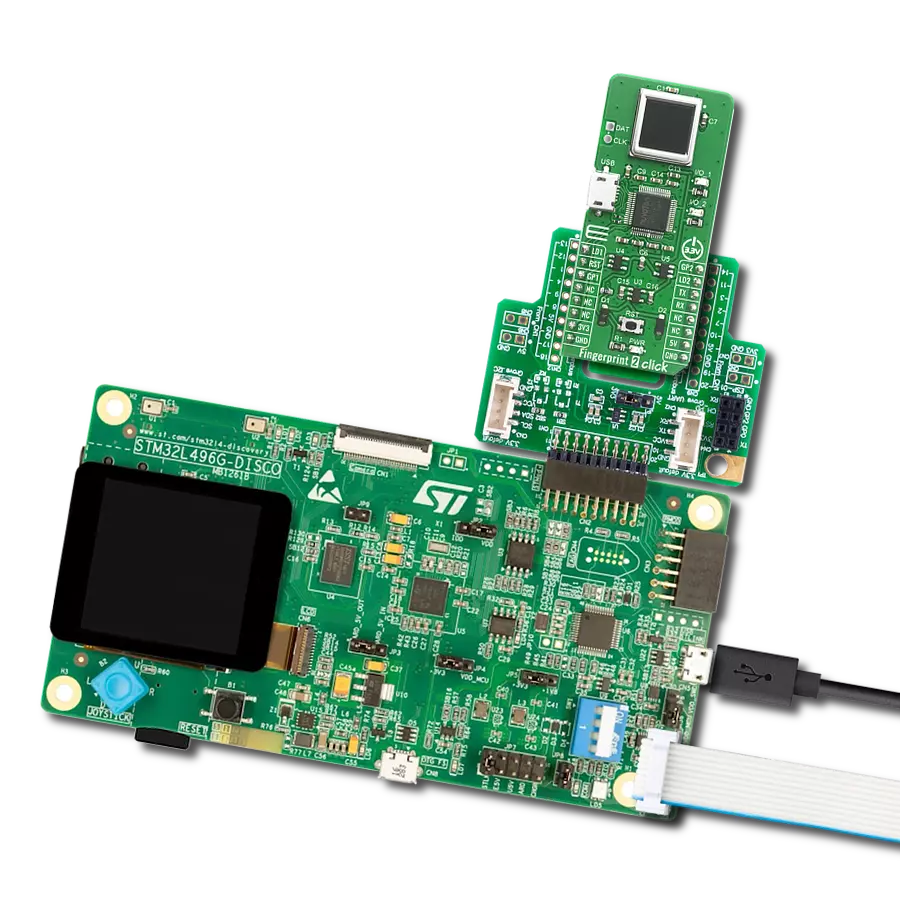

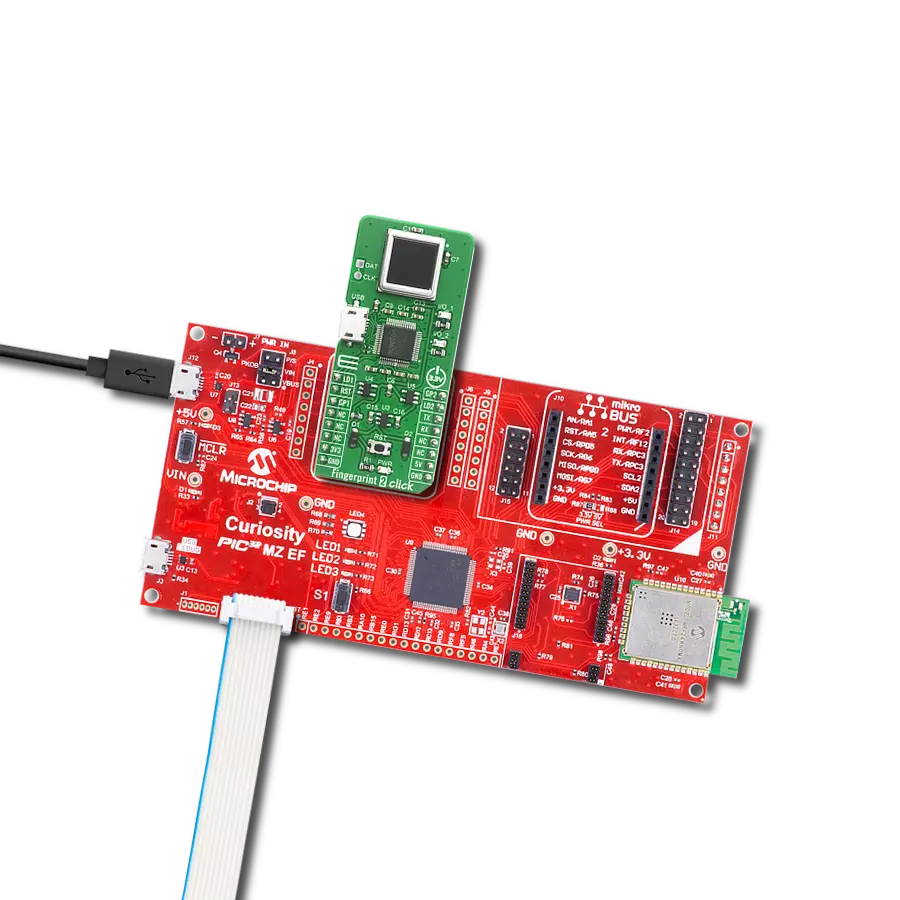

Hardware Overview

How does it work?

Fingerprint 2 Click is based on the A-172-MRQ, a 2D capacitive fingerprint sensor from ByNew Technology with an active scanning area of 8.8 x 8x8 mm and a 176 x 176 pixels resolution. The sensor is based on capacitive-contact technology with a hardened surface and enhanced ESD immunity. On board, Nuvoton M2301 MCU, which serves as interface IC and control unit, interfaces this sensor over a high-speed SPI interface and comes with built-in fingerprint matching capability while leaving most of the chip resource to application developers. Developers can develop fingerprint-related products based on the

communication protocol without advanced knowledge of fingerprint identification. The Fingerprint 2 Click has stable performance and a simple structure. The simplified functions for faster and easy development include fingerprint comparison, image scanning transmission, search, registered fingerprint storage, and the system's unique internal code protection mechanism. The fingerprint comparison program can register at most 24 fingerprints, the comparison speed is fast, and the correct rate is very high. Thanks to the Nuvoton MCU with the on-chip crypto-accelerator, Cortex-M23 TrustZone, and XOM facilities that

communicate with the fingerprint sensor and provide information to the host, the Fingerprint 2 Click board can be interfaced with commands over UART protocol (baud rate 115200) or USB 2.0 full speed. Fingerprint 2 Click needs to be supplied with 3.3V and 5V for proper operation. However, note that this board is designed to be operated only with 3.3V logic levels. Therefore a proper logic voltage level conversion should be performed before the Click board™ is used with MCUs with logic levels of 5V.

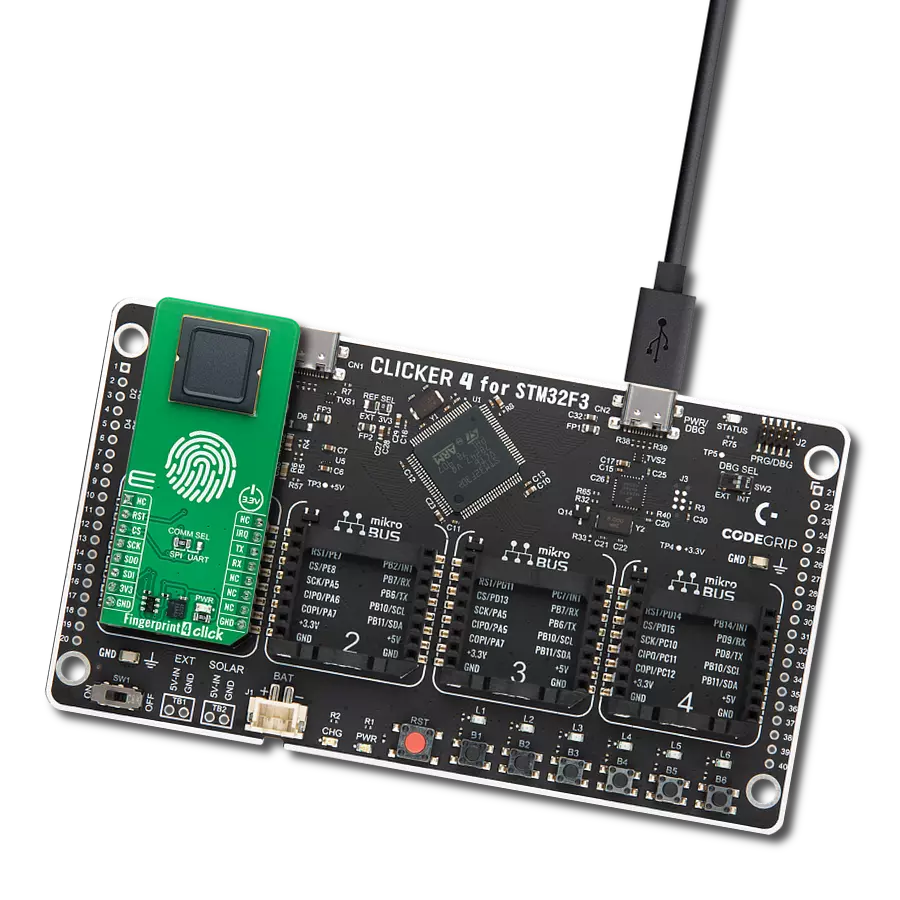

Features overview

Development board

Nucleo-64 with STM32G474R MCU offers a cost-effective and adaptable platform for developers to explore new ideas and prototype their designs. This board harnesses the versatility of the STM32 microcontroller, enabling users to select the optimal balance of performance and power consumption for their projects. It accommodates the STM32 microcontroller in the LQFP64 package and includes essential components such as a user LED, which doubles as an ARDUINO® signal, alongside user and reset push-buttons, and a 32.768kHz crystal oscillator for precise timing operations. Designed with expansion and flexibility in mind, the Nucleo-64 board features an ARDUINO® Uno V3 expansion connector and ST morpho extension pin

headers, granting complete access to the STM32's I/Os for comprehensive project integration. Power supply options are adaptable, supporting ST-LINK USB VBUS or external power sources, ensuring adaptability in various development environments. The board also has an on-board ST-LINK debugger/programmer with USB re-enumeration capability, simplifying the programming and debugging process. Moreover, the board is designed to simplify advanced development with its external SMPS for efficient Vcore logic supply, support for USB Device full speed or USB SNK/UFP full speed, and built-in cryptographic features, enhancing both the power efficiency and security of projects. Additional connectivity is

provided through dedicated connectors for external SMPS experimentation, a USB connector for the ST-LINK, and a MIPI® debug connector, expanding the possibilities for hardware interfacing and experimentation. Developers will find extensive support through comprehensive free software libraries and examples, courtesy of the STM32Cube MCU Package. This, combined with compatibility with a wide array of Integrated Development Environments (IDEs), including IAR Embedded Workbench®, MDK-ARM, and STM32CubeIDE, ensures a smooth and efficient development experience, allowing users to fully leverage the capabilities of the Nucleo-64 board in their projects.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

512

Silicon Vendor

STMicroelectronics

Pin count

64

RAM (Bytes)

128k

You complete me!

Accessories

Click Shield for Nucleo-64 comes equipped with two proprietary mikroBUS™ sockets, allowing all the Click board™ devices to be interfaced with the STM32 Nucleo-64 board with no effort. This way, Mikroe allows its users to add any functionality from our ever-growing range of Click boards™, such as WiFi, GSM, GPS, Bluetooth, ZigBee, environmental sensors, LEDs, speech recognition, motor control, movement sensors, and many more. More than 1537 Click boards™, which can be stacked and integrated, are at your disposal. The STM32 Nucleo-64 boards are based on the microcontrollers in 64-pin packages, a 32-bit MCU with an ARM Cortex M4 processor operating at 84MHz, 512Kb Flash, and 96KB SRAM, divided into two regions where the top section represents the ST-Link/V2 debugger and programmer while the bottom section of the board is an actual development board. These boards are controlled and powered conveniently through a USB connection to program and efficiently debug the Nucleo-64 board out of the box, with an additional USB cable connected to the USB mini port on the board. Most of the STM32 microcontroller pins are brought to the IO pins on the left and right edge of the board, which are then connected to two existing mikroBUS™ sockets. This Click Shield also has several switches that perform functions such as selecting the logic levels of analog signals on mikroBUS™ sockets and selecting logic voltage levels of the mikroBUS™ sockets themselves. Besides, the user is offered the possibility of using any Click board™ with the help of existing bidirectional level-shifting voltage translators, regardless of whether the Click board™ operates at a 3.3V or 5V logic voltage level. Once you connect the STM32 Nucleo-64 board with our Click Shield for Nucleo-64, you can access hundreds of Click boards™, working with 3.3V or 5V logic voltage levels.

Used MCU Pins

mikroBUS™ mapper

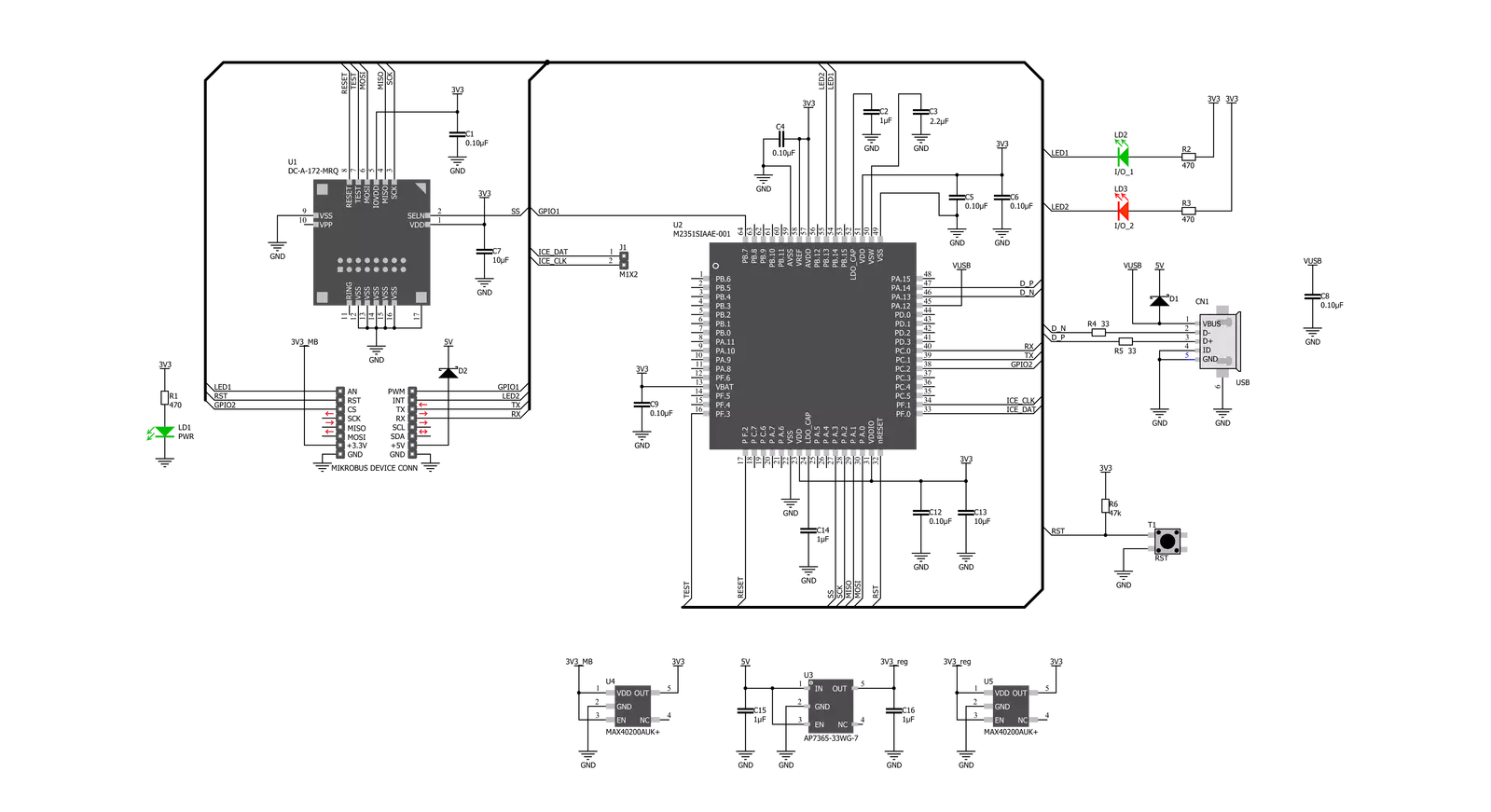

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Fingerprint 2 Click driver.

Key functions:

fingerprint2_reg_one_fp- This function registrates fingerprint on indexfingerprint2_delete_one_fp- This function deletes fingerprint on indexfingerprint2_reset- This function restarts device

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Fingerprint2 Click example

*

* # Description

* This example demonstrates the use of Fingerprint 2 Click board.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver, enables the Click board, and then executes a command for

* registering a fingerprint.

*

* ## Application Task

* Compares a fingerprint on input to the registered fingerprint and

* displays the results on the USB UART every 5 seconds.

*

* ## Additional Functions

* - fingerprint2_process ( ) - The general process of collecting data the module sends.

* - fp_reg_one ( uint8_t fngr_number ) - Registers a fingerprint at a specific index number.

* - fp_clr_one ( uint8_t fngr_number ) - Deletes a fingerprint from a specific index number.

* - fp_clr_all ( ) - Clears all fingerprints.

* - fp_curr_state ( ) - Lists the registration status and returns the number of registered fingerprints.

* - fp_compare ( ) - Compares a fingerprint on input to all other fingerprints that are memorized.

*

* @note

* In the registration state each fingerprint needs to be enrolled 3 times.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "fingerprint2.h"

#include "string.h"

#define PROCESS_COUNTER 100

#define PROCESS_RX_BUFFER_SIZE 800

// ------------------------------------------------------------------ VARIABLES

static fingerprint2_t fingerprint2;

static log_t logger;

uint8_t flag;

// ------------------------------------------------------- ADDITIONAL FUNCTIONS

static void fingerprint2_process ( void )

{

int32_t rsp_size;

uint8_t check_buf_cnt;

uint8_t process_cnt = PROCESS_COUNTER;

char uart_rx_buffer[ PROCESS_RX_BUFFER_SIZE ] = { 0 };

flag = 0;

while( process_cnt != 0 )

{

rsp_size = fingerprint2_generic_read( &fingerprint2, &uart_rx_buffer, PROCESS_RX_BUFFER_SIZE );

if ( rsp_size > 0 )

{

// Validation of the received data

for ( check_buf_cnt = 0; check_buf_cnt < rsp_size; check_buf_cnt++ )

{

if ( uart_rx_buffer[ check_buf_cnt ] == 0 )

{

uart_rx_buffer[ check_buf_cnt ] = 13;

}

}

log_printf( &logger, "%s", uart_rx_buffer );

if ( strstr( uart_rx_buffer, "</R>" ) )

{

flag = 1;

process_cnt = 5;

}

// Clear RX buffer

memset( uart_rx_buffer, 0, PROCESS_RX_BUFFER_SIZE );

}

else

{

process_cnt--;

// Process delay

Delay_100ms( );

}

}

}

//Write index number of fingeprint to be store: from 0 to 23

void fp_reg_one ( uint8_t fngr_number )

{

log_printf( &logger, "Registration process\r\n" );

Delay_ms ( 500 );

fingerprint2_reg_one_fp( &fingerprint2, fngr_number );

do

{

fingerprint2_process( );

}

while ( flag == 0 );

}

// Write index number of fingeprint to be deleted: from 0 to 23

void fp_clr_one ( uint8_t fngr_number )

{

log_printf( &logger, "Deleting process\r\n" );

Delay_ms ( 500 );

fingerprint2_delete_one_fp( &fingerprint2, fngr_number );

do

{

fingerprint2_process( );

}

while ( flag == 0 );

}

// Delete all fingeprints: from 0 to 23

void fp_clr_all ( )

{

uint8_t cnt = 0;

log_printf( &logger, "Process of deleting all fingeprints\r\n" );

Delay_ms ( 500 );

while ( cnt < 23 )

{

fingerprint2_delete_one_fp( &fingerprint2, cnt );

cnt++;

do

{

fingerprint2_process( );

}

while ( flag == 0 );

}

}

// Current state ( number of memorized fingerprints )

void fp_curr_state ( )

{

fingerprint2_generic_write( &fingerprint2, FINGERPRINT2_CMD_FP_REG_NO, strlen( FINGERPRINT2_CMD_FP_REG_NO ) );

do

{

fingerprint2_process( );

}

while ( flag == 0 );

}

// Compare fingerprint on input with all other fingerprints that are memorized.

void fp_compare ( )

{

fingerprint2_generic_write( &fingerprint2, FINGERPRINT2_CMD_FP_CMP, strlen( FINGERPRINT2_CMD_FP_CMP ) );

fingerprint2_process( );

do

{

fingerprint2_process( );

}

while ( flag == 0 );

}

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

fingerprint2_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

fingerprint2_cfg_setup( &cfg );

FINGERPRINT2_MAP_MIKROBUS( cfg, MIKROBUS_1 );

fingerprint2_init( &fingerprint2, &cfg );

fingerprint2_reset ( &fingerprint2 );

Delay_ms ( 1000 );

fp_reg_one( 0 );

Delay_ms ( 1000 );

}

void application_task ( void )

{

fp_compare( );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Fingerprint