Lighten the bar graph display according to the sound quality

A

A

Hardware Overview

How does it work?

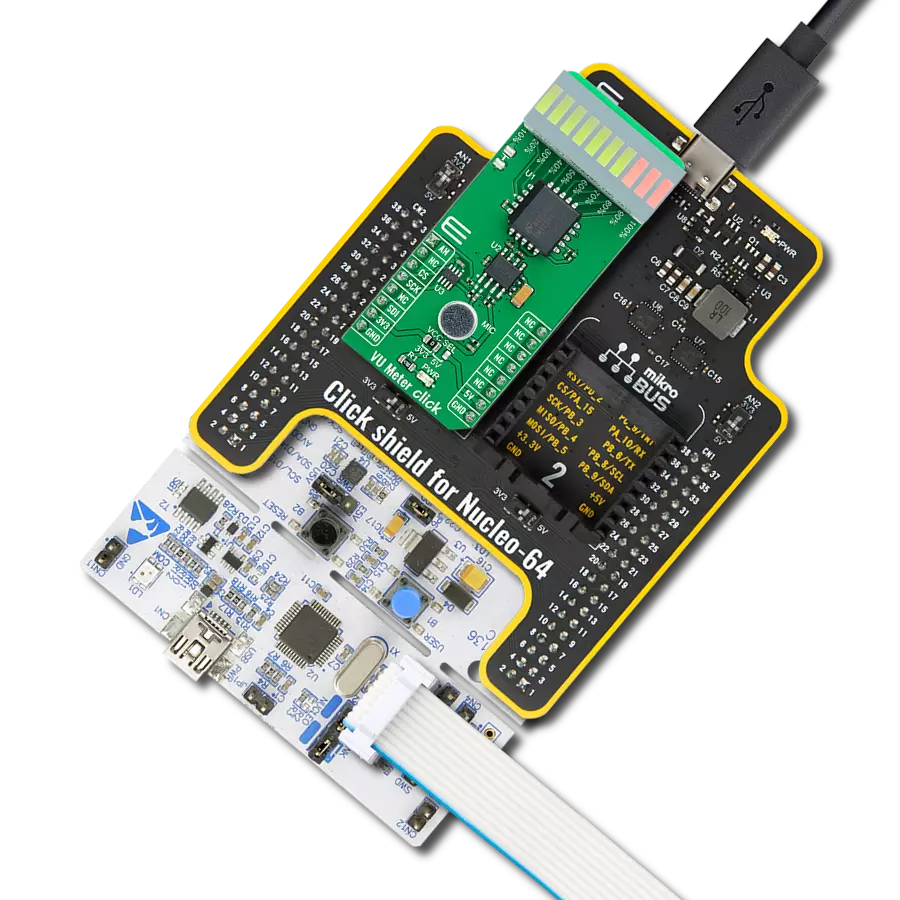

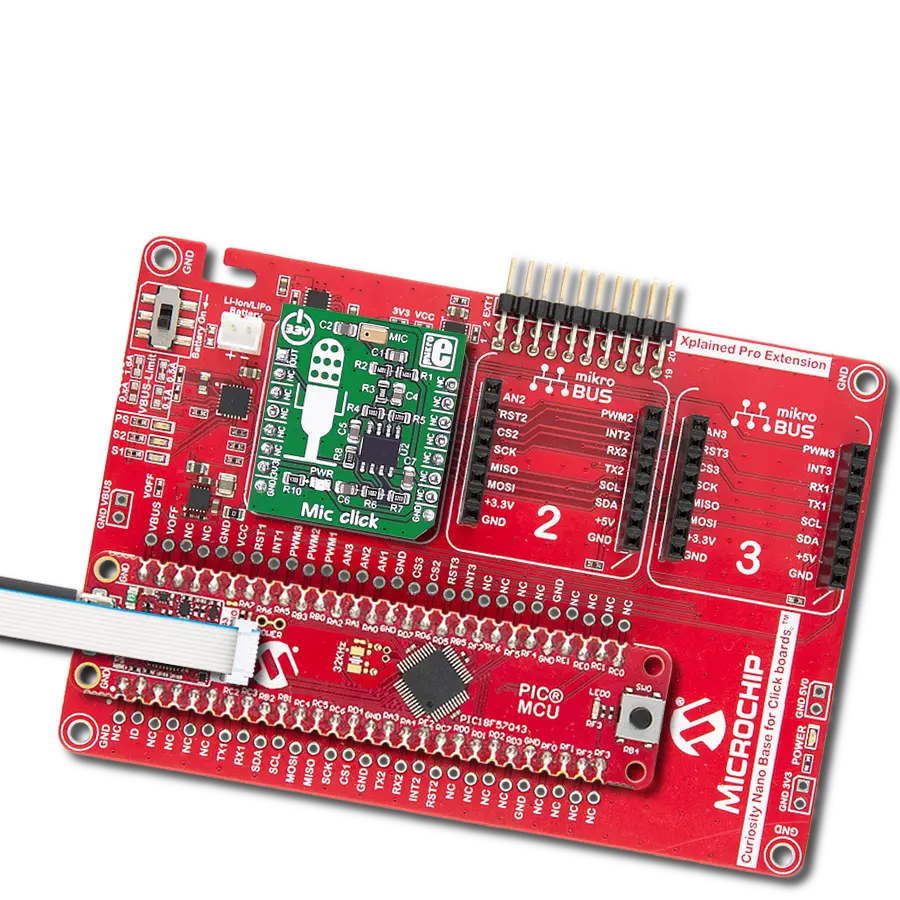

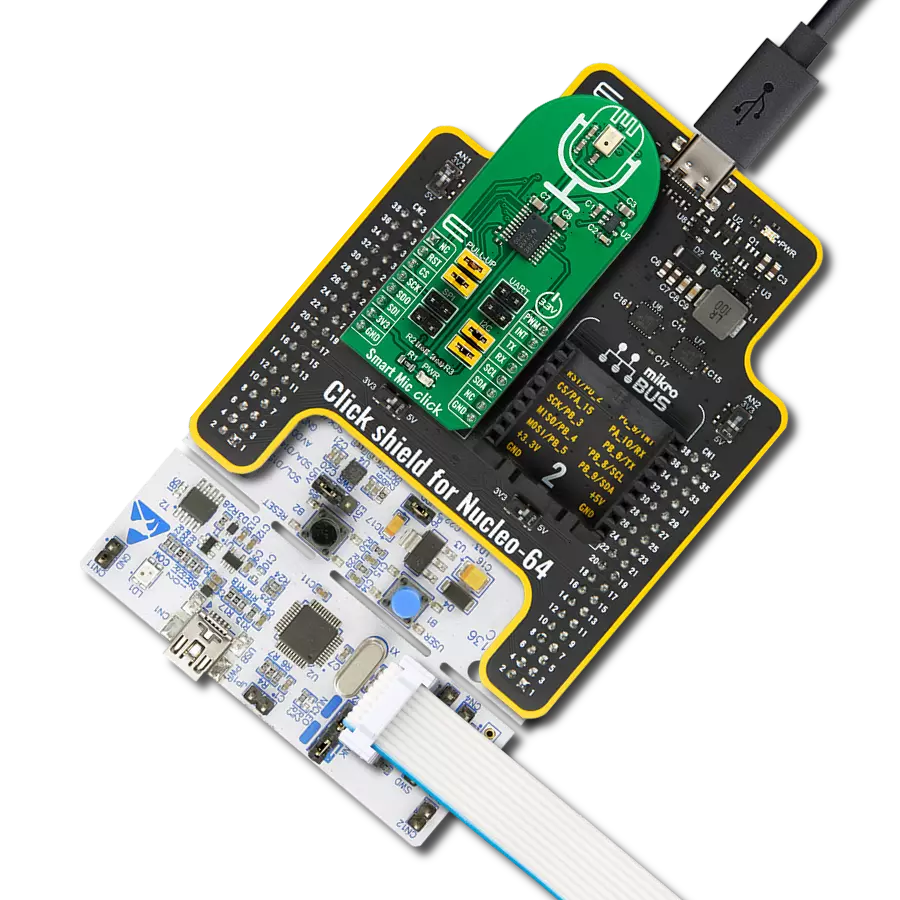

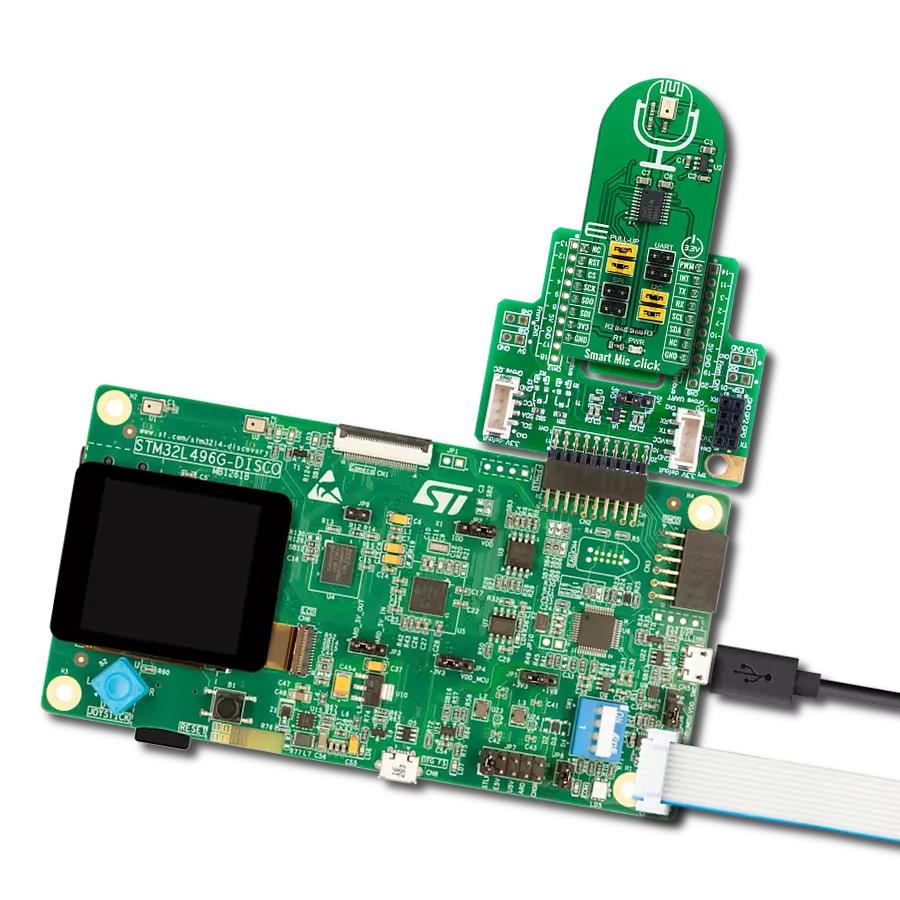

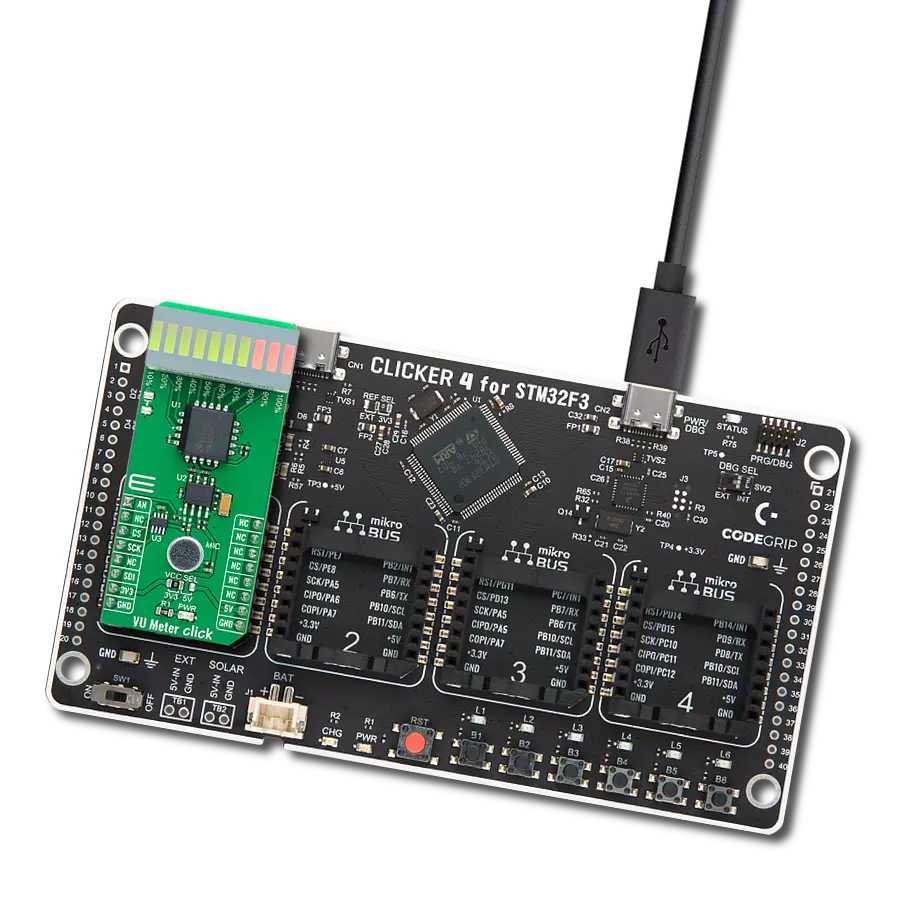

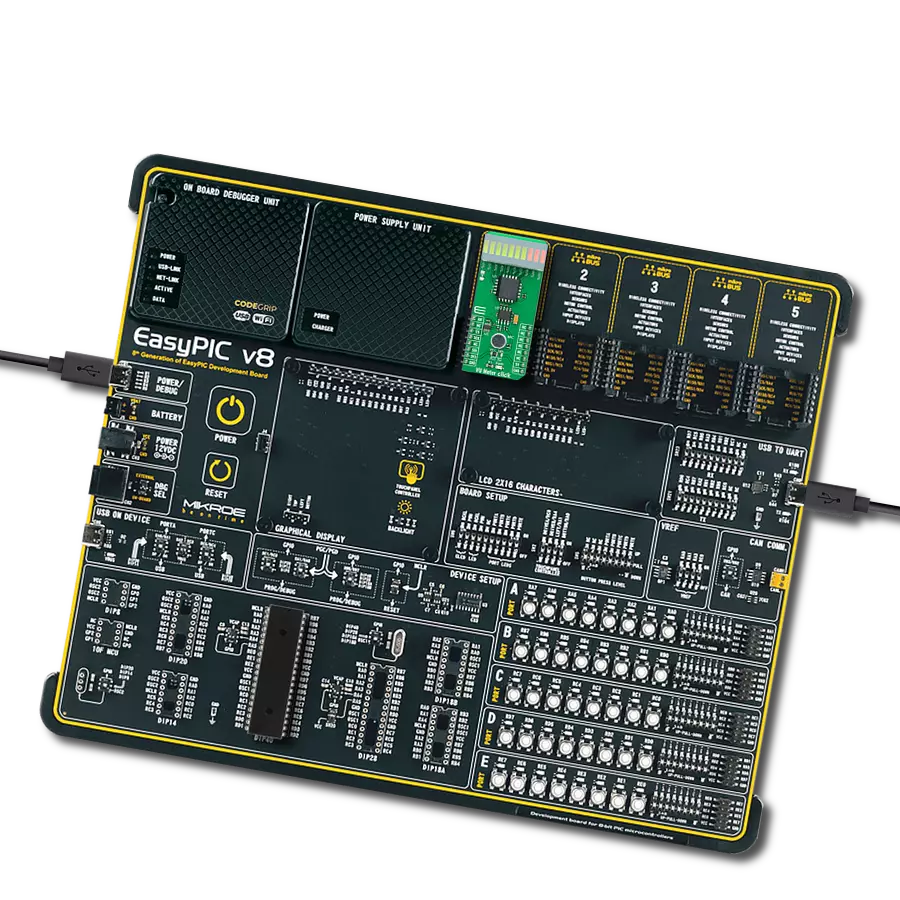

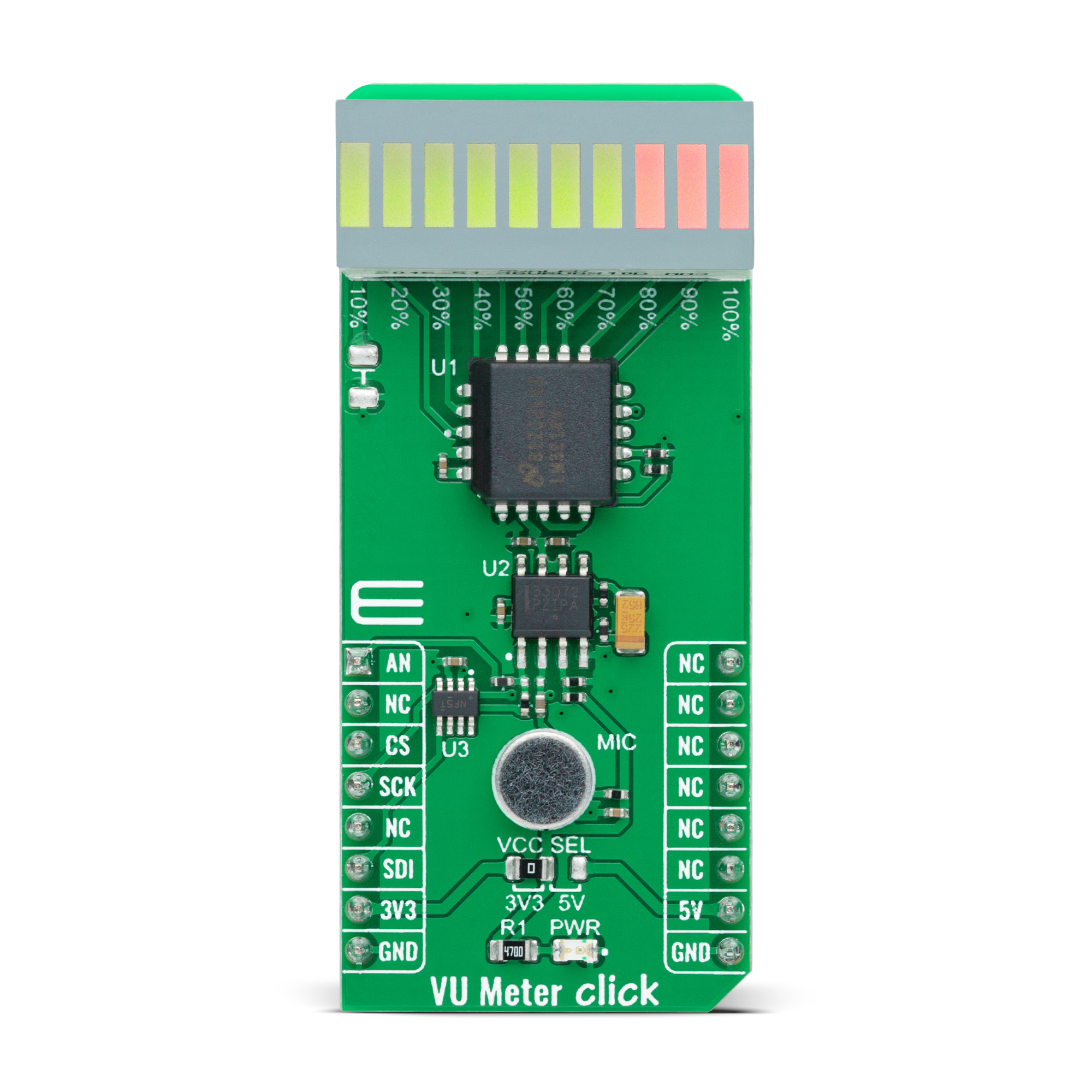

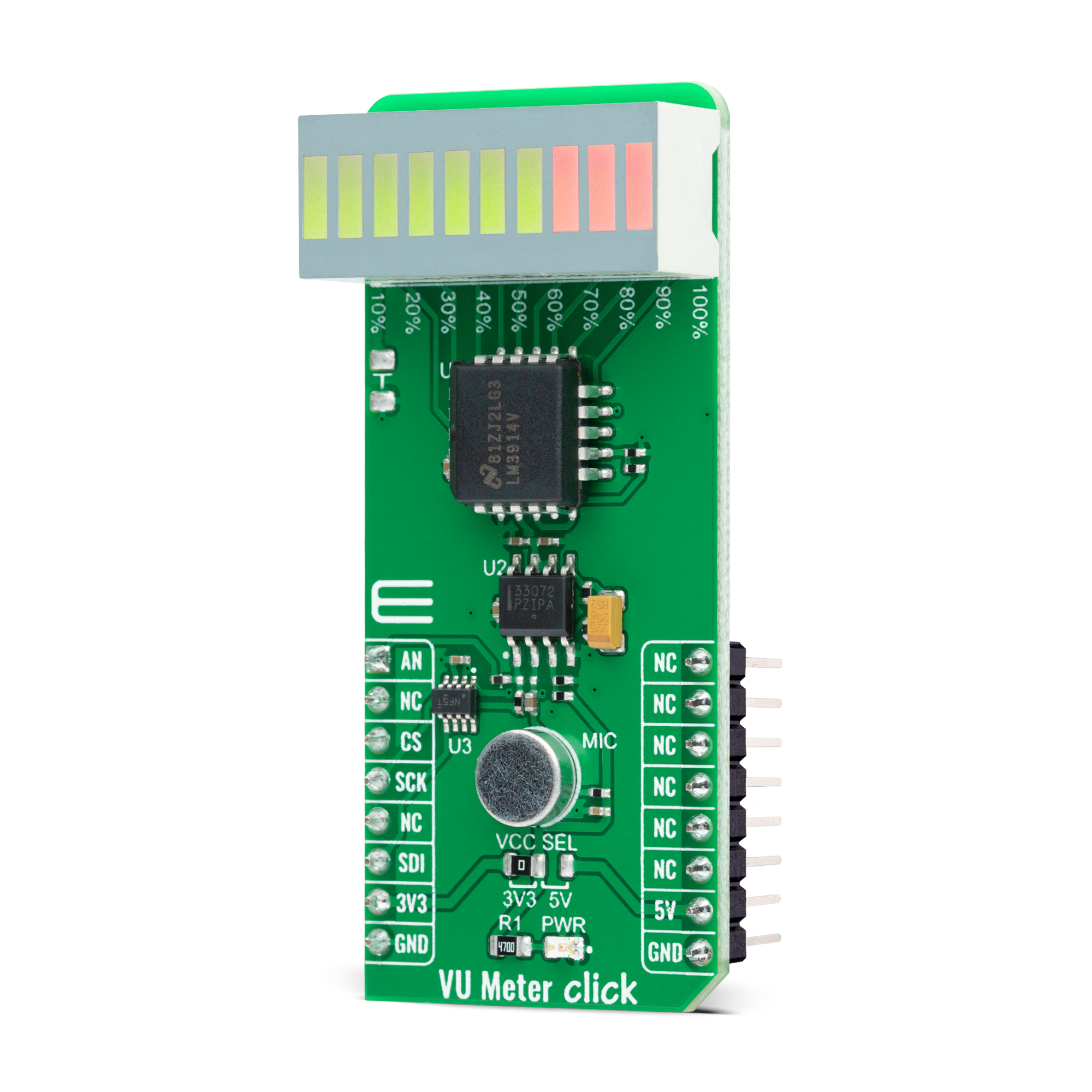

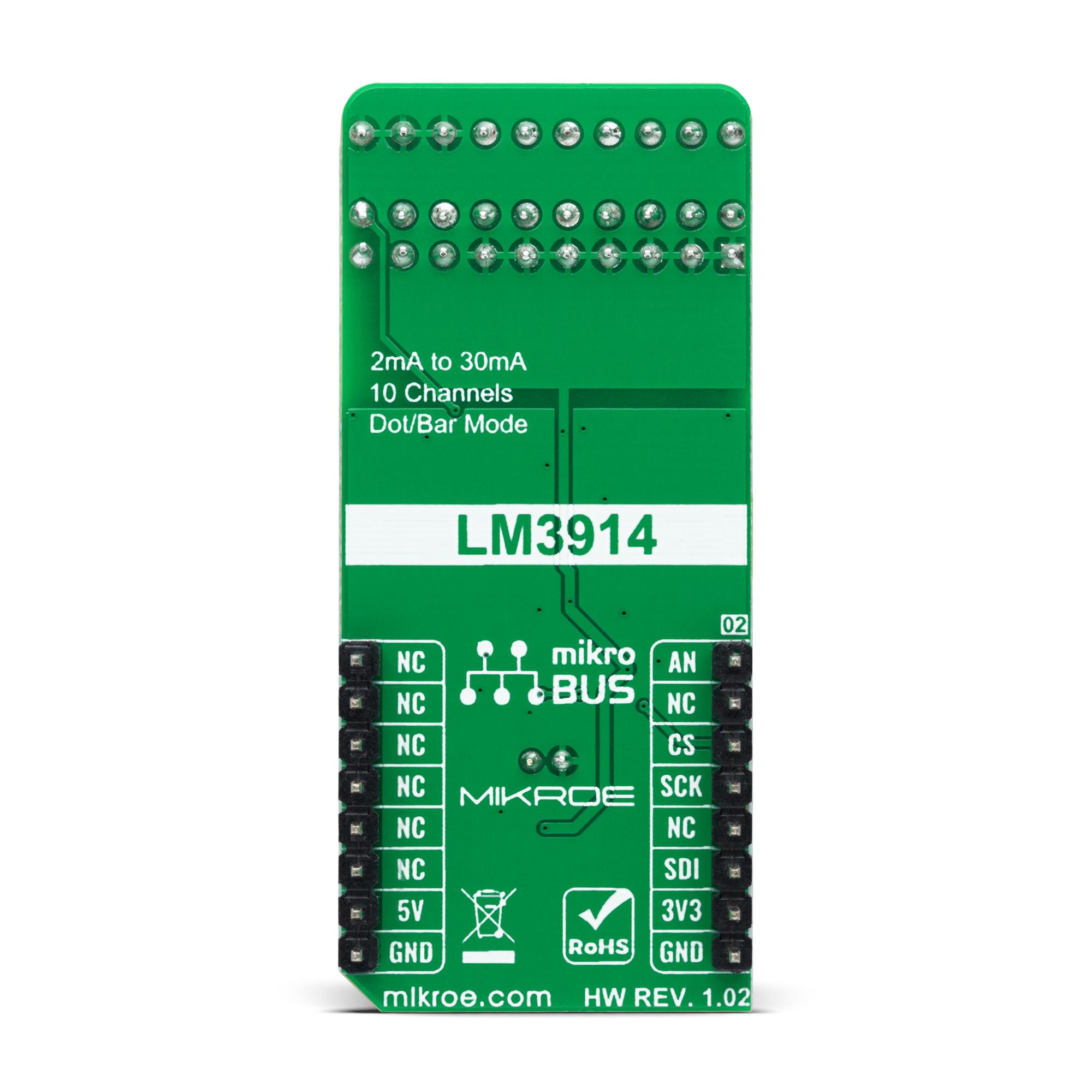

VU Meter Click is based on the LM3914, a monolithic integrated circuit that senses analog voltage levels and drives a 10-segment bar graph display from Texas Instruments. This solution is a compact volume unit meter. This analog-controlled driver means it can control display by an analog input voltage and eliminates the need for additional programming. A volume unit meter represents a device that displays the intensity of an audio signal; more specifically, it is used to visualize analog signals. That's why VU Meter Click is suitable as a volume measurement gadget. The LM3914 is configured to work in bar mode, where all parts of the bar graph display below a certain point turn on. This board is manufactured with an onboard sound-detecting device (microphone), the MC33072 Op-Amp, and the LM3914, which gleams the bar graph display according to the sound's quality.

Initially, the microphone captures and transforms the sound into linear voltages to sound amplitude. The capacitor then stops the DC component of the transmission, allowing the AC input from the microphone to enter the MC33072 Op-Amp. One part of the MC33072 represents a variable gain inverting amplifier using the TPL0501, an SPI-configurable digital potentiometer from Texas Instruments, while the second part represents a signal buffer. After filtration and amplification, these filtered and amplified signals are finally provided to LM3914. Considering that this driver is analog controlled, this Click board™ also provides the ability to monitor the analog signal by the MCU via the AN pin of the mikroBUS™ socket. The LM3914 operates in a voltmeter format and lights the XGURUGX10D, a ten-segment bar graph array, according to the strength of the given signal.

The onboard bar graph display segments are bright and uniformly colored, providing pleasant and clean visual feedback. Each segment is composed of green and red-colored LEDs, making it possible to have various essential states marked in a different colors. It can use green, red, and a combination of these two, resulting in amber-colored segments. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. However, the Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used, as a reference, for further development.

Features overview

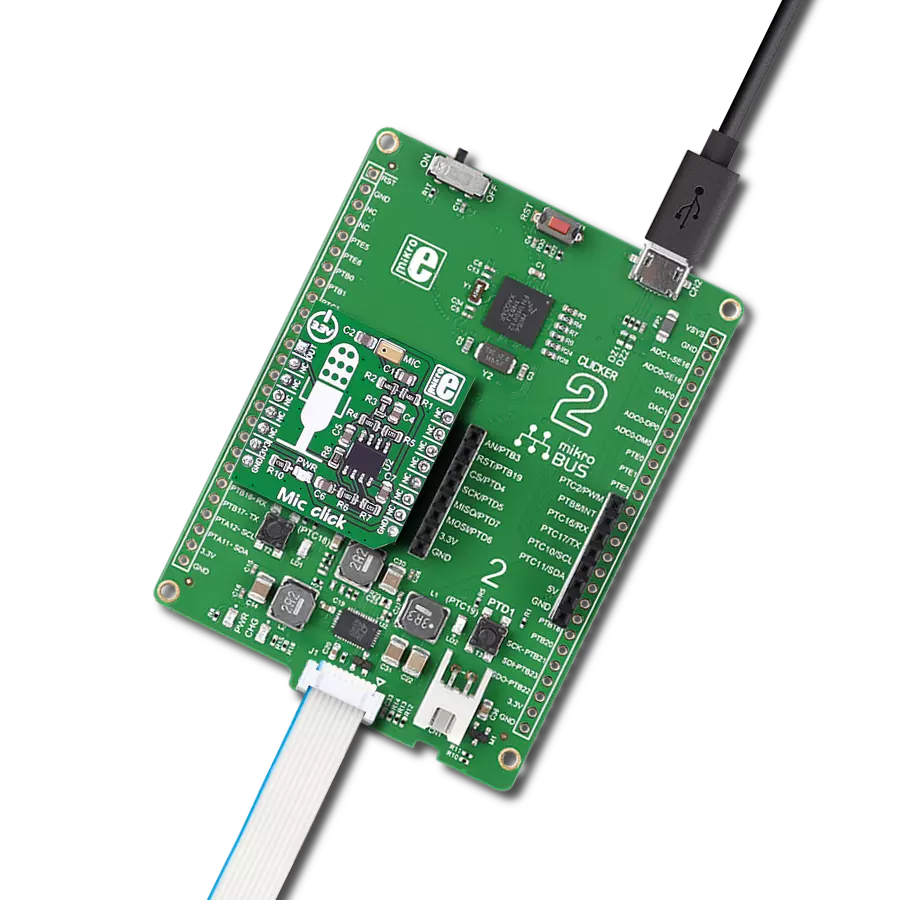

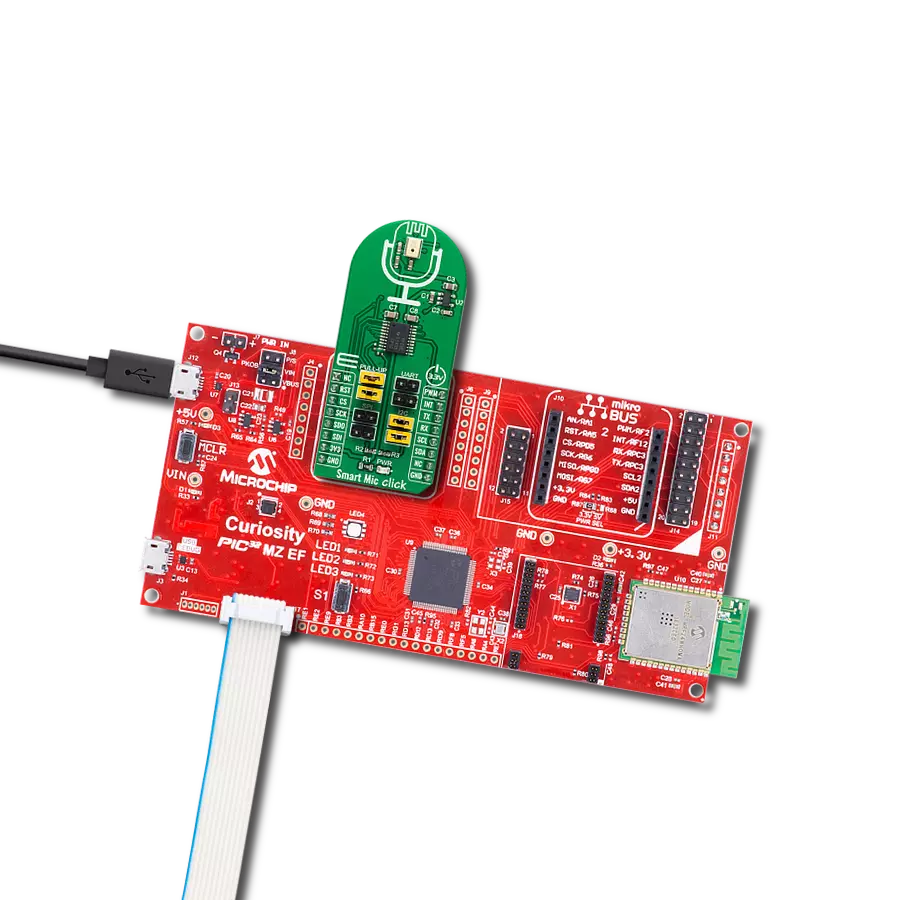

Development board

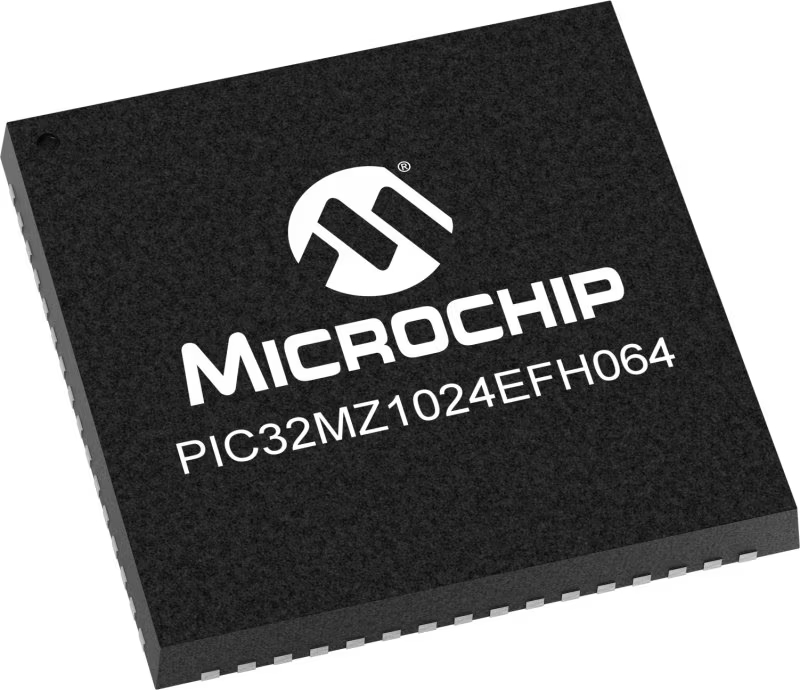

PIC32MZ Clicker is a compact starter development board that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit PIC32MZ microcontroller with FPU from Microchip, a USB connector, LED indicators, buttons, a mikroProg connector, and a header for interfacing with external electronics. Thanks to its compact design with clear and easy-recognizable silkscreen markings, it provides a fluid and immersive working experience, allowing access anywhere and under

any circumstances. Each part of the PIC32MZ Clicker development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the PIC32MZ Clicker programming method, using USB HID mikroBootloader, or through an external mikroProg connector for PIC, dsPIC, or PIC32 programmer, the Clicker board also includes a clean and regulated power supply module for the development kit. The USB Micro-B connection can provide up to 500mA of current, which is more than enough to operate all onboard

and additional modules. All communication methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, reset button, and several buttons and LED indicators. PIC32MZ Clicker is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

1024

Silicon Vendor

Microchip

Pin count

64

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for VU Meter Click driver.

Key functions:

vumeter_read_an_pin_voltageThis function reads the results of the AD conversion of the AN pin and converts them to a proportional voltage level.vumeter_set_gain_levelThis function sets the input signal gain level (the microphone sensitivity).vumeter_calculate_vu_levelThis function calculates the VU level from the analog voltage input.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief VUMeter Click example

*

* # Description

* This example demonstrates the use of VU Meter Click board.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and sets the gain level (the microphone sensitivity) to maximum.

*

* ## Application Task

* Calculates VU level from the analog voltage read from AN pin, and displays the results

* on the USB UART approximately every 100ms.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "vumeter.h"

static vumeter_t vumeter;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

vumeter_cfg_t vumeter_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

vumeter_cfg_setup( &vumeter_cfg );

VUMETER_MAP_MIKROBUS( vumeter_cfg, MIKROBUS_1 );

err_t init_flag = vumeter_init( &vumeter, &vumeter_cfg );

if ( SPI_MASTER_ERROR == init_flag )

{

log_error( &logger, " Application Init Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

vumeter_set_gain_level ( &vumeter, VUMETER_GAIN_LEVEL_MAX );

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

log_printf( &logger, " VU level: %.3f VU\r\n", vumeter_calculate_vu_level ( &vumeter, 100 ) );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Microphone