Fast and non-volatile magneto-resistive random-access memory

A

A

Hardware Overview

How does it work?

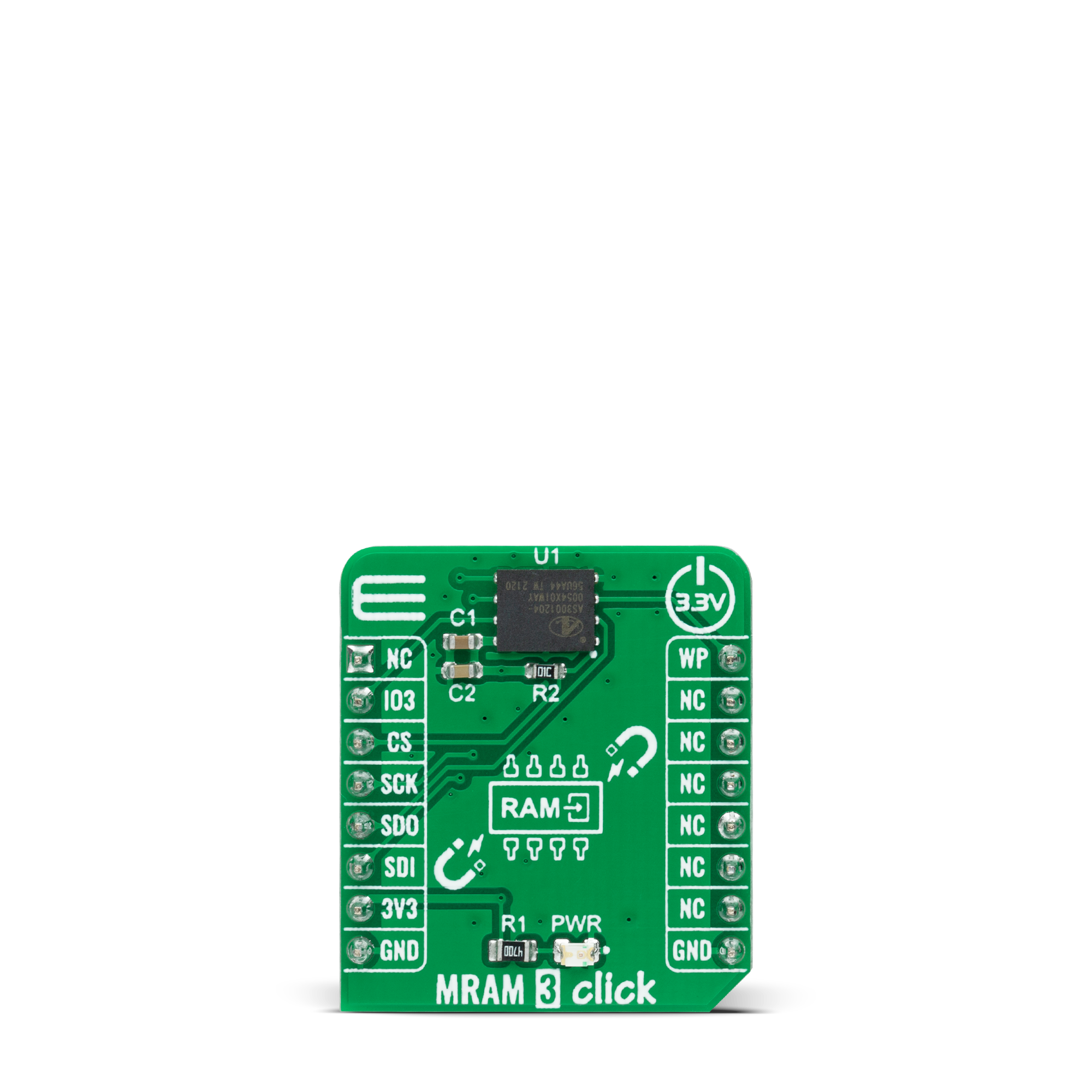

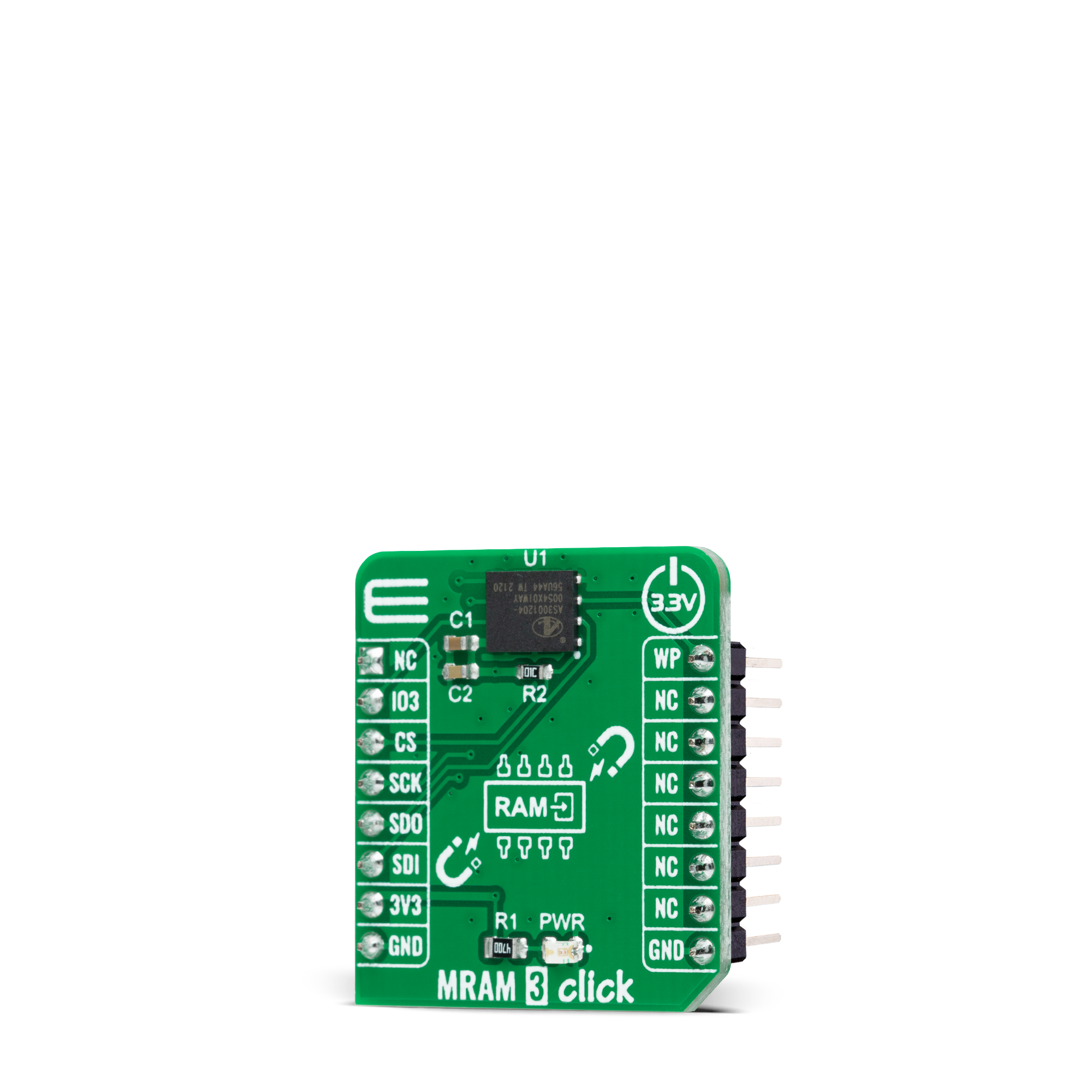

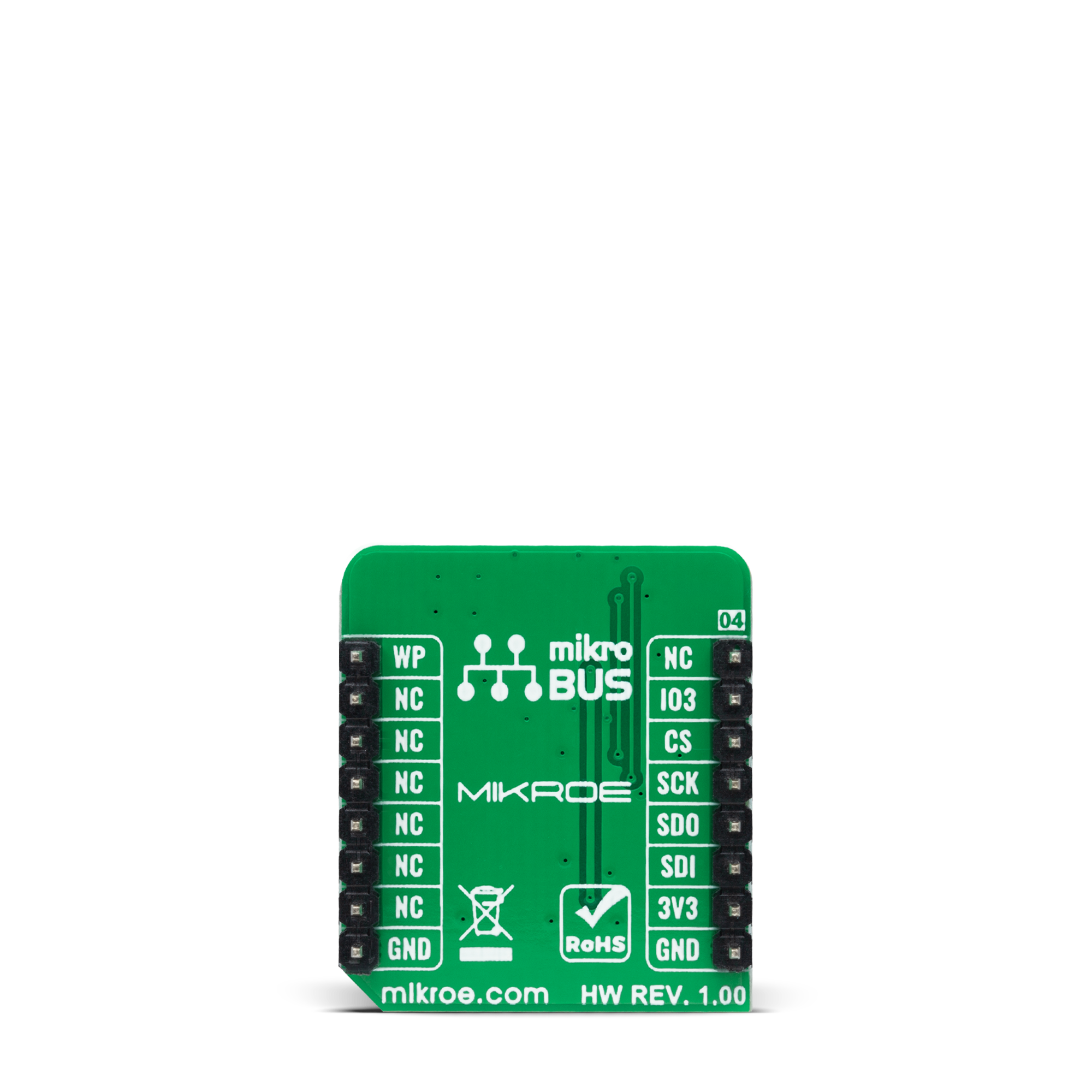

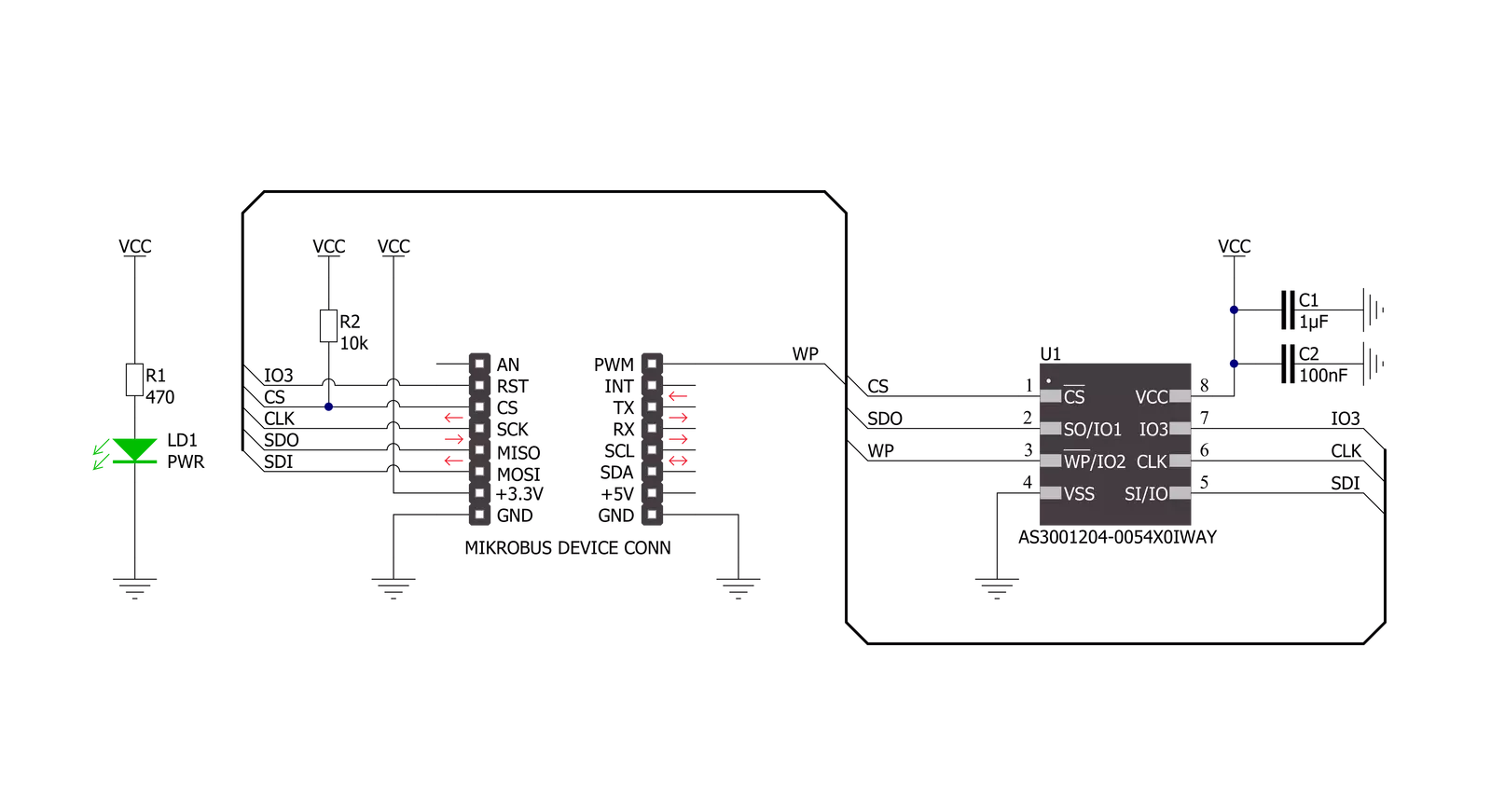

MRAM 3 Click is based on the AS3001204, a 1Mb MRAM memory with an SPI interface and Write Protection feature from Avalanche Technology. The AS3001204 is organized as 128K words of 8 bits each and benefits from 1.000.000 years of data retention combining their unprecedented data storage with excellent energy efficiency. It is highly reliable, lasting 1014 full-memory read/write/erase cycles, which makes this Click board™ suitable for high-reliability applications as a non-volatile storage media or temporary RAM expansion for storing data in any embedded application. The AS3001204 is an accurate random-access memory that allows both reads and writes to occur randomly. It offers low latency, low power, and scalable non-volatile memory

technology. The MRAM technology is analog to Flash technology with SRAM-compatible read/write timings (Persistent SRAM, P-SRAM), where data is always non-volatile. MRAM 3 Click communicates with MCU using the SPI serial interface that supports the Dual/Quad SPI and the two most common modes, SPI Mode 0 and 3, with a maximum SPI frequency of 108MHz. Alongside an SPI-compatible bus interface, the AS3001204 also features an eXecute-In-Place (XIP) functionality which allows completing a series of reading and writing instructions without having to individually load the read or write command for each instruction and hardware/software-based data protection mechanisms. Hardware Write Protection function, labeled and routed to the WP pin

of the mikroBUS™ socket, allows the user to freeze the entire memory area, thus protecting it from writing instructions. The IO3 pin of the mikroBUS™ socket is bidirectional I/O that transfers data into and out of the device in Dual and Quad SPI modes. This Click board™ can only be operated from a 3.3V logic voltage level. Therefore, the board must perform appropriate logic voltage conversion before using MCUs with different logic levels. However, the Click board™ comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

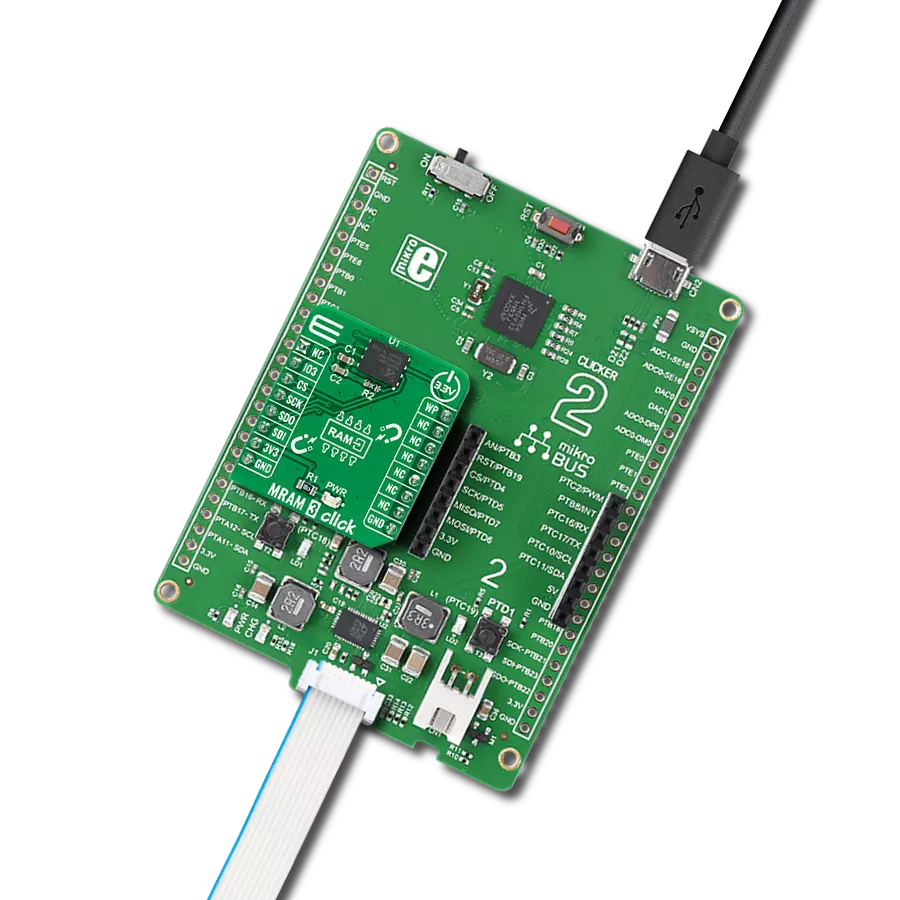

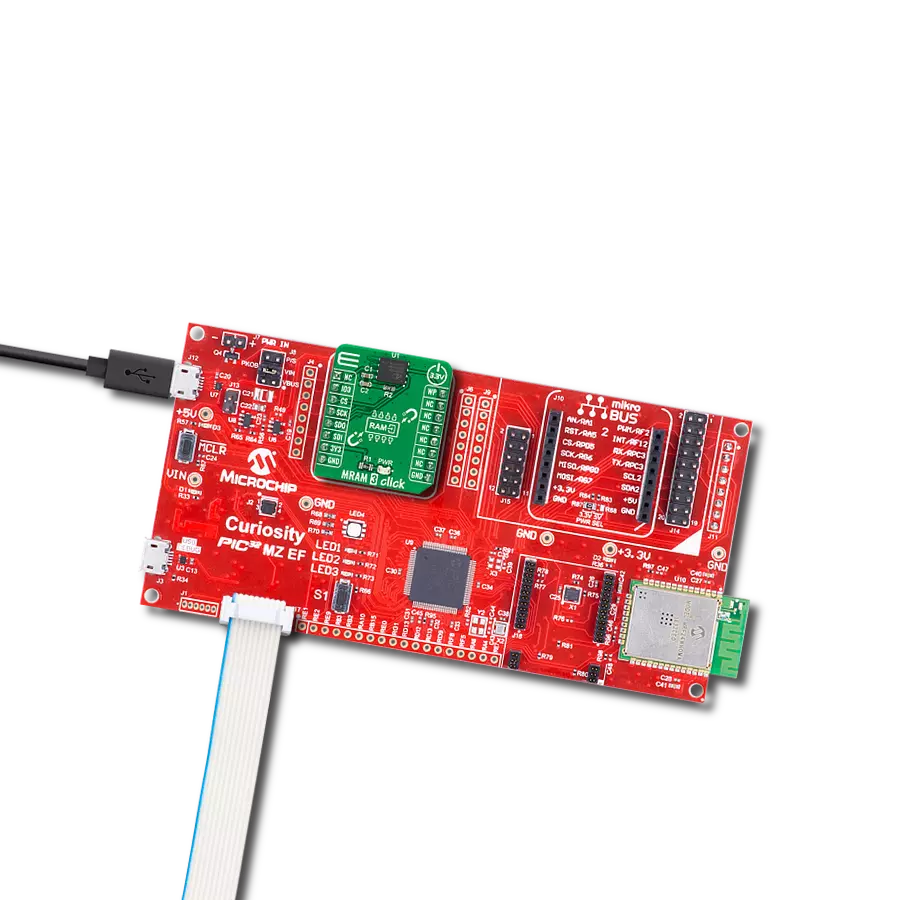

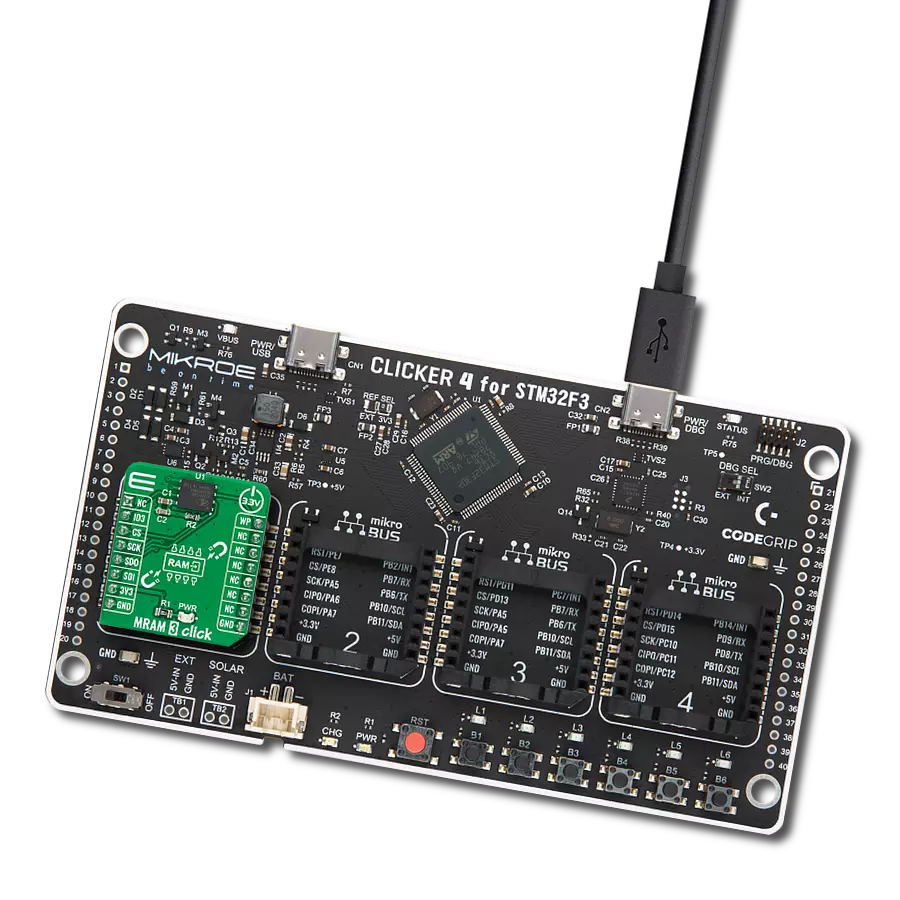

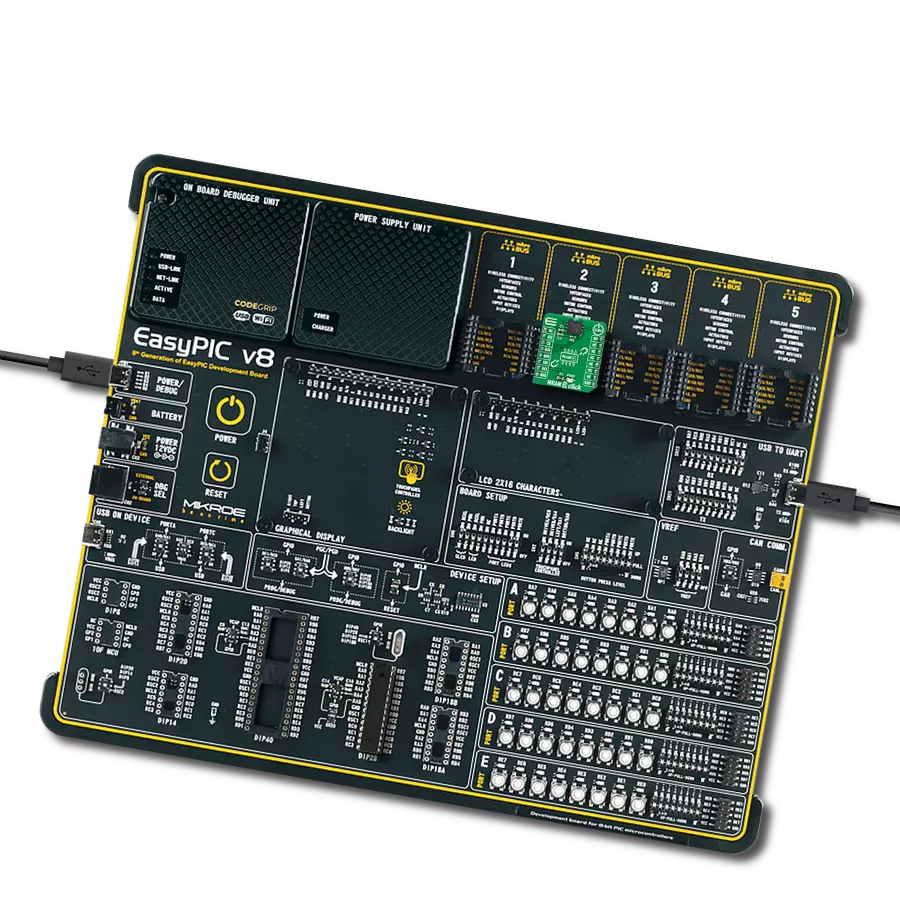

Development board

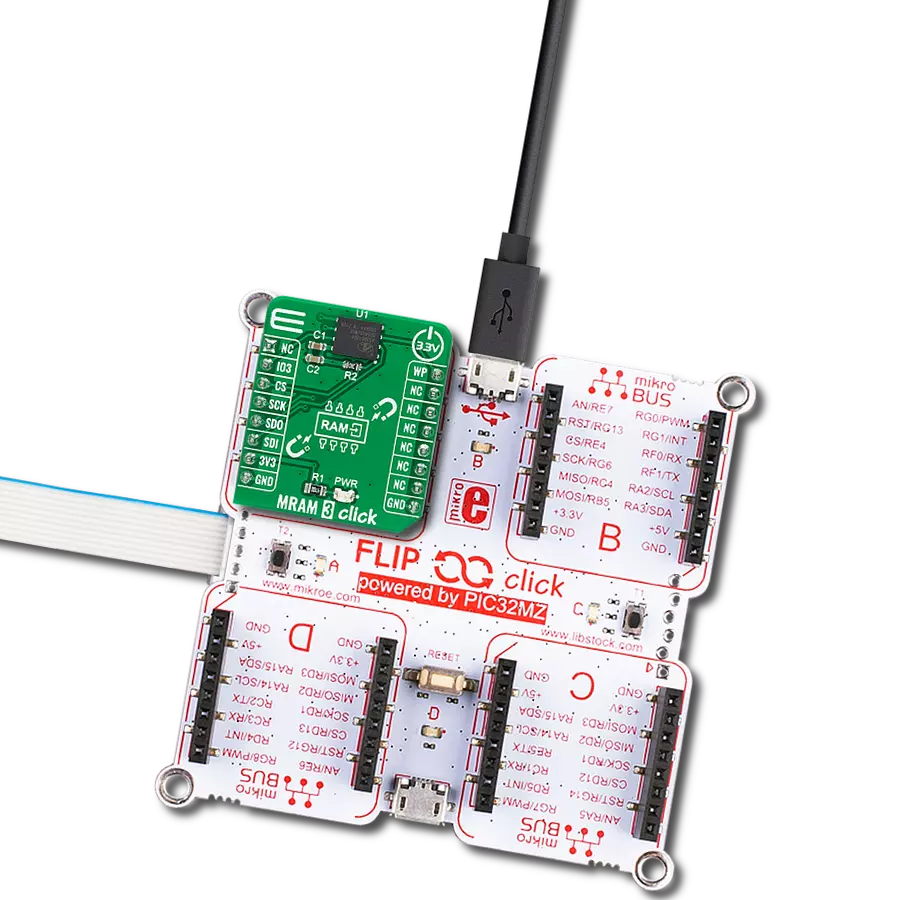

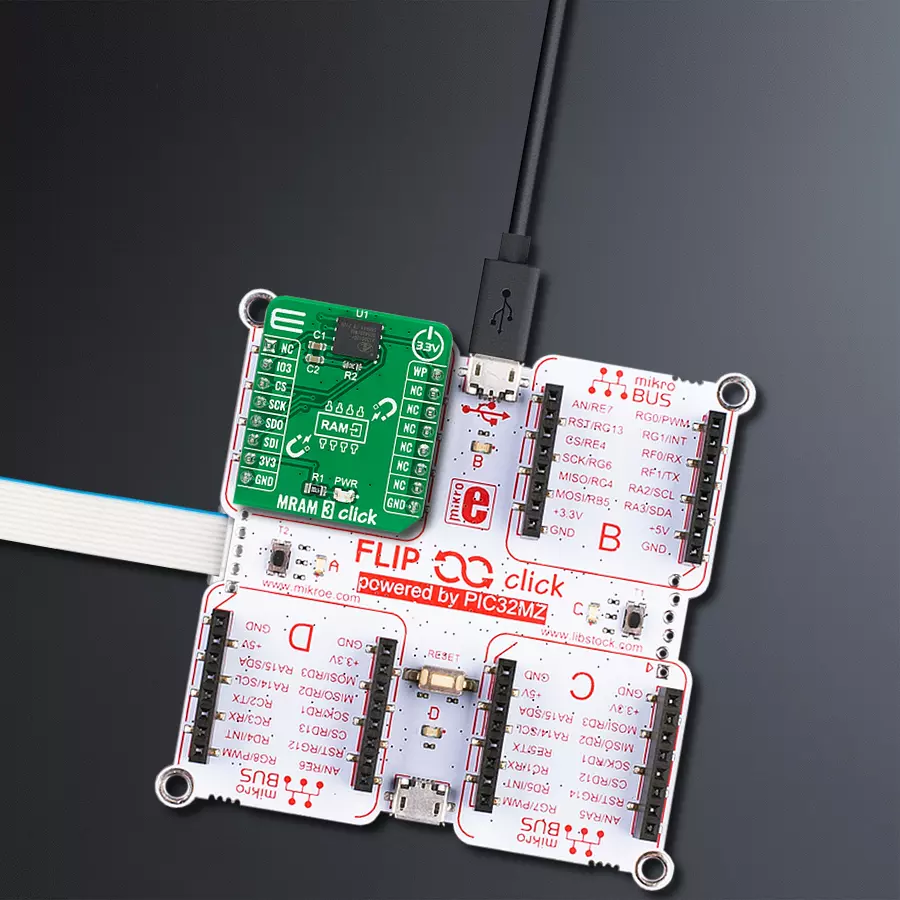

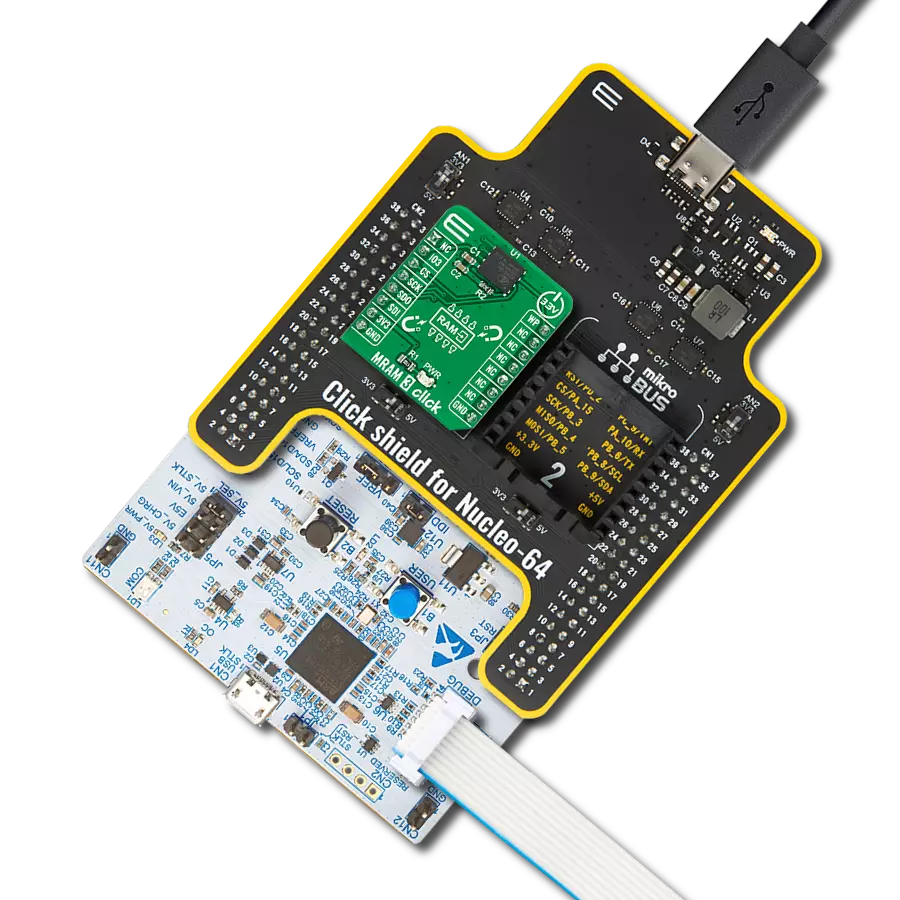

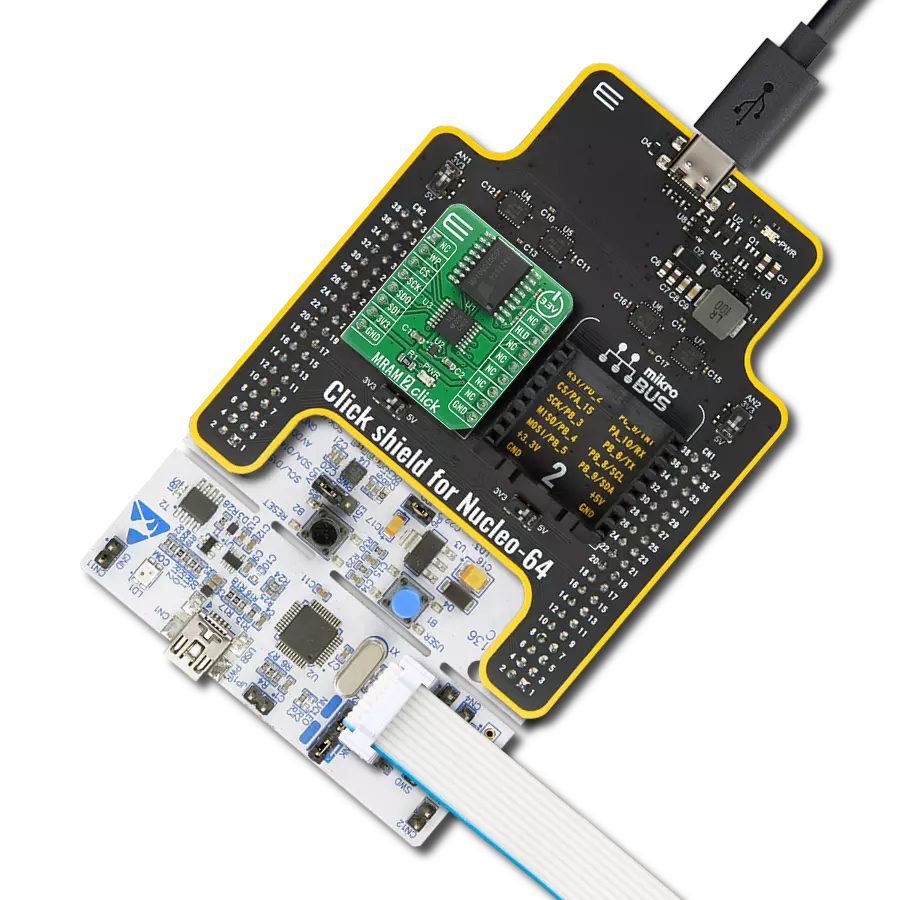

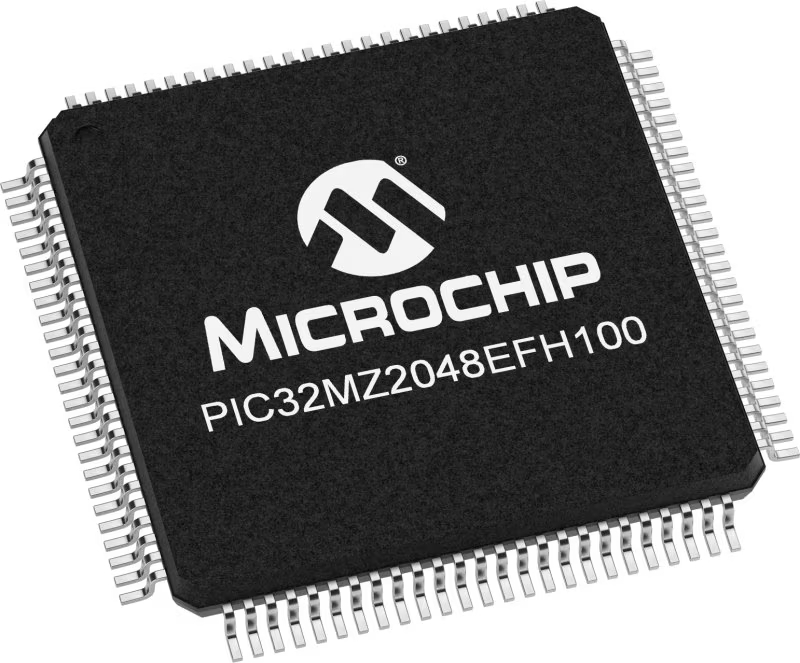

Flip&Click PIC32MZ is a compact development board designed as a complete solution that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit PIC32MZ microcontroller, the PIC32MZ2048EFH100 from Microchip, four mikroBUS™ sockets for Click board™ connectivity, two USB connectors, LED indicators, buttons, debugger/programmer connectors, and two headers compatible with Arduino-UNO pinout. Thanks to innovative manufacturing technology,

it allows you to build gadgets with unique functionalities and features quickly. Each part of the Flip&Click PIC32MZ development kit contains the components necessary for the most efficient operation of the same board. In addition, there is the possibility of choosing the Flip&Click PIC32MZ programming method, using the chipKIT bootloader (Arduino-style development environment) or our USB HID bootloader using mikroC, mikroBasic, and mikroPascal for PIC32. This kit includes a clean and regulated power supply block through the USB Type-C (USB-C) connector. All communication

methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, user-configurable buttons, and LED indicators. Flip&Click PIC32MZ development kit allows you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

2048

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for MRAM 3 Click driver.

Key functions:

mram3_memory_writeThis function writes a desired number of data bytes starting from the selected memory address.mram3_memory_readThis function reads a desired number of data bytes starting from the selected memory address.mram3_aug_memory_writeThis function writes a desired number of data bytes starting from the selected augmented memory address.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief MRAM3 Click example

*

* # Description

* This example demonstrates the use of MRAM 3 Click board by writing specified data to

* the memory and reading it back.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and performs the Click default configuration.

*

* ## Application Task

* Writes a desired number of bytes to the memory and then verifies if it is written correctly

* by reading from the same memory location and displaying the memory content on the USB UART.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "mram3.h"

static mram3_t mram3;

static log_t logger;

#define DEMO_TEXT_MESSAGE_1 "MikroE"

#define DEMO_TEXT_MESSAGE_2 "MRAM 3 Click"

#define STARTING_ADDRESS 0x01234

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

mram3_cfg_t mram3_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

mram3_cfg_setup( &mram3_cfg );

MRAM3_MAP_MIKROBUS( mram3_cfg, MIKROBUS_1 );

if ( SPI_MASTER_ERROR == mram3_init( &mram3, &mram3_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( MRAM3_ERROR == mram3_default_cfg ( &mram3 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

uint8_t data_buf[ 128 ] = { 0 };

memcpy ( data_buf, DEMO_TEXT_MESSAGE_1, strlen ( DEMO_TEXT_MESSAGE_1 ) );

if ( MRAM3_OK == mram3_memory_write ( &mram3, STARTING_ADDRESS,

data_buf, sizeof ( data_buf ) ) )

{

log_printf ( &logger, "Data written to address 0x%.5LX: %s\r\n", ( uint32_t ) STARTING_ADDRESS,

data_buf );

}

memset ( data_buf, 0, sizeof ( data_buf ) );

if ( MRAM3_OK == mram3_memory_read ( &mram3, STARTING_ADDRESS,

data_buf, sizeof ( data_buf ) ) )

{

log_printf ( &logger, "Data read from address 0x%.5LX: %s\r\n", ( uint32_t ) STARTING_ADDRESS,

data_buf );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

memcpy ( data_buf, DEMO_TEXT_MESSAGE_2, strlen ( DEMO_TEXT_MESSAGE_2 ) );

if ( MRAM3_OK == mram3_memory_write ( &mram3, STARTING_ADDRESS,

data_buf, sizeof ( data_buf ) ) )

{

log_printf ( &logger, "Data written to address 0x%.5LX: %s\r\n", ( uint32_t ) STARTING_ADDRESS,

data_buf );

}

memset ( data_buf, 0, sizeof ( data_buf ) );

if ( MRAM3_OK == mram3_memory_read ( &mram3, STARTING_ADDRESS,

data_buf, sizeof ( data_buf ) ) )

{

log_printf ( &logger, "Data read from address 0x%.5LX: %s\r\n\n", ( uint32_t ) STARTING_ADDRESS,

data_buf );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:MRAM