Responsive haptic feedback with real-time auto-resonance tracking and ultra-low power operation for enhanced tactile user interaction

A

A

Hardware Overview

How does it work?

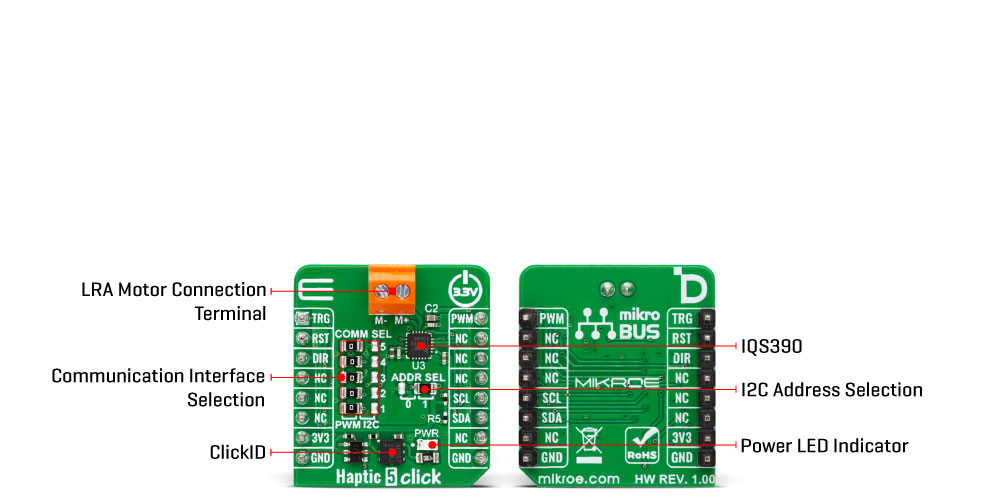

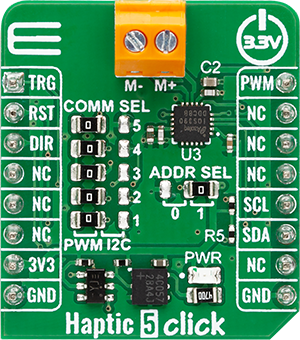

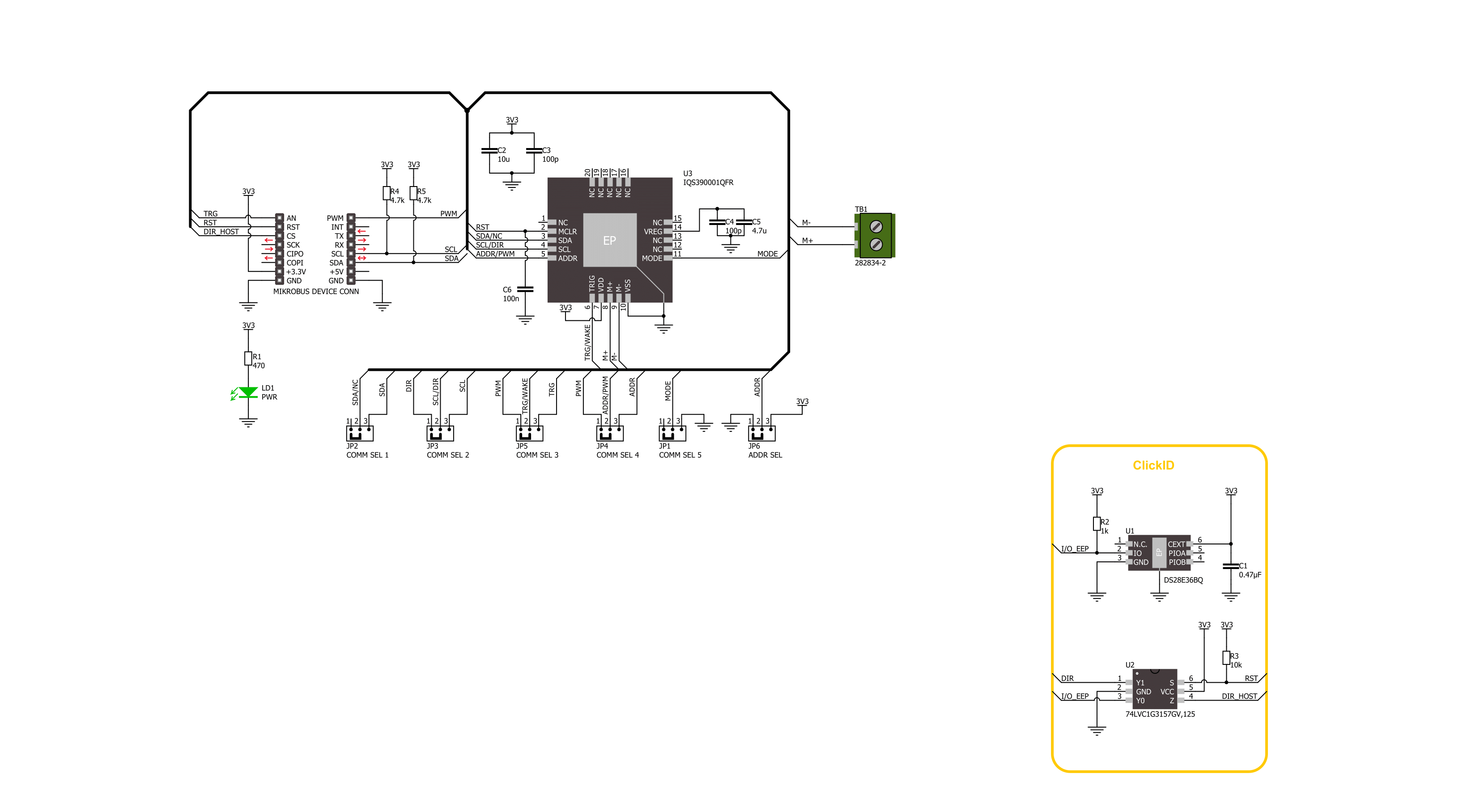

Haptic 5 Click is based on the IQS390 haptic driver IC from Azoteq, designed to provide high-performance haptic feedback using Linear Resonant Actuators (LRA). This board supports two operating modes— I2C and PWM— selectable via the COMM SEL jumpers. To ensure proper operation, all jumpers must be aligned to the same mode side. In I2C mode, the IQS390 employs a real-time closed-loop auto-resonance algorithm that dynamically tracks and matches the resonant frequency of the connected LRA motor, ensuring efficient and consistent vibration output. Haptic 5 Click is ideal for applications that require precise

and responsive tactile feedback, such as mouse wheel scrolling effects, trackpad interactions, doorbell notifications, and membrane keypads. The I2C interface supports communication speeds of up to Fast Mode Plus (1 MHz), with a selectable I2C address configured via the ADDR SEL jumper, enabling flexible integration into various systems. Additionally, the IQS390 includes a dedicated RST pin for hardware reset, and haptic pulses can be triggered either through I2C commands or externally via the TRG pin. In PWM mode, the board accepts an external Pulse Width Modulated signal along with a motor drive direction input via

the DIR pin. Both operating modes feature automatic power mode management, including an ultra-low power state to reduce energy consumption during inactivity. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. It also comes equipped with a library containing functions and example code that can be used as a reference for further development.

Features overview

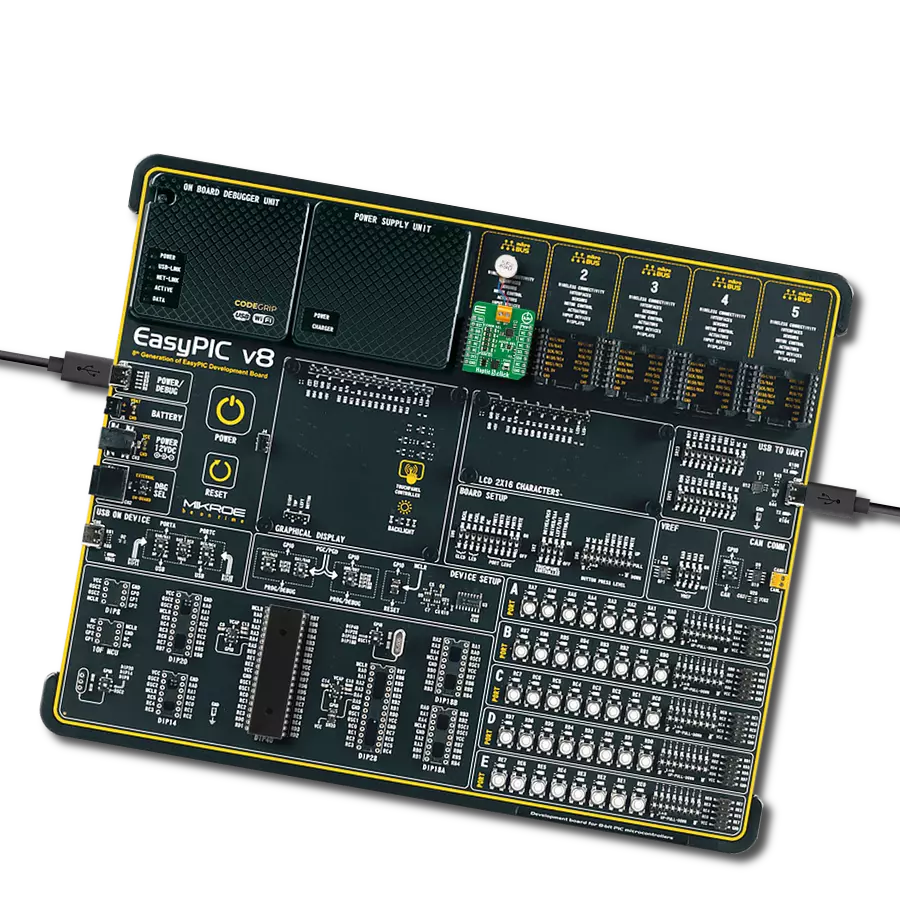

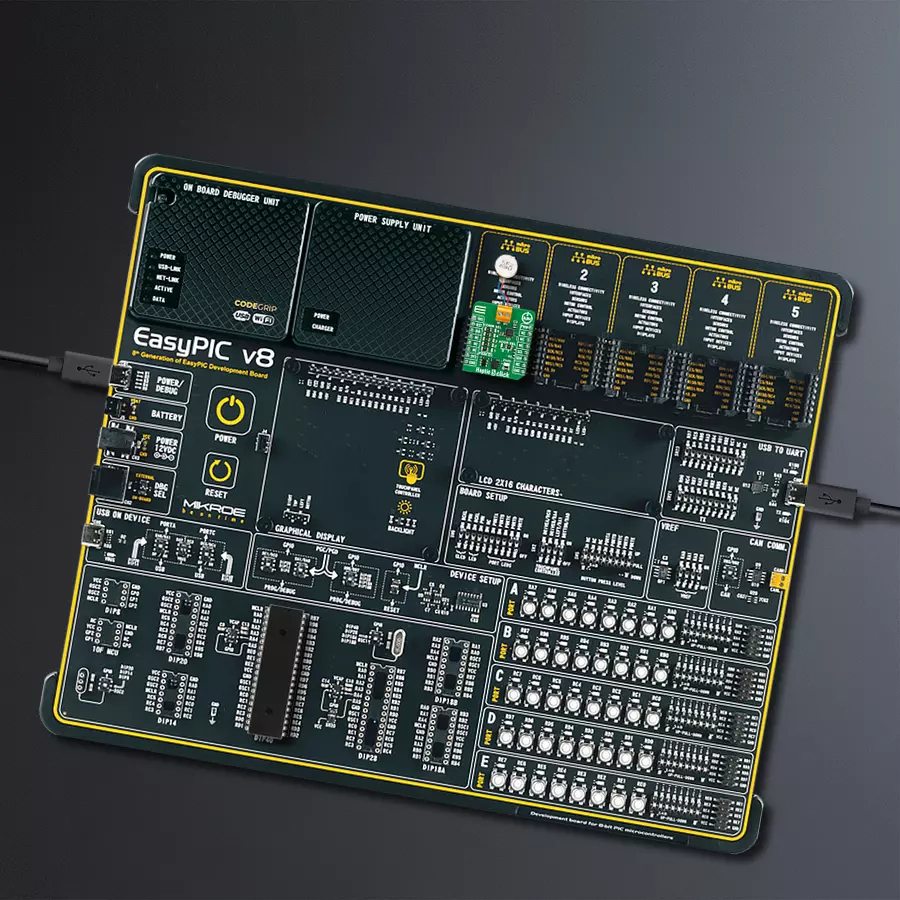

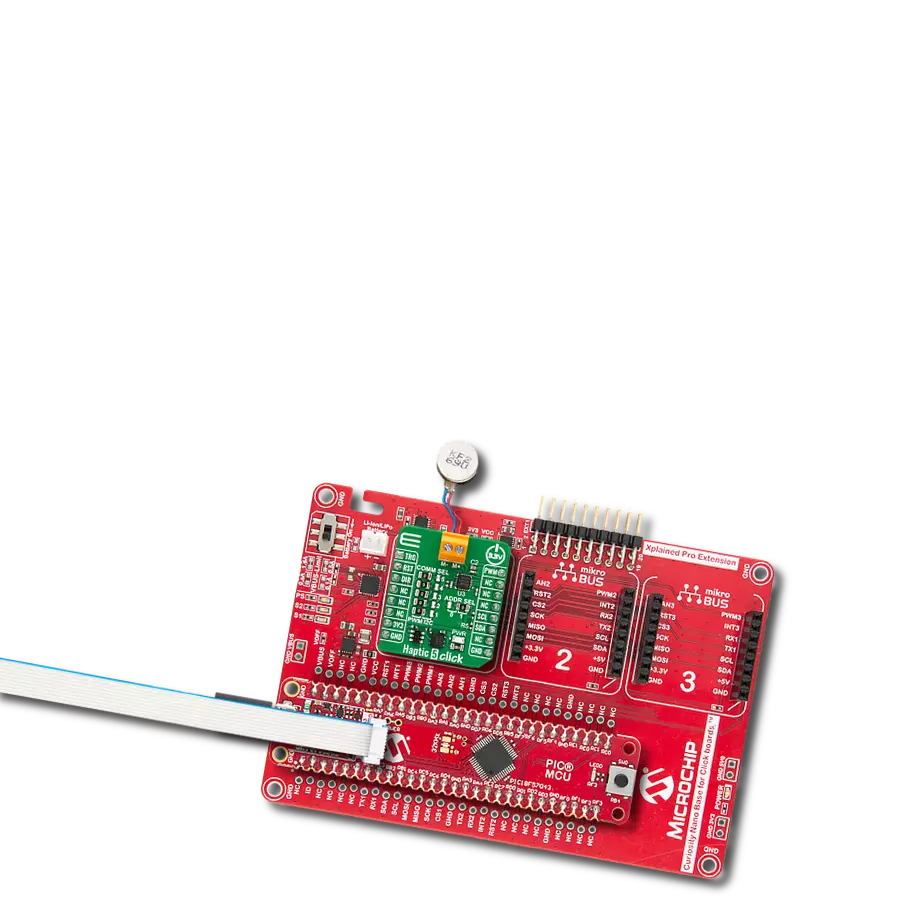

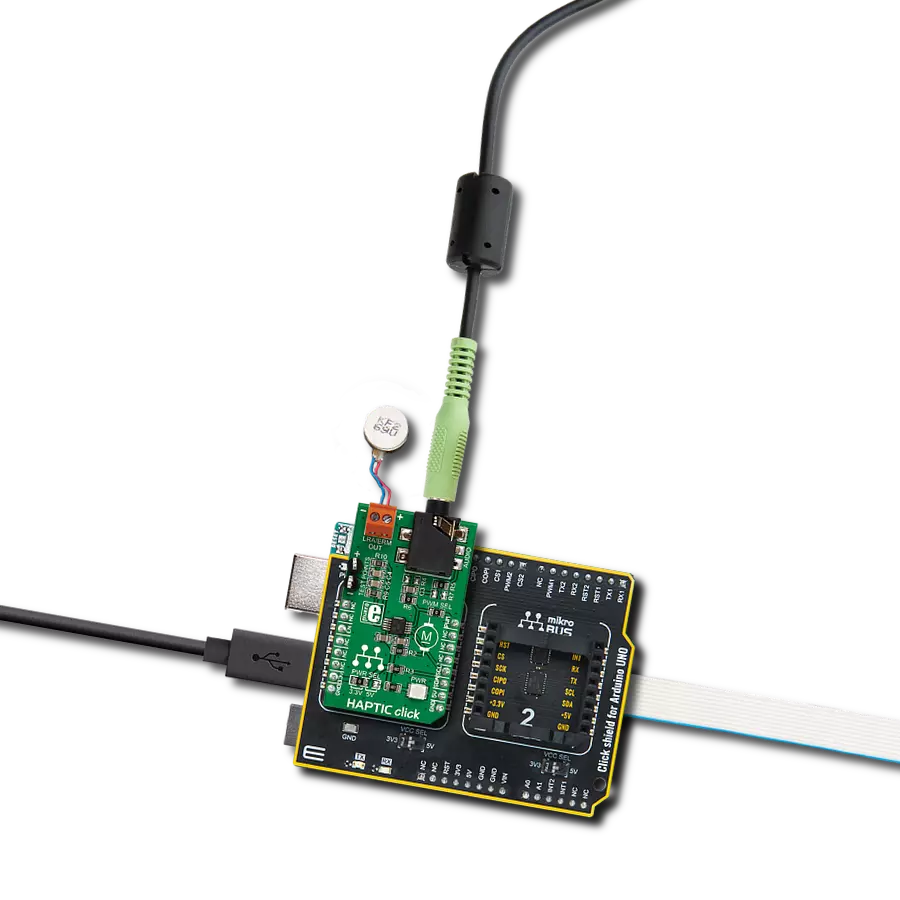

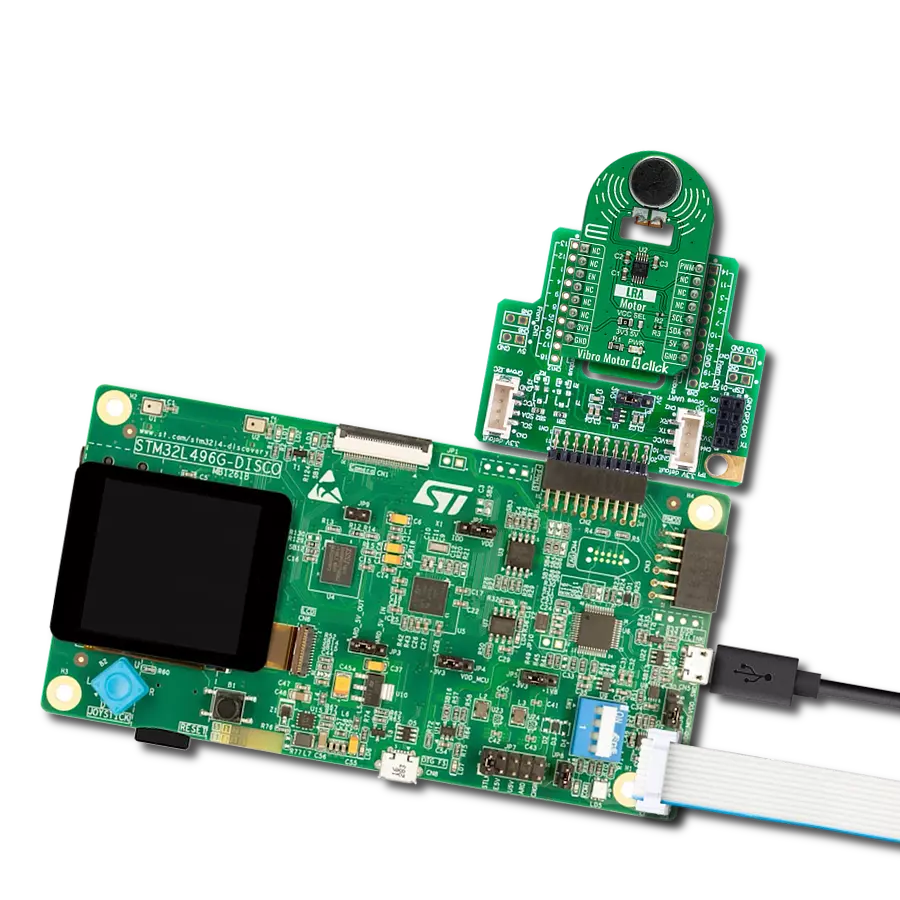

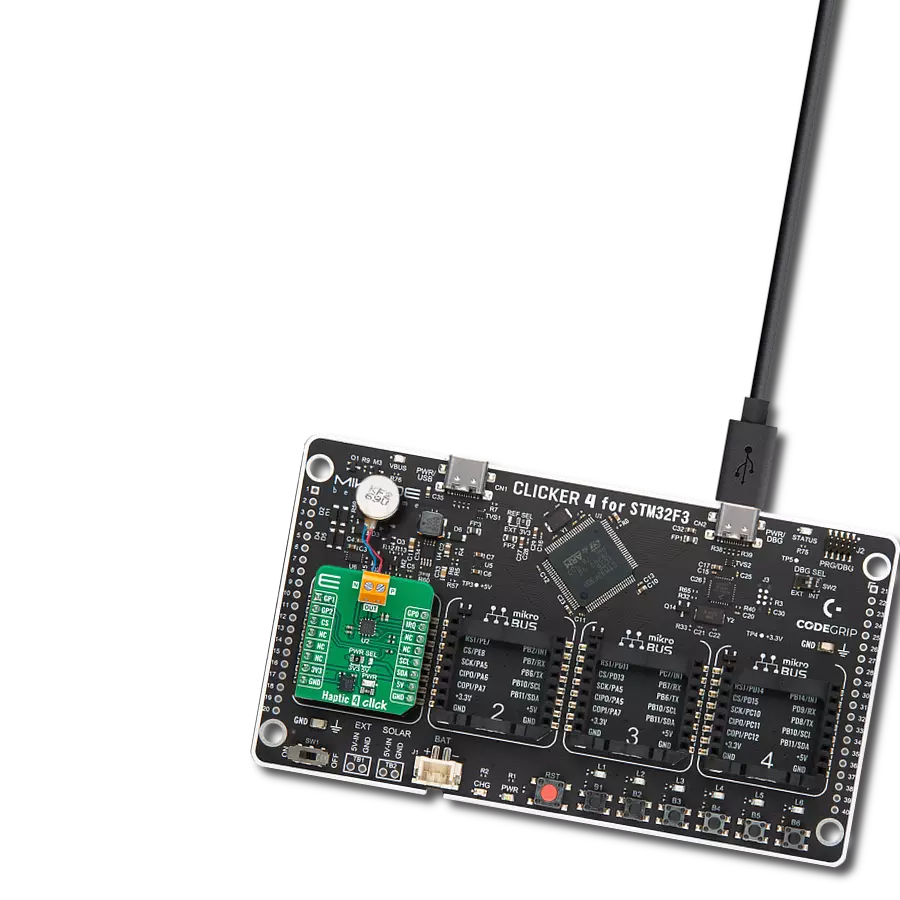

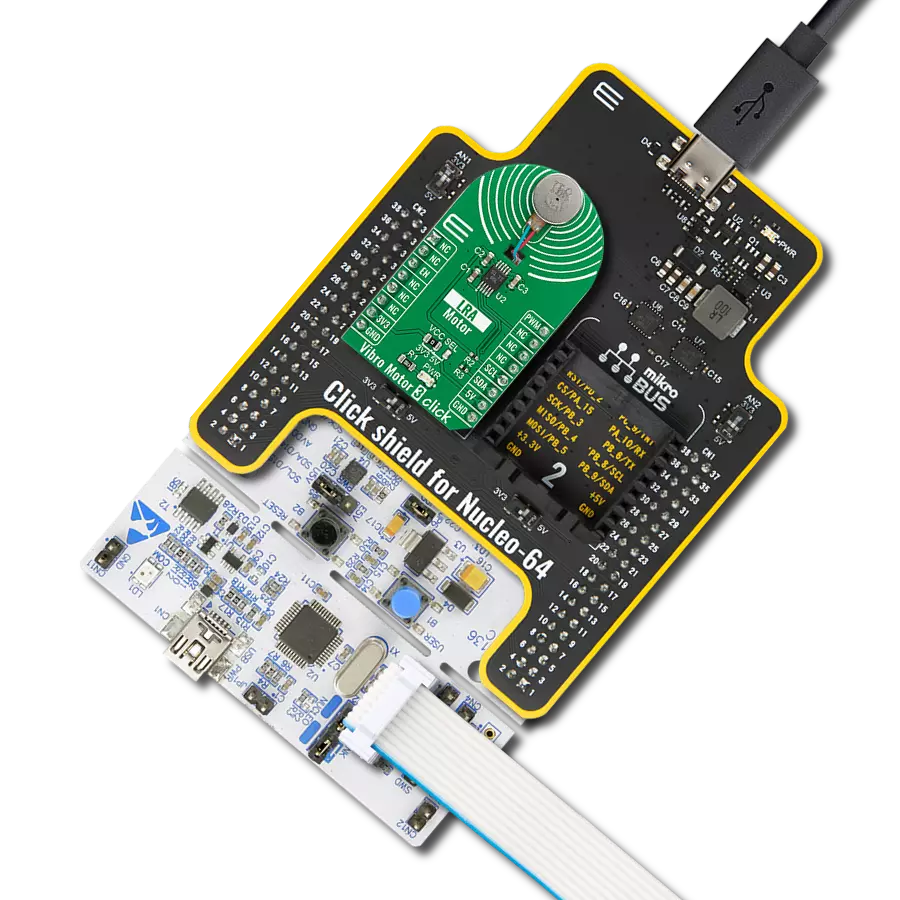

Development board

EasyPIC v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports many high pin count 8-bit PIC microcontrollers from Microchip, regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, EasyPIC v8 provides a fluid and immersive working experience, allowing access anywhere and under any

circumstances at any time. Each part of the EasyPIC v8 development board contains the components necessary for the most efficient operation of the same board. In addition to the advanced integrated CODEGRIP programmer/debugger module, which offers many valuable programming/debugging options and seamless integration with the Mikroe software environment, the board also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector.

Communication options such as USB-UART, USB DEVICE, and CAN are also included, including the well-established mikroBUS™ standard, two display options (graphical and character-based LCD), and several different DIP sockets. These sockets cover a wide range of 8-bit PIC MCUs, from the smallest PIC MCU devices with only eight up to forty pins. EasyPIC v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC

MCU Memory (KB)

64

Silicon Vendor

Microchip

Pin count

40

RAM (Bytes)

4096

You complete me!

Accessories

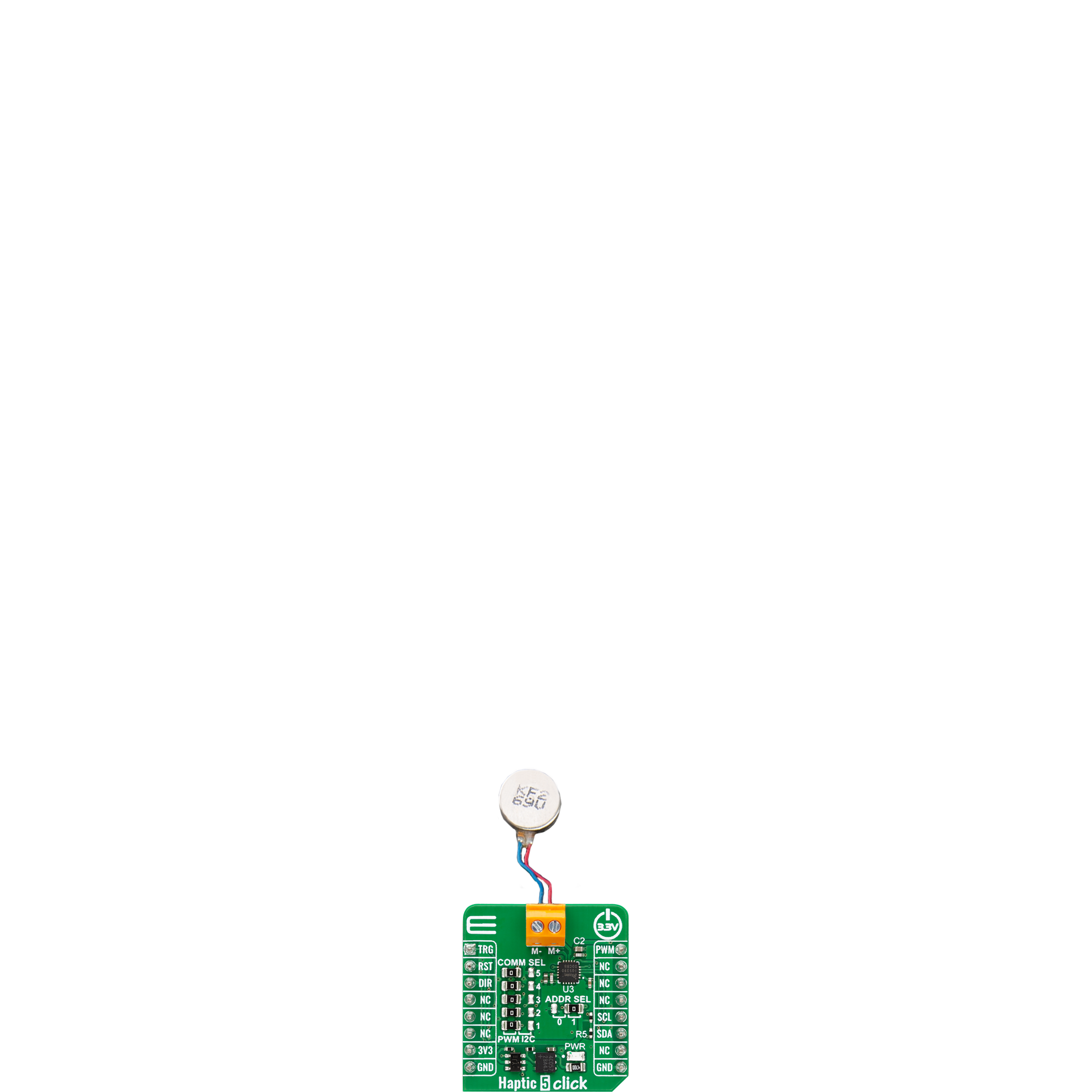

The LRA0825BC-0167F is a precision linear resonant actuator (LRA) designed for compact haptic feedback applications, featuring an 8mm diameter and 2.5mm thickness. Optimized for Z-axis vibration output, it operates at a resonant frequency of 240 ±10Hz, producing a minimum vibration acceleration of 0.7 Grms. With a rated voltage of 1.2 Vrms AC and a maximum current consumption of 90 mA, it ensures responsive performance with a rise time of up to 50 ms and a fall time of up to 80 ms. Its operating voltage range of 0.1 to 1.25 Vrms AC allows flexible control, making it ideal for wearable devices, handheld instruments, and other space-constrained designs requiring precise and efficient tactile feedback.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

Haptic 5 Click demo application is developed using the NECTO Studio, ensuring compatibility with mikroSDK's open-source libraries and tools. Designed for plug-and-play implementation and testing, the demo is fully compatible with all development, starter, and mikromedia boards featuring a mikroBUS™ socket.

Example Description

This example demonstrates the control of the Haptic 5 Click board. In I2C mode, the example toggles the haptic trigger pin periodically to generate vibration pulses. In PWM mode, it gradually increases and decreases the output duty cycle to modulate the vibration intensity, while toggling the direction when the duty reaches 0%.

Key functions:

haptic5_cfg_setup- This function initializes Click configuration structure to initial values.haptic5_init- This function initializes all necessary pins and peripherals used for this Click board.haptic5_default_cfg- This function executes a default configuration of Haptic 5 Click board.haptic5_set_duty_cycle- This function sets the PWM duty cycle.haptic5_toggle_dir- This function toggles the state of the DIR pin.

Application Init

Initializes the logger and the Click board driver, and applies the default configuration.

Application Task

Depending on the selected communication interface (I2C or PWM), toggles the haptic trigger (I2C), or changes PWM duty cycle and direction (PWM).

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief Haptic 5 Click example

*

* # Description

* This example demonstrates the control of the Haptic 5 Click board.

* In I2C mode, the example toggles the haptic trigger pin periodically to generate vibration pulses.

* In PWM mode, it gradually increases and decreases the output duty cycle to modulate the vibration intensity,

* while toggling the direction when the duty reaches 0%.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the logger and the Click board driver, and applies the default configuration.

*

* ## Application Task

* Depending on the selected communication interface (I2C or PWM), toggles the haptic trigger (I2C),

* or changes PWM duty cycle and direction (PWM).

*

* @note

* The mode is selected via the @b HAPTIC5_DEFAULT_COM macro. Ensure proper configuration and wiring

* based on the selected mode before running the example.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "haptic5.h"

static haptic5_t haptic5;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

haptic5_cfg_t haptic5_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

haptic5_cfg_setup( &haptic5_cfg );

HAPTIC5_MAP_MIKROBUS( haptic5_cfg, MIKROBUS_1 );

if ( PWM_ERROR == haptic5_init( &haptic5, &haptic5_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( HAPTIC5_ERROR == haptic5_default_cfg ( &haptic5 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

#if ( HAPTIC5_DEFAULT_COM == HAPTIC5_COM_I2C )

log_printf( &logger, " Haptic state: Active\r\n\n" );

haptic5_set_trg_high ( &haptic5 );

Delay_ms ( 1000 );

log_printf( &logger, " Haptic state: Idle\r\n\n" );

haptic5_set_trg_low ( &haptic5 );

Delay_ms ( 1000 );

#else

static int8_t duty_cnt = 1;

static int8_t duty_inc = 1;

float duty = duty_cnt / 10.0;

haptic5_set_duty_cycle ( &haptic5, duty );

log_printf( &logger, "> Duty: %d%%\r\n", ( uint16_t )( duty_cnt * 10 ) );

Delay_ms ( 500 );

if ( 10 == duty_cnt )

{

duty_inc = -1;

}

else if ( 0 == duty_cnt )

{

duty_inc = 1;

haptic5_toggle_dir ( &haptic5 );

}

duty_cnt += duty_inc;

#endif

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Haptic