In today's dynamic landscape of vibrational applications, our solution aims to simplify motor control and enhance vibrational experiences, offering a user-friendly way to manage ERM motors

A

A

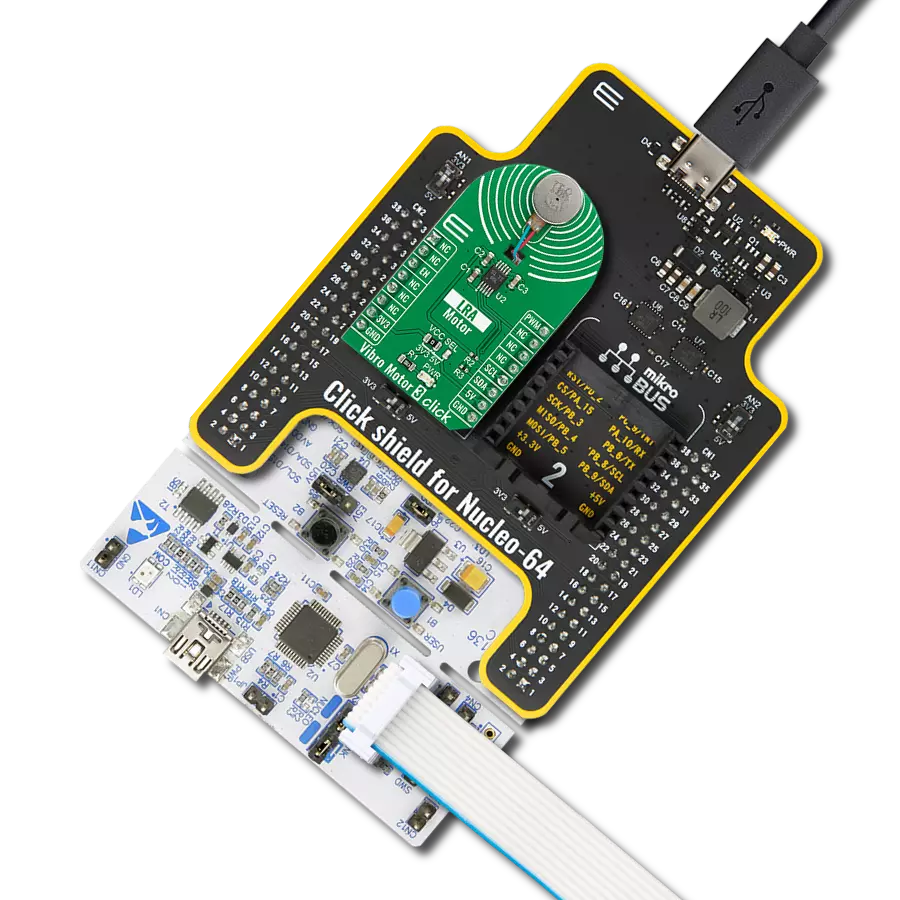

Hardware Overview

How does it work?

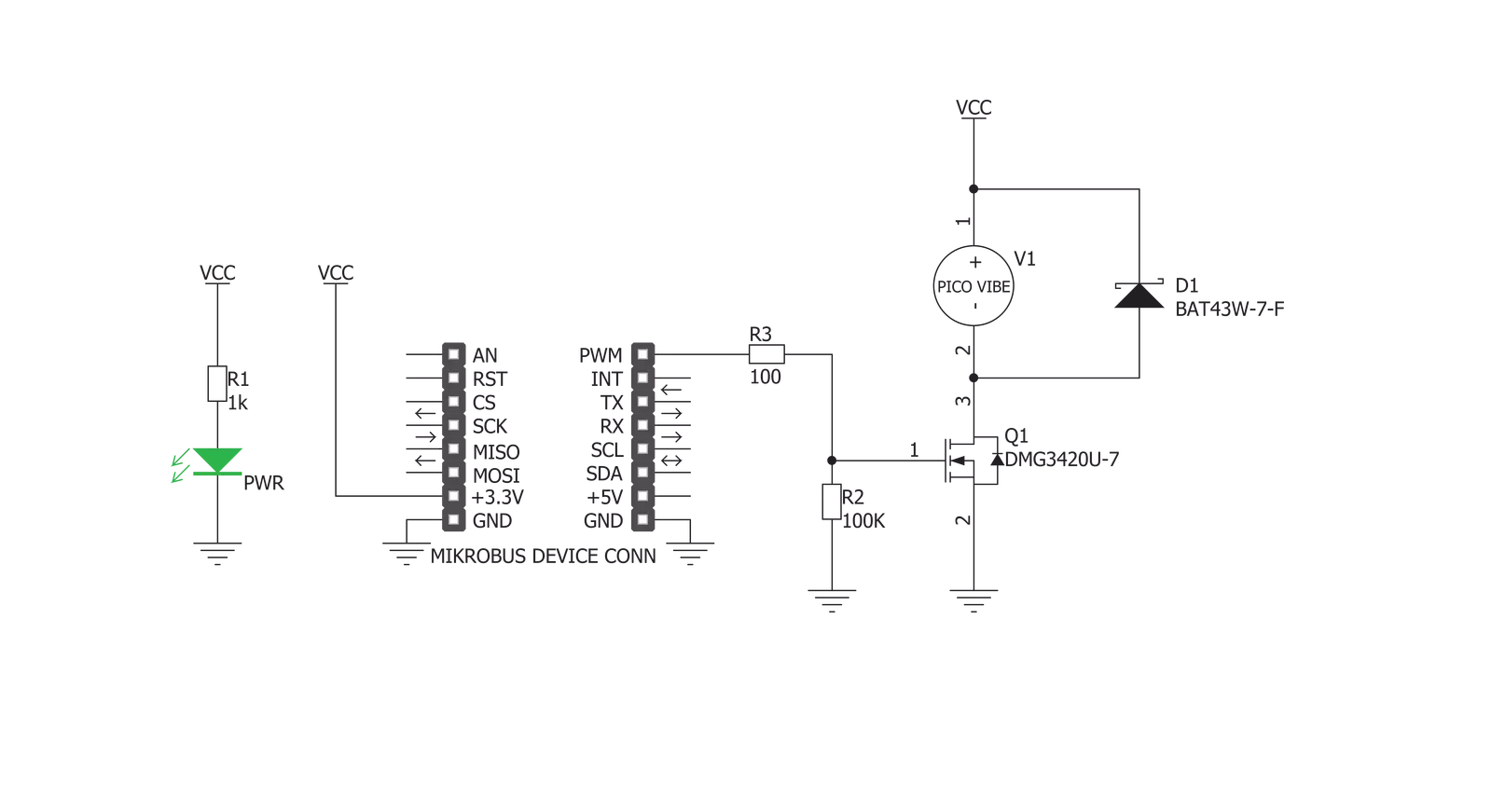

Vibro Motor Click is based on the C1026B002F, a compact-size Eccentric Rotating Mass (ERM) motor. This type of motor is often used for haptic feedback on many small handheld devices, such as cellphones, pagers, RFID scanners, and similar devices. This motor contains a small eccentric weight on its rotor, so it also produces a vibration effect while rotating. This kind of motor is sometimes called a coin motor due to its shape. Besides the vibration motor, the click is also equipped with the DMG3420U, a small MOSFET used to drive the motor. The Vibro Motor click is ideal for adding simple, one-pin-driven haptic feedback on any design. The circuit also contains

a protection diode, which protects the transistor from the reverse voltage since the motor represents an inductive load, and turning off its current can produce a kickback voltage that can damage the transistor. The gate of the MOSFET is driven by the PWM signal, routed through the PWM pin of the mikroBUS™. The PWM signal toggles the gate of the MOSFET with pulses of a certain width. As a result, the current through the motor is varied depending on the pulse width of the PWM signal, which directly affects the speed of the motor, effectively controlling the vibration force that way. The small, eccentric weight attached to the rotor of the coin motor generates

the centrifugal force while it rotates, which in turn results in the wobbling effect of the motor itself. The faster the rotation is, the bigger the force gets. Controlling the motor speed allows for the vibration intensity to be controlled. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, it comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

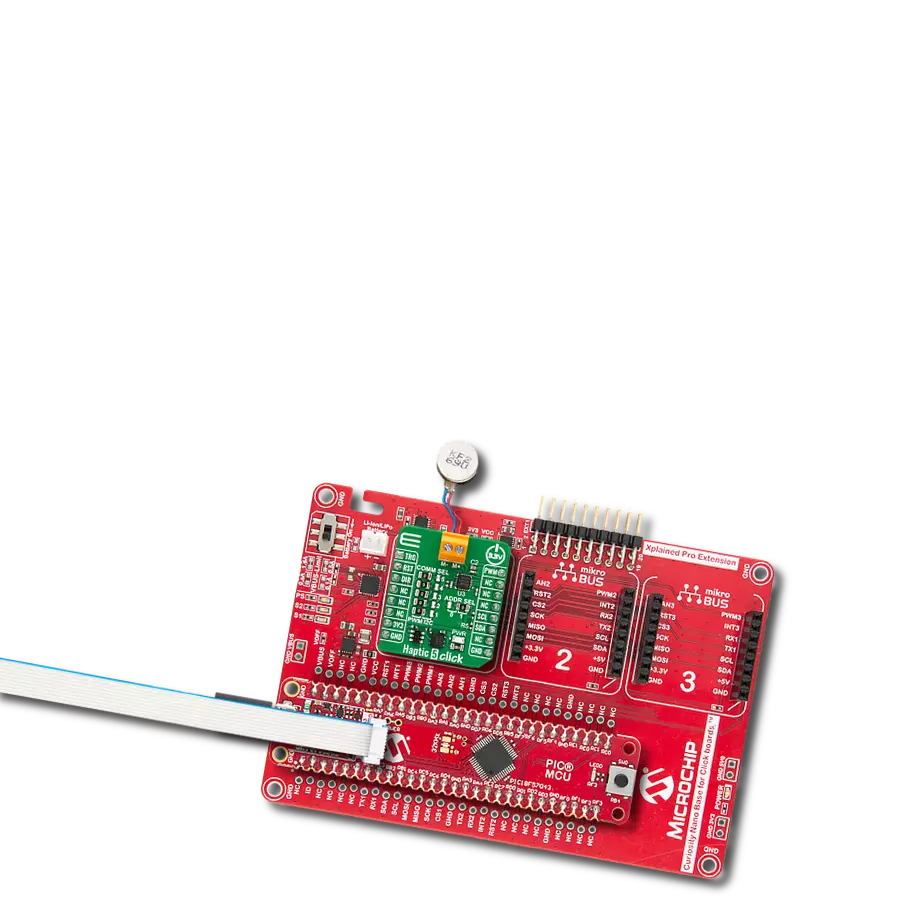

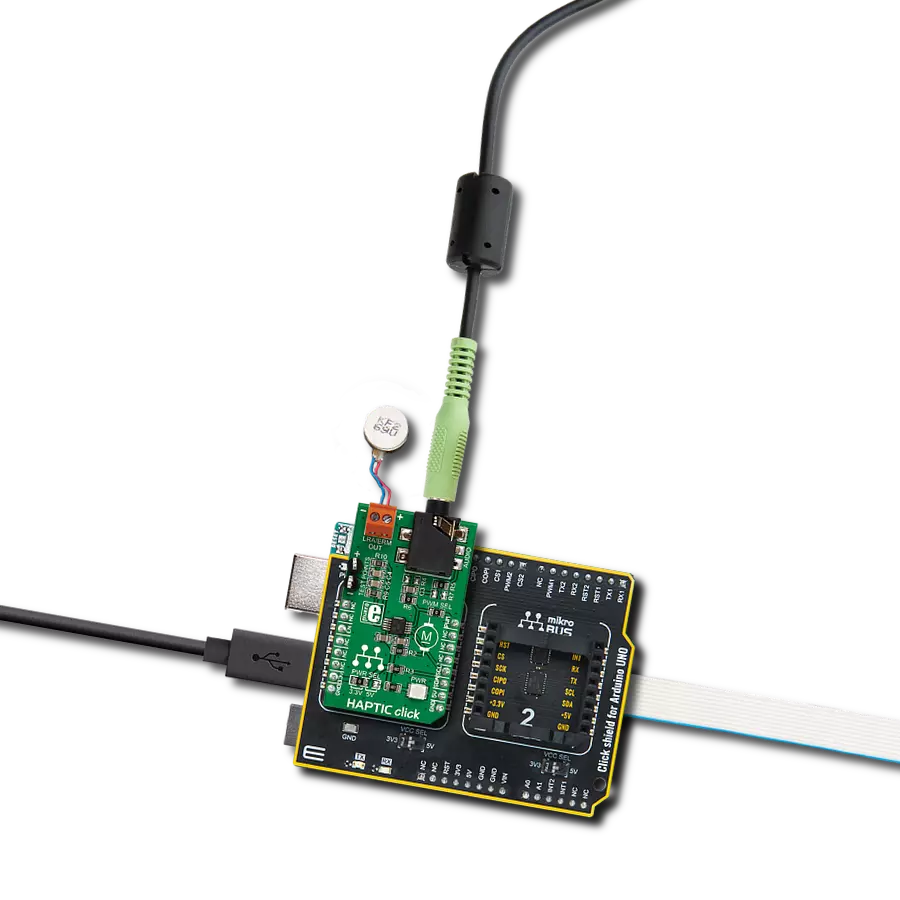

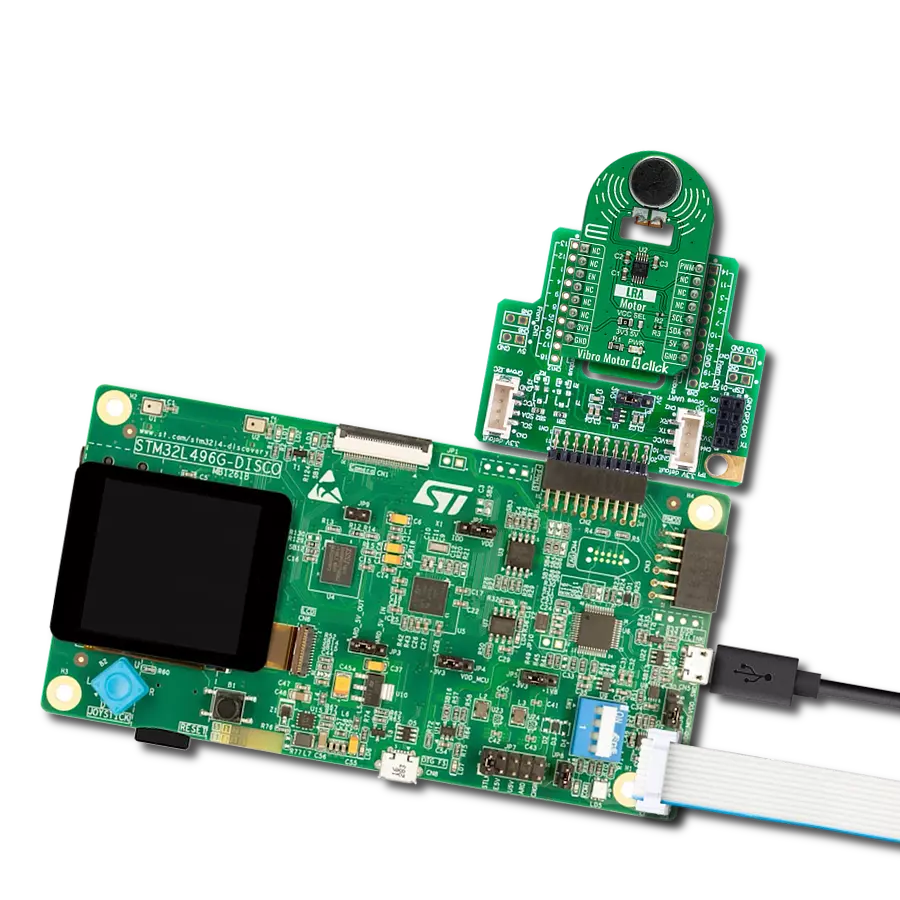

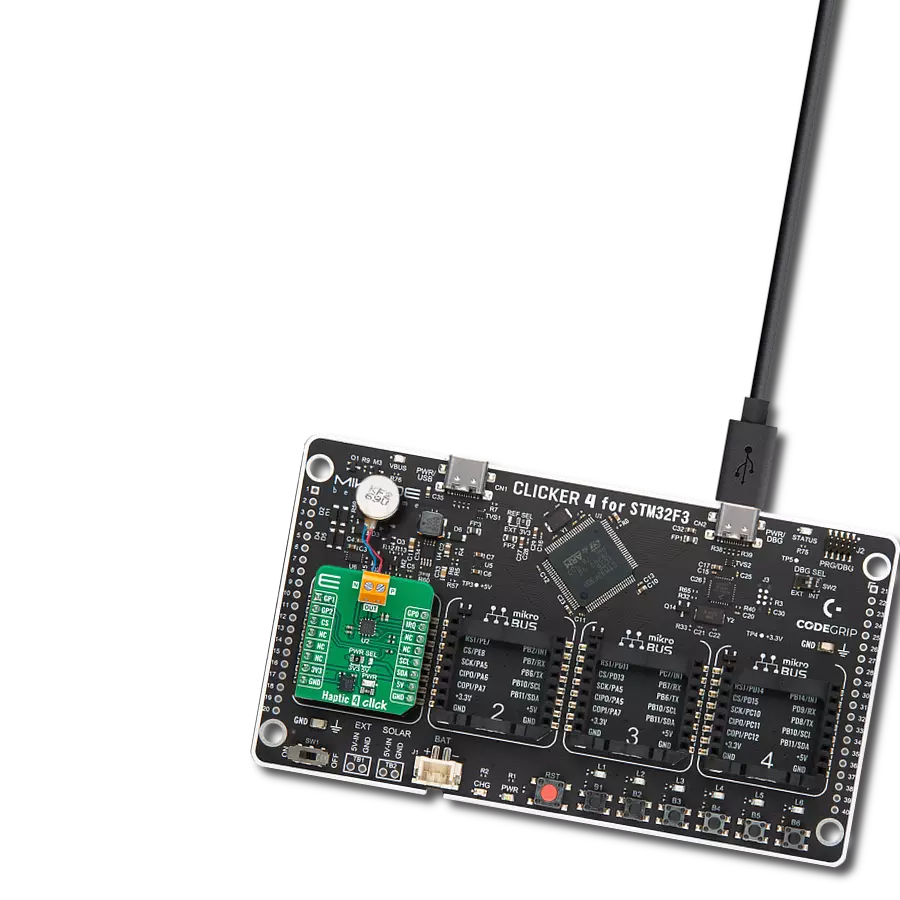

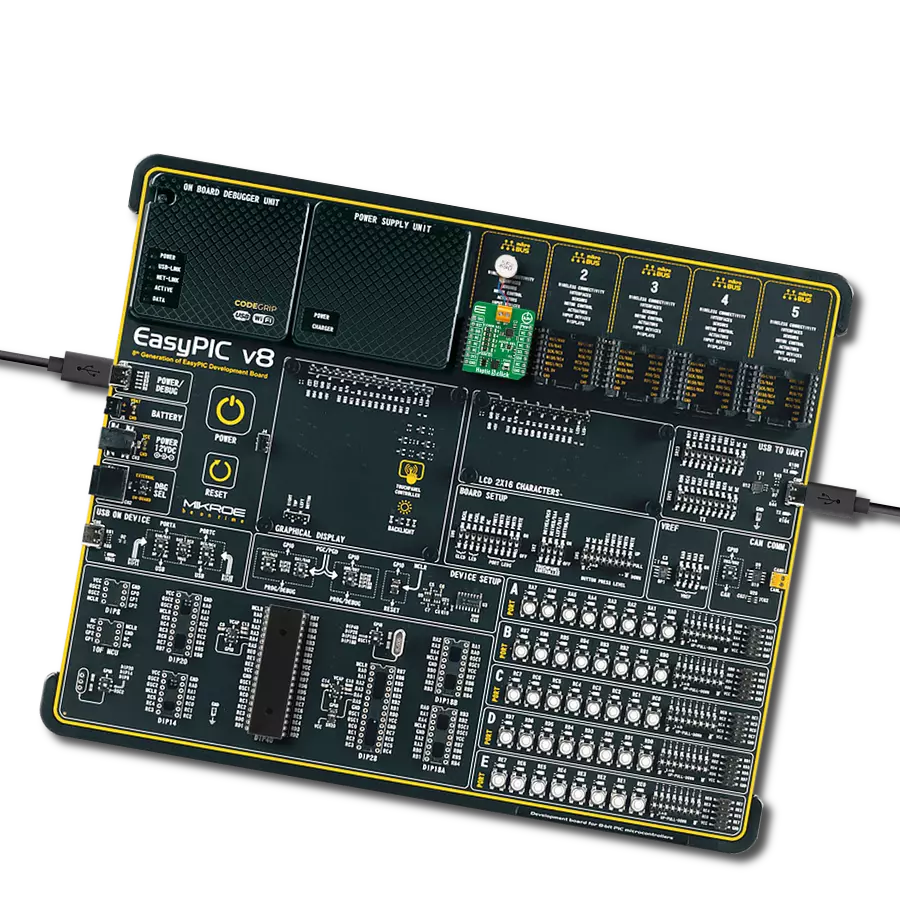

Development board

Curiosity PIC32 MZ EF development board is a fully integrated 32-bit development platform featuring the high-performance PIC32MZ EF Series (PIC32MZ2048EFM) that has a 2MB Flash, 512KB RAM, integrated FPU, Crypto accelerator, and excellent connectivity options. It includes an integrated programmer and debugger, requiring no additional hardware. Users can expand

functionality through MIKROE mikroBUS™ Click™ adapter boards, add Ethernet connectivity with the Microchip PHY daughter board, add WiFi connectivity capability using the Microchip expansions boards, and add audio input and output capability with Microchip audio daughter boards. These boards are fully integrated into PIC32’s powerful software framework, MPLAB Harmony,

which provides a flexible and modular interface to application development a rich set of inter-operable software stacks (TCP-IP, USB), and easy-to-use features. The Curiosity PIC32 MZ EF development board offers expansion capabilities making it an excellent choice for a rapid prototyping board in Connectivity, IOT, and general-purpose applications.

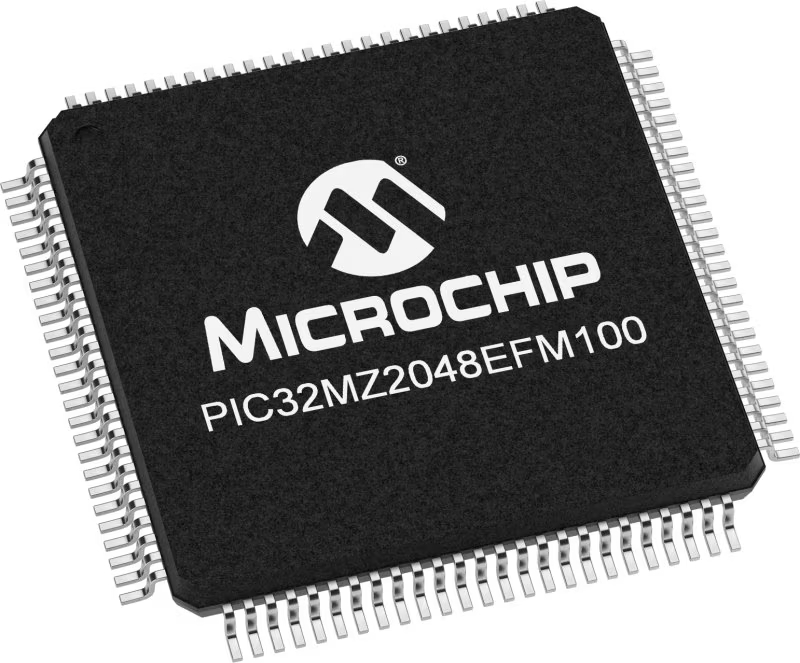

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

2048

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Vibro Motor Click driver.

Key functions:

vibromotor_set_duty_cycle- This function sets the PWM duty cycle in percentages ( Range[ 0..1 ] )vibromotor_pwm_stop- This function stops the PWM moudle outputvibromotor_pwm_start- This function starts the PWM moudle output.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief VibroMotor Click example

*

* # Description

* This application contorl the speed of vibro motor.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes GPIO driver and PWM.

* Configures PWM to 5kHz frequency, calculates maximum duty ratio and starts PWM

* with duty ratio value 0.

*

* ## Application Task

* Allows user to enter desired command to control

* Vibro Motor Click board.

*

* @author Stefan Ilic

*

*/

#include "board.h"

#include "log.h"

#include "vibromotor.h"

static vibromotor_t vibromotor;

static log_t logger;

void application_init ( void ) {

log_cfg_t log_cfg; /**< Logger config object. */

vibromotor_cfg_t vibromotor_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

vibromotor_cfg_setup( &vibromotor_cfg );

VIBROMOTOR_MAP_MIKROBUS( vibromotor_cfg, MIKROBUS_1 );

err_t init_flag = vibromotor_init( &vibromotor, &vibromotor_cfg );

if ( PWM_ERROR == init_flag ) {

log_error( &logger, " Application Init Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

vibromotor_set_duty_cycle ( &vibromotor, 0.0 );

vibromotor_pwm_start( &vibromotor );

log_info( &logger, " Application Task " );

}

void application_task ( void ) {

static int8_t duty_cnt = 1;

static int8_t duty_inc = 1;

float duty = duty_cnt / 10.0;

vibromotor_set_duty_cycle ( &vibromotor, duty );

log_printf( &logger, "> Duty: %d%%\r\n", ( uint16_t )( duty_cnt * 10 ) );

Delay_ms ( 500 );

if ( 10 == duty_cnt ) {

duty_inc = -1;

} else if ( 0 == duty_cnt ) {

duty_inc = 1;

}

duty_cnt += duty_inc;

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Haptic