Our digital differential pressure sensor is engineered to provide precise and reliable readings for a wide range of applications, from industrial automation to environmental monitoring

A

A

Hardware Overview

How does it work?

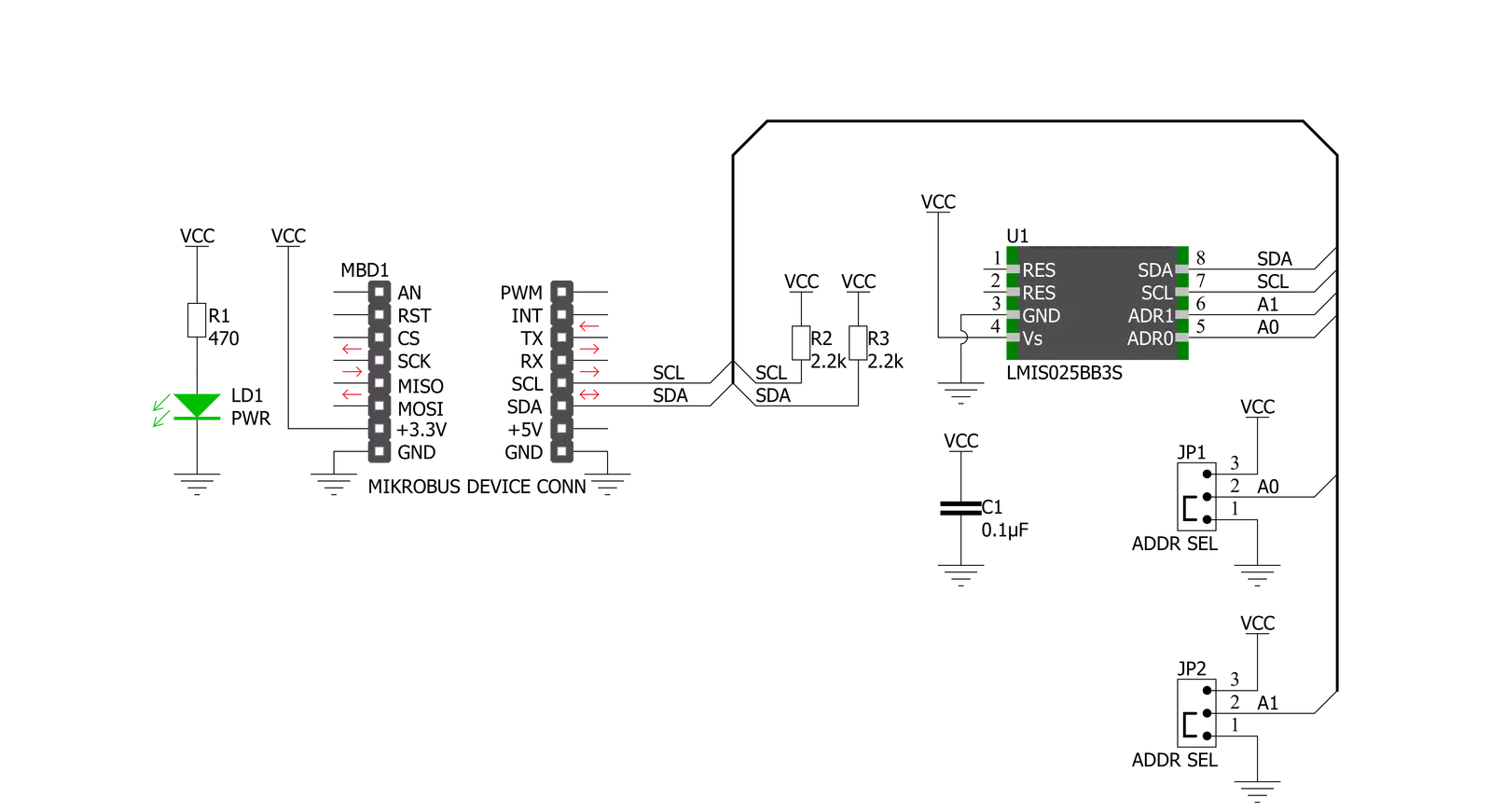

VAV Press Click is based on the LMIS025B, a low differential pressure sensor from TE Connectivity that offers a digital output for reading pressure over the specified pressure span. The innovative LMI technology features superior sensitivity, especially for ultra-low pressures ranging from 0 to 25Pa / 0 to 0.25mbar (0.1 in H2O). It is based on thermal flow measurement of gas through a micro-flow channel integrated within the sensor chip. The extremely low gas flow through the sensor ensures high immunity to dust contamination, humidity, and long tubing compared to other flow-based pressure sensors,

including the outstanding long-term stability, precision with patented real-time offset compensation, and linearization techniques. The LMIS025B offers two modes of operation: Continuous mode with a 5ms sampling time, which provides a near-continuous stream of pressure data, and low-power mode with a 400μA Standby current which wakes the device from Sleep to serve pressure data “on-demand”. The first measurement in either mode is available after a warm-up and conversion sequence, which takes approximately 25 ms. VAV Press Click communicates with MCU using the standard I2C

2-Wire interface, offering linearized digital output through a 16-bit sigma-delta A/D conversion. Besides, it also allows the choice of the least significant bit of its I2C slave address by positioning the SMD jumper labeled as ADDR SEL to an appropriate position marked as 0 and 1. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, it comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

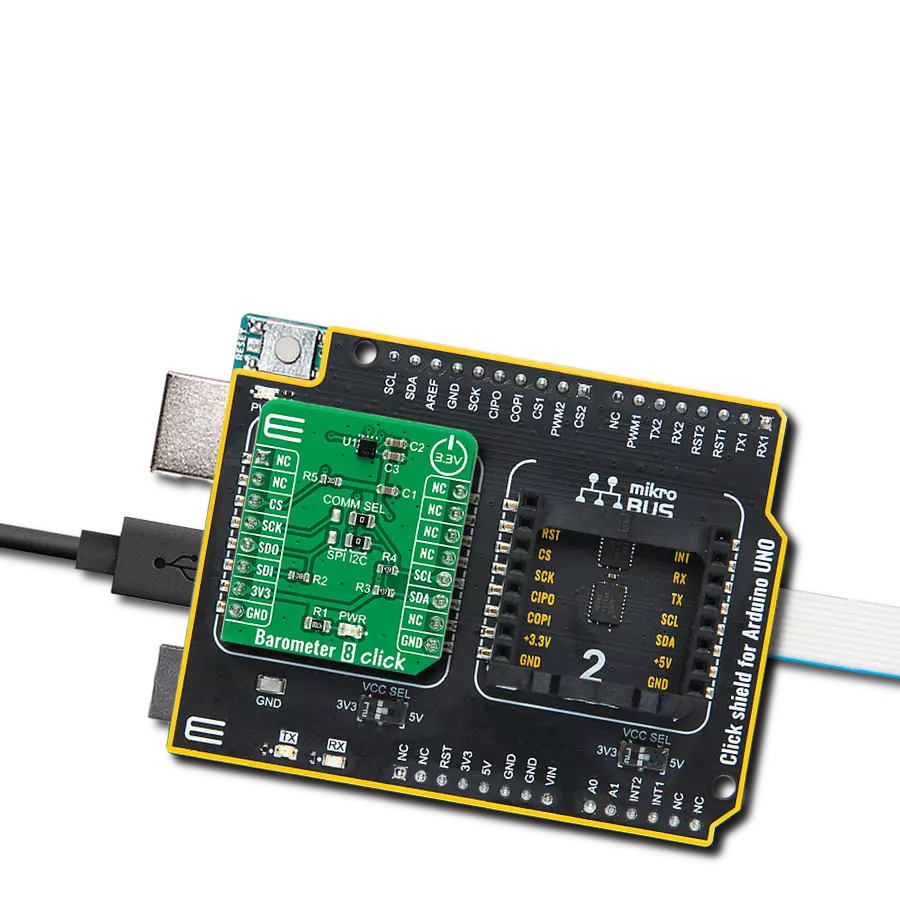

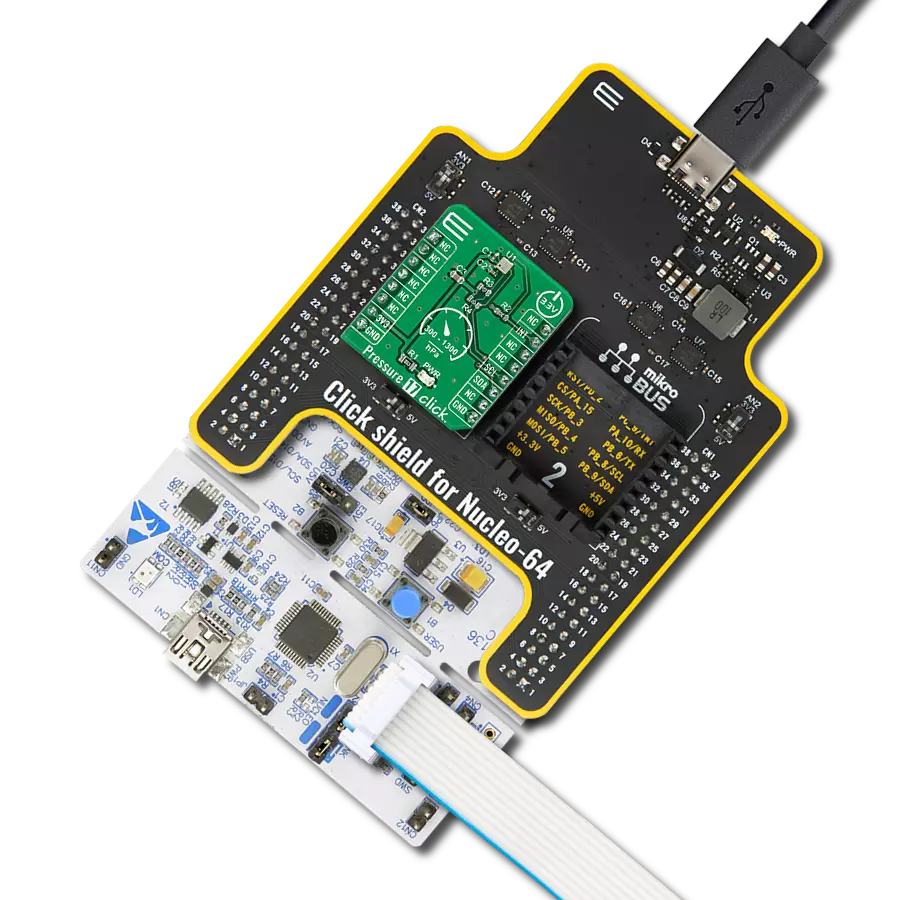

Development board

UNI-DS v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports a wide range of microcontrollers, such as different STM32, Kinetis, TIVA, CEC, MSP, PIC, dsPIC, PIC32, and AVR MCUs regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer over WiFi. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, UNI-DS v8 provides a fluid and immersive working experience, allowing access anywhere and under any

circumstances at any time. Each part of the UNI-DS v8 development board contains the components necessary for the most efficient operation of the same board. An advanced integrated CODEGRIP programmer/debugger module offers many valuable programming/debugging options, including support for JTAG, SWD, and SWO Trace (Single Wire Output)), and seamless integration with the Mikroe software environment. Besides, it also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector. Communication options such as USB-UART, USB

HOST/DEVICE, CAN (on the MCU card, if supported), and Ethernet is also included. In addition, it also has the well-established mikroBUS™ standard, a standardized socket for the MCU card (SiBRAIN standard), and two display options for the TFT board line of products and character-based LCD. UNI-DS v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

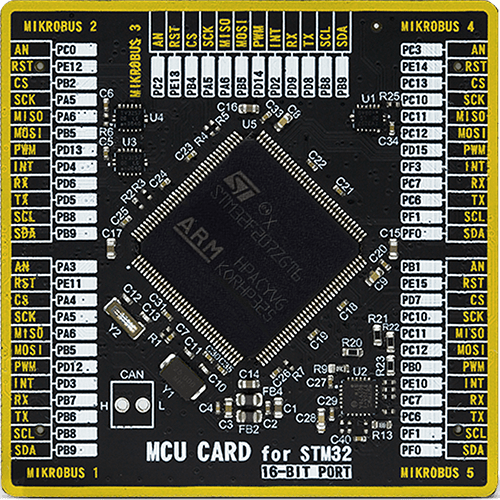

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

ARM Cortex-M3

MCU Memory (KB)

1024

Silicon Vendor

STMicroelectronics

Pin count

144

RAM (Bytes)

131072

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for VAV Press Click driver.

Key functions:

vavpress_set_default_sensor_param- VAV Press set default sensor parameter functionvavpress_get_dif_press_and_temp- VAV Press get differential pressure and temperature functionvavpress_retrieve_electronic_signature- VAV Press retrieve electronic signature function

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief VavPress Click example

*

* # Description

* This library contains API for the Vav Press Click driver.

* This demo application shows an example of

* differential pressure and temperature measurement.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization of I2C module and log UART.

* After driver initialization and default settings,

* the app display retrieve the electronic signature

* and set the sensor parameters data.

*

* ## Application Task

* This is an example that shows the use of a Vav Press Click board™.

* Logs pressure difference value [ Pa ] and temperature [ degree Celsius ] value.

* Results are being sent to the Usart Terminal where you can track their changes.

*

*

* @author Nenad Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "vavpress.h"

static vavpress_t vavpress;

static log_t logger;

static float diff_press;

static float temperature;

vavpress_el_signature_data_t el_signature_data;

vavpress_sensor_param_data_t param_data;

void application_init ( void ) {

log_cfg_t log_cfg; /**< Logger config object. */

vavpress_cfg_t vavpress_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_printf( &logger, "\r\n" );

log_info( &logger, " Application Init " );

// Click initialization.

vavpress_cfg_setup( &vavpress_cfg );

VAVPRESS_MAP_MIKROBUS( vavpress_cfg, MIKROBUS_1 );

err_t init_flag = vavpress_init( &vavpress, &vavpress_cfg );

if ( init_flag == I2C_MASTER_ERROR ) {

log_error( &logger, " Application Init Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

vavpress_default_cfg ( &vavpress );

log_info( &logger, " Application Task " );

Delay_ms ( 100 );

vavpress_retrieve_electronic_signature( &vavpress, &el_signature_data );

Delay_ms ( 100 );

log_printf( &logger, "--------------------------------\r\n" );

log_printf( &logger, " Firmware Version : %.3f \r\n", el_signature_data.firmware_version );

log_printf( &logger, " Pressure Range : %d Pa \r\n", el_signature_data.pressure_range );

log_printf( &logger, " Part # : %.11s \r\n", el_signature_data.part_number );

log_printf( &logger, " Lot # : %.7s \r\n", el_signature_data.lot_number );

log_printf( &logger, " Output Type : %c \r\n", el_signature_data.output_type );

log_printf( &logger, " Scale Factor : %d \r\n", el_signature_data.scale_factor );

log_printf( &logger, " Calibration ID : %.2s \r\n", el_signature_data.calibration_id );

log_printf( &logger, " Week number : %d \r\n", el_signature_data.week_number );

log_printf( &logger, " Year number : %d \r\n", el_signature_data.year_number );

log_printf( &logger, " Sequence number : %d \r\n", el_signature_data.sequence_number );

log_printf( &logger, "--------------------------------\r\n" );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

param_data.scale_factor_temp = 72;

param_data.scale_factor_press = el_signature_data.scale_factor;

param_data.readout_at_known_temperature = 50;

param_data.known_temperature_c = 24.0;

Delay_ms ( 100 );

}

void application_task ( void ) {

err_t error_flag = vavpress_get_dif_press_and_temp( &vavpress, ¶m_data, &diff_press, &temperature );

if ( error_flag == VAVPRESS_OK ) {

log_printf( &logger, " Diff. Pressure : %.4f Pa\r\n", diff_press );

log_printf( &logger, " Temperature : %.4f C\r\n", temperature );

log_printf( &logger, "--------------------------------\r\n" );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

} else {

log_error( &logger, " Communcation Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END