With its ability to detect subtle pressure variations, this solution helps you make informed decisions regarding outdoor activities and travel plans

A

A

Hardware Overview

How does it work?

Barometer Click is based on the LPS25HB, a high-resolution, digital output pressure sensor from STMicroelectronics. The LPS25HB includes a sensing element based on a piezoresistive Wheatstone bridge approach. When pressure is applied, the membrane deflection induces an imbalance in the Wheatstone bridge piezoresistance, whose output signal is converted into a 24-bit digital value by the selectable digital interface. The LPS25HB's interface is factory-calibrated at three temperatures and two pressures for sensitivity and accuracy. The LPS25HB delivers low-pressure noise with low power consumption and operates over an extended temperature range. It has a selectable

absolute pressure range, from 260 up to 1260hPa, with typical absolute pressure and temperature accuracy of ±0.2hPa and ±2°C, ideally suited for various pressure-based applications. Barometer Click allows the use of both I2C and SPI interfaces with a maximum frequency of 400kHz for I2C and 10MHz for SPI communication. The selection can be made by positioning SMD jumpers in an appropriate position marked as I2C or SPI. Note that all the jumpers' positions must be on the same side, or the Click board™ may become unresponsive. While the I2C interface is selected, the LPS25HB allows choosing the least significant bit (LSB) of its I2C slave address using the SMD jumper labeled I2C ADR. This Click board™

also possesses an additional interrupt pin, routed to the INT pin on the mikroBUS™ socket labeled as RDY, indicating when a new measured pressure data is available, simplifying data synchronization in digital systems or optimizing system power consumption. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. However, the Click board™ comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

Development board

Fusion for STM32 v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports a wide range of microcontrollers, such as different 32-bit ARM® Cortex®-M based MCUs from STMicroelectronics, regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer over WiFi. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, Fusion for STM32 v8 provides a fluid and immersive working experience, allowing

access anywhere and under any circumstances at any time. Each part of the Fusion for STM32 v8 development board contains the components necessary for the most efficient operation of the same board. An advanced integrated CODEGRIP programmer/debugger module offers many valuable programming/debugging options, including support for JTAG, SWD, and SWO Trace (Single Wire Output)), and seamless integration with the Mikroe software environment. Besides, it also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector.

Communication options such as USB-UART, USB HOST/DEVICE, CAN (on the MCU card, if supported), and Ethernet is also included. In addition, it also has the well-established mikroBUS™ standard, a standardized socket for the MCU card (SiBRAIN standard), and two display options for the TFT board line of products and character-based LCD. Fusion for STM32 v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

ARM Cortex-M7

MCU Memory (KB)

1024

Silicon Vendor

STMicroelectronics

Pin count

144

RAM (Bytes)

327680

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Schematic

Step by step

Project assembly

Track your results in real time

Application Output

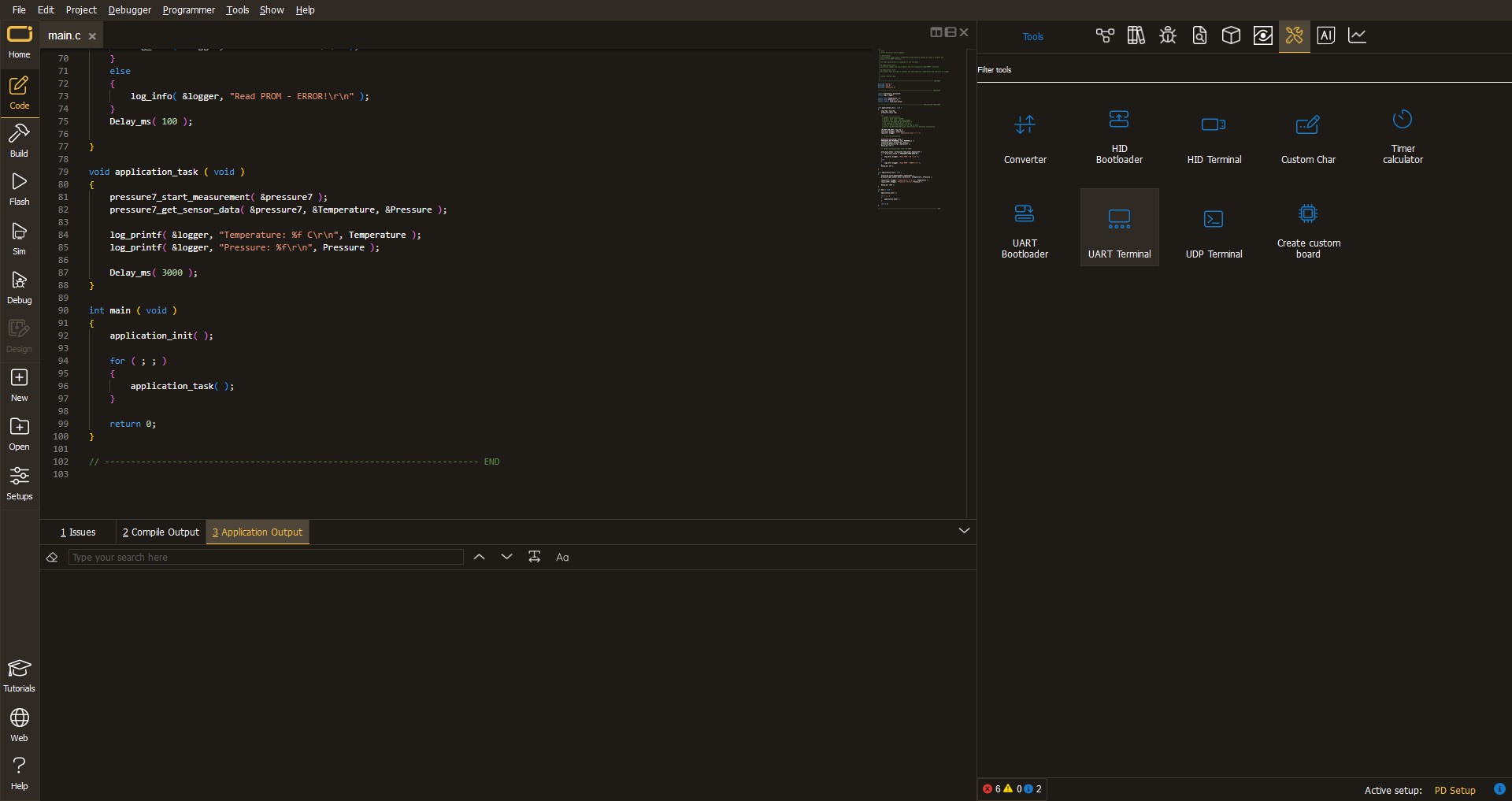

After pressing the "FLASH" button on the left-side panel, it is necessary to open the UART terminal to display the achieved results. By clicking on the Tools icon in the right-hand panel, multiple different functions are displayed, among which is the UART Terminal. Click on the offered "UART Terminal" icon.

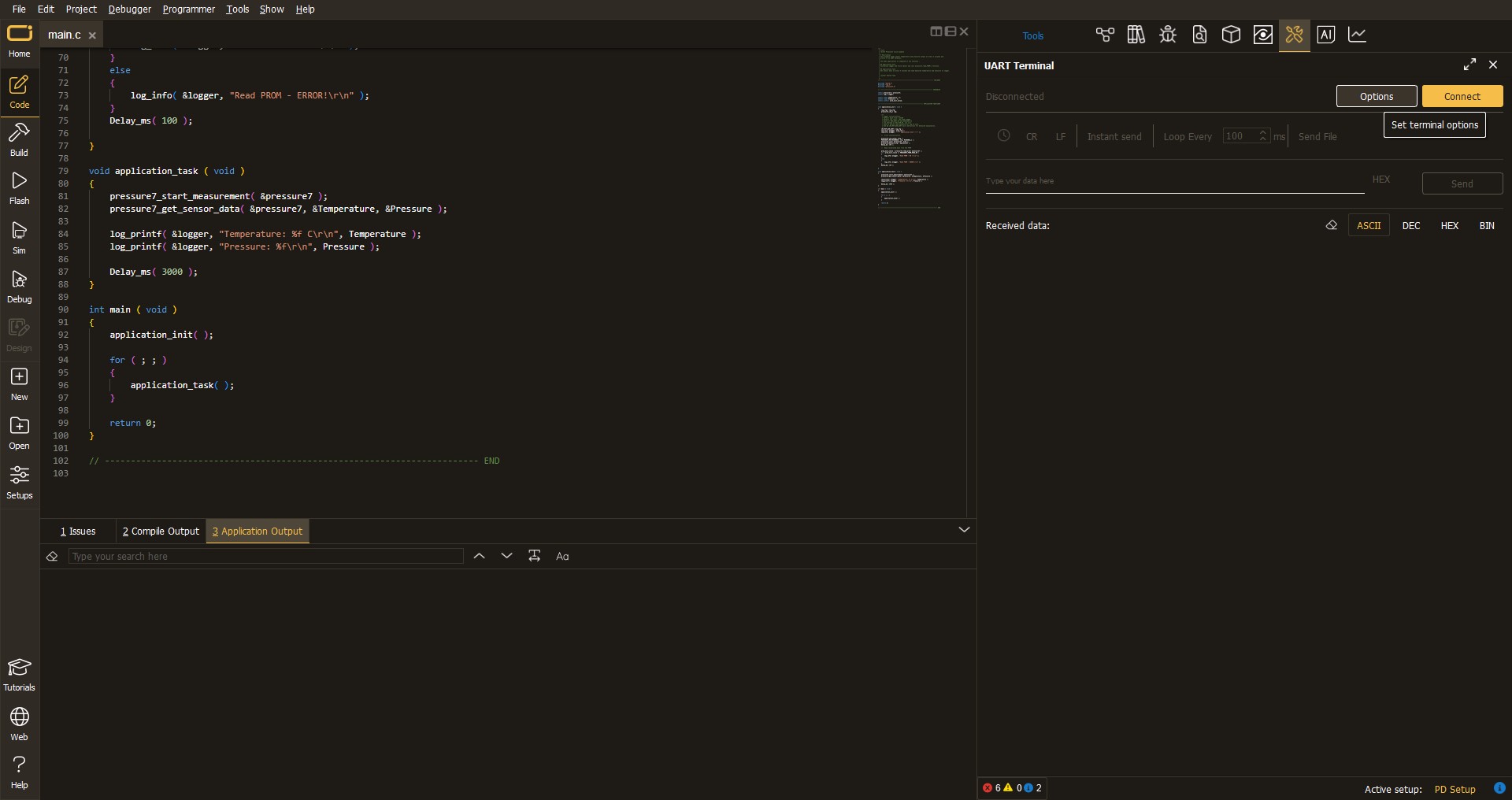

Once the UART terminal is opened, the window takes on a new form. At the top of the tab are two buttons, one for adjusting the parameters of the UART terminal and the other for connecting the UART terminal. The tab's lower part is reserved for displaying the achieved results. Before connecting, the terminal has a Disconnected status, indicating that the terminal is not yet active. Before connecting, it is necessary to check the set parameters of the UART terminal. Click on the "OPTIONS" button.

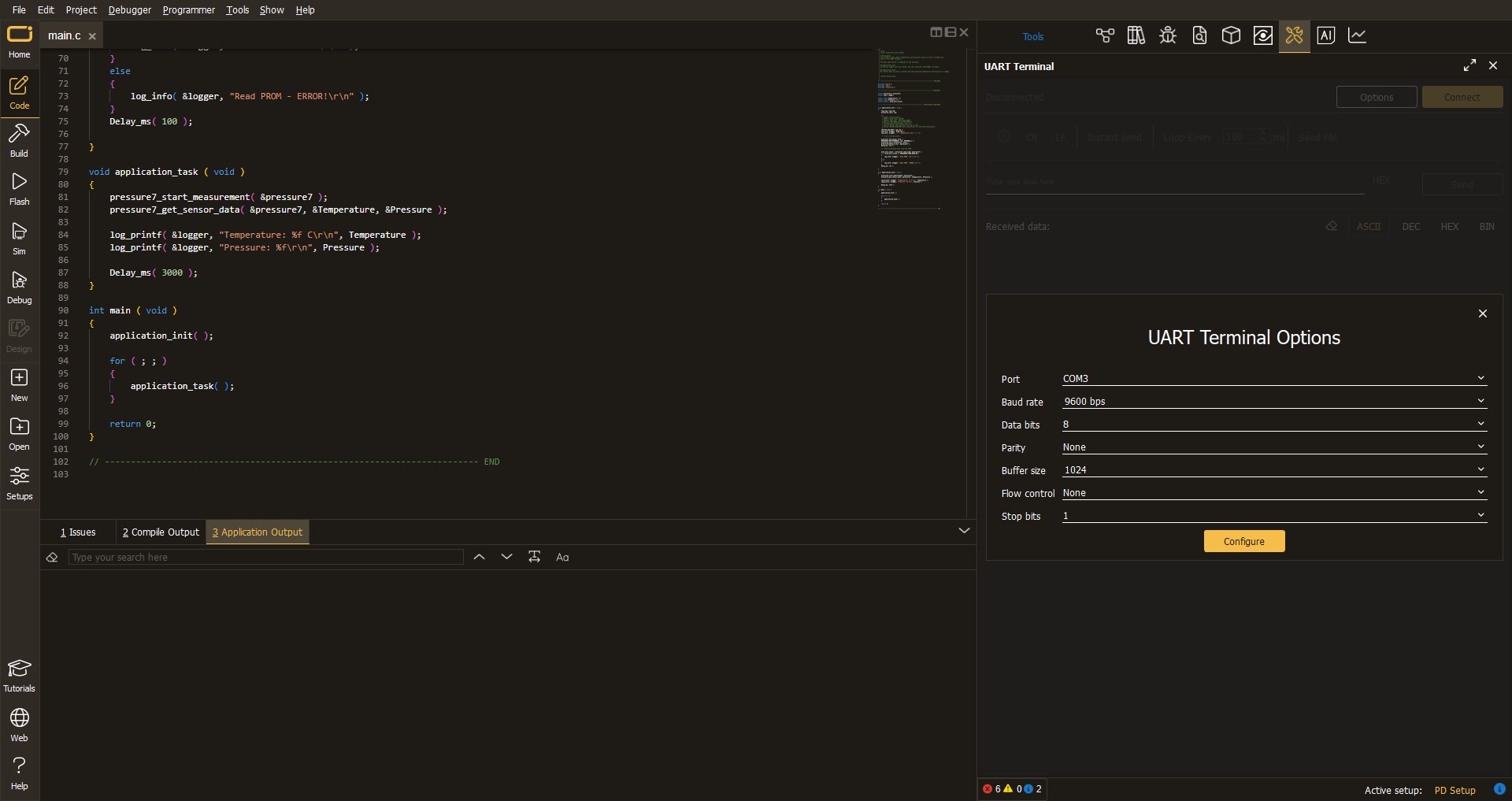

In the newly opened UART Terminal Options field, we check if the terminal settings are correct, such as the set port and the Baud rate of UART communication. If the data is not displayed properly, it is possible that the Baud rate value is not set correctly and needs to be adjusted to 115200. If all the parameters are set correctly, click on "CONFIGURE".

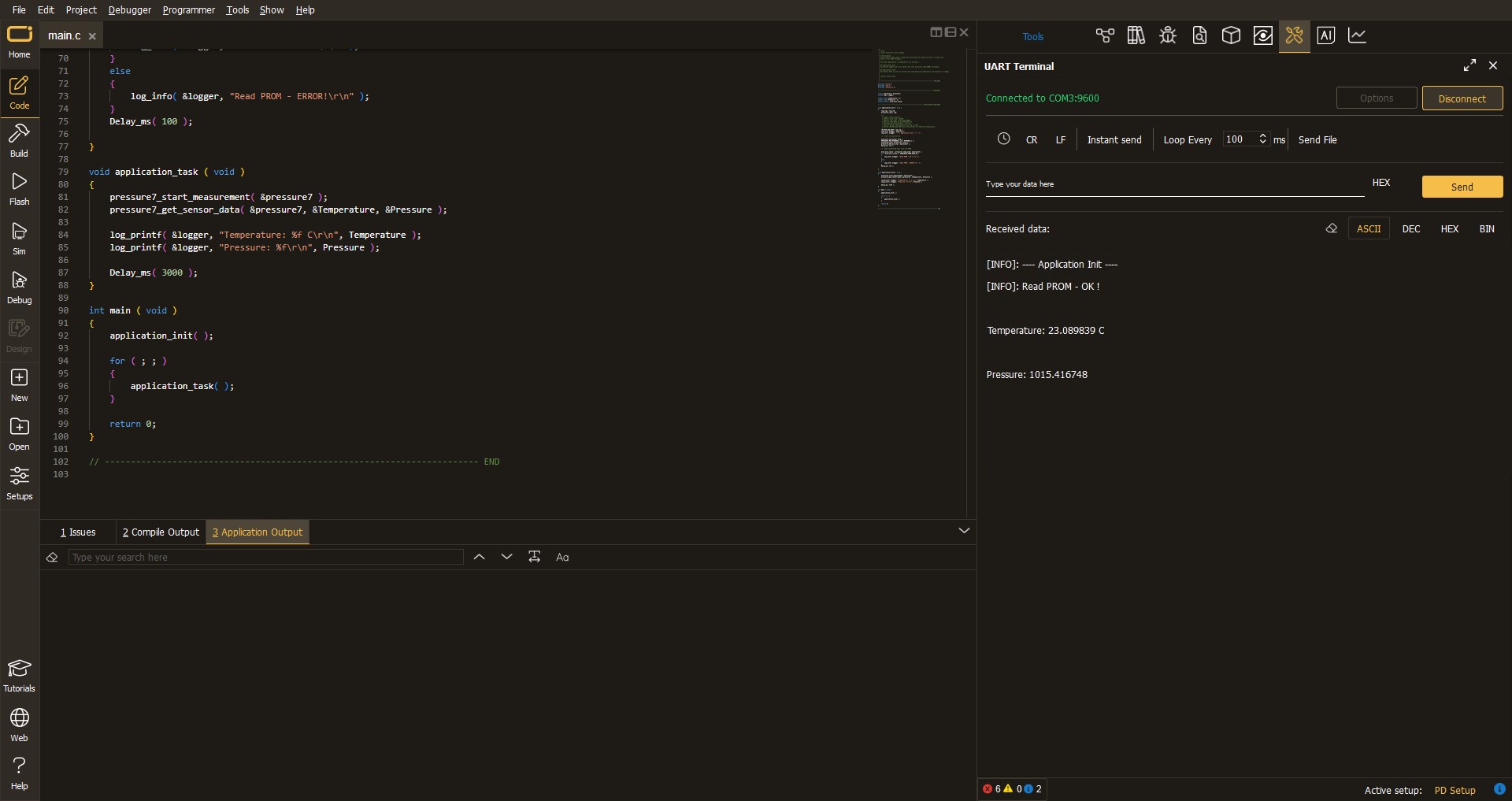

The next step is to click on the "CONNECT" button, after which the terminal status changes from Disconnected to Connected in green, and the data is displayed in the Received data field.

Software Support

Library Description

This library contains API for Barometer Click driver.

Key functions:

barometer_get_temperature_c- Read temperature in degrees Celsius functionbarometer_get_pressure- Read pressure in milibars functionbarometer_check_status- Check sensor status function

Open Source

Code example

This example can be found in NECTO Studio. Feel free to download the code, or you can copy the code below.

/*!

* \file

* \brief Barometer Click example

*

* # Description

* This application measures temperature and pressure data.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization driver enable's - I2C, set default configuration and start write log.

*

* ## Application Task

* This is a example which demonstrates the use of Barometer Click board.

* ## NOTE

* External pull-up resistors are required on I2C lines, if the click board is configured for I2C mode.

*

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "barometer.h"

// ------------------------------------------------------------------ VARIABLES

static barometer_t barometer;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

barometer_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

barometer_cfg_setup( &cfg );

BAROMETER_MAP_MIKROBUS( cfg, MIKROBUS_1 );

barometer_init( &barometer, &cfg );

barometer_default_cfg( &barometer );

// Check sensor id

if ( barometer_check_id( &barometer ) != BAROMETER_DEVICE_ID )

{

log_printf( &logger, " ERROR \r\n " );

}

else

{

log_printf( &logger, " Initialization \r\n" );

}

log_printf( &logger, "-------------------------------- \r\n" );

Delay_100ms( );

}

void application_task ( void )

{

float temperature_c;

float pressure;

temperature_c = barometer_get_temperature_c( &barometer );

Delay_100ms( );

pressure = barometer_get_pressure( &barometer );

Delay_100ms( );

log_printf( &logger, " Temperature : %.2f\r\n", temperature_c );

log_printf( &logger, " Pressure : %.2f\r\n", pressure );

log_printf( &logger, "-------------------------------- \r\n" );

Delay_1sec( );

}

void main ( void )

{

application_init( );

for ( ; ; )

{

application_task( );

}

}

// ------------------------------------------------------------------------ END