Our fan speed management solution optimizes airflow, ensuring efficient cooling and energy savings throughout your space

A

A

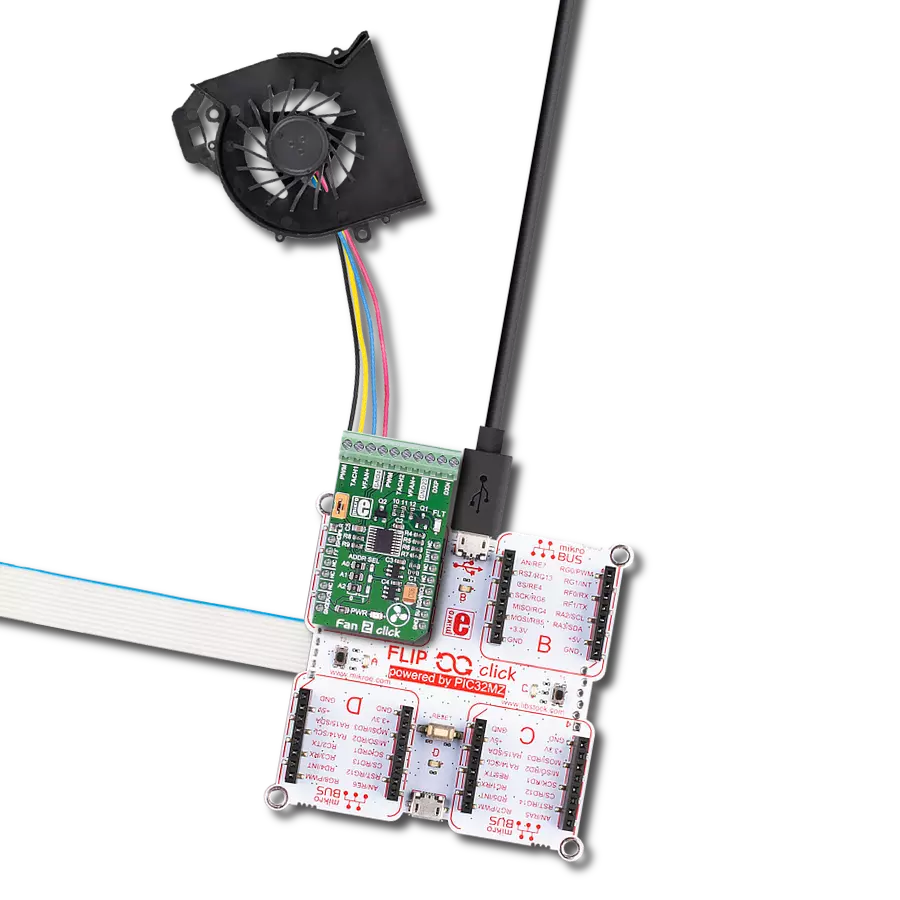

Hardware Overview

How does it work?

Fan 4 Click is based on the LTC1695, an I2C fan speed controller from Analog Devices. It offers a programmable output voltage regulation, primarily aimed at controlling the speed of the 5V DC brushless fan drivers, which otherwise can't be controlled by the PWM signal, phase commutation, or some other method, leaving only the option to be controlled by changing the power supply voltage. This controller IC uses a very compact SOT23 package case, requires a low number of additional components, and is really easy to control by the two-wire I2C bus. This makes it a perfect solution for the fan speed regulator, which can be used for components cooling in various electronic designs. Speed control is very desirable in such applications. Still, the complexity associated with driving other, more advanced types of fan motors that offer speed regulation often leads to cheaper, two-wire 5V DC brushless fans, which do not offer any other means to control their speed but to reduce the power supply voltage. Brushless motors can sometimes

exhibit the stall effect if started with reduced voltage. Although the fan will not rotate, the current will still be consumed, making the stall condition sensing difficult. Therefore, the LTC1695 driver features an internal boost timer, which users can activate via the I2C command. During the time-out period of the boost timer (250ms), the voltage at the output will be set at the maximum value (4.92V) so the reliable startup sequence of the fan motor is ensured. The LTC1695 datasheet offers some fan models tested with this IC. If there is still a problem with the specific fan model, the firmware on the host MCU can always be utilized to apply a startup boost with an arbitrary interval. The LTC1965 also features an undervoltage protection (UVLO). If the input voltage stays below 2.9V, the IC will not be enabled, preventing erratic behavior on the output. However, when used with the MikroElektronika development system, the power supply is taken from the regulated power supply unit of the development board. The internal logic structure of the LTC1695 is also

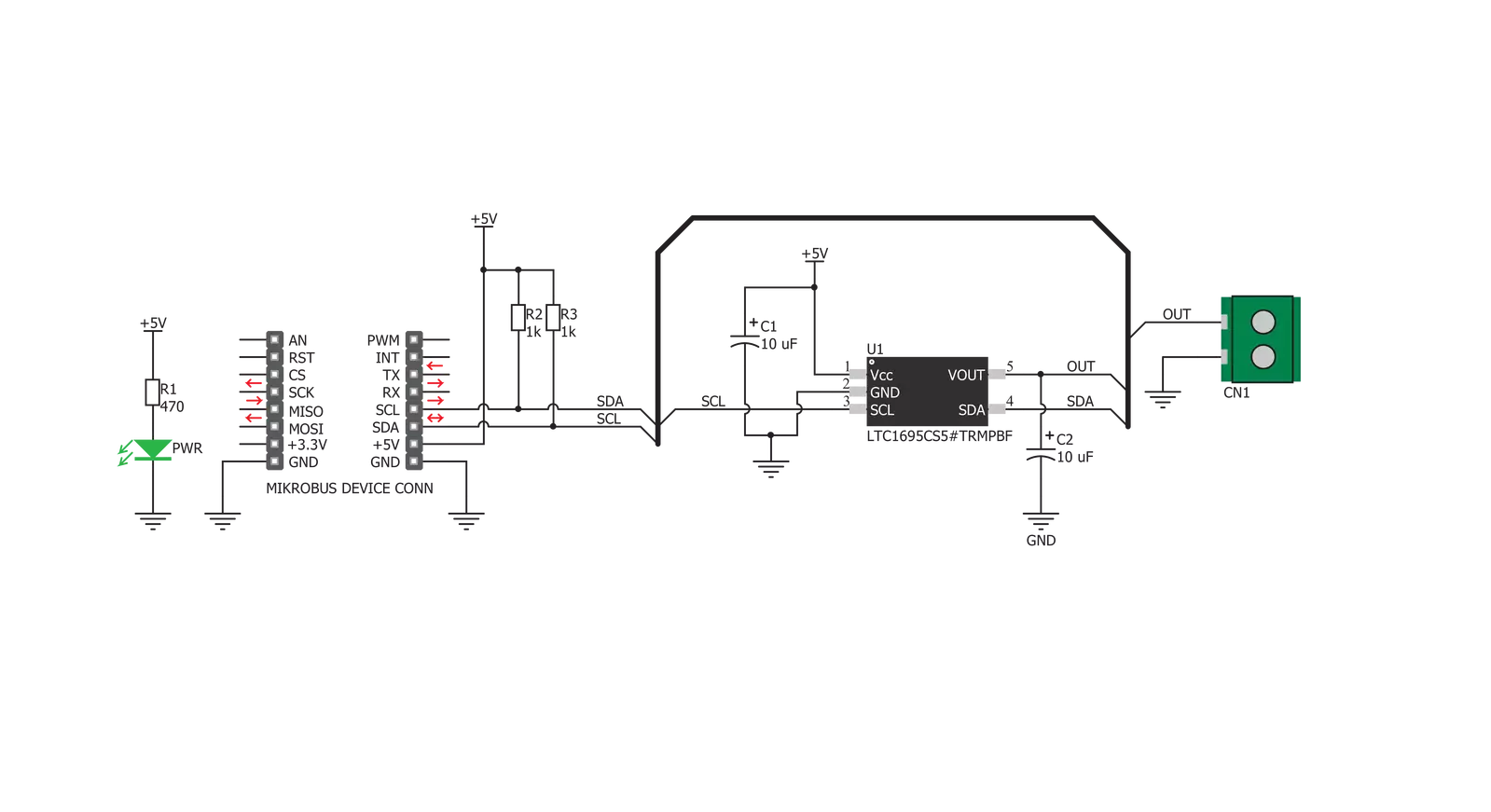

simple. It only has one 8-bit register. When writing to this register, bits D0 to D5 set the DAC output voltage, while the D6 bit is used to enable the boost timer. Bit D7 needs to be considered. When reading out the data, this register reflects the status of the LTC1695 IC; bit D7 indicates overcurrent condition, while bit D6 indicates thermal shutdown. The remaining six bits are disregarded. The internal DAC is set to 0 during the startup sequence, so there will be no voltage at the output. The Click board™ has its I2C pins routed to the corresponding pins of the mikroBUS™, and it uses the power from the mikroBUS™ +5V power rail, as already mentioned. The mikroBUS™ is quite capable of supplying the LTC1965 with the maximum amount of current it can draw (about 180 mA). The output 2-pole screw terminal allows an external load to be connected. Although the Click board™ is aimed towards driving brushless fan motors, it can also be used as the programmable low drop regulator (LDO), or it can be used as a LED driver.

Features overview

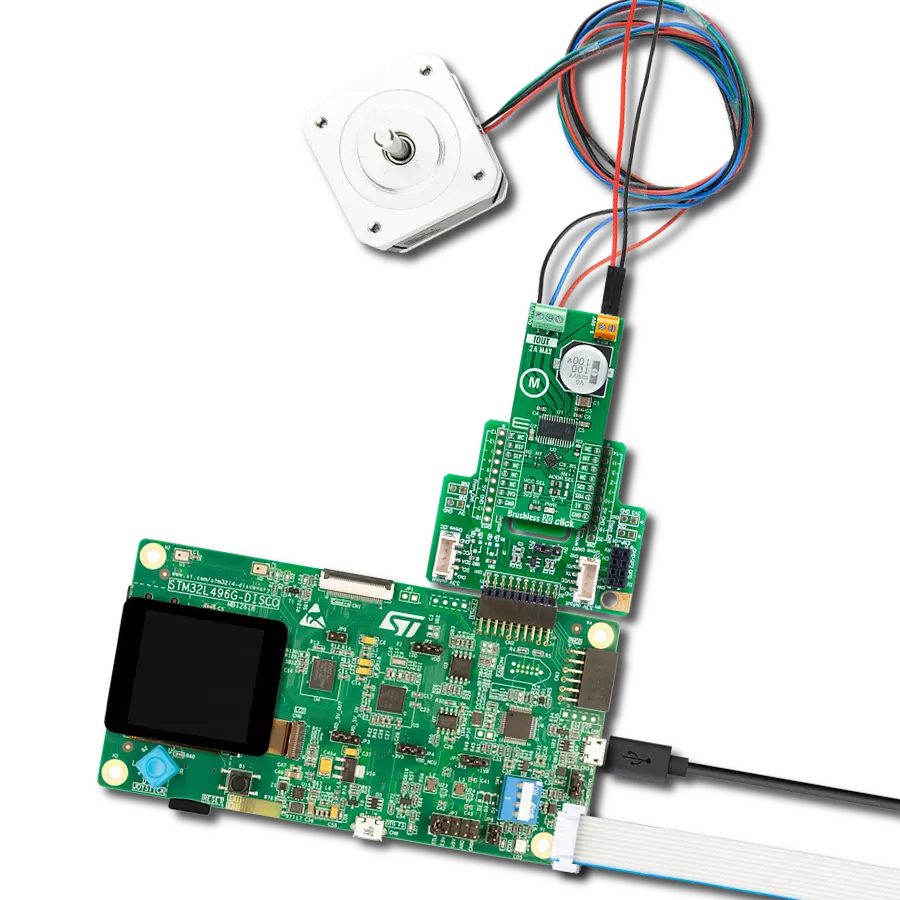

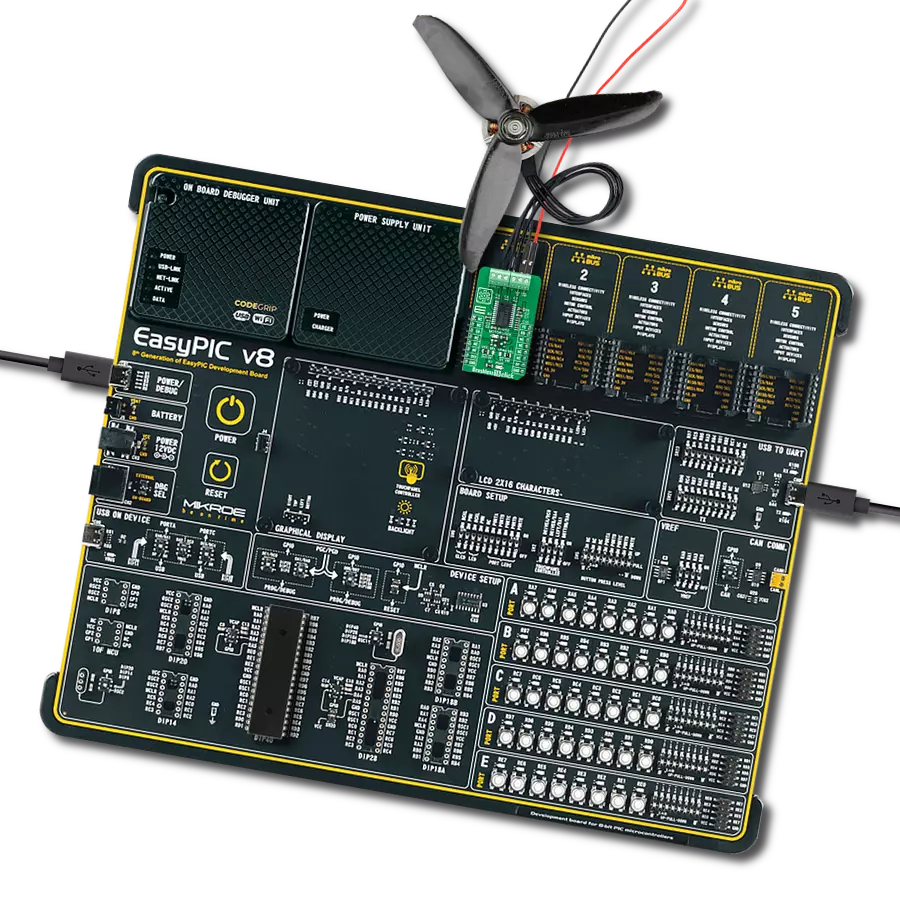

Development board

UNI-DS v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports a wide range of microcontrollers, such as different STM32, Kinetis, TIVA, CEC, MSP, PIC, dsPIC, PIC32, and AVR MCUs regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer over WiFi. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, UNI-DS v8 provides a fluid and immersive working experience, allowing access anywhere and under any

circumstances at any time. Each part of the UNI-DS v8 development board contains the components necessary for the most efficient operation of the same board. An advanced integrated CODEGRIP programmer/debugger module offers many valuable programming/debugging options, including support for JTAG, SWD, and SWO Trace (Single Wire Output)), and seamless integration with the Mikroe software environment. Besides, it also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector. Communication options such as USB-UART, USB

HOST/DEVICE, CAN (on the MCU card, if supported), and Ethernet is also included. In addition, it also has the well-established mikroBUS™ standard, a standardized socket for the MCU card (SiBRAIN standard), and two display options for the TFT board line of products and character-based LCD. UNI-DS v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

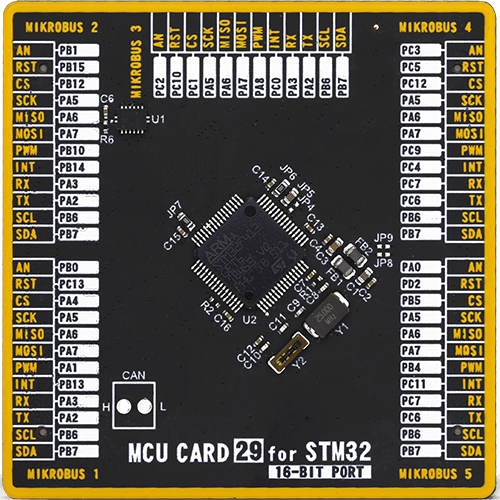

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

ARM Cortex-M4

MCU Memory (KB)

1536

Silicon Vendor

STMicroelectronics

Pin count

64

RAM (Bytes)

327680

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Fan 4 Click driver.

Key functions:

fan4_check_diagnostic- Check diagnosticfan4_set_output- Set output voltage

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Fan4 Click example

*

* # Description

* Demo application shows basic use of Fan 4 Click.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Configuring Clicks and log objects.

* Settings the Click in the default configuration.

*

* ## Application Task

* Increases the output voltage every 500 ms until it reaches the maximum fan voltage.

* Prints current voltase data on usbuart.

*

* \author Katarina Perendic

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "fan4.h"

// ------------------------------------------------------------------ VARIABLES

static fan4_t fan4;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

fan4_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

fan4_cfg_setup( &cfg );

FAN4_MAP_MIKROBUS( cfg, MIKROBUS_1 );

fan4_init( &fan4, &cfg );

fan4_default_cfg( &fan4 );

}

void application_task ( void )

{

uint16_t voltage;

// Task implementation.

voltage = FAN4_MIN_VOLT_SCALE;

while ( voltage <= FAN4_MAX_VOLT_SCALE )

{

voltage += ( FAN4_DAC_LSB * 4 );

log_info( &logger, "** Voltage is %d mV", voltage );

fan4_set_output( &fan4, voltage, FAN4_BOOST_START_TIMER_DIS );

Delay_ms ( 500 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END