The ultimate tool for vacuum experiments, our pressure sensor empowers researchers and engineers to explore new frontiers in science and technology, providing critical data with unmatched precision

A

A

Hardware Overview

How does it work?

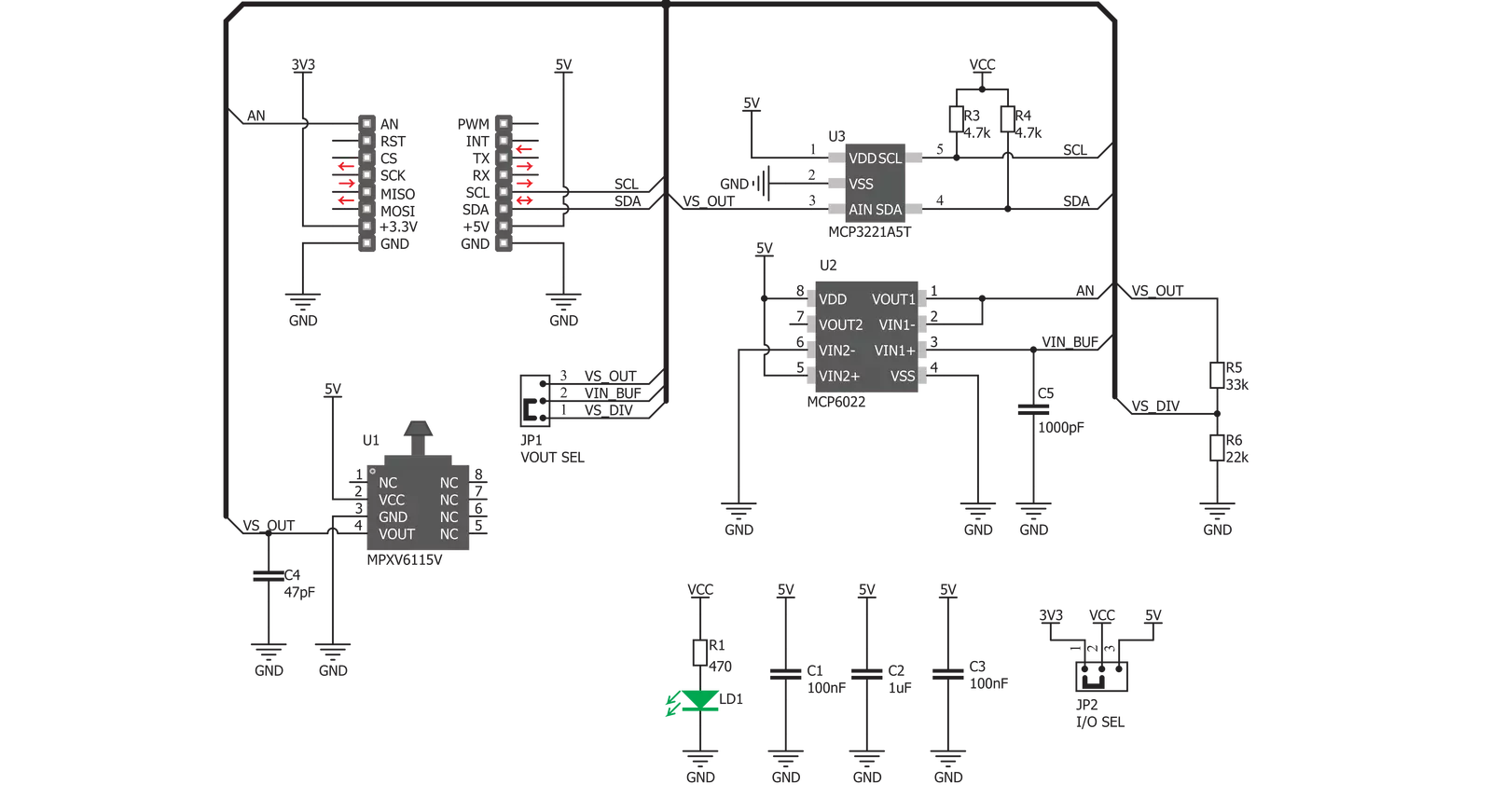

Vacuum Click is based on the MPXV6115V, a highly advanced monolithic vacuum pressure sensor from NXP. This sensor features the piezo-resistive MEMS sensing element, combined with the application-specific integrated circuit (ASIC) allowing a high degree of linearity, as well as a very low drift over the temperature. The lower part of the sensor contains the necessary sensing elements, while the upper part of the sensor is shaped as a small tube, and it is referred to as "port" in the datasheet. A small rubberized hose can easily be attached to the inlet, so that the vacuum producing counterpart can be securely connected with the sensor. The design of the inlet prevents leakage that might appear if the sealing is not good enough. The sensor itself outputs approximately 4.6V DC voltage on its output pin when it is located at the sea-level pressure. As the pressure decreases, the voltage drops towards 0V. The ASIC ensures that the voltage drop is linear with the pressure. The MPXV6115V datasheet

offers a diagram that illustrates the output voltage vs pressure dependency. The second section of the Click board™ is the converter section, and it contains an Analog-to-Digital converter (ADC) IC. Vacuum click utilizes the MCP3221, a 12-bit successive approximation ADC with I2C Interface, from Microchip. It is used to sample the output voltage from the sensor, allowing the digitized value to be retrieved over the I2C interface. The ADC uses 5V power rail of the mikroBUS™ as a voltage reference. The voltage output of the sensor is also directly available on the AN output and it is buffered with an operational amplifier. It can be used if the 12-bit ADC accuracy is not high enough, or if some other type of output voltage converter has to be used. The AN pin of the mikroBUS™ offers two voltage output settings, selectable by the SMD jumper labeled as VOUT. The default position (1V8) routes the output voltage from the sensor to a voltage divider, reducing the maximum output value at

the AN pin. The maximum voltage value is approximately 1.85V in this case, when used at the sea level. This setting prevents damage in the case when the host MCU is not 5V tolerant. If the host MCU has 5V tolerant pins, the full voltage output can be used. If the VOUT jumper is soldered at the 4V6 position, the signal will not be routed to the voltage divider, so the voltage at the AN pin of the mikroBUS™ can swing up to the maximum voltage level available from the sensor. This voltage ranges up to 4.6V at sea level (101.325 kPa). Please note that the output can also increase above this value when a positive pressure is applied to the sensor (which is not advised). Another onboard jumper labeled as I/O SEL offers a selection of the I2C communication voltage levels. This jumper can be used to interface the Click board™ both with the 3.3V and 5V MCUs, allowing a wide range of different MCUs to be used with the Click board™.

Features overview

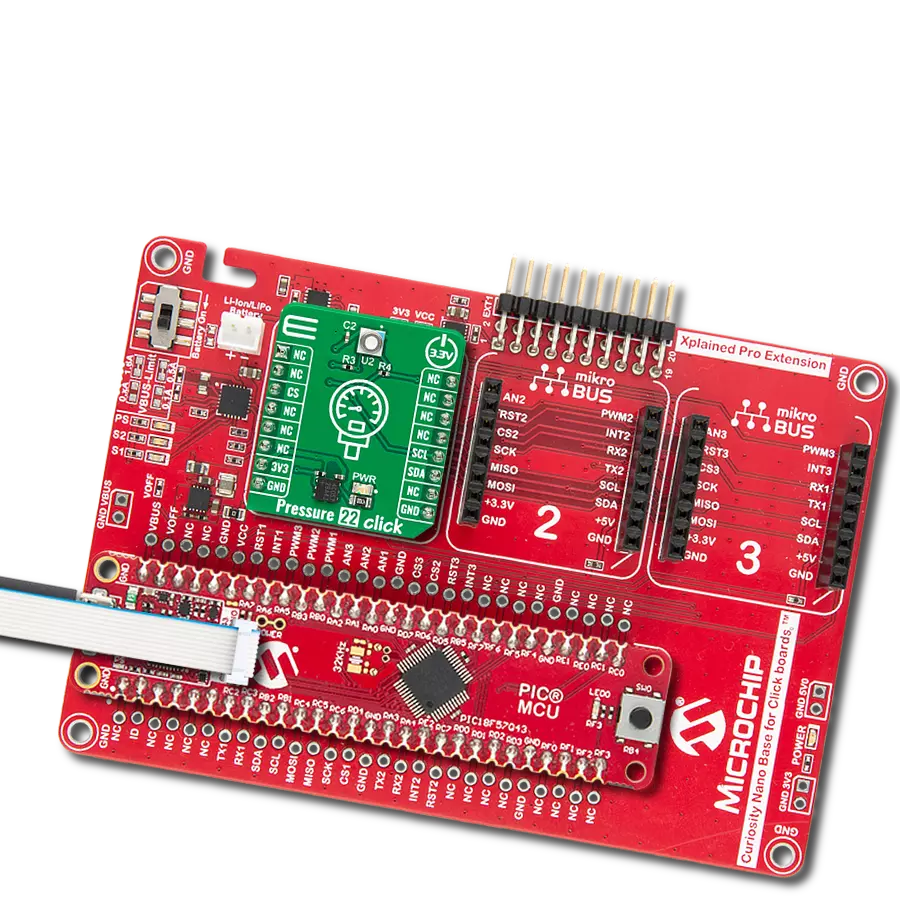

Development board

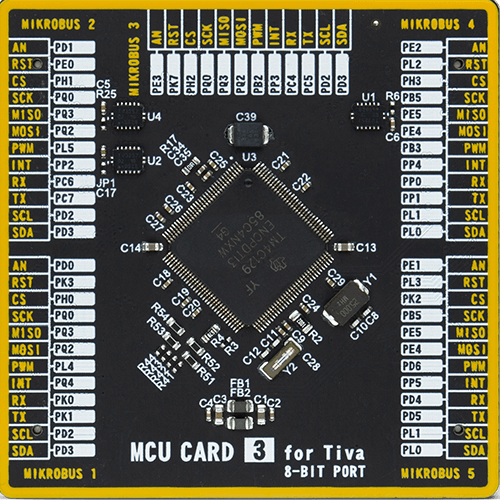

Fusion for TIVA v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports a wide range of microcontrollers, such as different 32-bit ARM® Cortex®-M based MCUs from Texas Instruments, regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer over a WiFi network. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, Fusion for TIVA v8 provides a fluid and immersive working experience, allowing access

anywhere and under any circumstances at any time. Each part of the Fusion for TIVA v8 development board contains the components necessary for the most efficient operation of the same board. An advanced integrated CODEGRIP programmer/debugger module offers many valuable programming/debugging options, including support for JTAG, SWD, and SWO Trace (Single Wire Output)), and seamless integration with the Mikroe software environment. Besides, it also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector.

Communication options such as USB-UART, USB HOST/DEVICE, CAN (on the MCU card, if supported), and Ethernet is also included. In addition, it also has the well-established mikroBUS™ standard, a standardized socket for the MCU card (SiBRAIN standard), and two display options for the TFT board line of products and character-based LCD. Fusion for TIVA v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

Texas Instruments

Pin count

128

RAM (Bytes)

262144

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Vacuum Click driver.

Key functions:

vacuum_generic_write- Generic write functionvacuum_get_voltage- Voltage reading functionvacuum_get_percentage_of_vacuum- Function for converting ADC value to percentage of Vacuum

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Vacuum Click example

*

* # Description

* This application measuring absolute pressure.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization driver init and calibration of the chip to start measuring.

*

* ## Application Task

* Reads vacuum percentage that sensor reads.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "vacuum.h"

// ------------------------------------------------------------------ VARIABLES

static vacuum_t vacuum;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

vacuum_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

vacuum_cfg_setup( &cfg );

VACCUM_MAP_MIKROBUS( cfg, MIKROBUS_1 );

vacuum_init( &vacuum, &cfg );

vacuum_calibration( &vacuum );

}

void application_task ( void )

{

float vacuum_data;

float vacuum_volt;

float pressure;

// Task implementation.

vacuum_volt = vacuum_get_voltage( &vacuum );

log_printf ( &logger, "Vacuum [V] : %.2f\r\n ", vacuum_volt );

pressure = vacuum_get_pressure( &vacuum );

log_printf ( &logger, "Pressure [mBar] : %.2f V\r\n ", pressure );

vacuum_data = vacuum_get_percentage_of_vacuum( &vacuum );

log_printf ( &logger, "Percentage of vacuum [%%] : %.2f : \r\n ", vacuum_data );

log_printf ( &logger, "------------------------------------------\r\n " );

Delay_ms ( 300 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END