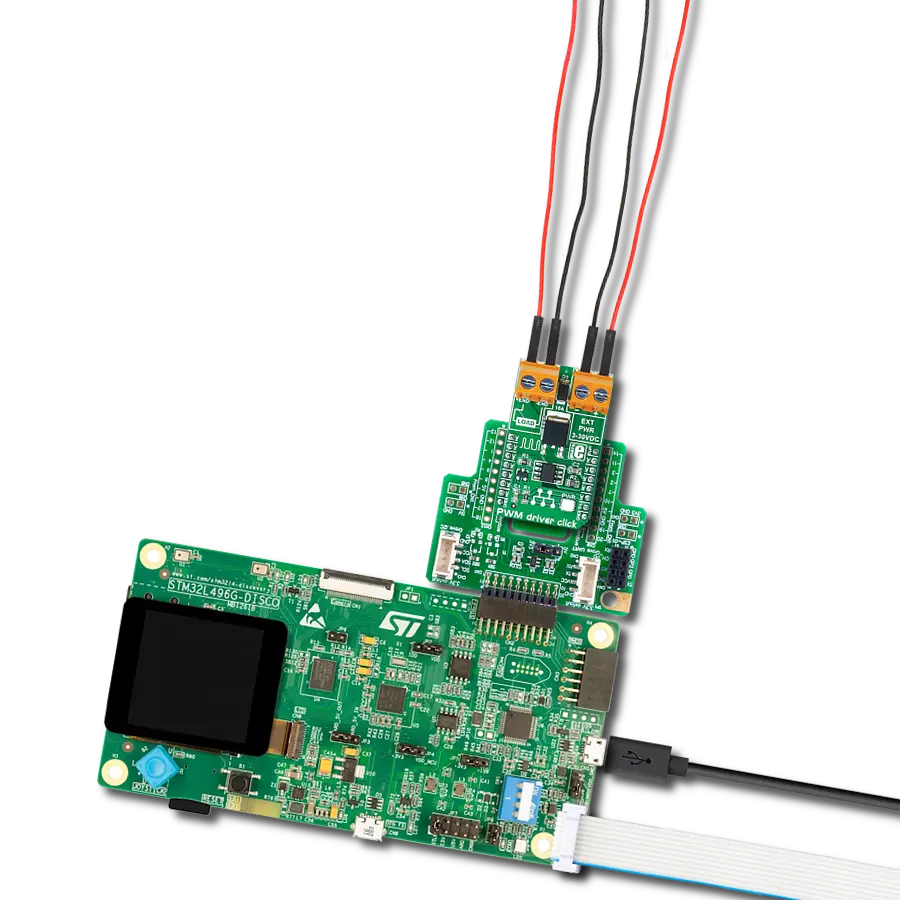

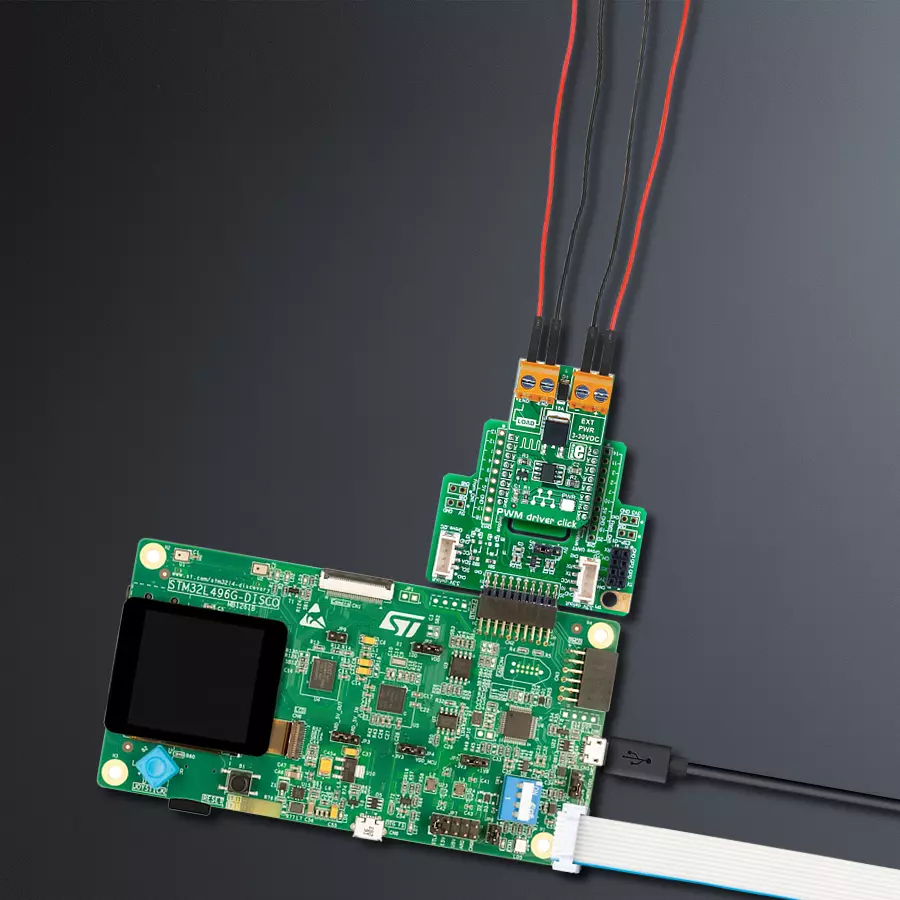

Unlock speed control possibilities with our PWM-controlled DC motor solution

A

A

Hardware Overview

How does it work?

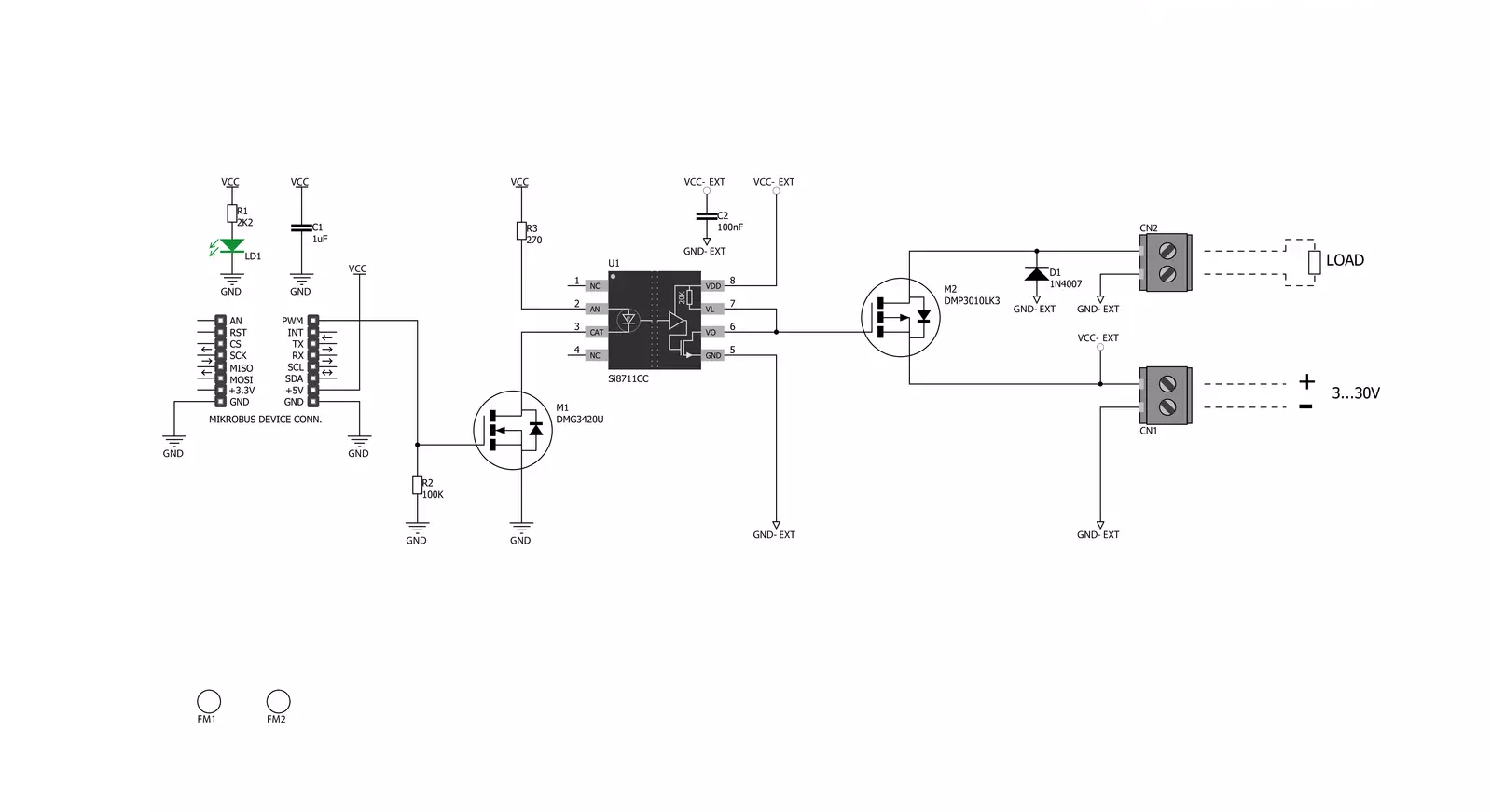

PWM driver Click is based on the Si8711CC, a 5kV LED emulator input, open collector output isolator from Skyworks. Compared to the optocouplers, the Si8711CC is more resistant to temperature, age, and forward current effects. It has a longer service life, higher common-mode transient immunity, and more. The Si8711CC is based on proprietary CMOS isolation technology for low-power, high-speed operation and is resistant to wear-out effects that, in the case of optocouplers, degrade the performance. The Si8711CC features up to 5000VRMS isolation and 10kV surge protection, making it a perfect isolator. For controlling the devices, it is capable of data rates DC of up to 15Mbps, with a propagation delay of 30ns. The Si8711CC controls the loads over the DMP3010LK3,

a P-channel enhancement mode MOSFET from Diodes Incorporated. This fast-switching diode has ESD protected gate, low input capacitance, and low on-resistance, designed to maintain superior switching performance, making it ideal for high-efficiency power management applications. The PWM Driver Click comes with the screw terminals labeled LOAD (+END, -END) to connect the load, which the Si7811CC controls over the DMP3010LK3 diode, and EXT for external power supply. It is not recommended to use this Click board™ with loads over 50W as the MOSFET can get overheated; this, however, does not apply if the Click board™ is used as an ON/OFF switch. The PWM Driver Click is controlled by the host MCU by PWM pulses over the PWM pin of the mikroBUS™ socket. The PWM

pin does not have direct control over the Si8711CC but rather through the DMG3420U, an N-channel enhancement mode MOSFET from Diodes Incorporated. This diode shares many features with the one mentioned above, such as low on-resistance, low input capacitance, fast switching speed, and more. This Click board™ can be operated only with a 5V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. However, the Click board™ comes equipped with a library containing functions and an example code that can be used, as a reference, for further development.

Features overview

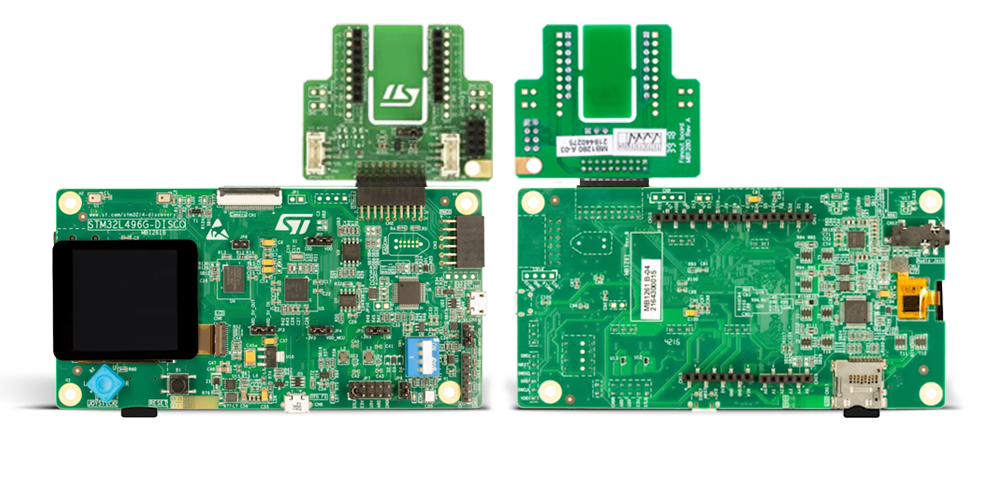

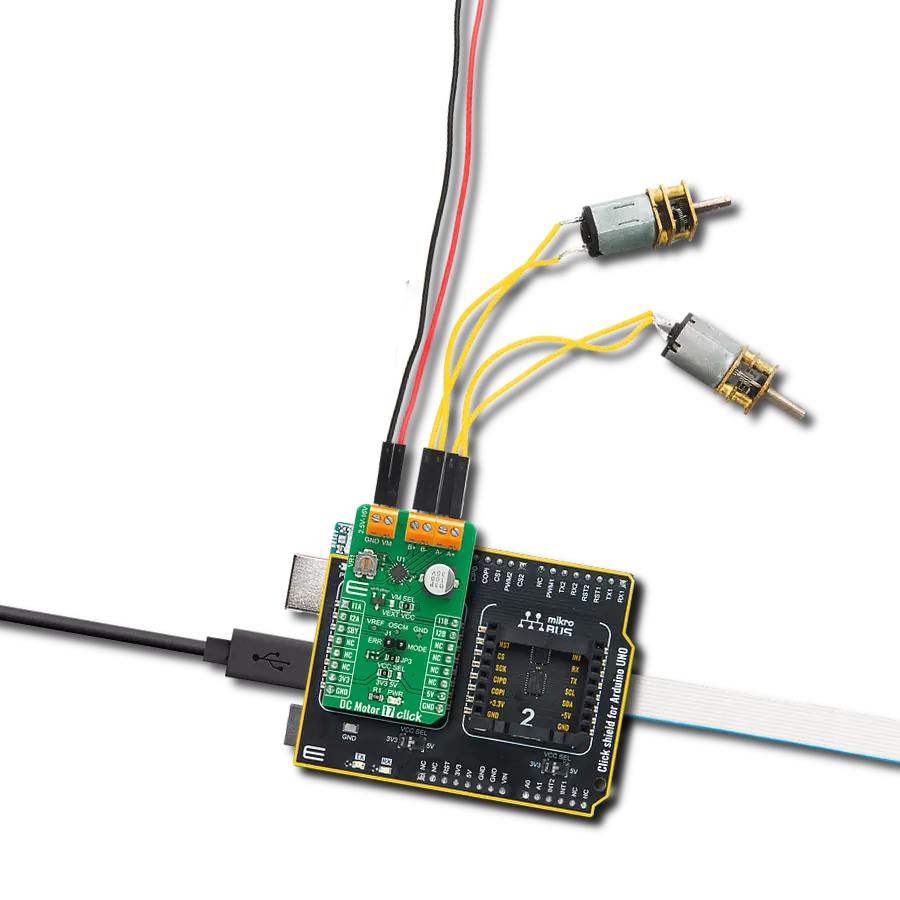

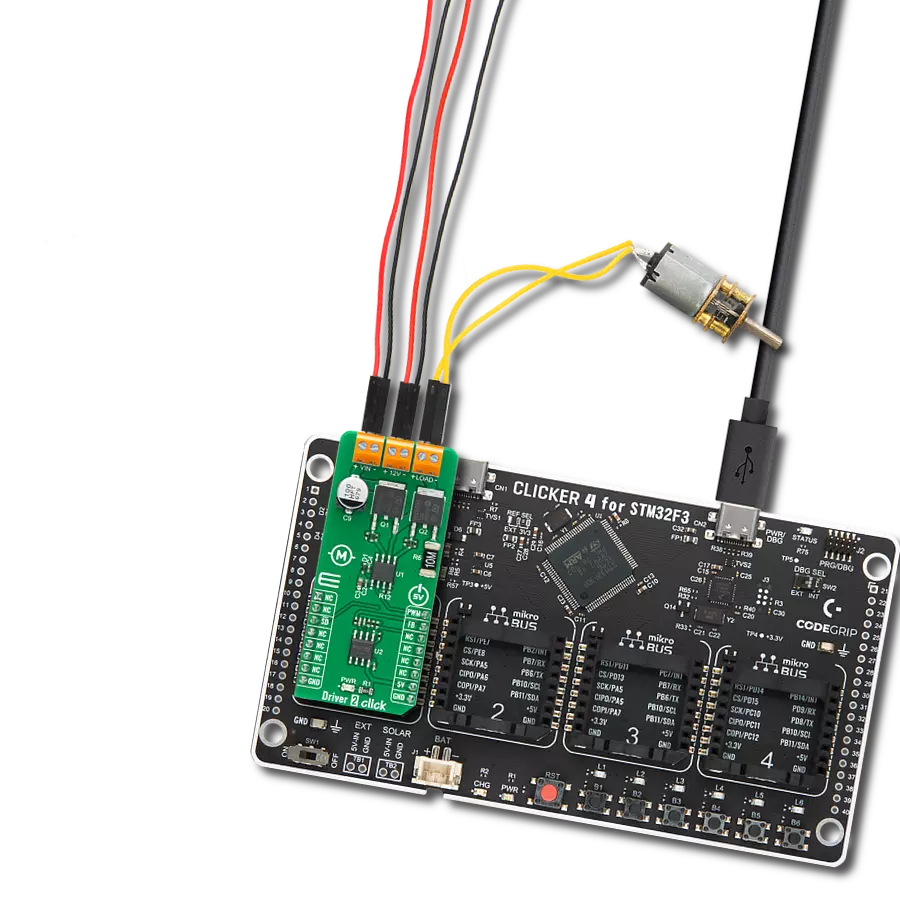

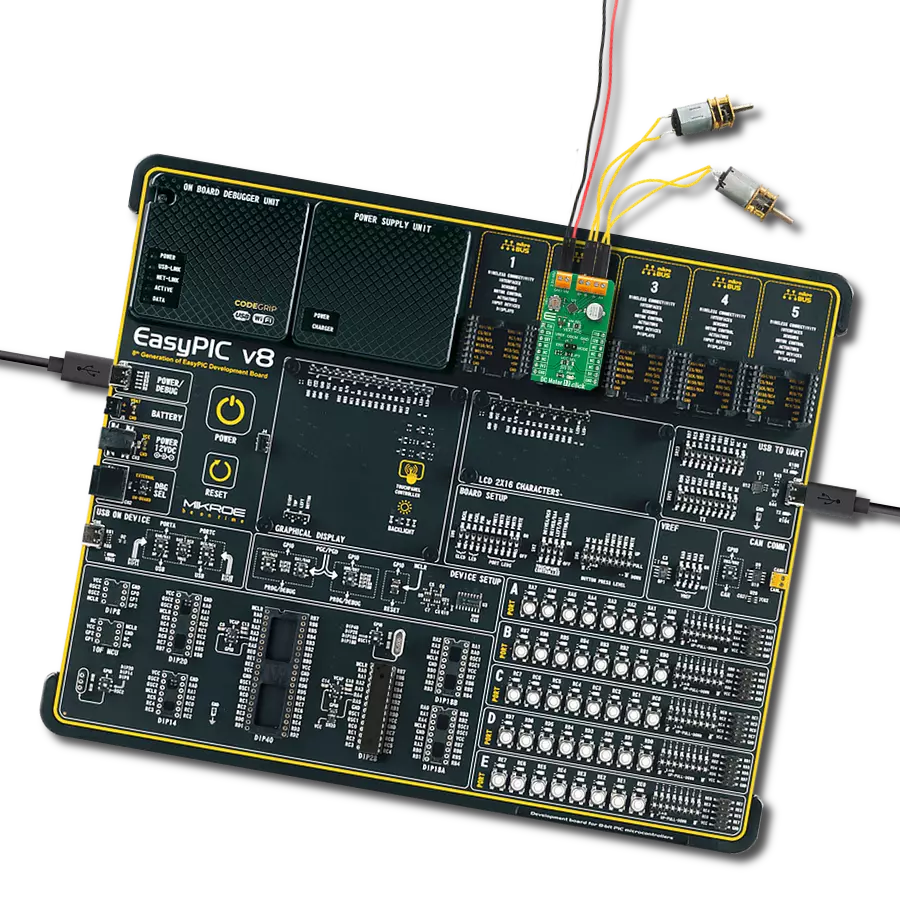

Development board

The 32L496GDISCOVERY Discovery kit serves as a comprehensive demonstration and development platform for the STM32L496AG microcontroller, featuring an Arm® Cortex®-M4 core. Designed for applications that demand a balance of high performance, advanced graphics, and ultra-low power consumption, this kit enables seamless prototyping for a wide range of embedded solutions. With its innovative energy-efficient

architecture, the STM32L496AG integrates extended RAM and the Chrom-ART Accelerator, enhancing graphics performance while maintaining low power consumption. This makes the kit particularly well-suited for applications involving audio processing, graphical user interfaces, and real-time data acquisition, where energy efficiency is a key requirement. For ease of development, the board includes an onboard ST-LINK/V2-1

debugger/programmer, providing a seamless out-of-the-box experience for loading, debugging, and testing applications without requiring additional hardware. The combination of low power features, enhanced memory capabilities, and built-in debugging tools makes the 32L496GDISCOVERY kit an ideal choice for prototyping advanced embedded systems with state-of-the-art energy efficiency.

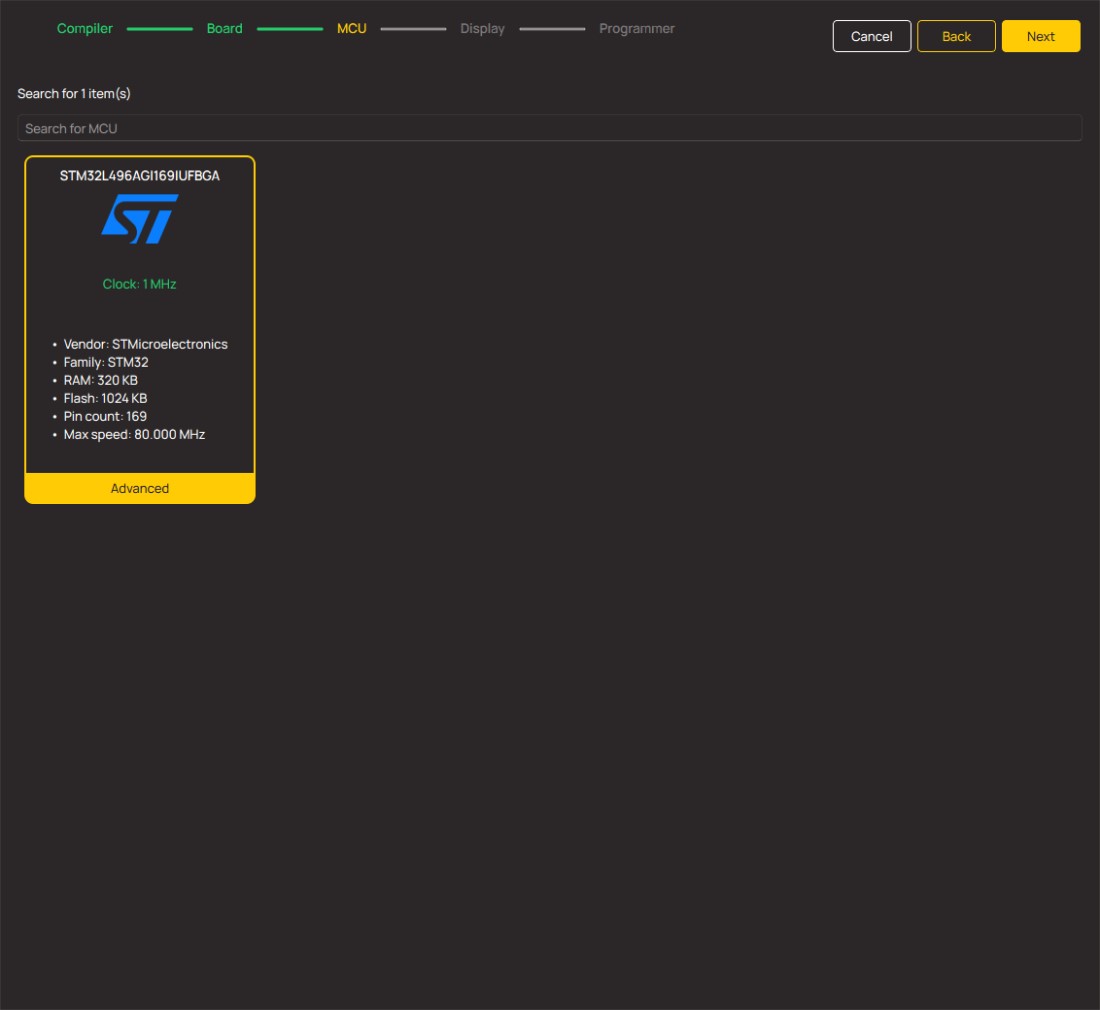

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

STMicroelectronics

Pin count

169

RAM (Bytes)

327680

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for PWM driver Click driver.

Key functions:

pwmdriver_set_duty_cycle- Generic sets PWM duty cyclepwmdriver_pwm_stop- Stop PWM modulepwmdriver_pwm_start- Start PWM module

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

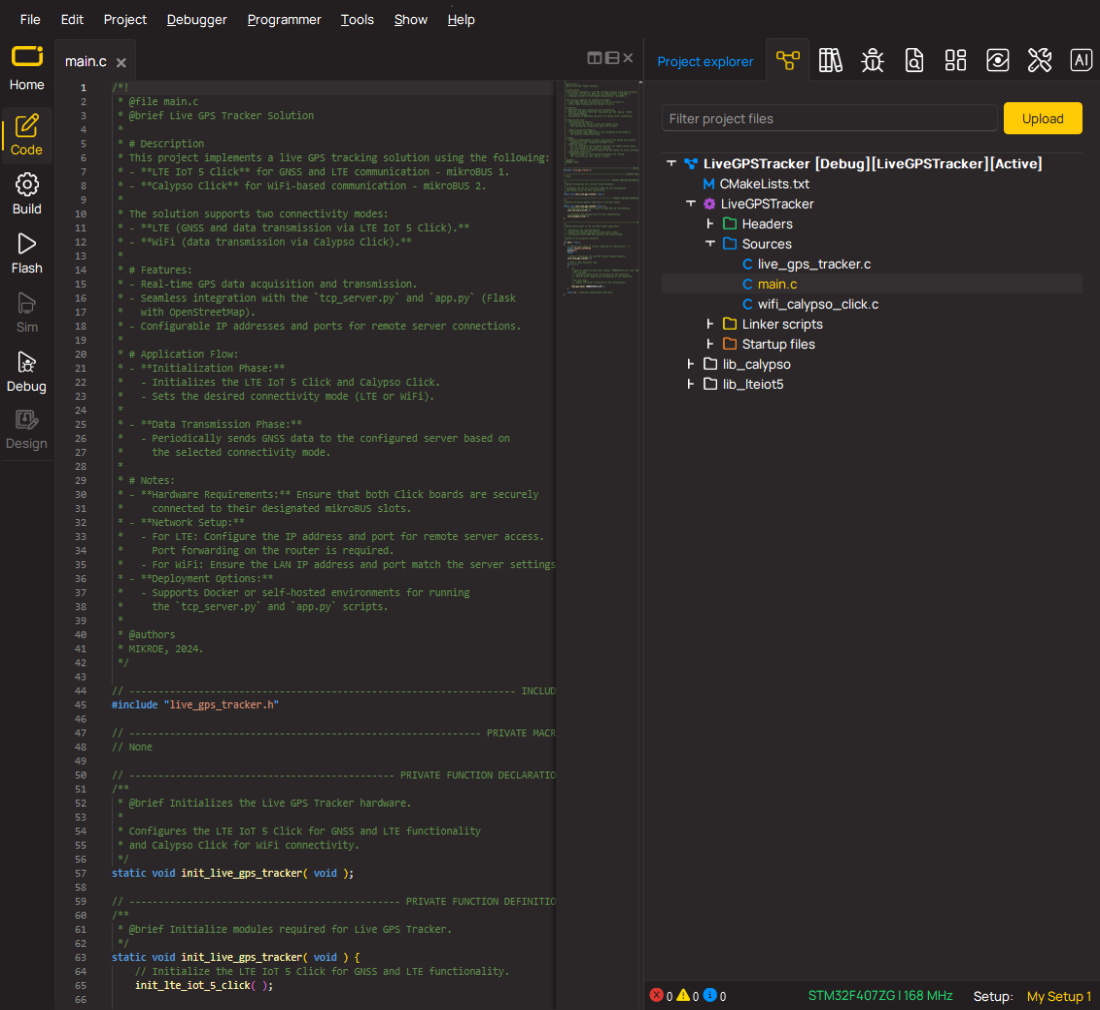

/*!

* @file

* @brief PwmDriver Click example

*

* # Description

* This application is controls the speed DC motors.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization driver enables - GPIO, PWM initialization set PWM duty cycle and PWM frequency,

* start PWM, enable the engine, and start to write log.

*

* ## Application Task

* This is an example that demonstrates the use of the PWM driver Click board.

* This example shows the automatic control of PWM,

* the first increases duty cycle and then the duty cycle is falling.

* Results are being sent to the Usart Terminal where you can track their changes.

*

* *note:*

* EXT PWR 3-30VDC

*

* @author Nikola Peric

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "pwmdriver.h"

// ------------------------------------------------------------------ VARIABLES

static pwmdriver_t pwmdriver;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

pwmdriver_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

pwmdriver_cfg_setup( &cfg );

PWMDRIVER_MAP_MIKROBUS( cfg, MIKROBUS_1 );

pwmdriver_init( &pwmdriver, &cfg );

Delay_ms ( 100 );

log_printf( &logger, " Initialization PWM \r\n " );

pwmdriver_set_duty_cycle( &pwmdriver, 0.0 );

pwmdriver_pwm_start( &pwmdriver );

Delay_ms ( 1000 );

log_info( &logger, "---- Application Task ----" );

}

void application_task ( void )

{

static int8_t duty_cnt = 1;

static int8_t duty_inc = 1;

float duty = duty_cnt / 10.0;

pwmdriver_set_duty_cycle ( &pwmdriver, duty );

log_printf( &logger, "Duty: %d%%\r\n", ( uint16_t )( duty_cnt * 10 ) );

Delay_ms ( 500 );

if ( 10 == duty_cnt )

{

duty_inc = -1;

}

else if ( 0 == duty_cnt )

{

duty_inc = 1;

}

duty_cnt += duty_inc;

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Brushed