Experience smoother and quieter operation with our brushless motor control system, enhancing user comfort and reducing noise in various applications

A

A

Hardware Overview

How does it work?

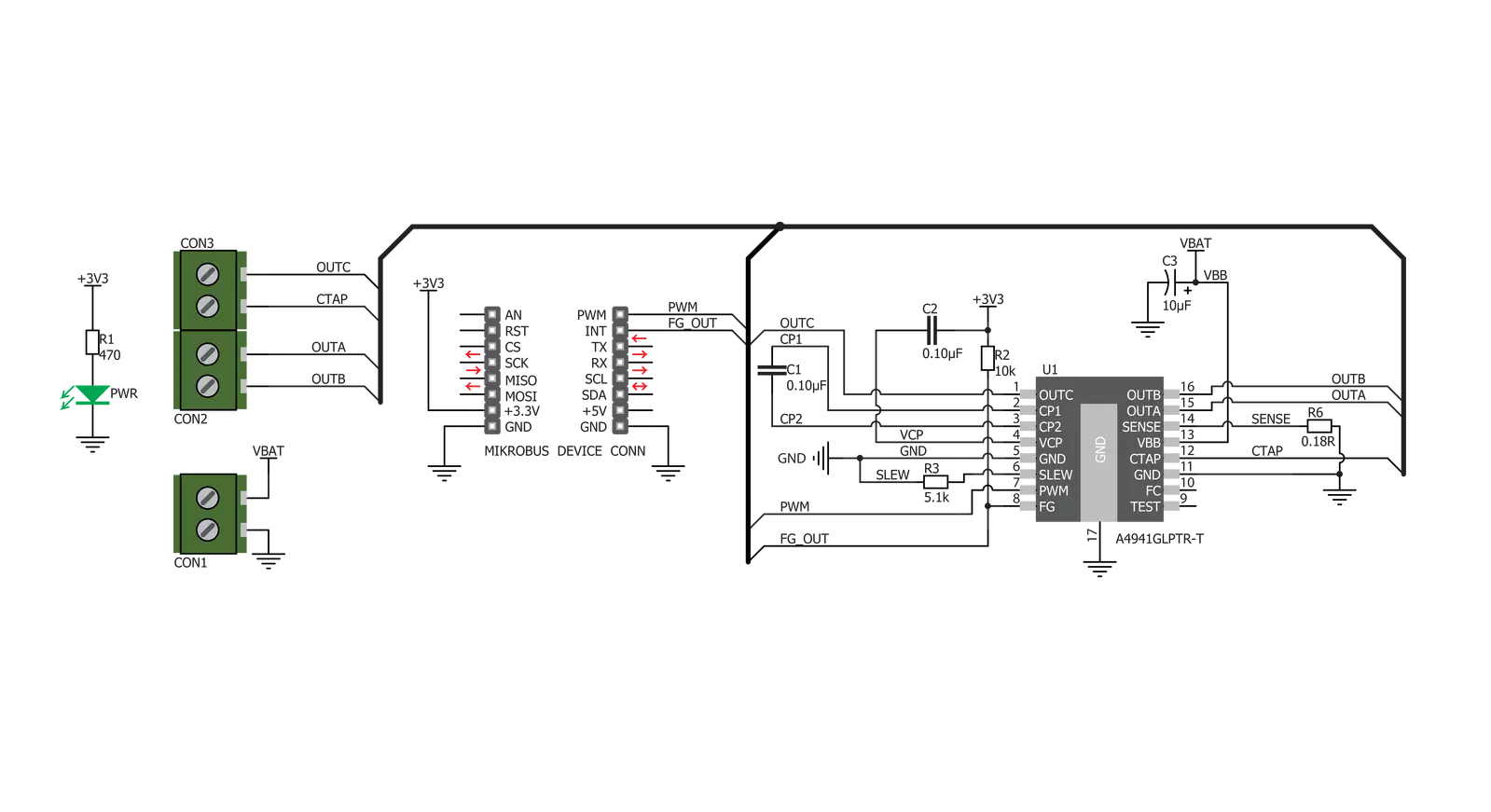

Brushless 5 Click is based on the A4941, a three-phase sensorless fan driver from Allegro MicroSystems. This IC features a proprietary sensorless BEMF zero-crossing sensing technique, which provides a speed reading via the FG output pin, routed to the INT pin of the mikroBUS™. The BEMF zero-crossing is the point where the voltage of the undriven motor winding (BEMF is short for Back Electromotive Force) crosses the motor center tap (neutral point) voltage. Neutral point voltage can be approximated using an internally generated reference voltage when the used motor does not provide one. BEMF zero-crossing occurs when a pole of the rotor is aligned with a pole of the stator and is used as a positional reference for the commutation controller section of the A4941. When the zero-crossing occurs, an internal signal is set to a HIGH state, while the beginning of the next phase commutation sets this signal to a LOW state. The signal is latched between the states so that commutation transients do not affect it. This provides a robust and accurate position-sensing system. The internal sequencer is used to commutate the phases based on the position feedback. During the startup period, the internal

oscillator provides the phase commutation instead until a valid BEMF positional signal sequence is detected. The current through the coils is maximum at this stage since the PWM signal with a 100% duty cycle is applied during a startup sequence. The Lock Detect feature prevents the motor from locking up or falling out of synchronization while protecting the coils and the IC from overheating. If a valid FG signal is not detected for 2 seconds, the outputs are turned off for 5 seconds. After this time-out, another restart is attempted. An internal peak overcurrent protection is set to about 1A. If the motor drains more than 1A, especially during the startup, the overcurrent protection will be activated, turning off the output stage for about 25µs. This can prevent the startup of some types of motors, so the longest startup delay of 200ms is chosen for this Click board™. The PWM pin is routed to the same pin of the mikroBUS™ and can be used to control the current through the coils. When the HIGH logic level is applied to the PWM input pin, the current from the power supply flows through the coils. No current is running through the coils when the LOW logic level is applied to the PWM

input pin. Applying a PWM signal with a frequency of 15 kHz to 30 kHz will result in a coil current corresponding to the applied PWM's duty cycle. The minimum pulse width is fixed at 6 μs, allowing the minimum speed to be maintained, even when applying PWM signals with a very low duty cycle. Applying a LOW logic level to the PWM pin for more than 500µs will put the device in low power consumption (standby) mode. The power supply for the motor coils is connected via the external two-pole terminal. VBAT+ input is connected to the positive voltage, while the GND input is connected to the power supply's ground. The voltage of the external power supply should stay between 5V and 16V. The most common use is with 12V motors. The BLDC motor coils should be connected to the four-pole output screw terminal. Respective motor phases are connected to the A, B, and C terminal outputs, while the central point of the BLDC motor can be connected to the output labeled as N. IF the used BLDC motor does not have the central (neutral) point output, the neutral point needed for the BEMF sensing will be generated internally.

Features overview

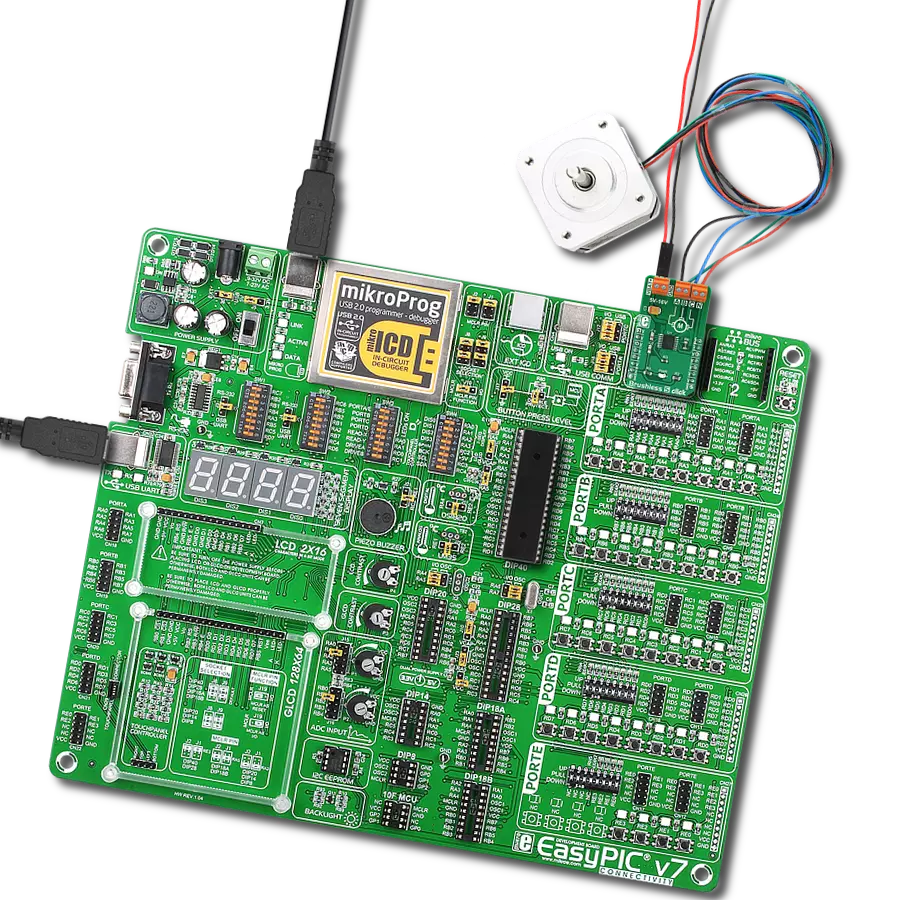

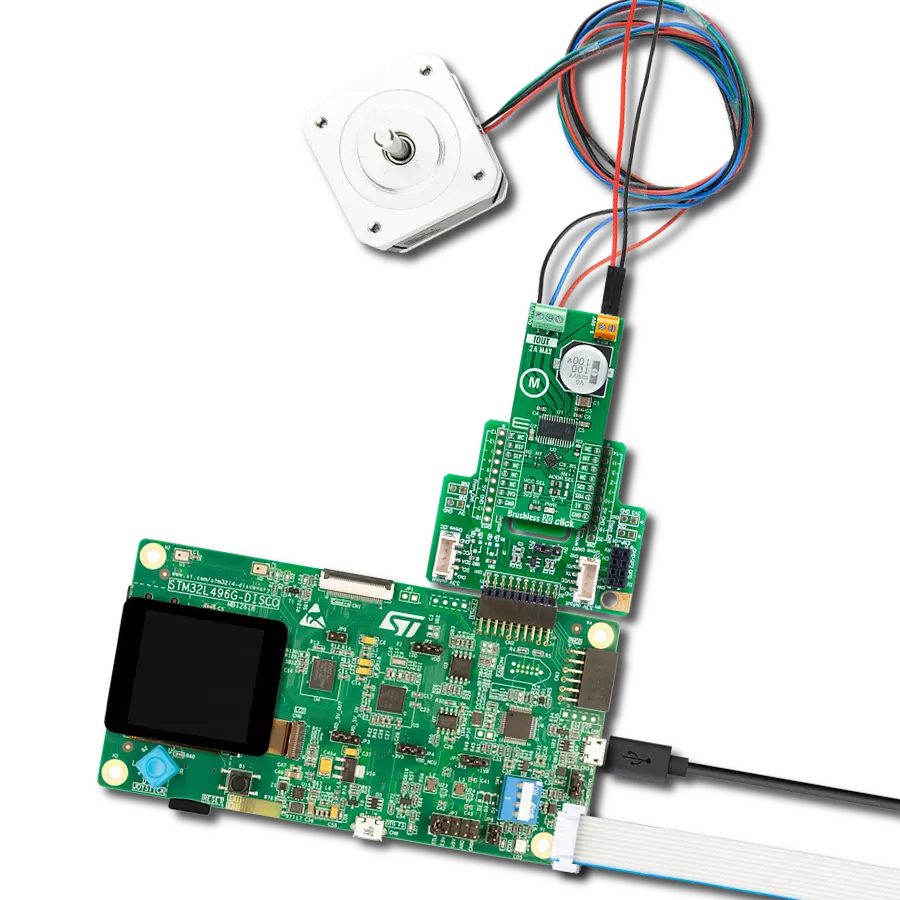

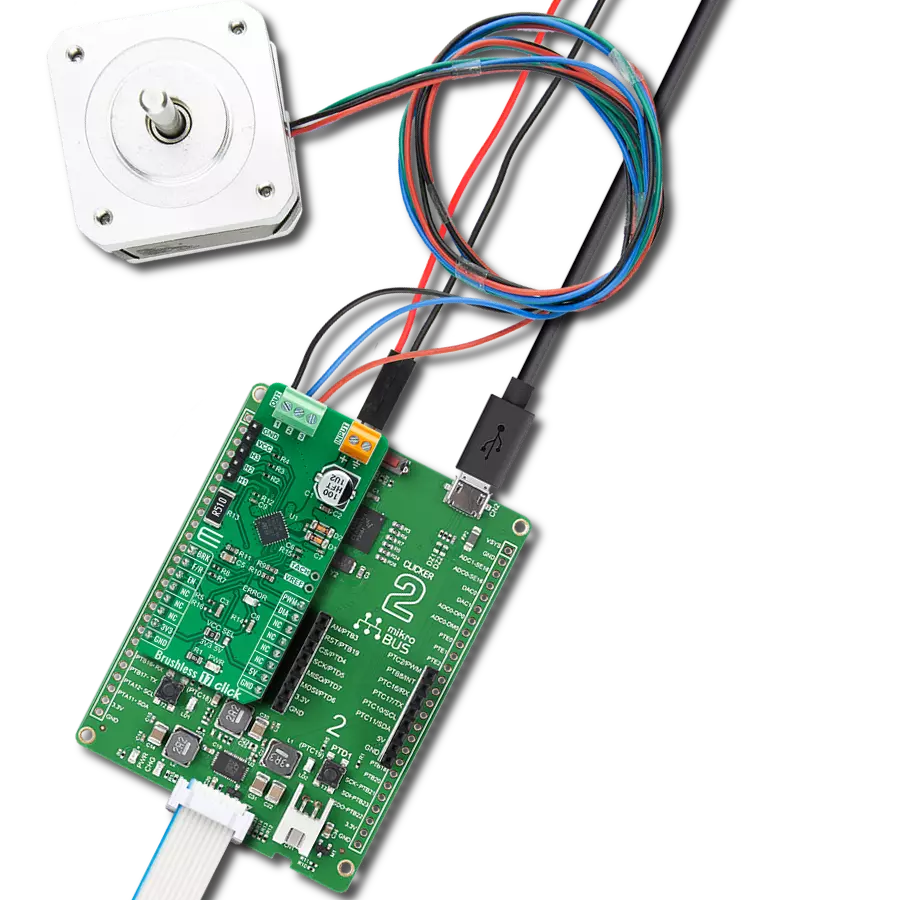

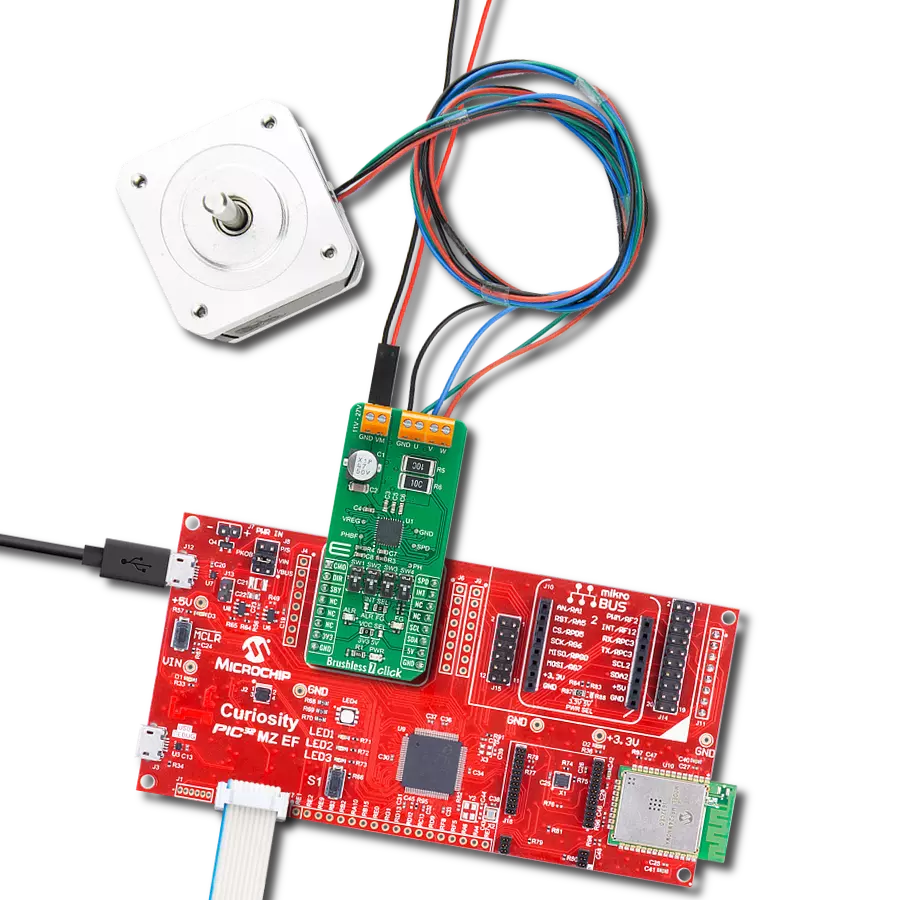

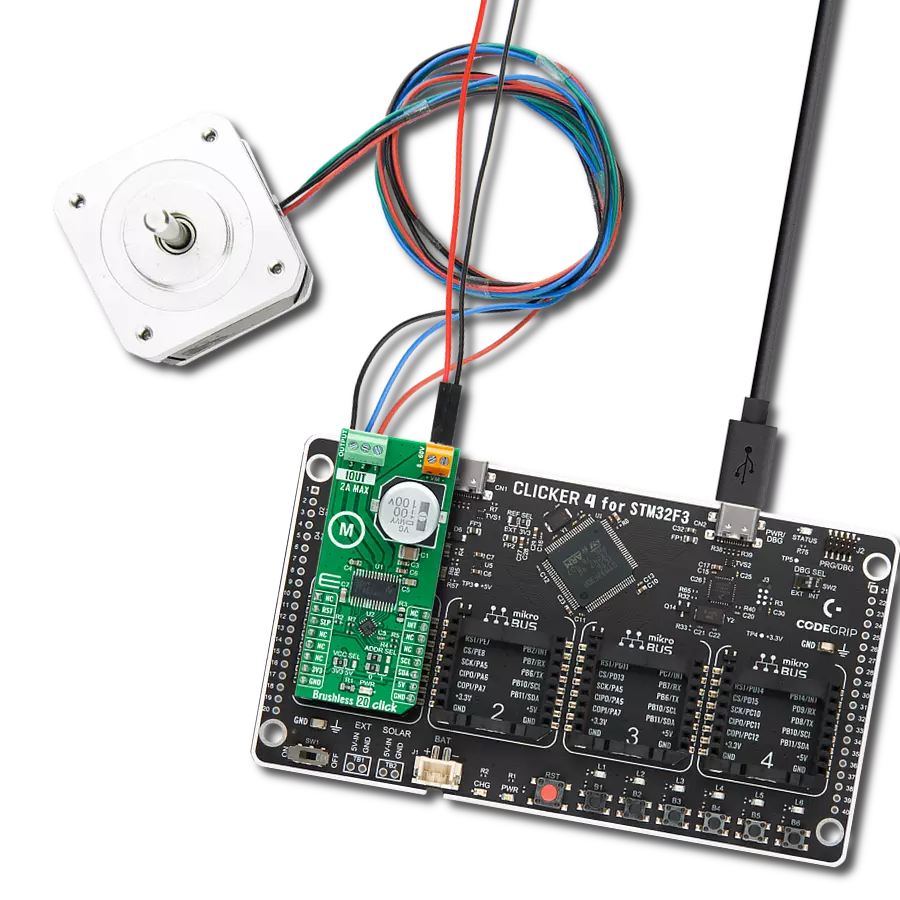

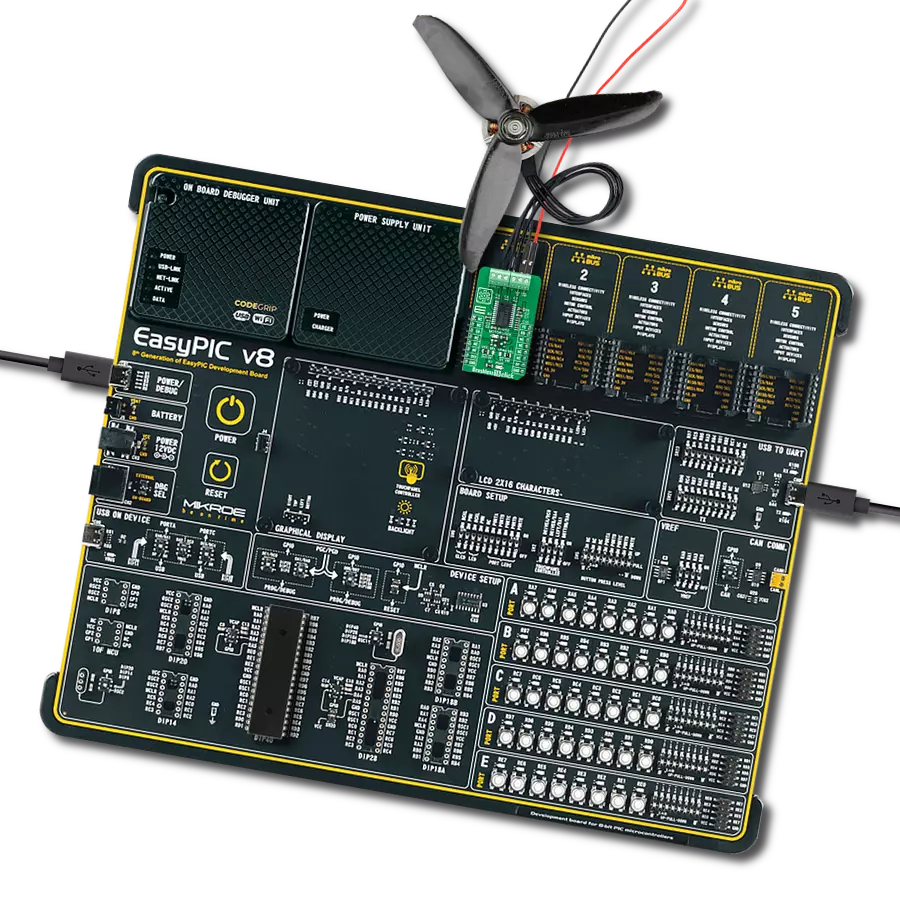

Development board

EasyPIC v7 is the seventh generation of PIC development boards specially designed to develop embedded applications rapidly. It supports a wide range of 8-bit PIC microcontrollers from Microchip and has a broad set of unique functions, such as a powerful onboard mikroProg programmer and In-Circuit debugger over USB-B. The development board is well organized and designed so that the end-user has all the necessary elements in one place, such as switches, buttons, indicators, connectors, and others. With four different connectors for each port, EasyPIC v7 allows you to connect accessory boards, sensors, and custom electronics more efficiently than ever. Each part of

the EasyPIC v7 development board contains the components necessary for the most efficient operation of the same board. An integrated mikroProg, a fast USB 2.0 programmer with mikroICD hardware In-Circuit Debugger, offers many valuable programming/debugging options and seamless integration with the Mikroe software environment. Besides it also includes a clean and regulated power supply block for the development board. It can use various external power sources, including an external 12V power supply, 7-23V AC or 9-32V DC via DC connector/screw terminals, and a power source via the USB Type-B (USB-B) connector. Communication options such as

USB-UART and RS-232 are also included, alongside the well-established mikroBUS™ standard, three display options (7-segment, graphical, and character-based LCD), and several different DIP sockets. These sockets cover a wide range of 8-bit PIC MCUs, from PIC10F, PIC12F, PIC16F, PIC16Enh, PIC18F, PIC18FJ, and PIC18FK families. EasyPIC v7 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC

MCU Memory (KB)

64

Silicon Vendor

Microchip

Pin count

40

RAM (Bytes)

3968

You complete me!

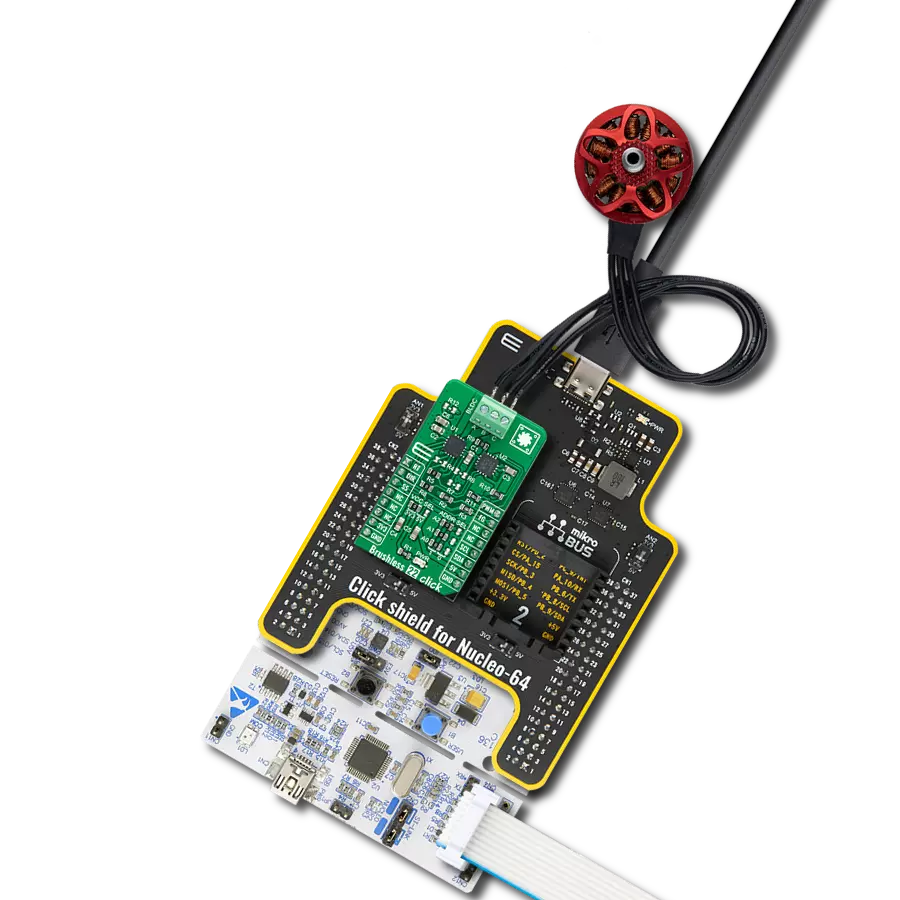

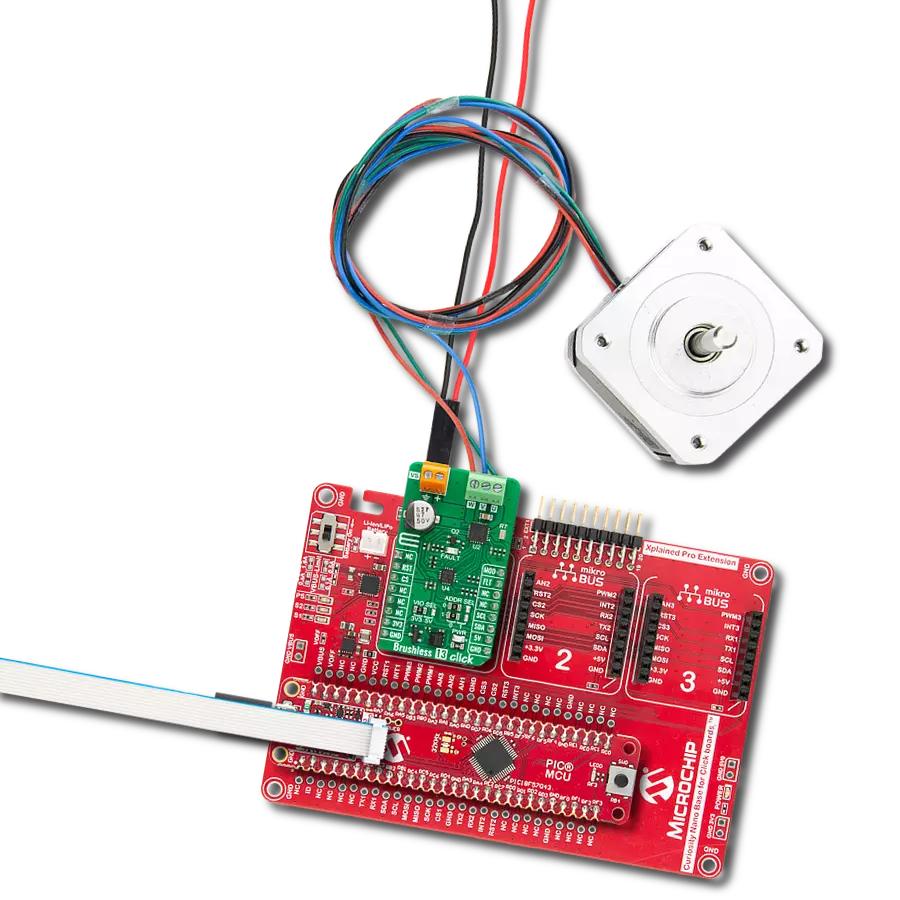

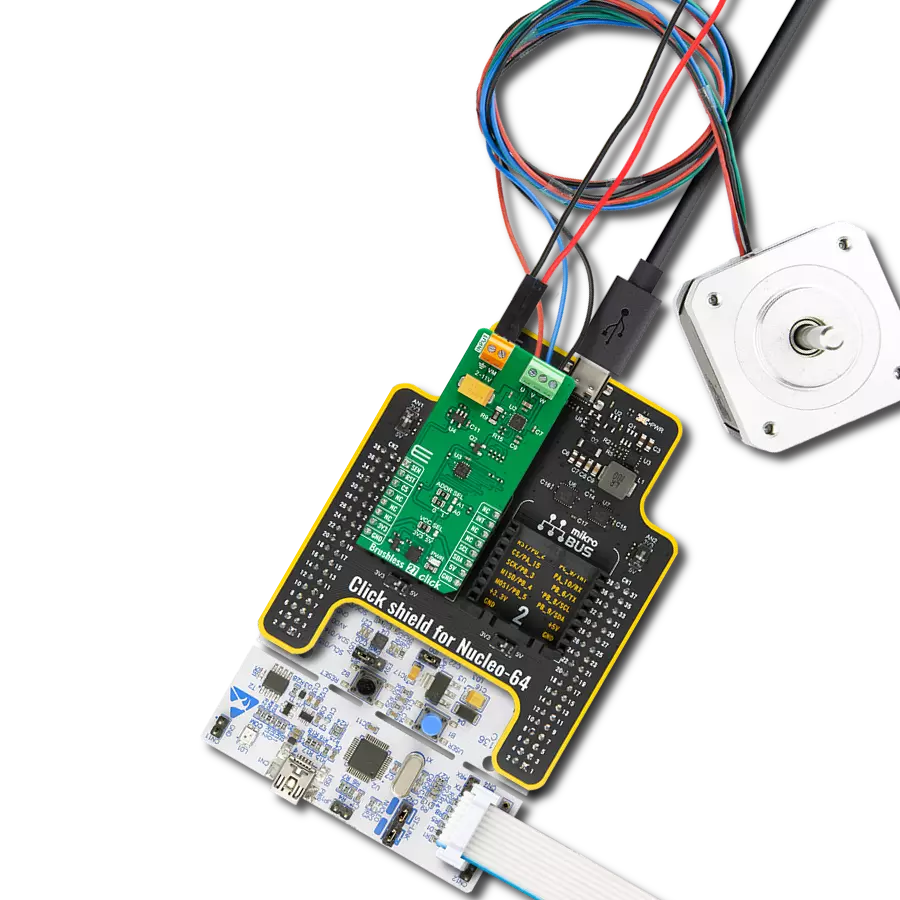

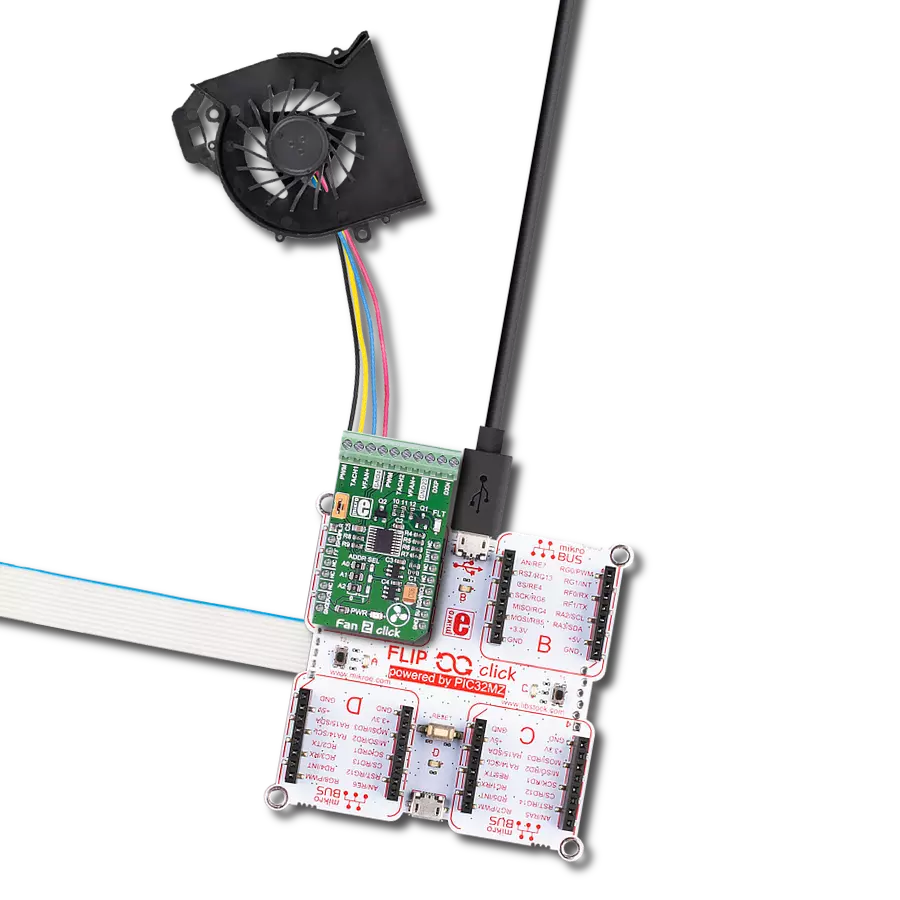

Accessories

Brushless DC (BLDC) Motor with a Hall sensor represents a high-performance motor from the 42BLF motor series. This motor, wired in a star configuration, boasts a Hall Effect angle of 120°, ensuring precise and reliable performance. With a compact motor length of 47mm and a lightweight design tipping the scales at just 0.29kg, this BLDC motor is engineered to meet your needs. Operating flawlessly at a voltage rating of 24VDC and a speed range of 4000 ± 10% RPM, this motor offers consistent and dependable power. It excels in a normal operational temperature range from -20 to +50°C, maintaining efficiency with a rated current of 1.9A. Also, this product seamlessly integrates with all Brushless Click boards™ and those that require BLDC motors with Hall sensors.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Brushless 5 Click driver.

Key functions:

brushless5_set_duty_cycle- Generic sets PWM duty cyclebrushless5_pwm_stop- Stop PWM modulebrushless5_pwm_start- Start PWM module

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file

* @brief Brushless5 Click example

*

* # Description

* This library contains an API for the Brushless5 Click driver.

* This example showcases how to initialize and use the Brushless 5 Click.

* The Click has a brushless 5 motor driver which controls the work

* of the motor through the BLDC terminal.

* In order for this example to work a motor and a power supply are needed.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the GPIO driver and configures the PWM peripheral for

* controlling the speed of the motor.

*

* ## Application Task

* This is an example that demonstrates the use of a Brushless 5 Click board.

* Brushless 5 Click communicates with the register via the PWM interface.

* Increases and decreasing the speed of the motor demonstrate speed control.

* Results are being sent to the Usart Terminal where you can track their changes.

*

* @author Nikola Peric

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "brushless5.h"

// ------------------------------------------------------------------ VARIABLES

static brushless5_t brushless5;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

brushless5_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

Delay_ms ( 100 );

// Click initialization.

brushless5_cfg_setup( &cfg );

BRUSHLESS5_MAP_MIKROBUS( cfg, MIKROBUS_1 );

brushless5_init( &brushless5, &cfg );

Delay_ms ( 100 );

brushless5_set_duty_cycle ( &brushless5, 0.0 );

brushless5_pwm_start( &brushless5 );

log_info( &logger, "---- Application Task ----" );

Delay_ms ( 1000 );

}

void application_task ( void )

{

static int8_t duty_cnt = 1;

static int8_t duty_inc = 1;

float duty = duty_cnt / 10.0;

brushless5_set_duty_cycle ( &brushless5, duty );

log_printf( &logger, "Duty: %d%%\r\n", ( uint16_t )( duty_cnt * 10 ) );

Delay_ms ( 500 );

if ( 10 == duty_cnt )

{

duty_inc = -1;

log_printf( &logger, " Slowing down... \r\n" );

}

else if ( 0 == duty_cnt )

{

duty_inc = 1;

log_printf( &logger, " Increasing the motor speed... \r\n" );

}

duty_cnt += duty_inc;

Delay_ms ( 500 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END