Ready to see the transformative impact of our high-performance battery charger on your solution? Let's embark on the journey together.

A

A

Hardware Overview

How does it work?

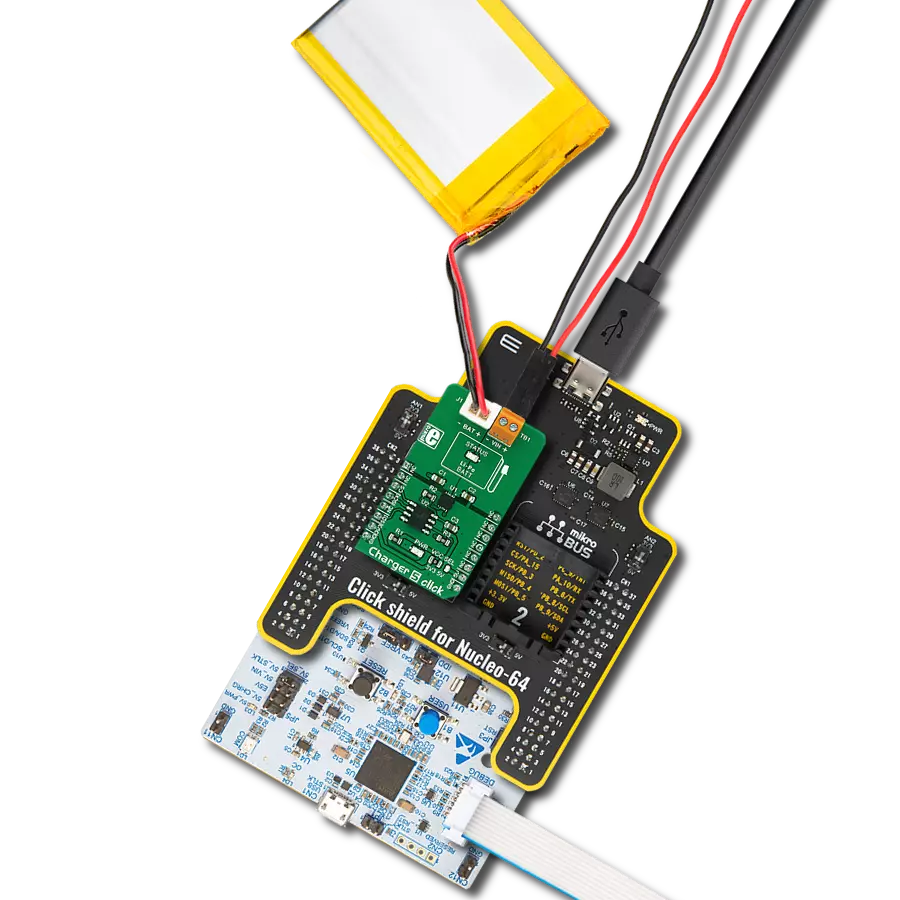

Charger 12 Click is based on the MAX1501, a highly integrated, linear battery charger with thermal regulation for portable applications from Analog Devices. The MAX1501 is an efficient Lithium-Ion battery charger, thanks to Microprocessor-Controlled specific charge algorithms for Li-Ion batteries to achieve optimal capacity and safety in the shortest charging time possible. Besides its small physical size, the low number of external components makes this IC ideal for various applications. The 4.2V factory preset reference voltage simplifies design. A digital potentiometer sets the fast charge constant current, the MCP4161, an 8-bit digital potentiometer from Microchip, with an external 1.5KΩ resistor in series. Thanks to proprietary programmable die temperature regulation, MAX1501 can limit the charge current based on the temperature during high power or ambient conditions. This thermal regulation optimizes the charge cycle time while maintaining device reliability. The MAX1501 IC is designed with reliability in mind: the IC prevents draining the battery below the protects it from overheating

(if the thermistor is used), critical level, offers prequel charging (for deeply depleted batteries), features overvoltage protection, charging status monitoring and more. The Click board™ is equipped with indicators to monitor the charging process and power distribution: CHARGE LED indicates the charge-in-progress status, and FAULT LED indicates an error during the charging process. The digital potentiometer on Charger 12 click is MCP4161 which offers a wide range of product offerings using an SPI interface. WiperLock technology allows application-specific calibration settings to be secured in EEPROM. This digital pot is tied with a charger IC over its wiper (P0W) pin. Battery charging can be controlled by assigning values on MCP4161 from 0 to 10-kilo ohms. As there is a 1.5K resistor in series, it can never be 0 ohms on the MAX1501 charger's PROG pin. However, maximum resistance cannot exceed 11.5 kiloohms. Fast charging can be regulated with 10K on the PROG pin to get 130 mA. To get 1000 mA digital potentiometer needs to go down to 0Ohm, along with an external resistor, which

makes 1.5K. Communication with a digital potentiometer on this Click, controlling the charger, is done through the SPI interface. On the left side of the click board is an input screw terminal with corresponding markings, where the recommended external voltage of 6V can be applied. The left screw terminal is reserved for a Lithium Iron Phosphate battery with GND and VBAT+ markings. The green PWR LED will indicate it when connected to a power source. Red LED1 and green LED2 can be used for visual charge monitoring. These two LEDs are multipurpose and can be used for various things. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. However, the Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used, as a reference, for further development.

Features overview

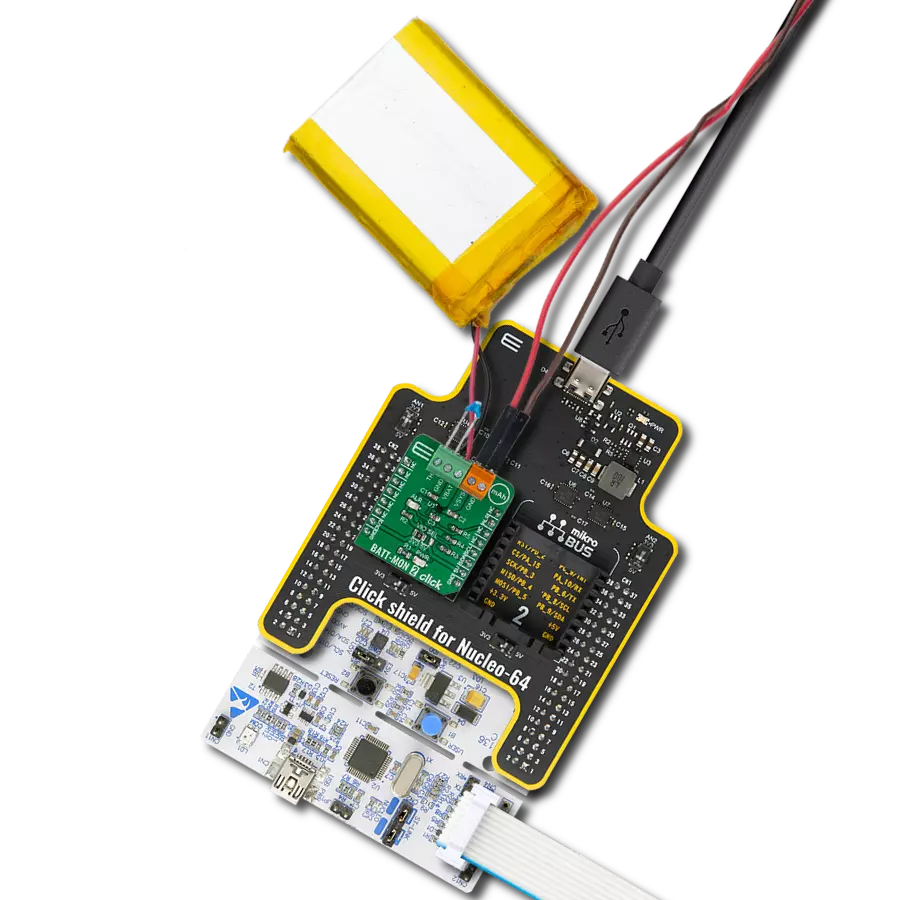

Development board

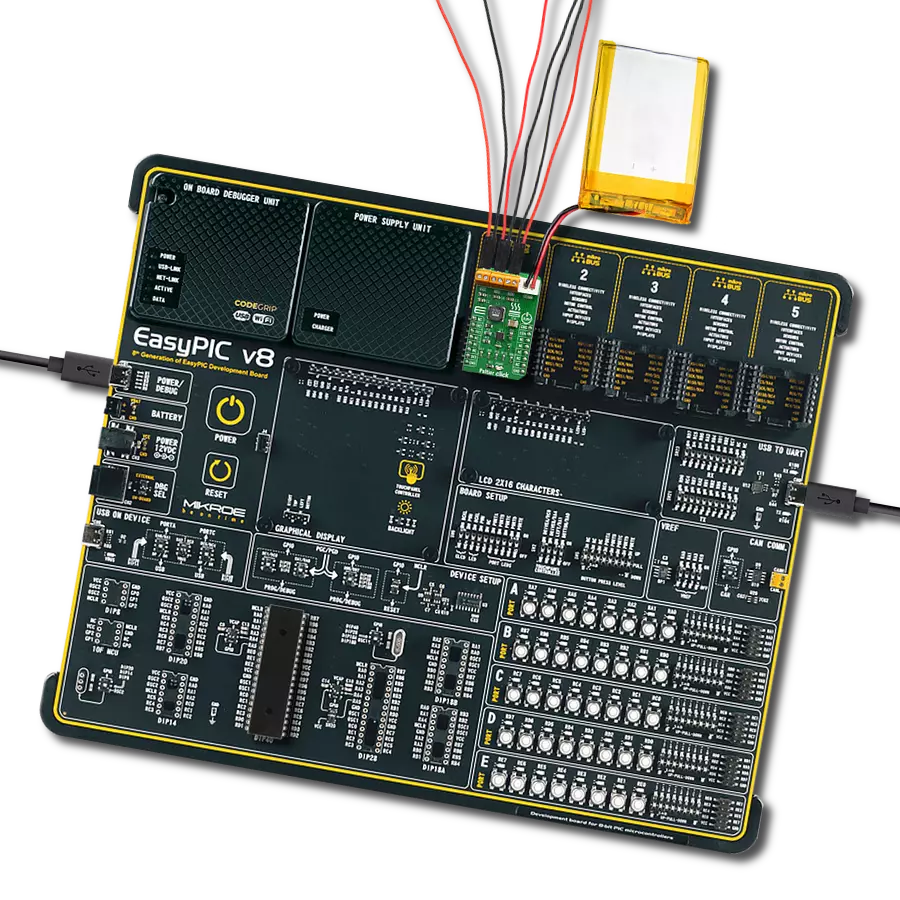

EasyAVR v7 is the seventh generation of AVR development boards specially designed for the needs of rapid development of embedded applications. It supports a wide range of 16-bit AVR microcontrollers from Microchip and has a broad set of unique functions, such as a powerful onboard mikroProg programmer and In-Circuit debugger over USB. The development board is well organized and designed so that the end-user has all the necessary elements in one place, such as switches, buttons, indicators, connectors, and others. With four different connectors for each port, EasyAVR v7 allows you to connect accessory boards, sensors, and custom electronics more

efficiently than ever. Each part of the EasyAVR v7 development board contains the components necessary for the most efficient operation of the same board. An integrated mikroProg, a fast USB 2.0 programmer with mikroICD hardware In-Circuit Debugger, offers many valuable programming/debugging options and seamless integration with the Mikroe software environment. Besides it also includes a clean and regulated power supply block for the development board. It can use a wide range of external power sources, including an external 12V power supply, 7-12V AC or 9-15V DC via DC connector/screw terminals, and a power source via the USB Type-B (USB-B)

connector. Communication options such as USB-UART and RS-232 are also included, alongside the well-established mikroBUS™ standard, three display options (7-segment, graphical, and character-based LCD), and several different DIP sockets which cover a wide range of 16-bit AVR MCUs. EasyAVR v7 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

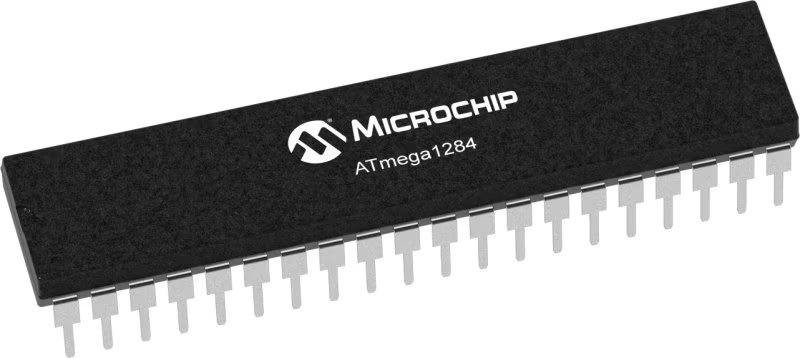

Microcontroller Overview

MCU Card / MCU

Architecture

AVR

MCU Memory (KB)

128

Silicon Vendor

Microchip

Pin count

40

RAM (Bytes)

16384

You complete me!

Accessories

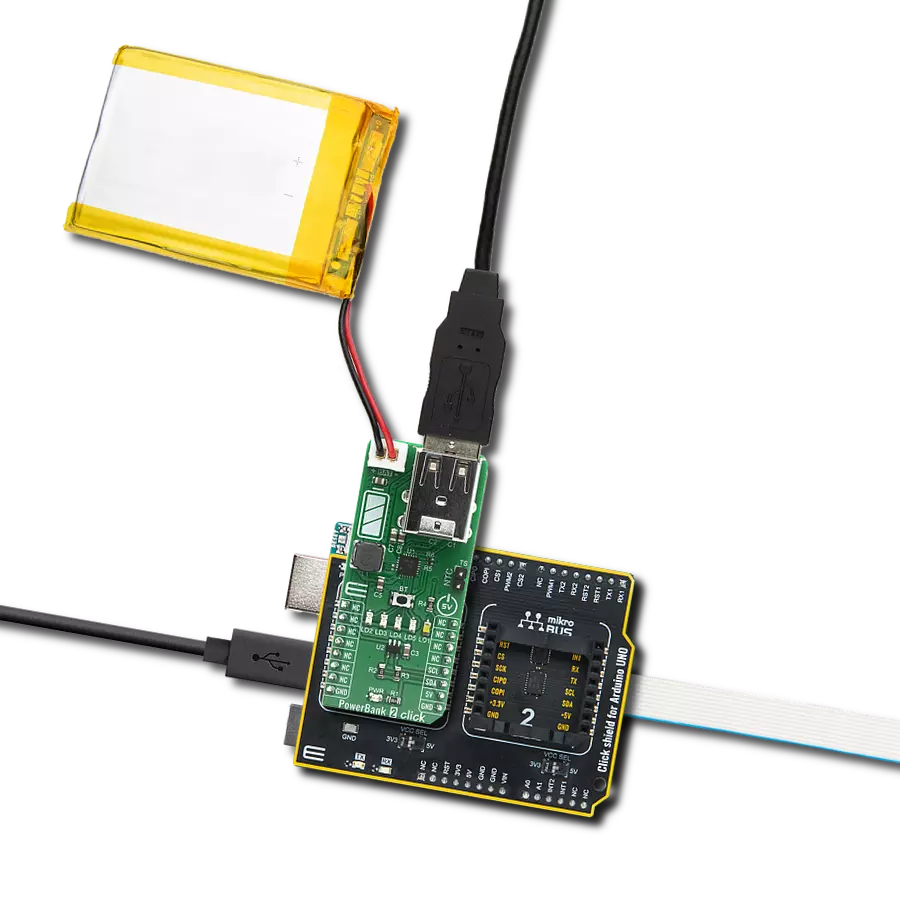

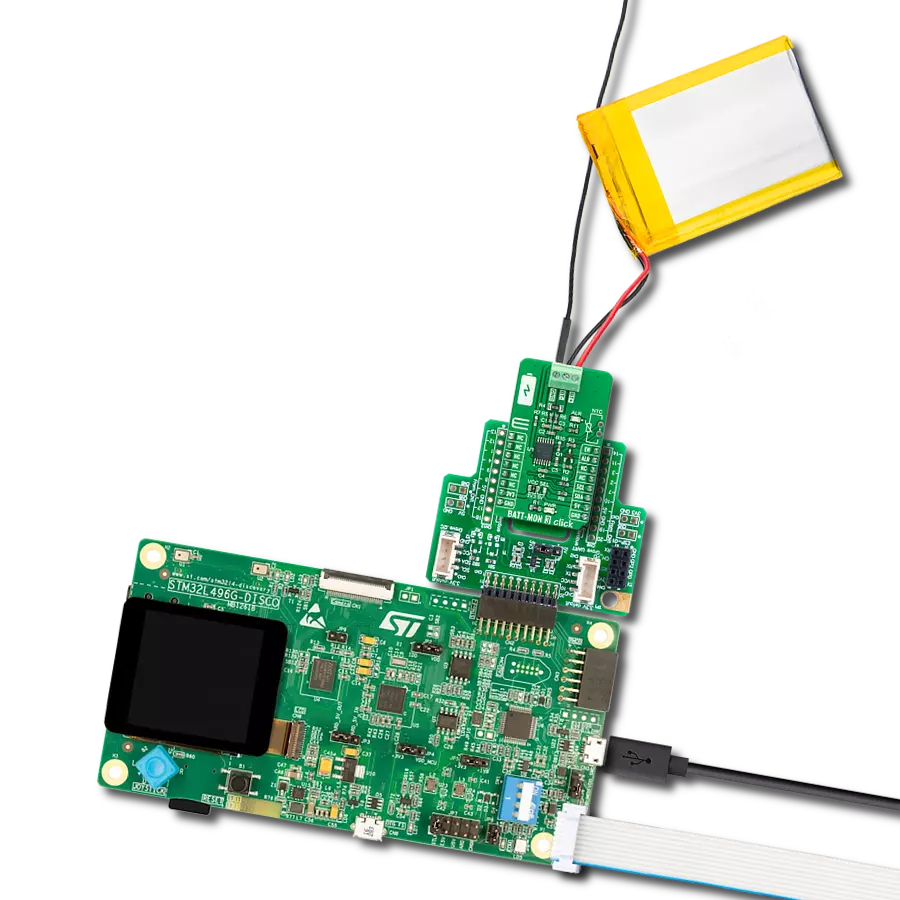

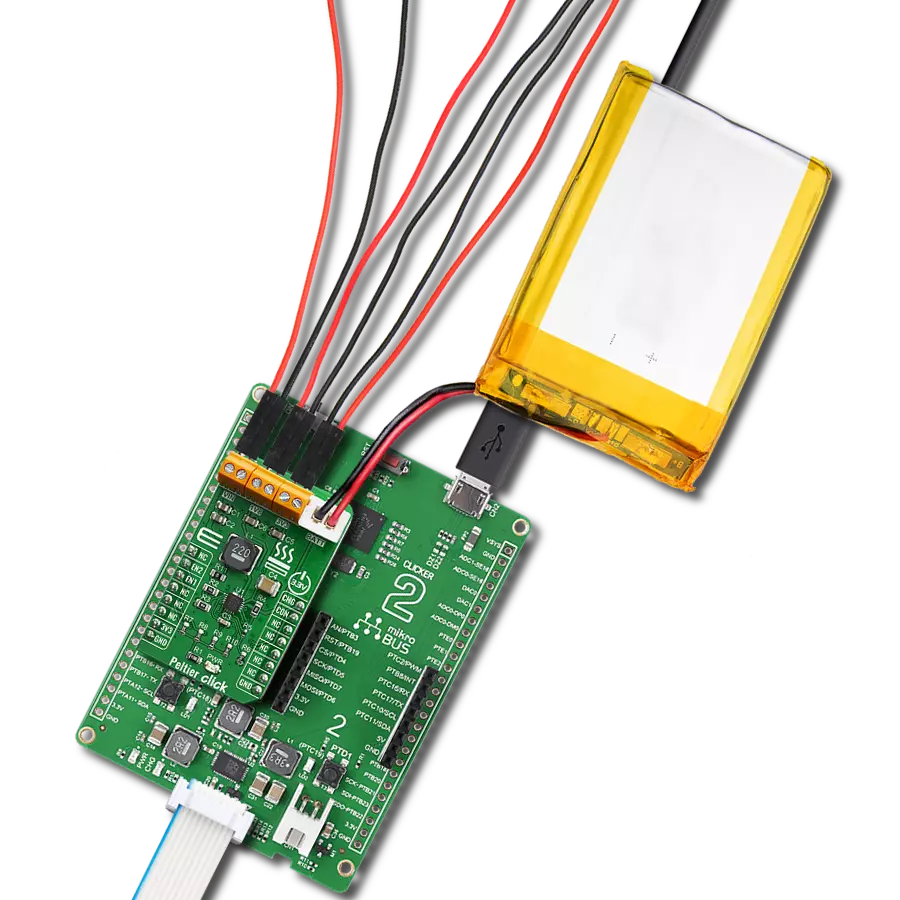

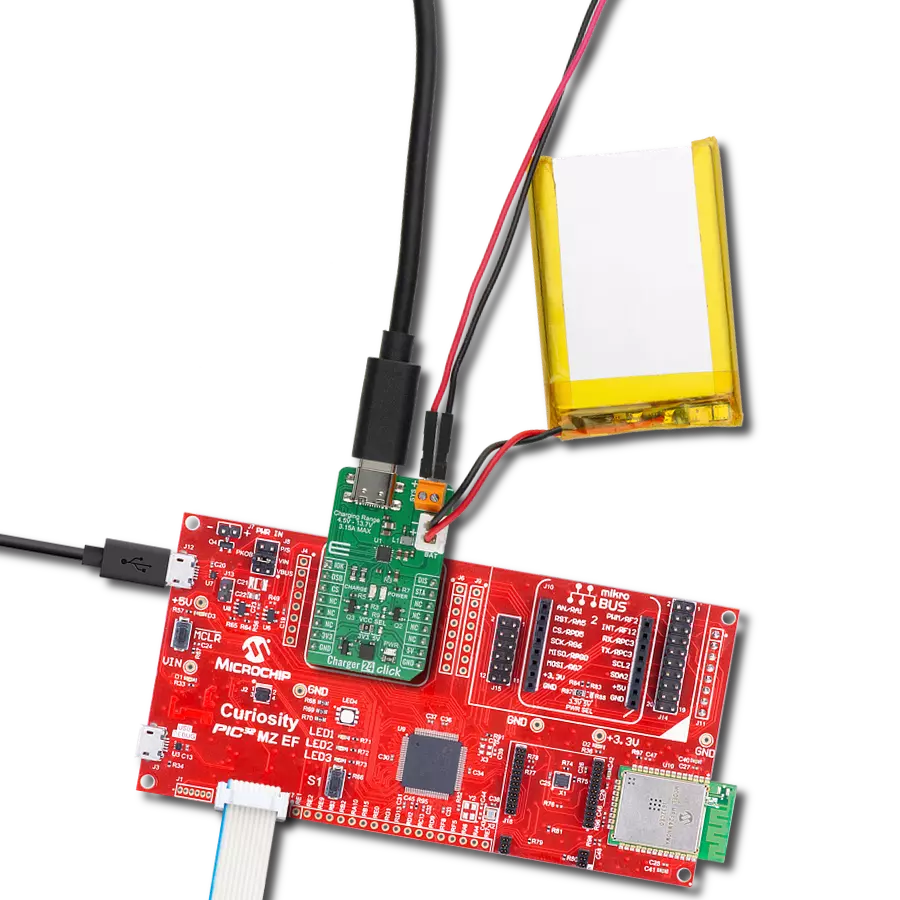

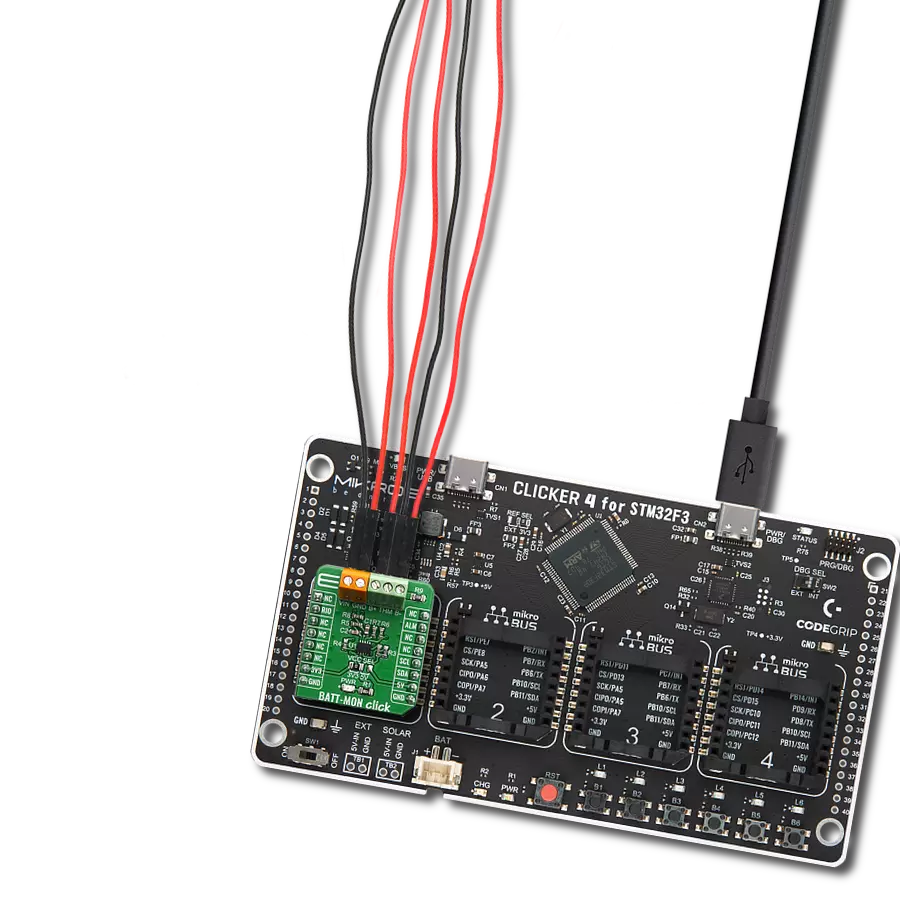

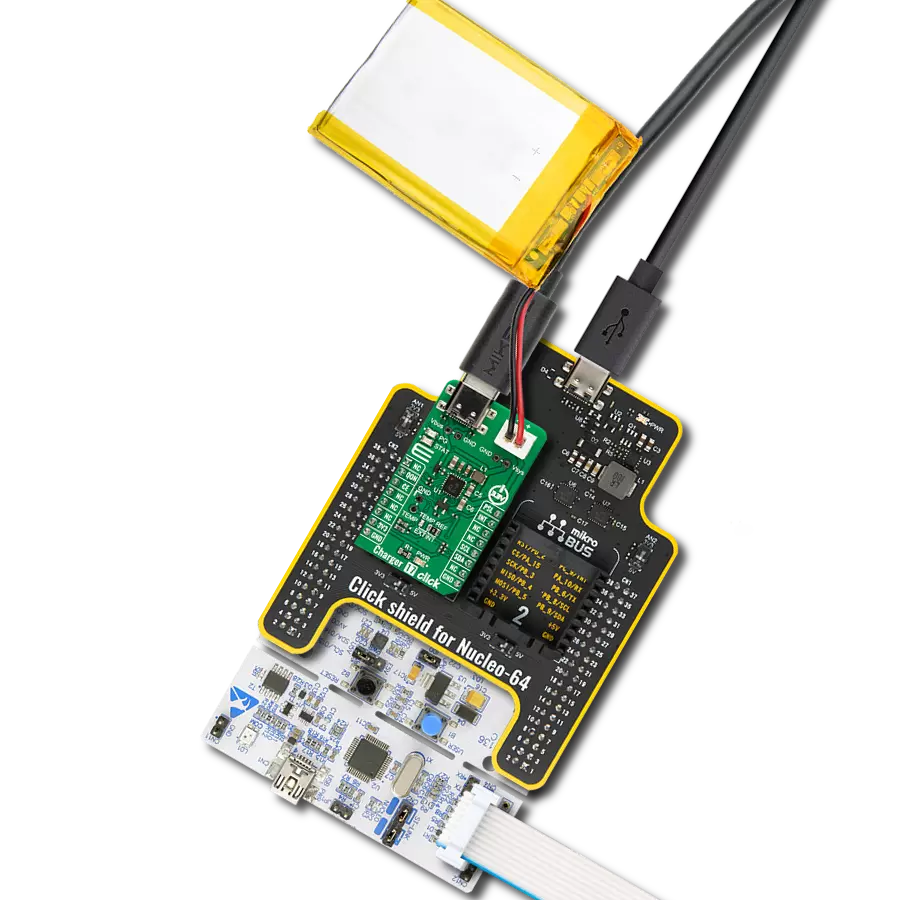

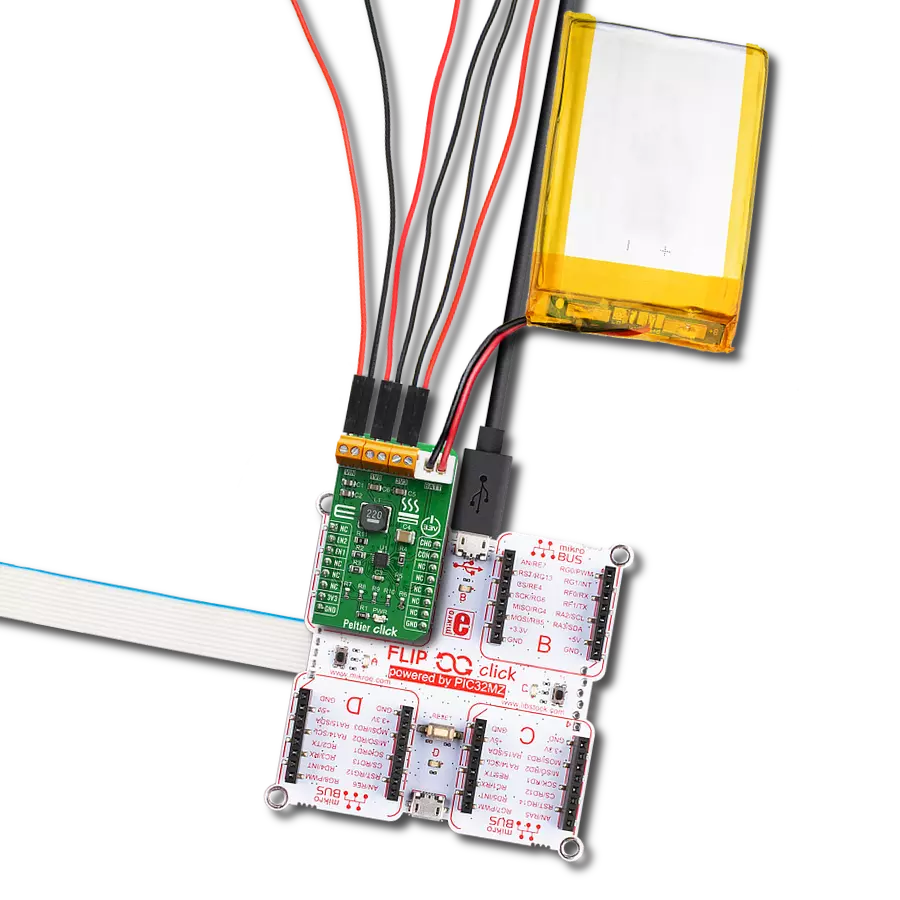

Li-Polymer Battery is the ideal solution for devices that demand a dependable and long-lasting power supply while emphasizing mobility. Its compatibility with mikromedia boards ensures easy integration without additional modifications. With a voltage output of 3.7V, the battery meets the standard requirements of many electronic devices. Additionally, boasting a capacity of 2000mAh, it can store a substantial amount of energy, providing sustained power for extended periods. This feature minimizes the need for frequent recharging or replacement. Overall, the Li-Polymer Battery is a reliable and autonomous power source, ideally suited for devices requiring a stable and enduring energy solution. You can find a more extensive choice of Li-Polymer batteries in our offer.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Charger 12 Click driver.

Key functions:

charger12_generic_transfer- Generic transfercharger12_mode_select- Charger mode selectioncharger12_spi_set_register- This function set spi register

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Charger12 Click example

*

* # Description

* This application charges the batery.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Iniztializes SPI driver.

*

* ## Application Task

* Executes additional functions based on user input.

*

* *note:*

* Additional Functions :

* - charger12_case_Plus() - Increments Wiper position.

* - charger12_case_Minus() - Decrements Wiper position.

* - charger12_case_One() - Selects 1st mode of operation.

* - charger12_case_Two() - Selects 2nd mode of operation.

* - charger12_case_Three() - Selects 3rd mode of operation.

* - charger12_case_Four() - Selects 4th mode of operation.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "charger12.h"

// ------------------------------------------------------------------ VARIABLES

static charger12_t charger12;

static log_t logger;

void charger12_case_plus( )

{

log_printf( &logger, "> Wiper incremented" );

charger12_spi_increment_wiper( &charger12 );

log_printf( &logger, "\r\n" );

}

void charger12_case_minus( )

{

log_printf( &logger, "> Wiper decremented" );

charger12_spi_increment_wiper( &charger12 );

log_printf( &logger, "\r\n" );

}

void charger12_case_one( )

{

charger12_mode_select( &charger12, CHARGER12_MODE_Li );

log_printf( &logger, "> Mode : Li+ Charge");

log_printf( &logger, "\r\n" );

}

void charger12_case_two( )

{

charger12_mode_select( &charger12, CHARGER12_MODE_NiMh_NiCd );

log_printf( &logger, "> Mode : NiMH/NiCd Charge" );

log_printf( &logger, "\r\n" );

}

void charger12_case_three( )

{

charger12_mode_select( &charger12, CHARGER12_MODE_DISABLE );

log_printf( &logger, "> Mode : Disable" );

log_printf( &logger, "\r\n" );

}

void charger12_case_four( )

{

charger12_mode_select( &charger12, CHARGER12_MODE_NO_BATTERY );

log_printf( &logger, "> Mode : No Battery" );

log_printf( &logger, "\r\n" );

}

void application_init ( void )

{

log_cfg_t log_cfg;

charger12_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

charger12_cfg_setup( &cfg );

CHARGER12_MAP_MIKROBUS( cfg, MIKROBUS_1 );

charger12_init( &charger12, &cfg );

Delay_ms ( 100 );

charger12_mode_select( &charger12, CHARGER12_MODE_DISABLE );

Delay_ms ( 100 );

log_printf( &logger, "> App init done" );

}

void application_task ( void )

{

charger12_case_plus( );

Delay_ms ( 1000 );

charger12_case_minus( );

Delay_ms ( 1000 );

charger12_case_one( );

Delay_ms ( 1000 );

charger12_case_two( );

Delay_ms ( 1000 );

charger12_case_three( );

Delay_ms ( 1000 );

charger12_case_four( );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END