Don't let a dead battery hold you back - integrate a high-quality battery charger into your solution today and always keep it powered up

A

A

Hardware Overview

How does it work?

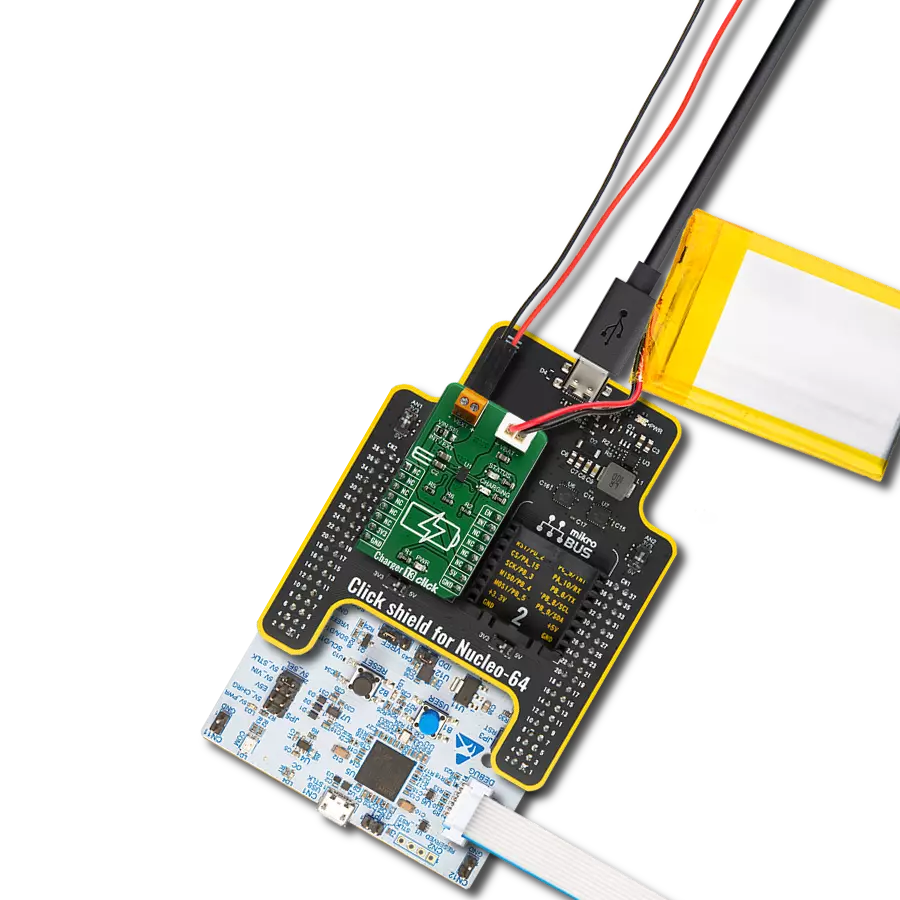

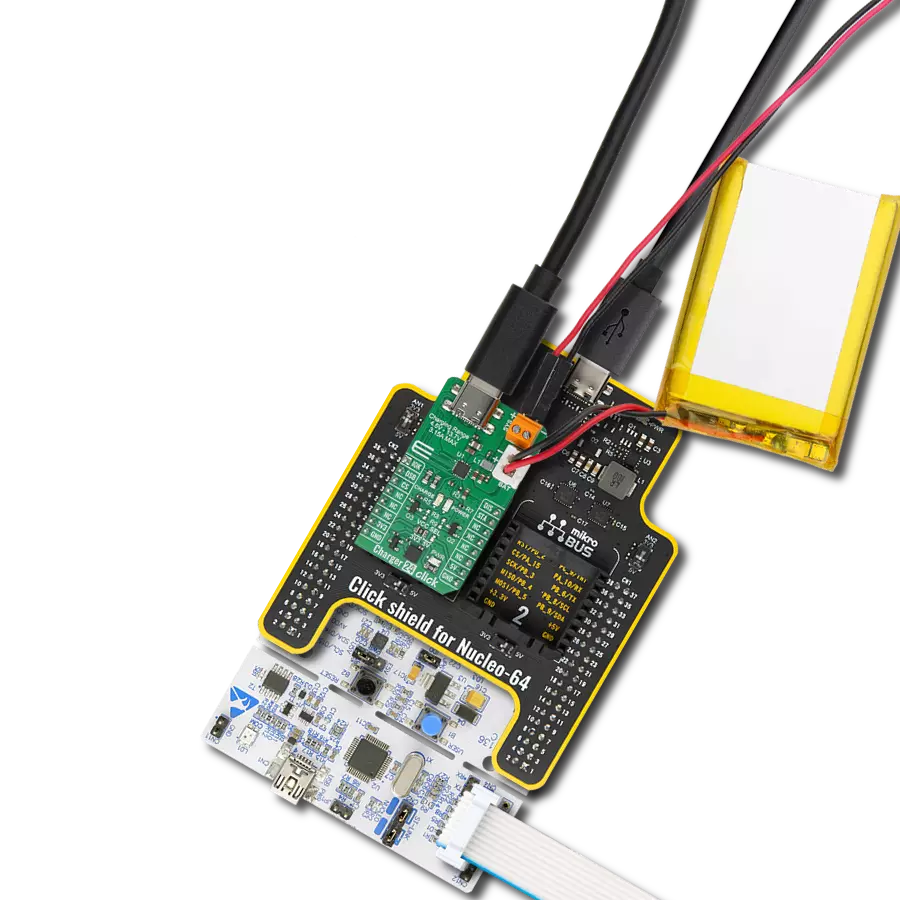

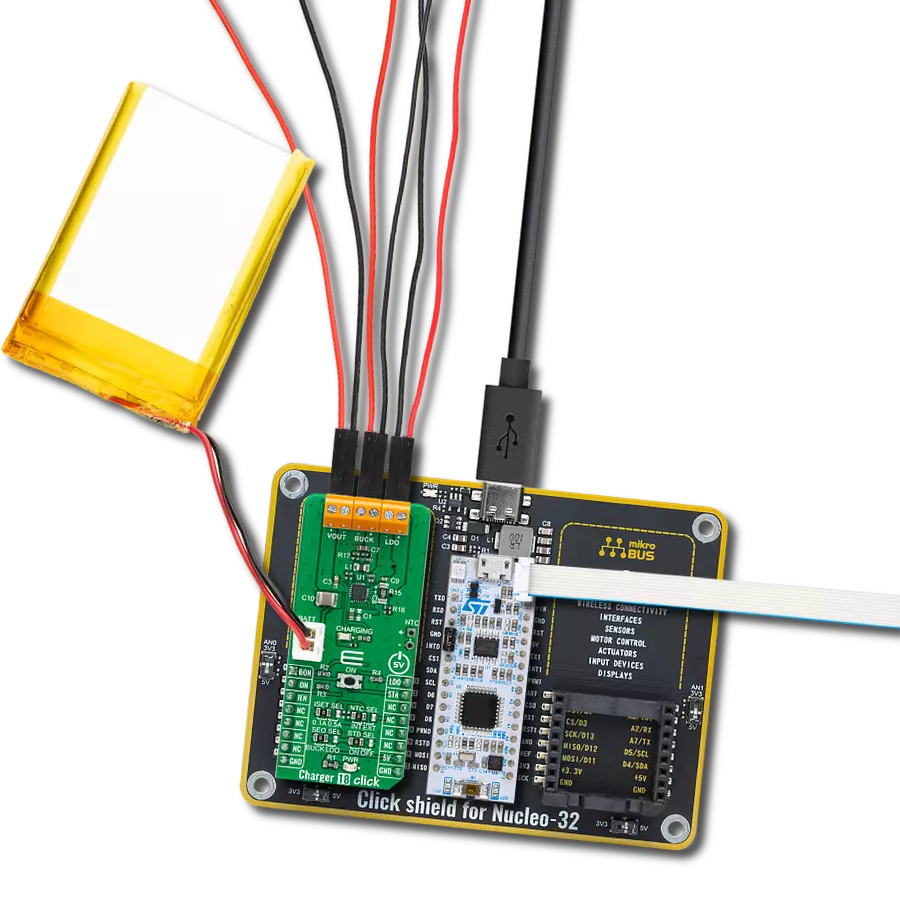

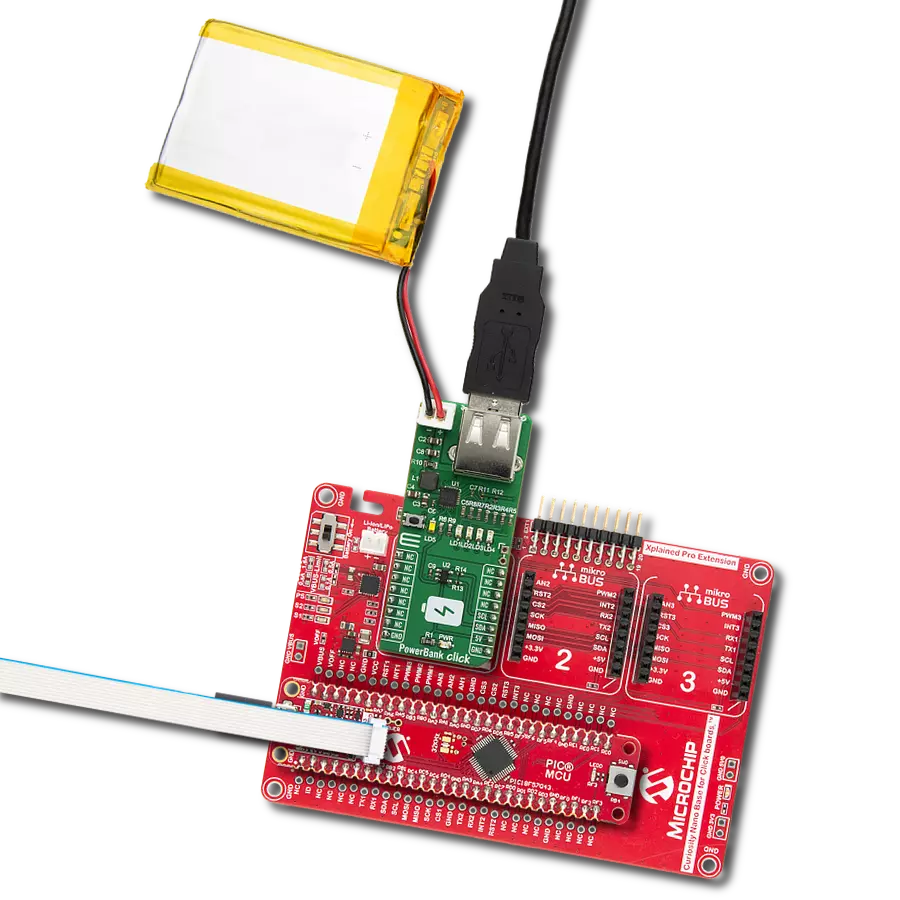

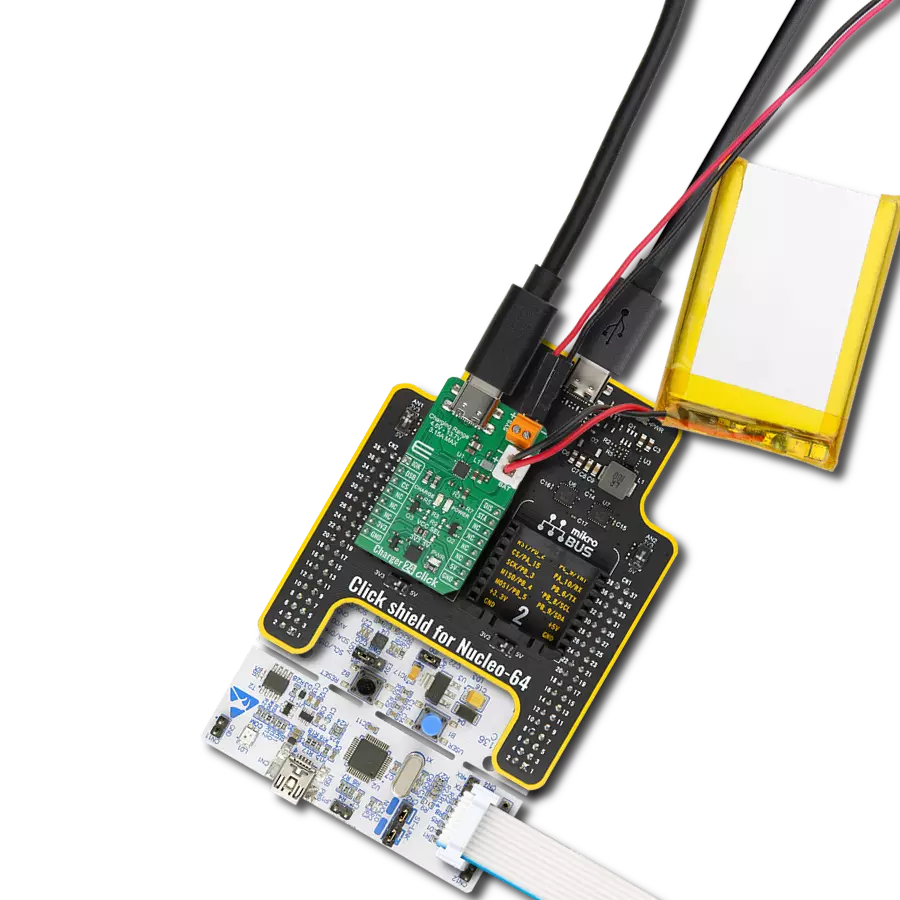

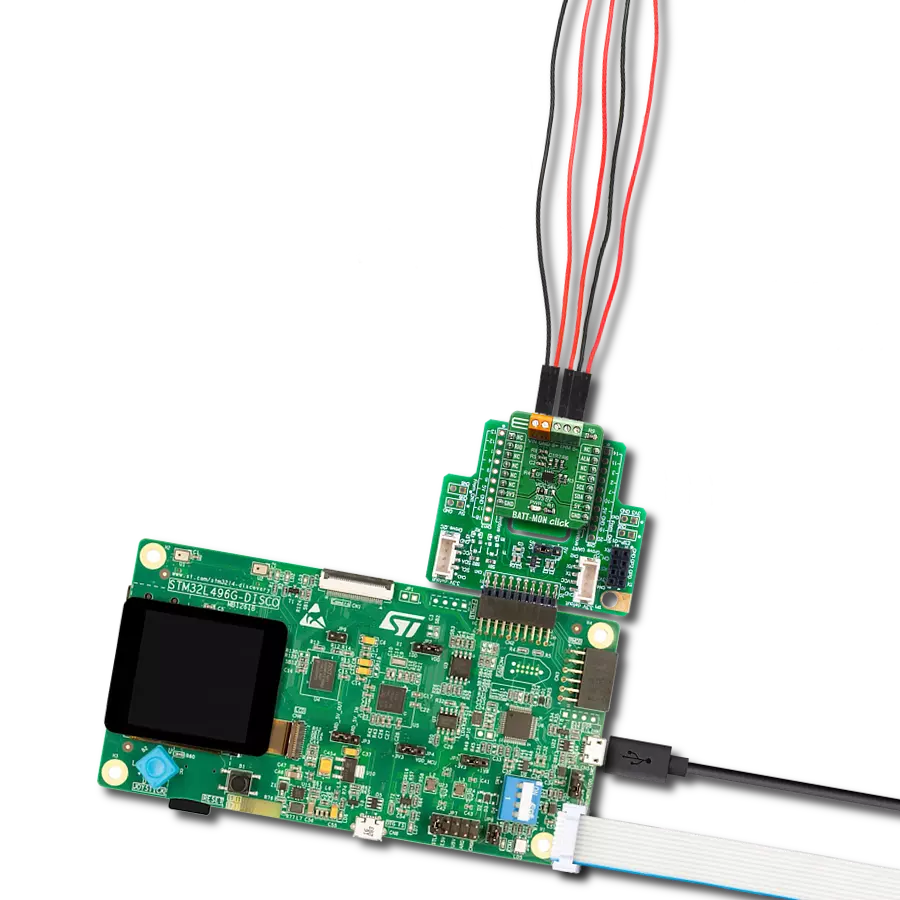

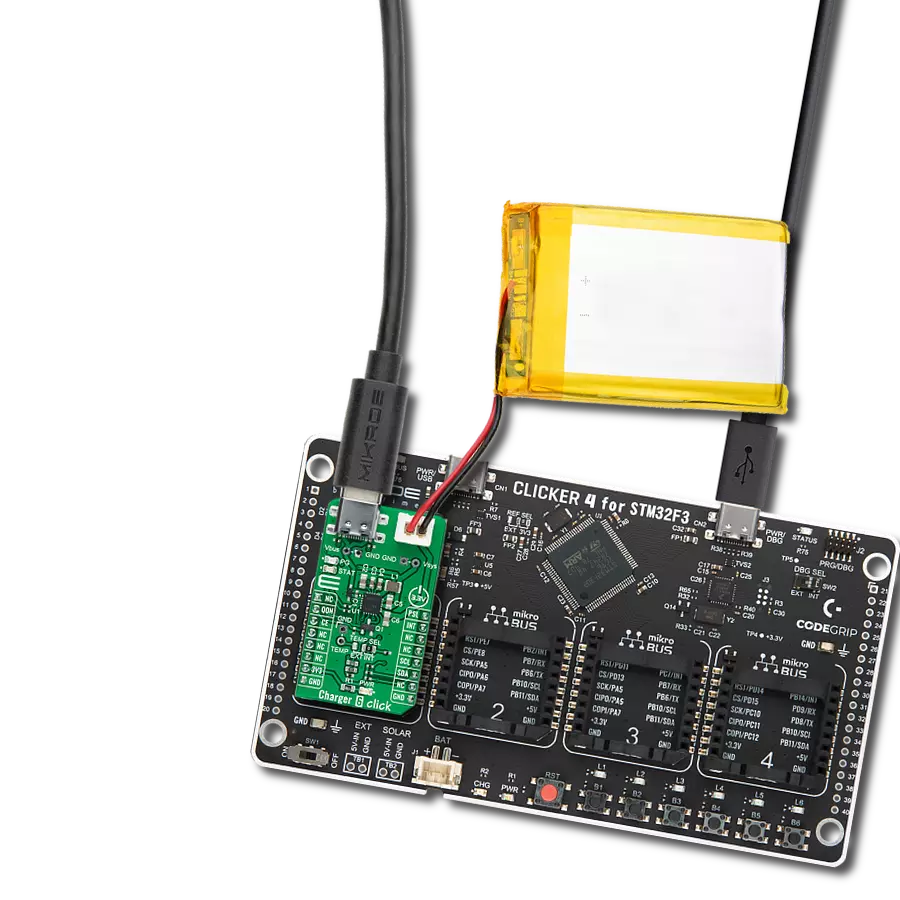

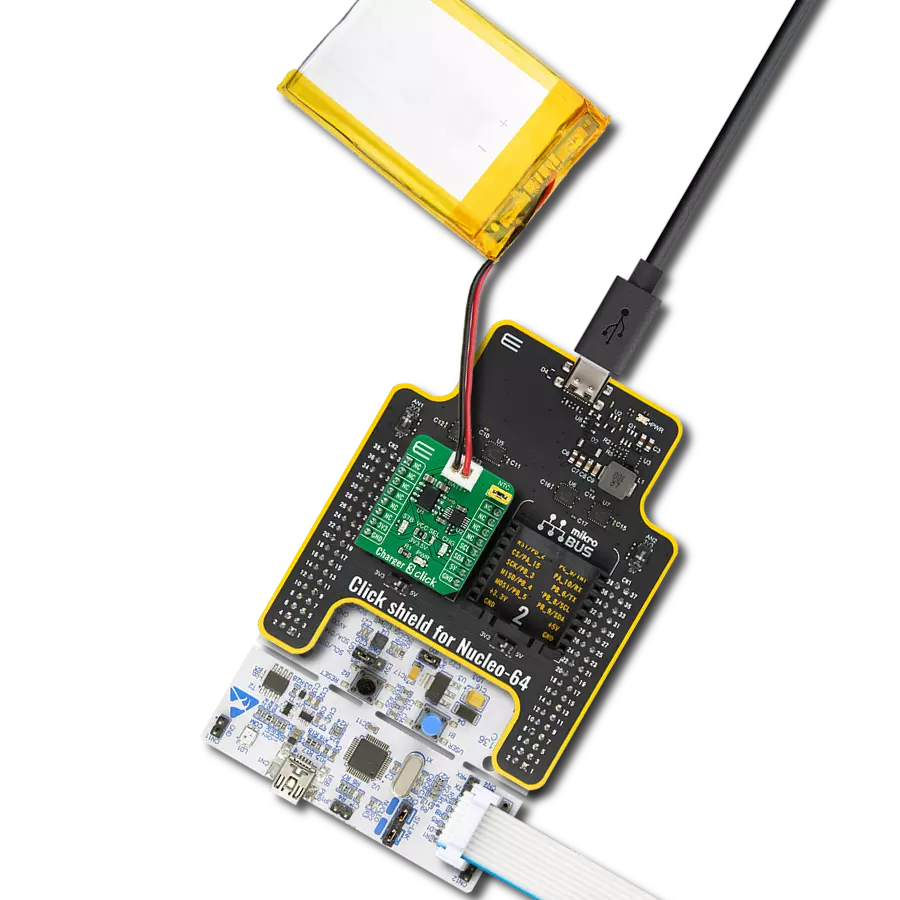

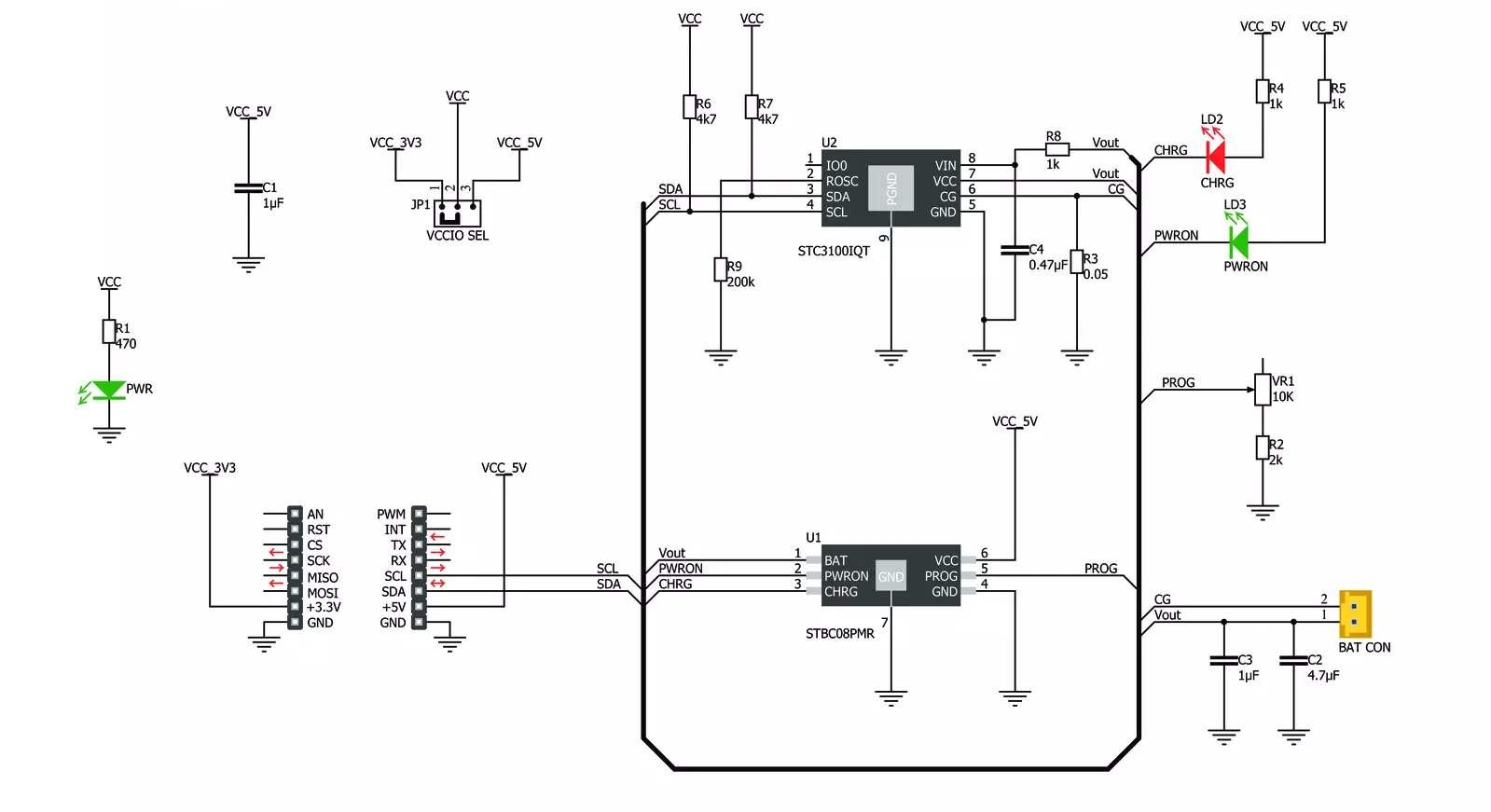

Charger 2 Click is based on the STBC08, a LiPo/Li-Ion battery charger from STMicroelectronics with the additional monitoring IC onboard. This Click board™, as a whole, offers unpreceded battery charging and monitoring solution for 3.7V LiPo/Li-Ion batteries, with the capacity measurement/gas gauge function, for up to 7000 mAh. It provides measurement data via the I2C interface and two signaling LEDs on the Click board™. It features two dedicated ICs - one for charging the battery and one for monitoring its status. The STBC08, a standalone linear battery charger, performs the charging function, while the STC3100, a battery monitor IC with Coulomb counter/gas gauge, monitors the critical battery parameters. The nominal charging voltage is set to 4.2V. The STBC08 maintains constant current/voltage, providing maximum charging rates while avoiding overheating the IC. The charging current is limited to about 450 mA with the onboard resistor connected to the PROG pin of the IC. It can be further adjusted to 80mA by the onboard potentiometer, connected in series with the PROG pin resistor. The charging is terminated when the battery is nearly fully charged and the charging current drops to 10% of the programmed value. The device automatically restarts the charge cycle when the battery voltage drops

below 4.05 V, maintaining the battery capacity value above 80%. Two LEDs are used to signalize the status of the STBC08 IC: a red LED is used to signalize the ongoing charge process. The green LED signalizes if the charging conditions are nominal and within the specs. It signalizes the validity of the charging voltage value. The battery connector is supplied with the regulated power from the STBC08 IC via the BAT pin. This pin outputs the current and voltage for the battery charging. This connector is mounted on the Click board™ PCB, and it is a standard 2.54mm pitch male pin battery connector used on most MIKROE products for connecting LiPo/Li-Ion batteries. With its lock-on feature, it provides a secure and reliable connection. For monitoring purposes, Charger 2 Click uses the STC3100, a battery monitor IC with Coulomb counter/gas gauge, also from STMicroelectronics. It monitors the voltage and current of the charging battery. It also includes hardware functions to implement a gas gauge for battery charge monitoring based on a programmable A/D converter. This IC can measure a battery capacity of up to 7000mAh. The gas gauge utilizes a sensing resistor of 50mΩ, and the voltage drop on this resistor is sampled by an internal 12-14 bit ADC. These measurements are integrated and stored in an internal

register. The host MCU can read this data via the I2C interface, with its lines routed to the appropriate I2C pins of the mikroBUS™. The resolution of the gas gauge measurement is 0.2 mAh. Battery voltage is measured and converted by a separate ADC, providing readings independent of the gauge section's readings. The battery output voltage is routed to the VIN pin of the STC3100 and can be read via the I2C interface. When the battery voltage drops under the defined threshold, the IC shuts down, and no current is drawn from the connected battery. The measurement resolution is 2.44 mV. The STC3100 also features 32 volatile RAM locations for storing various application-relevant data. The status of this memory is retained as long as there is a power supply to the IC itself. When the power supply is cut off, the content of this memory is lost. The Click board™ is equipped with the SMD jumper labeled as VCCIO SEL, used to choose between 3.3V or 5V operation. However, this Click board™ requires 5V to be present on its 5V mikroBUS™ rail because it is used as the power source for the battery charging IC. VCCIO SEL jumper only allows the logic voltage level to be selected to interface the Click board™ with both 3.3V and 5V MCUs.

Features overview

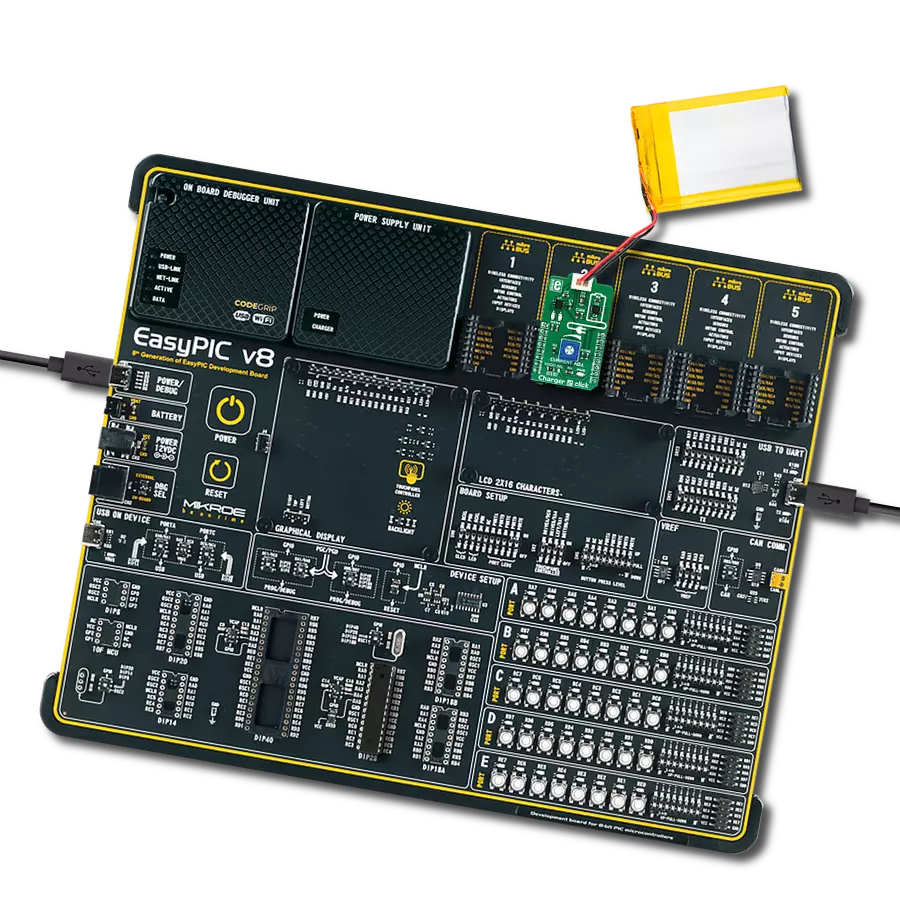

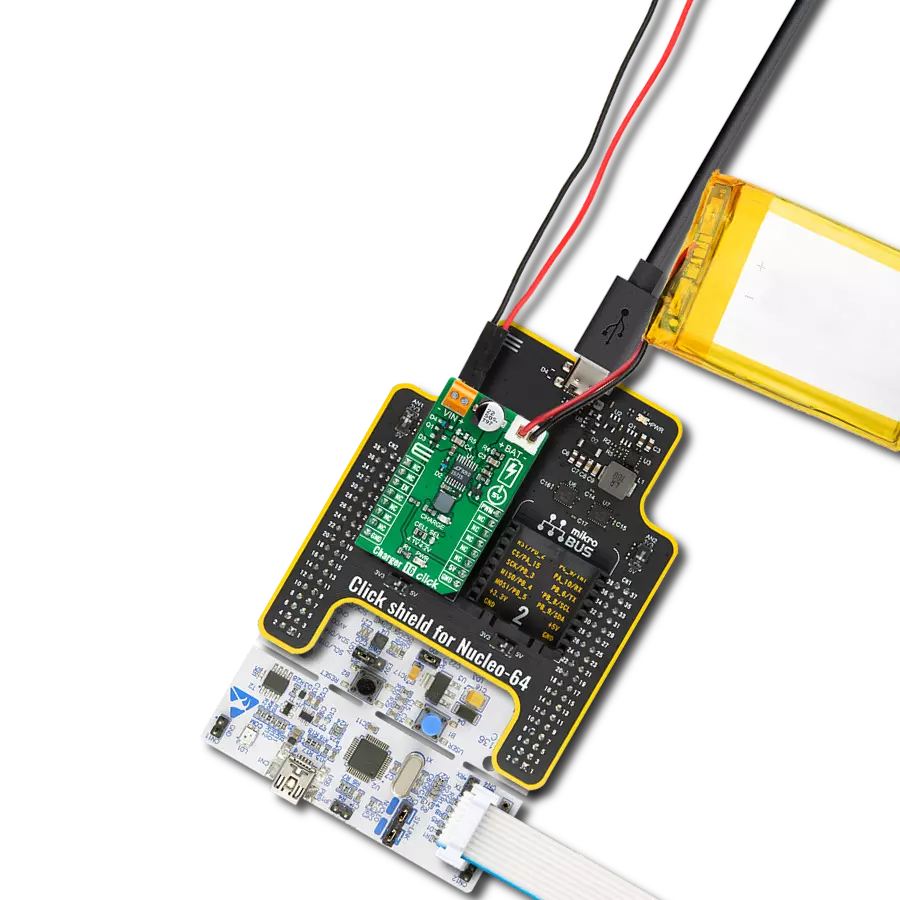

Development board

EasyAVR v7 is the seventh generation of AVR development boards specially designed for the needs of rapid development of embedded applications. It supports a wide range of 16-bit AVR microcontrollers from Microchip and has a broad set of unique functions, such as a powerful onboard mikroProg programmer and In-Circuit debugger over USB. The development board is well organized and designed so that the end-user has all the necessary elements in one place, such as switches, buttons, indicators, connectors, and others. With four different connectors for each port, EasyAVR v7 allows you to connect accessory boards, sensors, and custom electronics more

efficiently than ever. Each part of the EasyAVR v7 development board contains the components necessary for the most efficient operation of the same board. An integrated mikroProg, a fast USB 2.0 programmer with mikroICD hardware In-Circuit Debugger, offers many valuable programming/debugging options and seamless integration with the Mikroe software environment. Besides it also includes a clean and regulated power supply block for the development board. It can use a wide range of external power sources, including an external 12V power supply, 7-12V AC or 9-15V DC via DC connector/screw terminals, and a power source via the USB Type-B (USB-B)

connector. Communication options such as USB-UART and RS-232 are also included, alongside the well-established mikroBUS™ standard, three display options (7-segment, graphical, and character-based LCD), and several different DIP sockets which cover a wide range of 16-bit AVR MCUs. EasyAVR v7 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

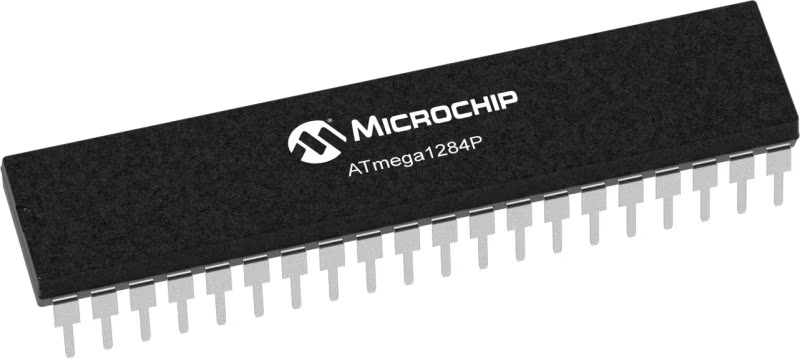

Microcontroller Overview

MCU Card / MCU

Architecture

AVR

MCU Memory (KB)

128

Silicon Vendor

Microchip

Pin count

40

RAM (Bytes)

16384

You complete me!

Accessories

Li-Polymer Battery is the ideal solution for devices that demand a dependable and long-lasting power supply while emphasizing mobility. Its compatibility with mikromedia boards ensures easy integration without additional modifications. With a voltage output of 3.7V, the battery meets the standard requirements of many electronic devices. Additionally, boasting a capacity of 2000mAh, it can store a substantial amount of energy, providing sustained power for extended periods. This feature minimizes the need for frequent recharging or replacement. Overall, the Li-Polymer Battery is a reliable and autonomous power source, ideally suited for devices requiring a stable and enduring energy solution. You can find a more extensive choice of Li-Polymer batteries in our offer.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Charger 2 Click driver.

Key functions:

charger2_write_reg- This function writes one byte data to the registercharger2_read_data- This function reads the desired data from data registers and converts this data to the appropriate unitcharger2_check_conv_cycle- This function checks is conversion cycle for battery current, or for battery voltage and temperature, finished, and if is not, waits until one of this conversions be finished

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Charger2 Click example

*

* # Description

* This app charges the battery.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes device.

*

* ## Application Task

* Reads the all necessary information for the battery charging status and logs this results on UART.

* Repeats operation every second.

* The LED diodes are used to indicate the Vcc presence when this voltage is in operating range, and to show the charging status.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "charger2.h"

// ------------------------------------------------------------------ VARIABLES

static charger2_t charger2;

static log_t logger;

uint32_t battery_data;

// ------------------------------------------------------- ADDITIONAL FUNCTIONS

void results_logger ( charger2_t *ctx )

{

switch ( ctx->unit_mode )

{

case CHARGER2_GAS_GAUGE_CHARGE_DATA :

{

log_printf( &logger, "Gas gauge charge data is: %u uV.h \r\n", battery_data );

break;

}

case CHARGER2_CONV_NUMBER :

{

log_printf( &logger, "Number of conversions is: %u \r\n", battery_data );

break;

}

case CHARGER2_SHUNT_VOLTAGE :

{

log_printf( &logger, "Voltage on shunt (CG pin): %u uV \r\n", battery_data );

break;

}

case CHARGER2_BATTERY_VOLTAGE :

{

log_printf( &logger, "Battery voltage is: %u mV \r\n", battery_data );

break;

}

case CHARGER2_TEMPERATURE :

{

log_printf( &logger, "Temperature is: %u Celsius \r\n", battery_data );

break;

}

case CHARGER2_BATTERY_CURRENT :

{

log_printf( &logger, "Battery current is: %u uA \r\n", battery_data );

break;

}

default :

{

break;

}

}

}

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

charger2_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

charger2_cfg_setup( &cfg );

CHARGER2_MAP_MIKROBUS( cfg, MIKROBUS_1 );

charger2_init( &charger2, &cfg );

Delay_ms ( 500 );

charger2_reset( &charger2, CHARGER2_RESET_COUNTER_MODE );

Delay_ms ( 1000 );

charger2_write_reg( &charger2, CHARGER2_REG_MODE, CHARGER2_AUTO_DETECT | CHARGER2_14_BITS_RESOLUTION | CHARGER2_OPERATING_MODE );

log_printf( &logger, "Charger 2 is initialized \r\n" );

log_printf( &logger, "------------------------------ \r\n" );

Delay_ms ( 300 );

}

void application_task ( void )

{

charger2_read_data( &charger2, CHARGER2_GAS_GAUGE_CHARGE_DATA, &battery_data );

results_logger( &charger2 );

charger2_read_data( &charger2, CHARGER2_CONV_NUMBER, &battery_data );

results_logger( &charger2 );

charger2_read_data( &charger2, CHARGER2_SHUNT_VOLTAGE, &battery_data );

results_logger( &charger2 );

charger2_read_data( &charger2, CHARGER2_BATTERY_VOLTAGE, &battery_data );

results_logger( &charger2 );

charger2_read_data( &charger2, CHARGER2_TEMPERATURE, &battery_data );

results_logger( &charger2 );

charger2_read_data( &charger2, CHARGER2_BATTERY_CURRENT, &battery_data );

results_logger( &charger2 );

log_printf( &logger, "------------------------------ \r\n" );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Battery charger