Upgrade your solution with state-of-the-art battery charger technology and ensure reliable charging performance every time

A

A

Hardware Overview

How does it work?

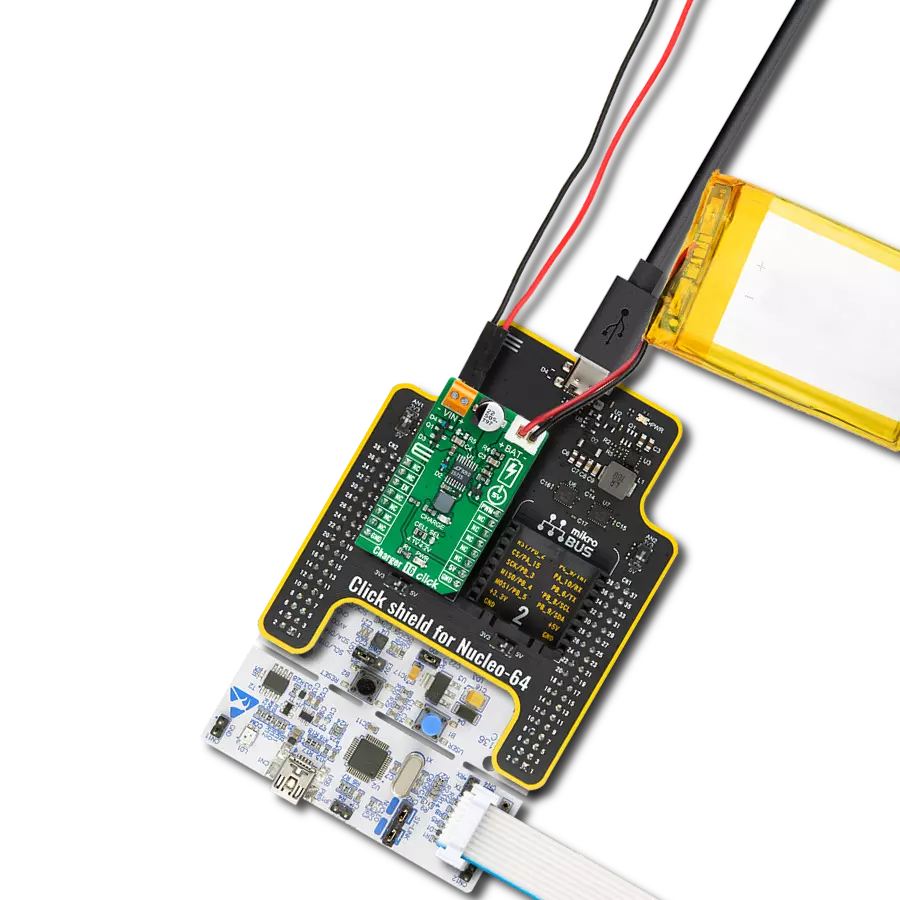

MCP73871 Click is based on the MCP73871, a system load sharing and Li-Po/Li-Ion battery charge management integrated circuit from Microchip. This device completely manages the power distribution, utilizing many different steps. The input voltage is constantly monitored, and with no battery connected or with a battery element that is deeply depleted, the power to the connected load will be delivered straight from the external power supply provided by the 5V rail of the mikroBUS™ socket. The current that can be delivered in this mode depends on the limiting factor selected by the PRG2 pin. If the PRG2 pin is set to a LOW logic level, the current will be limited to 80mA - 100mA. If the PRG2 pin is set to a HIGH logic level, the current supplied to the load will be limited to 400mA - 500mA. Several conditions set by the MCP73871 device define the behavior of the power management logic. If a Li-Po/Li-Ion battery is connected to the battery connector, the charging procedure will go through the following steps.

The preconditioning mode is activated if the connected battery is deeply depleted and the CE (Charge Enable) pin is set to a HIGH logic level. The charging current is only a fraction of the regulated charging current used for fast charging, preventing battery damage and overheating. Suppose the battery voltage exceeds the preconditioning threshold voltage set by the MCP73871 device. In that case, the fast charging will begin, and the charging current is set by the PRG2 pin, as described above, and a voltage equal to 4.35V, as per factory settings of the MCP73871 IC. The charger circuit will stop the charging process when the complete charging conditions are met. The battery voltage is monitored, and another charging cycle will be repeated when it falls under the recharge threshold. During all the charging modes, the temperature of the MCP73871 die is monitored, so the charging current is regulated accordingly. The overtemperature protection will put the device in shutdown mode, preventing damage.

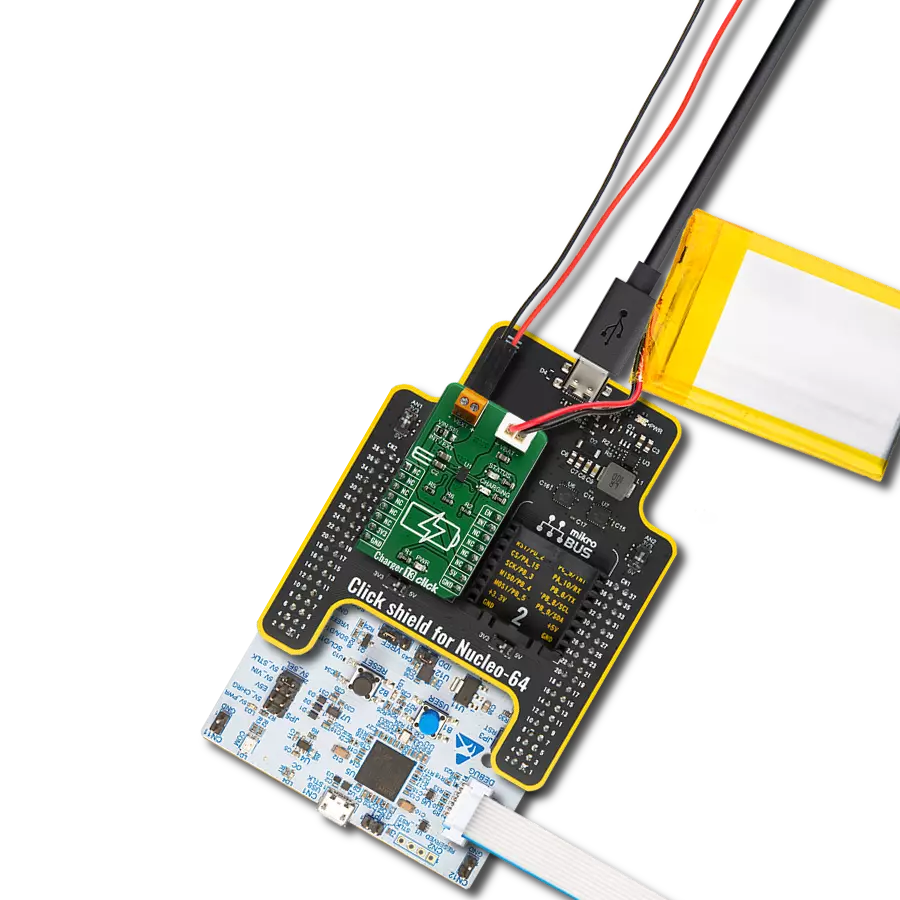

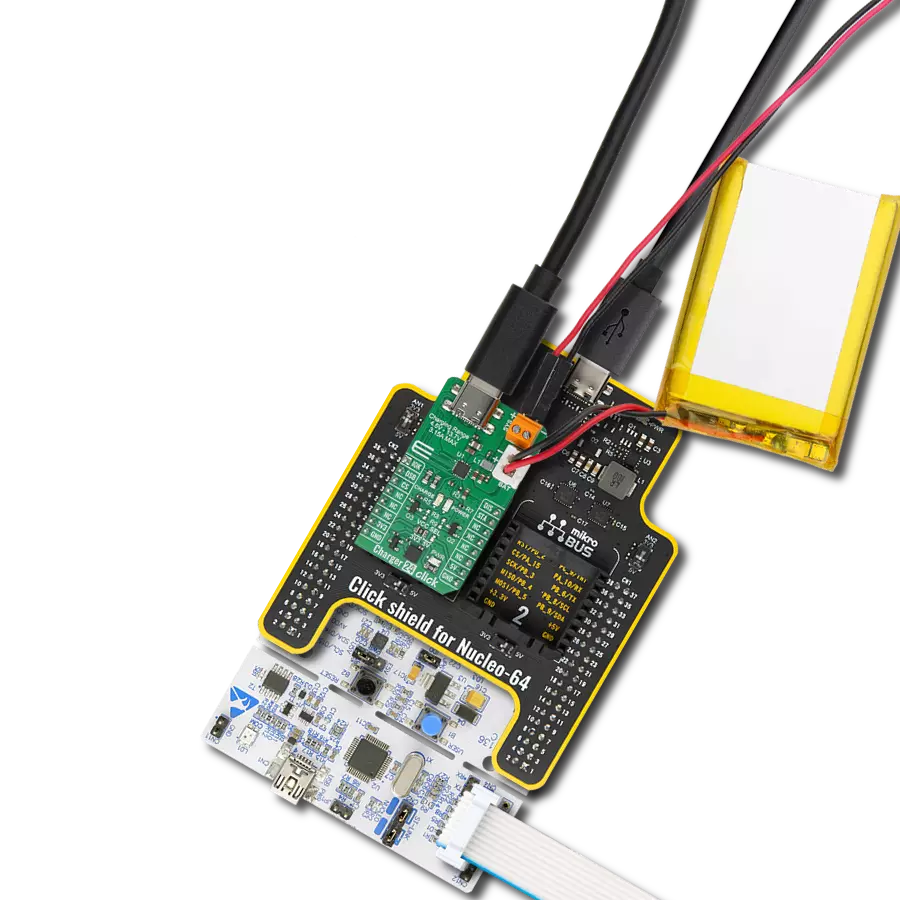

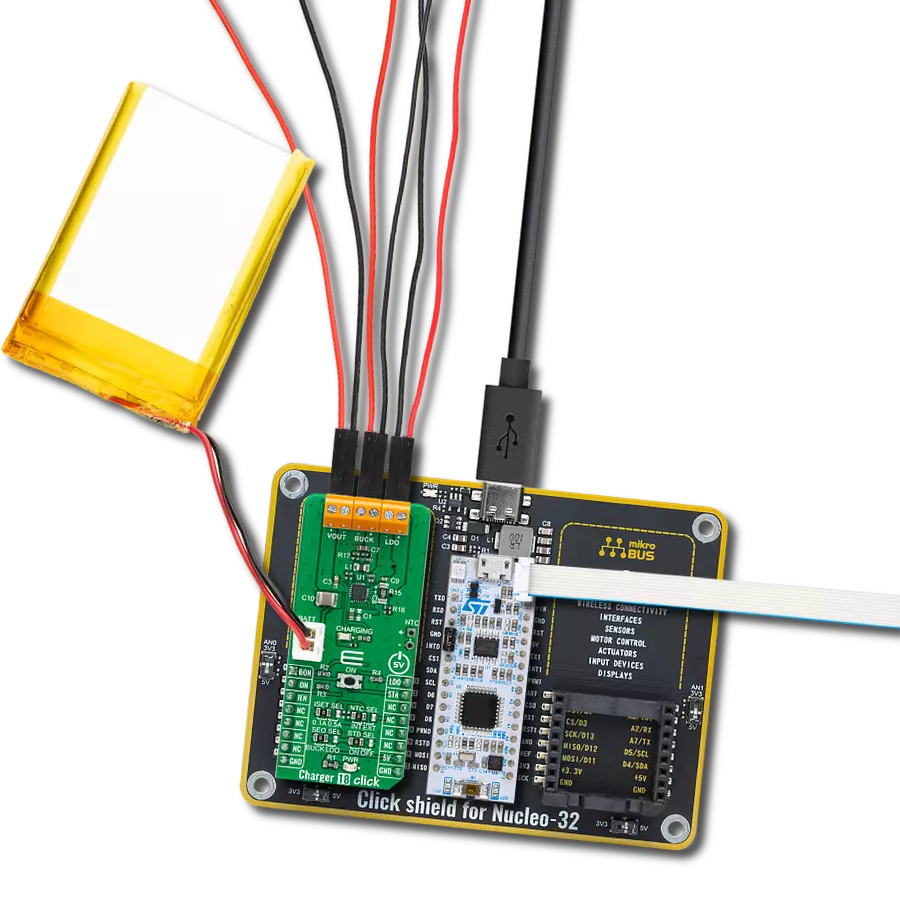

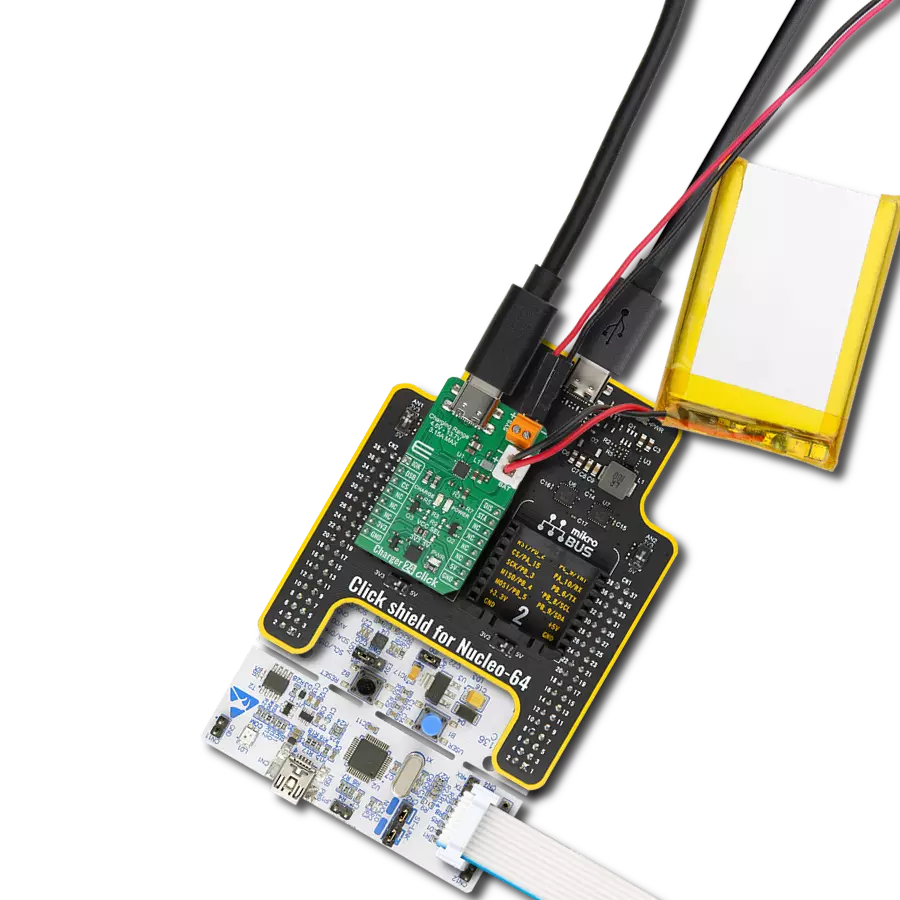

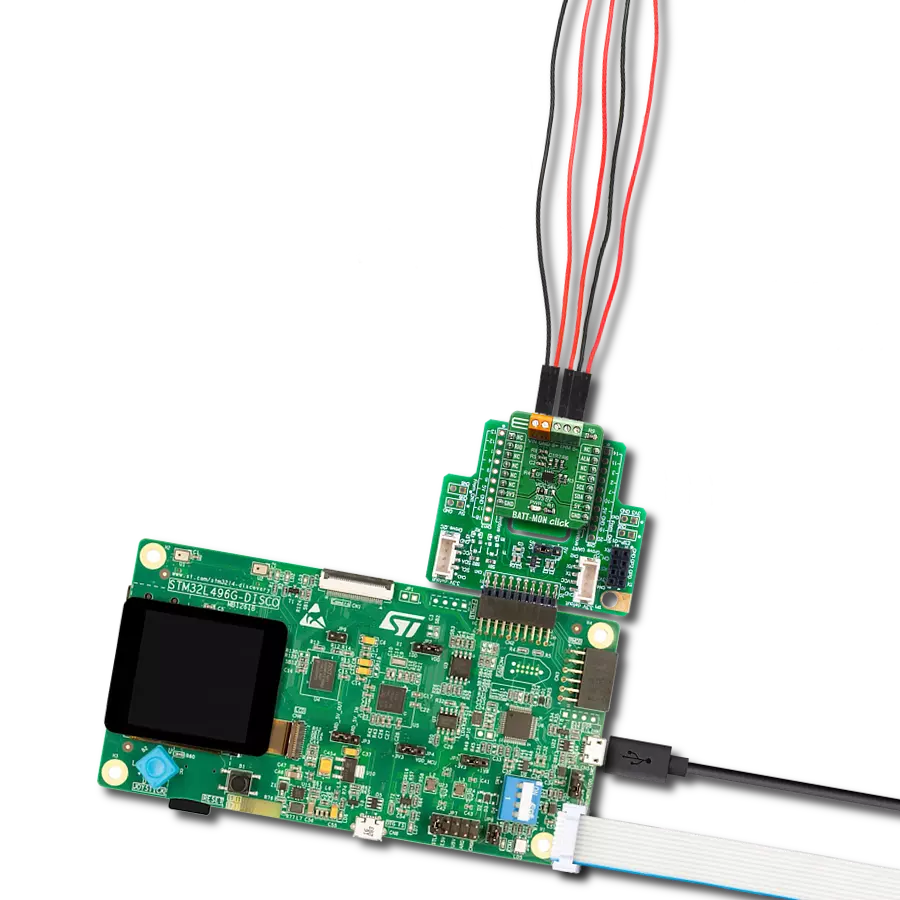

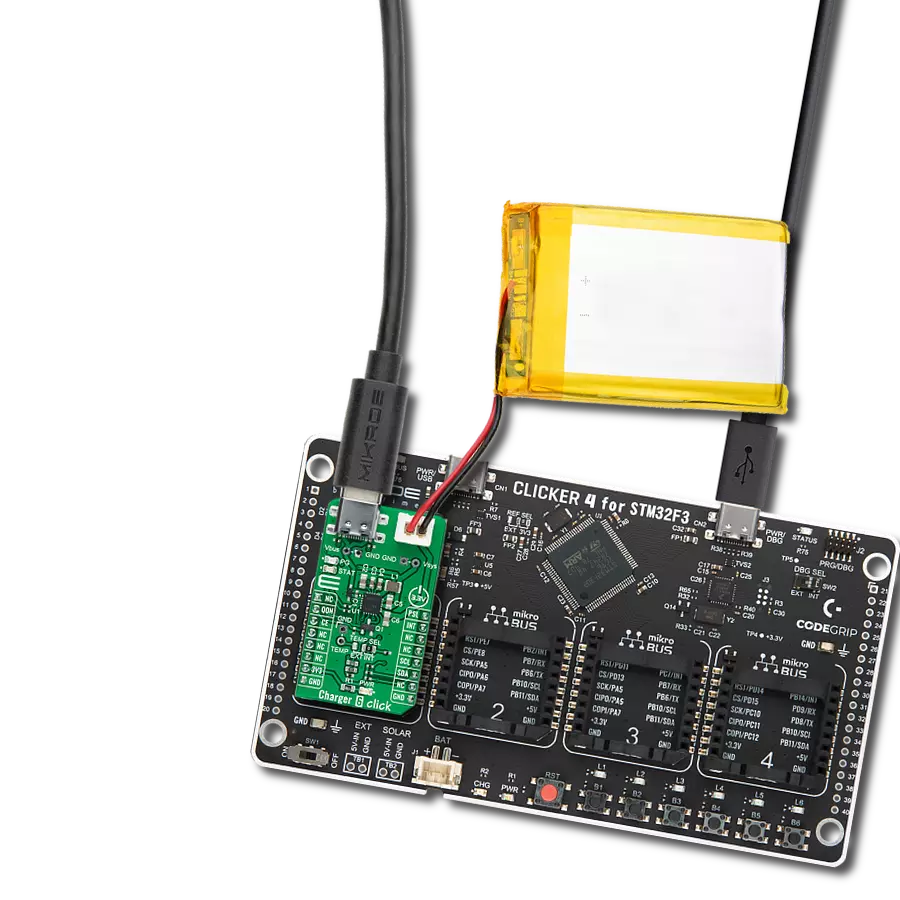

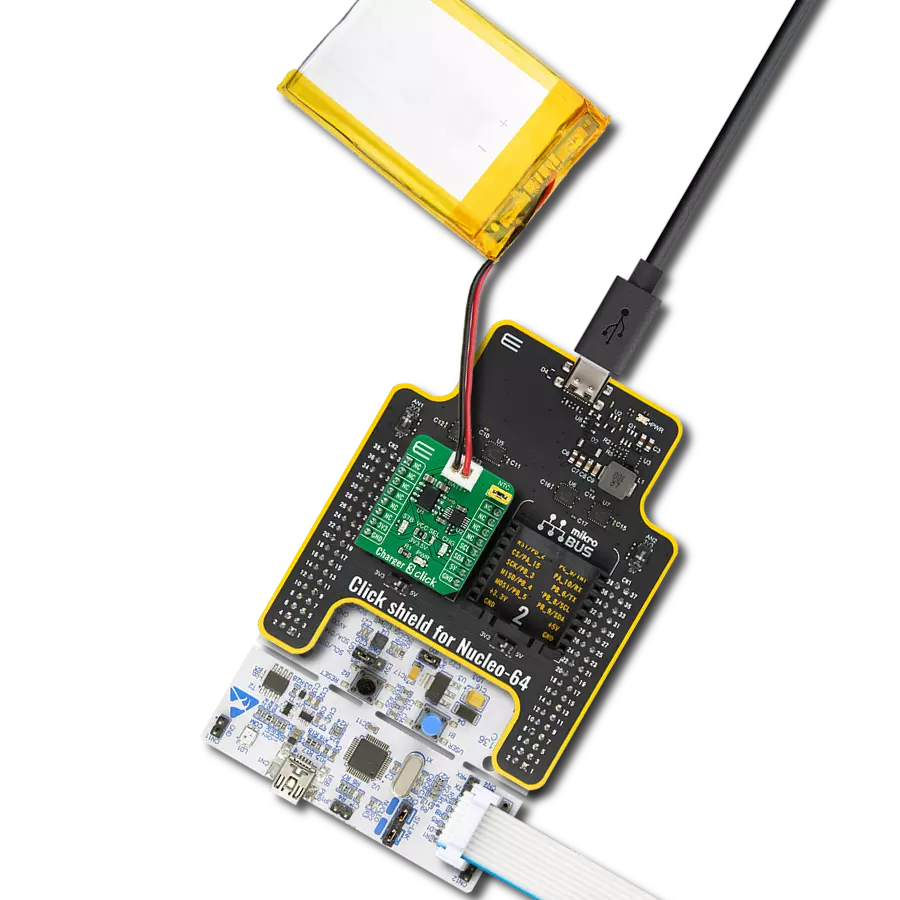

If the TE pin enables the Timer, it will limit the charging time if the battery voltage never reaches the end-of-charge condition. The MCP73871 power-sharing system logic enables simultaneously charging and powering up the system load, connected to the onboard output screw terminal. The power-sharing system is always active and prioritizes connected load over battery charging. Li-Po/Li-Ion battery can be connected to the onboard 2.54mm two-pin header. Three LEDs are used to indicate good power status, as well as the charging status. This Click board™ can only be operated with a 5V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. However, the Click board™ comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

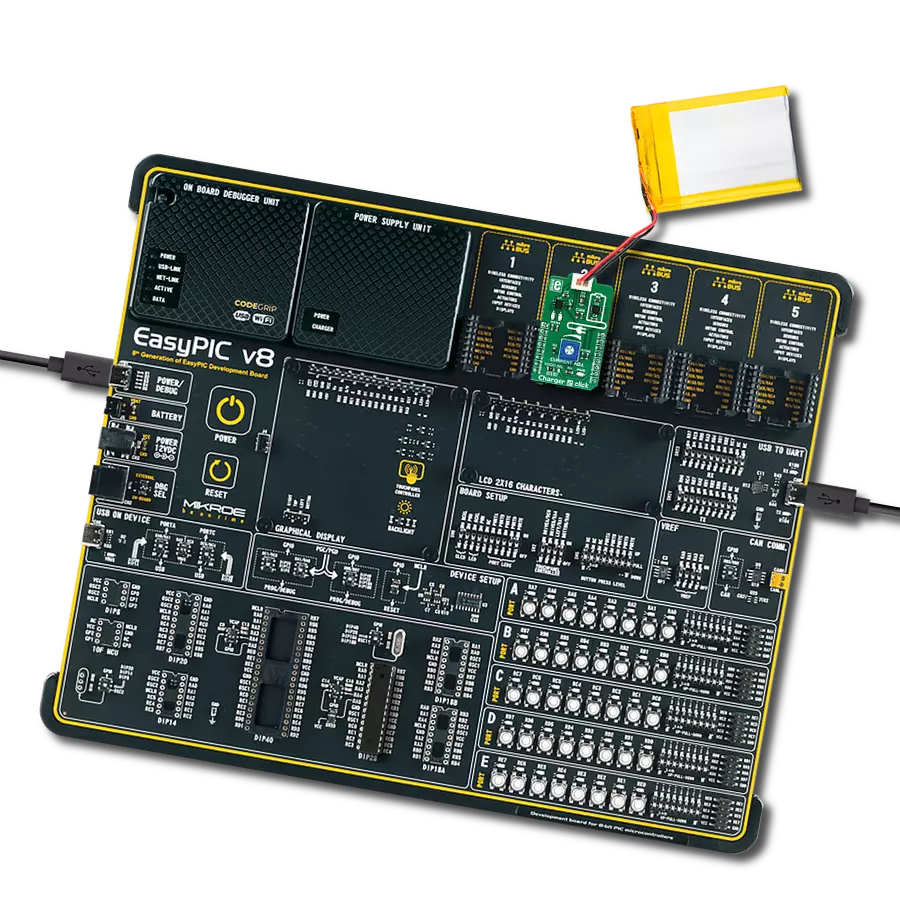

Development board

PIC32MZ Clicker is a compact starter development board that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit PIC32MZ microcontroller with FPU from Microchip, a USB connector, LED indicators, buttons, a mikroProg connector, and a header for interfacing with external electronics. Thanks to its compact design with clear and easy-recognizable silkscreen markings, it provides a fluid and immersive working experience, allowing access anywhere and under

any circumstances. Each part of the PIC32MZ Clicker development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the PIC32MZ Clicker programming method, using USB HID mikroBootloader, or through an external mikroProg connector for PIC, dsPIC, or PIC32 programmer, the Clicker board also includes a clean and regulated power supply module for the development kit. The USB Micro-B connection can provide up to 500mA of current, which is more than enough to operate all onboard

and additional modules. All communication methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, reset button, and several buttons and LED indicators. PIC32MZ Clicker is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

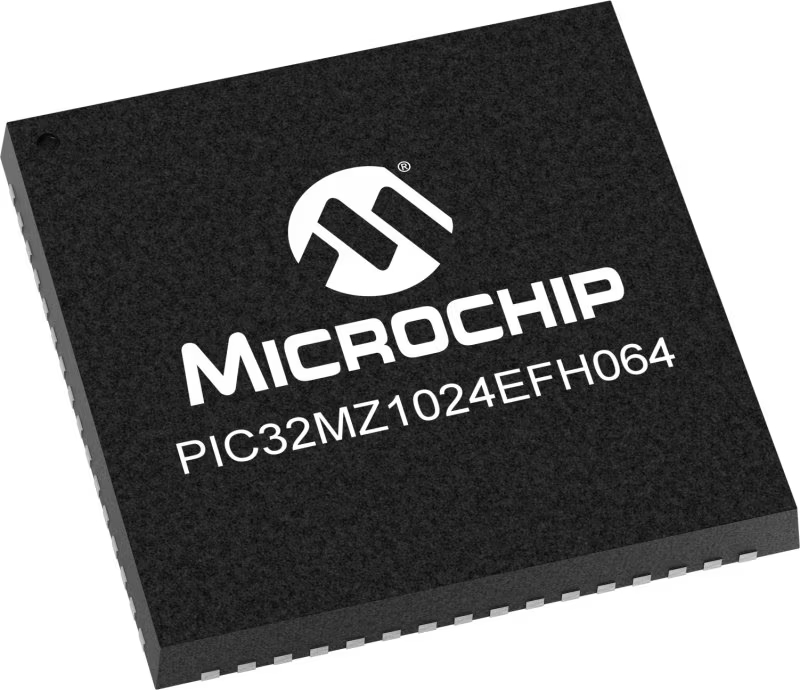

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

1024

Silicon Vendor

Microchip

Pin count

64

RAM (Bytes)

524288

You complete me!

Accessories

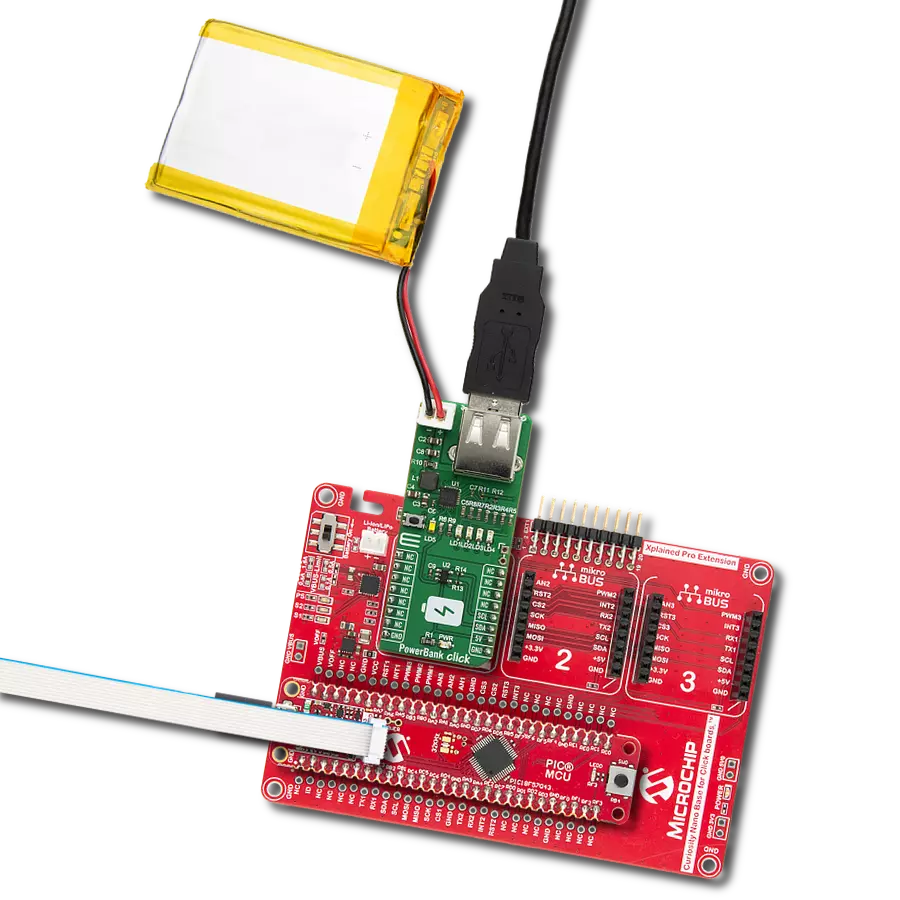

Li-Polymer Battery is the ideal solution for devices that demand a dependable and long-lasting power supply while emphasizing mobility. Its compatibility with mikromedia boards ensures easy integration without additional modifications. With a voltage output of 3.7V, the battery meets the standard requirements of many electronic devices. Additionally, boasting a capacity of 2000mAh, it can store a substantial amount of energy, providing sustained power for extended periods. This feature minimizes the need for frequent recharging or replacement. Overall, the Li-Polymer Battery is a reliable and autonomous power source, ideally suited for devices requiring a stable and enduring energy solution. You can find a more extensive choice of Li-Polymer batteries in our offer.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for MCP73871 Click driver.

Key functions:

mcp73871_enable_pin_control- Enable pin controlmcp73871_prog_pin_control-Prog pin controlmcp73871_timer_pin_control- Timer pin control

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief MCP73871 Click example

*

* # Description

* This application is battery charger.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the Click driver, and enables the Click board.

*

* ## Application Task

* This is the example of MCP73871 Click functions usage.

* It enables this Click, sets input current to 100mA,

* and enables safety timer.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "mcp73871.h"

// ------------------------------------------------------------------ VARIABLES

static mcp73871_t mcp73871;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

mcp73871_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

mcp73871_cfg_setup( &cfg );

MCP73871_MAP_MIKROBUS( cfg, MIKROBUS_1 );

mcp73871_init( &mcp73871, &cfg );

}

void application_task ( void )

{

mcp73871_enable_pin_control( &mcp73871, 1 );

mcp73871_prog_pin_control( &mcp73871, 0 );

mcp73871_timer_pin_control( &mcp73871, 0 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Battery charger