Unlock precise vertical velocity insights and determine your application's exact rate of ascent or descent

A

A

Hardware Overview

How does it work?

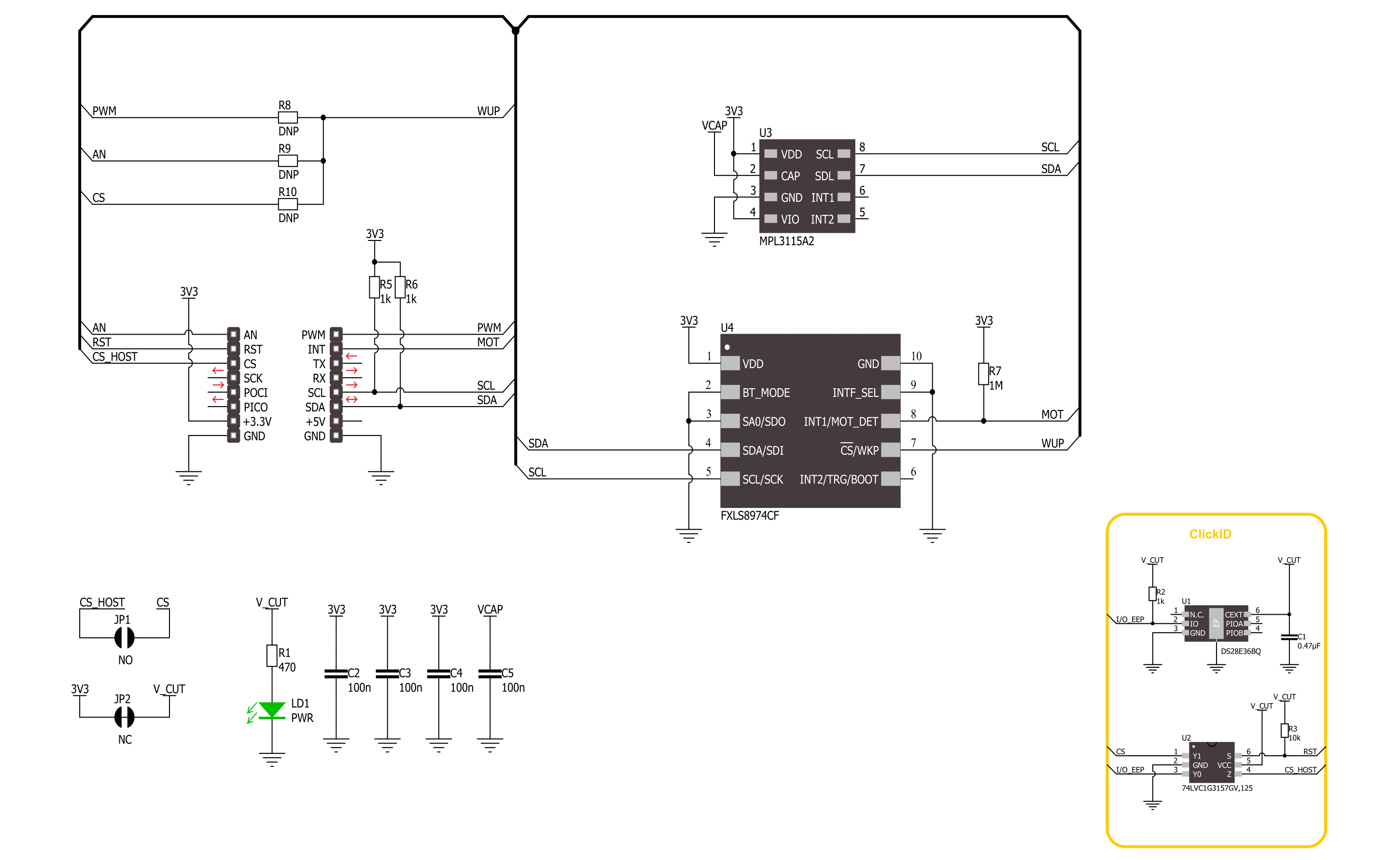

Accel&Pressure Click is based on the FXLS8974CF, a 3-axis low-g accelerometer, and the MPL3115A2, a precision pressure sensor with altimetry, both from NXP Semiconductor. The accelerometer has a ±2/4/8/16 g user-selectable, full-scale measurement range with a 12-bit acceleration data output. It can work in several modes, such as active, hibernate, standby, and more. The integrated FIFO/LIFO buffer of 144 bytes can store 32 12-bit X/Y/Z/ data triplets. The sensor also has flexible data change detection, such as motion, freefall, and other inertial events. The pressure sensor has an absolute operating range of

20kPa to 110kPa in 20-bit measurements. Besides the pressure, the MPL3115A2 can also measure the altitude in a range of -698 up to 11775 meters in a 20-bit resolution. It also comes with an embedded FIFO (32 samples) and up to 12 days of data logging using the FIFO. Both sensors have an integrated temperature sensor and are temperature-compensated. Accel&Pressure Click uses a standard 2-wire I2C interface to allow the host MCU to communicate with both sensors. If the motion is detected, the FXLS8974CF uses a motion MOT pin to interrupt the host MCU. Depending on your application, you can choose one of the

available pins (PWM, AN, CS) by soldering one of the jumpers (R8, R9, R10) to control the hibernation mode wake-up function of the FXLS8974CF. In addition, there are LP Cut jumpers at the bottom of the Accel&Pressure Click board™, with which a low power consumption feature can be achieved. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, it comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

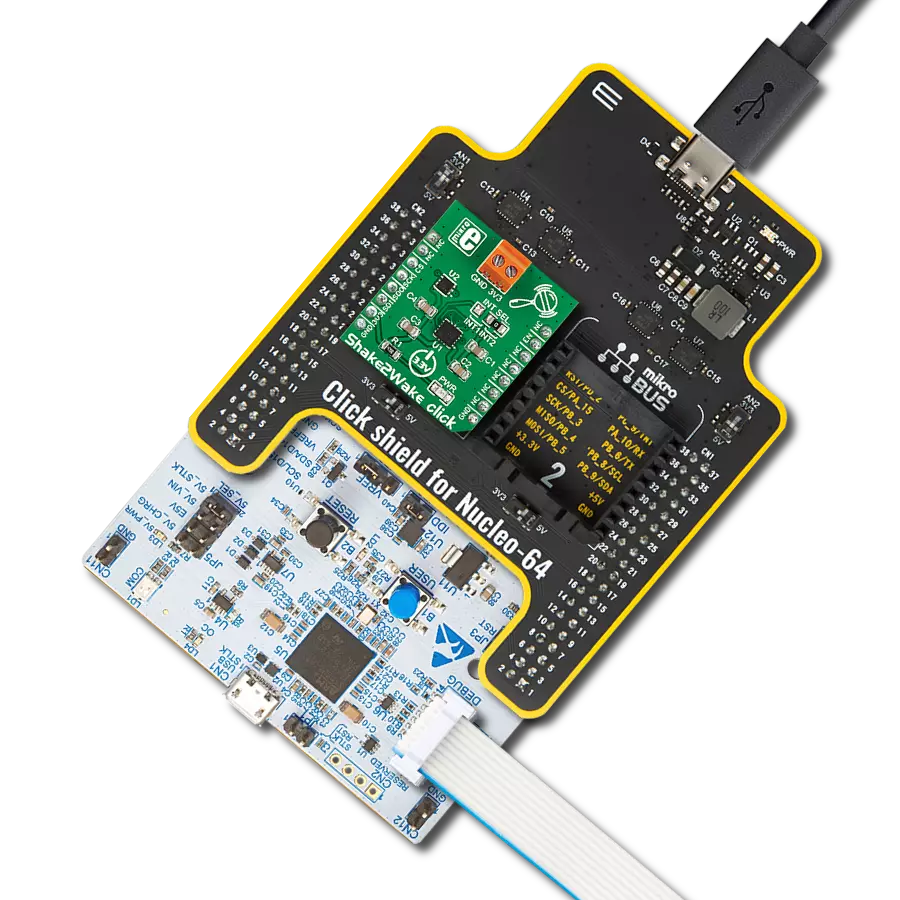

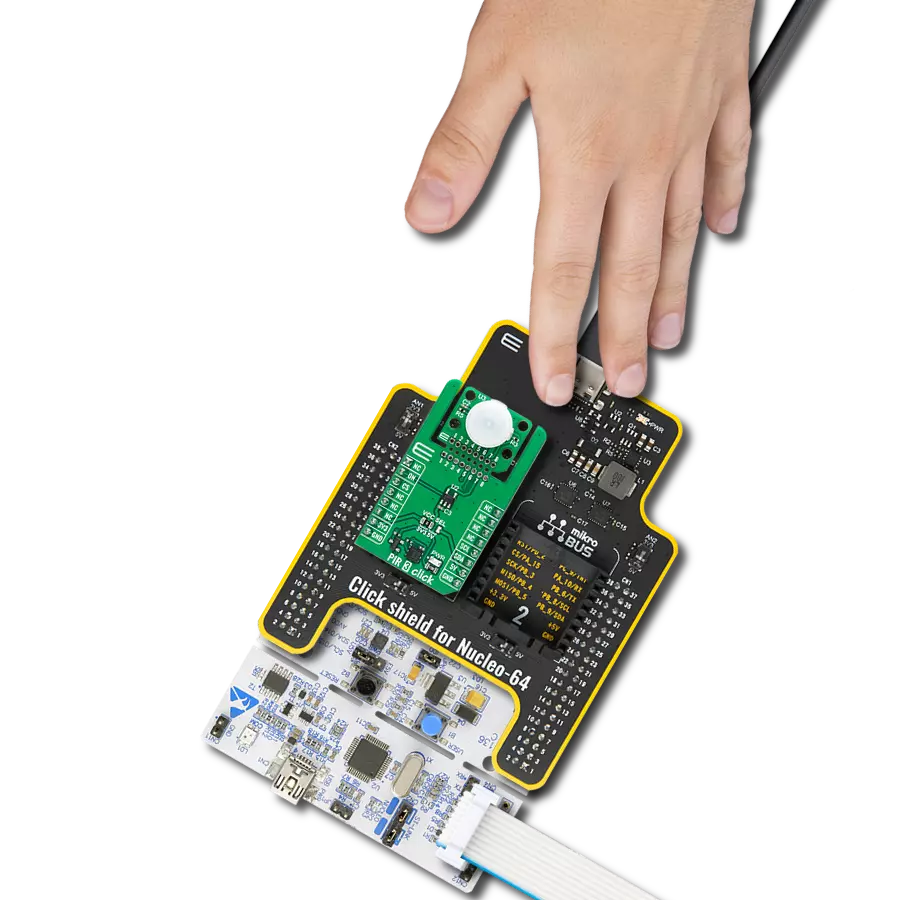

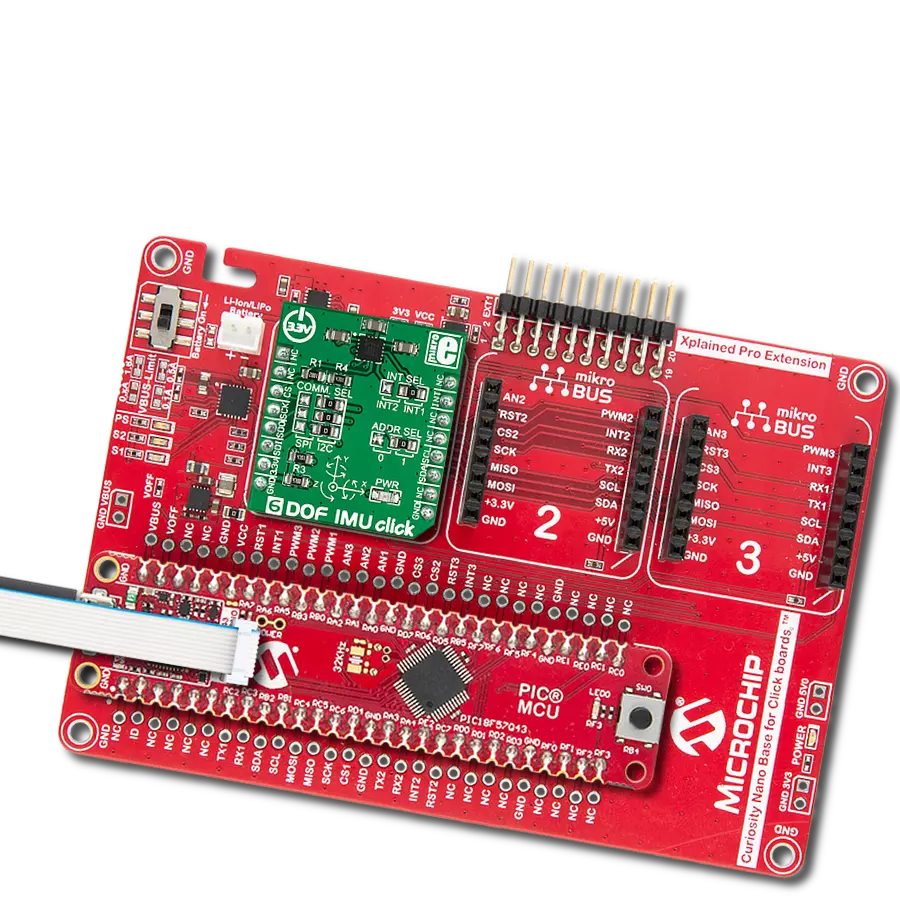

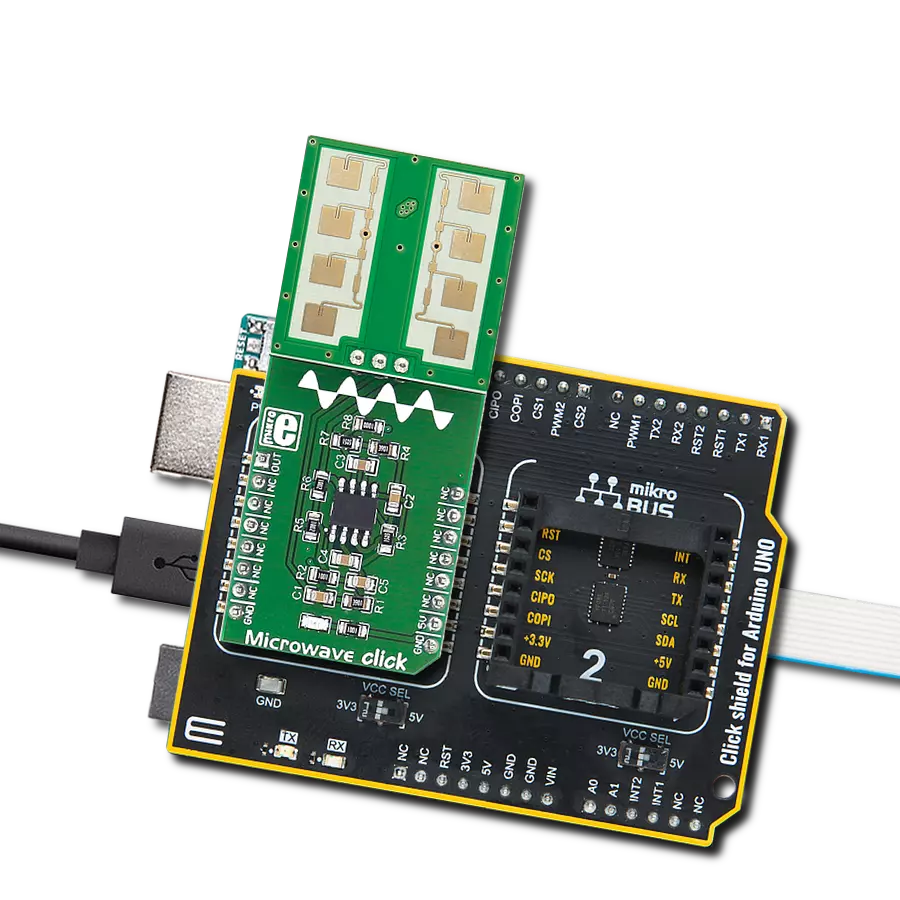

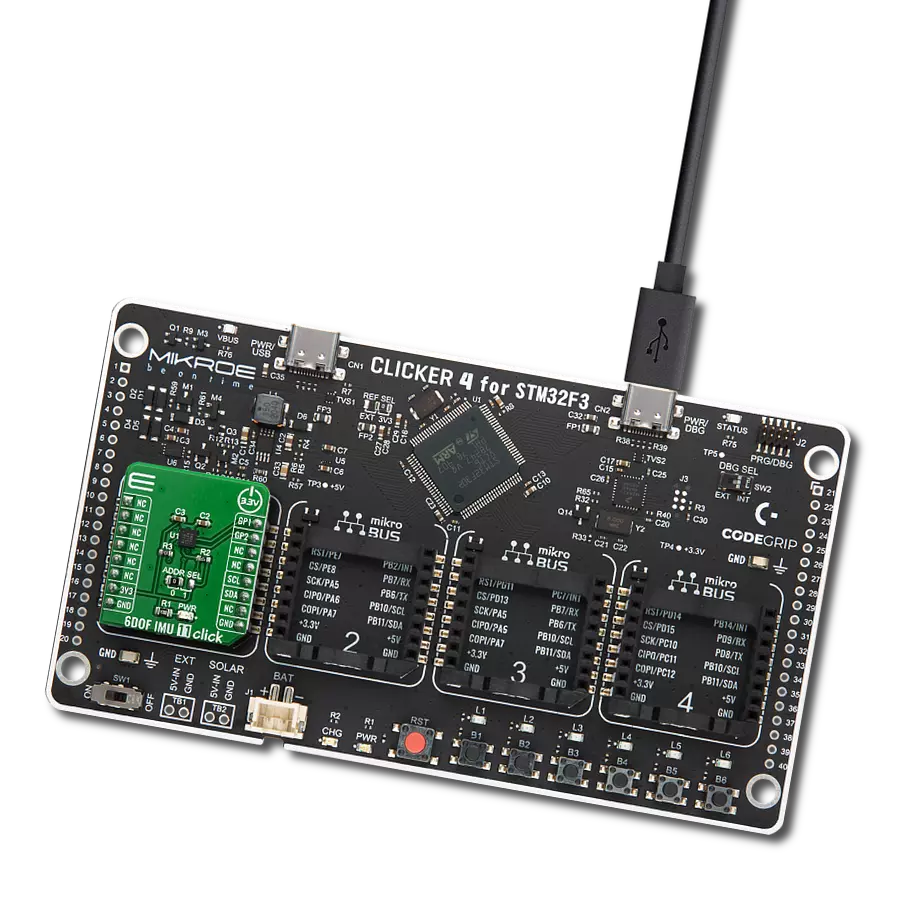

Development board

Clicker 2 for Kinetis is a compact starter development board that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit ARM Cortex-M4F microcontroller, the MK64FN1M0VDC12 from NXP Semiconductors, two mikroBUS™ sockets for Click board™ connectivity, a USB connector, LED indicators, buttons, a JTAG programmer connector, and two 26-pin headers for interfacing with external electronics. Its compact design with clear and easily recognizable silkscreen markings allows you to build gadgets with unique functionalities and

features quickly. Each part of the Clicker 2 for Kinetis development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the Clicker 2 for Kinetis programming method, using a USB HID mikroBootloader or an external mikroProg connector for Kinetis programmer, the Clicker 2 board also includes a clean and regulated power supply module for the development kit. It provides two ways of board-powering; through the USB Micro-B cable, where onboard voltage regulators provide the appropriate voltage levels to each component on the board, or

using a Li-Polymer battery via an onboard battery connector. All communication methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, reset button, and several user-configurable buttons and LED indicators. Clicker 2 for Kinetis is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

NXP

Pin count

121

RAM (Bytes)

262144

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Accel&Pressure Click driver.

Key functions:

accelpressure_get_axes_data- This function reads the accelerometer sensor axes data.accelpressure_get_pressure- This function reads the sensor pressure data conversion in mbar.accelpressure_get_temperature- This function reads the conversion of sensor pressure data in degrees Celsius.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief AccelPressure Click example

*

* # Description

* This library contains API for the AccelPressure Click driver.

* The library initializes and defines the I2C drivers to

* write and read data from registers, as well as the default configuration

* for reading the accelerator, pressure, and temperature data.

*

* The demo application is composed of two sections :

*

* ## Application Init

* The initialization of the I2C module, log UART, and additional pins.

* After the driver init, the app executes a default configuration.

*

* ## Application Task

* This example demonstrates the use of the AccelPressure Click board.

* Measures and displays acceleration data for the X-axis, Y-axis, and Z-axis [mg],

* pressure [mBar], and temperature [degree Celsius] data.

* Results are being sent to the UART Terminal, where you can track their changes.

*

* @author Nenad Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "accelpressure.h"

static accelpressure_t accelpressure;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

accelpressure_cfg_t accelpressure_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

accelpressure_cfg_setup( &accelpressure_cfg );

ACCELPRESSURE_MAP_MIKROBUS( accelpressure_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == accelpressure_init( &accelpressure, &accelpressure_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( ACCELPRESSURE_ERROR == accelpressure_default_cfg ( &accelpressure ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

log_printf( &logger, "_________________\r\n" );

}

void application_task ( void )

{

accelpressure_axes_t acc_axis;

float pressure = 0, temperature = 0;

if ( ACCELPRESSURE_OK == accelpressure_get_axes_data( &accelpressure, &acc_axis ) )

{

log_printf( &logger, " Accel X: %.2f mg\r\n", acc_axis.x );

log_printf( &logger, " Accel Y: %.2f mg\r\n", acc_axis.y );

log_printf( &logger, " Accel Z: %.2f mg\r\n", acc_axis.z );

}

log_printf( &logger, "_________________\r\n" );

Delay_ms ( 100 );

if ( ACCELPRESSURE_OK == accelpressure_get_pressure( &accelpressure, &pressure ) )

{

log_printf( &logger, " Pressure: %.2f mbar\r\n", pressure );

}

Delay_ms ( 100 );

if ( ACCELPRESSURE_OK == accelpressure_get_temperature( &accelpressure, &temperature ) )

{

log_printf( &logger, " Temperature: %.2f mbar\r\n", temperature );

}

log_printf( &logger, "_________________\r\n" );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END