Our solution seamlessly transforms UART signals to RS485, empowering industrial automation systems with faster and more reliable data communication.

A

A

Hardware Overview

How does it work?

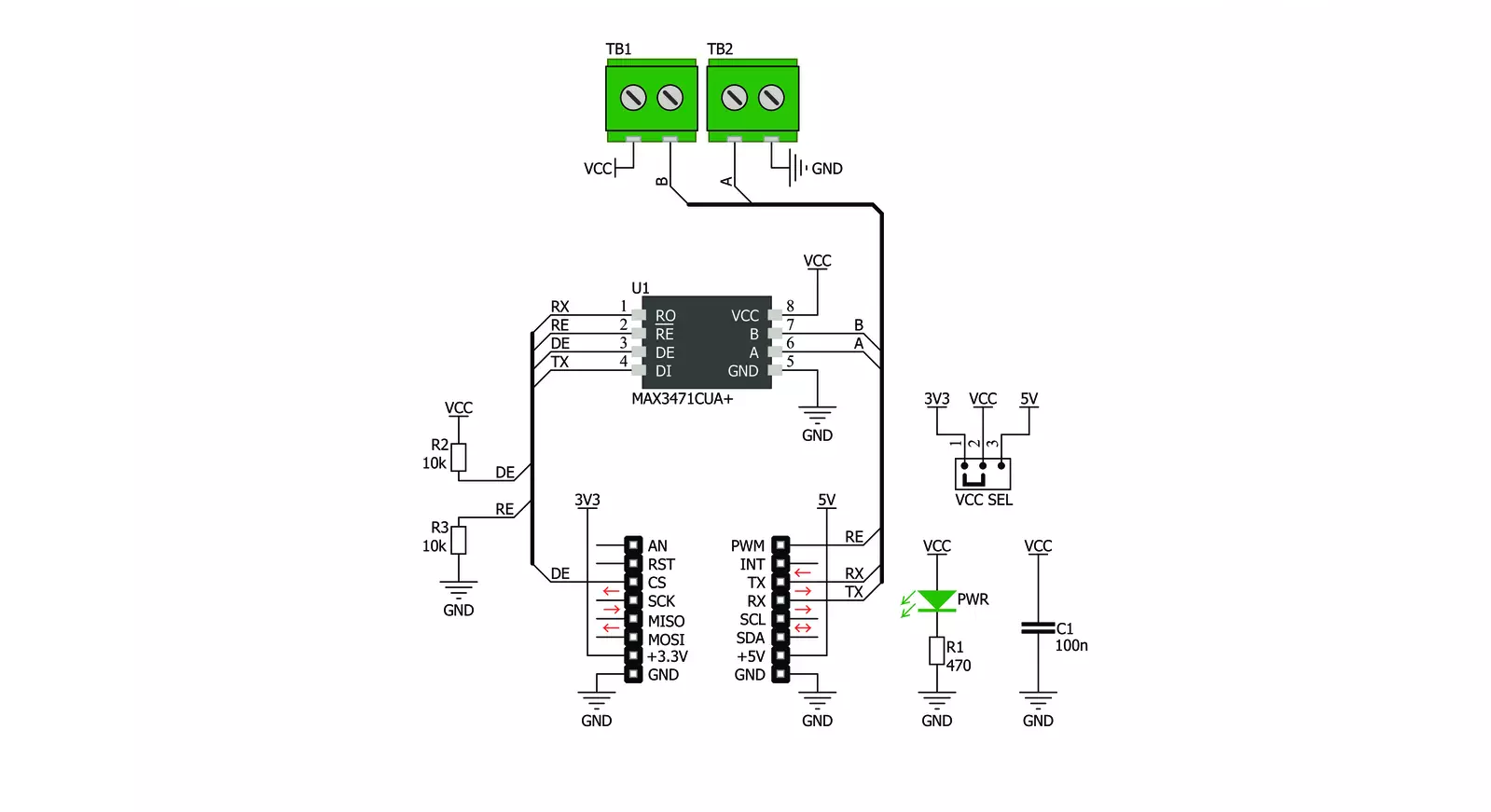

RS485 2 Click is based on the MAX3471, an RS-422/485, half-duplex, differential transceiver for battery-powered systems, from Analog Devices. This click is intended to be used as a physical layer device, often referred to as PHY, providing physical interfacing of the MCU TTL level UART lines with the RS422/485 bus. It is well suited for transmitting smaller blocks of data over long distances, using a shielded differential pair, for both TX and RX signals, allowing for half-duplex asynchronous communication. The MAX3471 transceiver consists of a separate driver and receiver sections, with Driver Enable and Receiver Enable pins (#RE and DE), used to enable appropriate sections. Driver section is used to drive the RS422/485 bus with the signal received on the UART RX line labeled as RO on the IC, while the receiver section returns data from the bus back to the MCU via the UART TX line, labeled as DI on the IC in the schematics. RS422/485 standard only specifies electrical characteristics of the transmitter and the receiver. It does not specify or recommend any communications protocol, only the physical layer. The top layer communication protocol of choice can be used, such as the MODBUS or similar protocols. Therefore RS485 2 click offers UART RX and TX pins, routed to the appropriate mikroBUS™ TX and RX UART pins. These pins are used by the MCU to send data to the RS485 bus, in a form determined by the user protocol. Additional DE and RE pins are routed to the mikroBUS™ CS and PWM pin respectively. These pins are labeled on

the Click board™ as DE and RE, the same as on the IC itself. Pull-up and pull-down are used to determine states on these pins when they are left floating. MAX3471 IC allows data rates up to 64kbps. In general, the maximal transfer speed is determined by the bus length: longer bus lines will result in less transfer speed. The RS485/422 bus needs to be terminated with the resistor on both ends, which is equal to the characteristic impedance of the used cable, in order to prevent line reflections. However, the MAX3471 IC features a reduced slew rate on its driver outputs, resulting with slower speed, but with far more robust signal at the same time, which is immune to EMI and other types of interferences that appear on long lines or connection stubs (unterminated parts of the bus). This IC is also able to work on the unterminated bus, commonly used in low speed and low power systems. The RS-485 standard specifies that a compliant driver must be able to drive 32 unit loads (UL), where 1 unit load represents a load impedance of approximately 12 kΩ. Since the MAX3471 IC device is 1/8 UL, up to 256 such receivers can be supported by a single driver. In cases when the RS485/422 bus voltage is close to 2.5V, the device is able to drive up to 8 loads, which means that it can drive up to 64 receivers. As the bus voltage rises, more drivers can be added, so that for 5V the device can drive the number of devices specified by the standard. There are situations on the RS485/422 bus, which might lead to a differential voltage which can

increase the current which runs through the driver output. This state is known as the bus contention, and it commonly appears during the initialization, bus fault conditions, or with multiple nodes, which have their drivers active at the same time. The MAX3471 IC provides driver output protection, which limits this current and prevents damage to the driver output stage. The MAX3471 receiver employs input filtering and input hysteresis to enhance noise immunity when differential signals have very slow rise and fall times. MAX3471 IC features a true fail-safe receiver input, which guarantees a logic HIGH receiver output in cases when the receiver inputs are open or shorted, or when they are connected to a terminated transmission line with all drivers disabled. There is one 4-pole screw terminal on board (VCC, RX, TX, GND) for connecting RS422/485 bus twisted pair cable, along with the GND and VCC. The jumper labeled as VCC SEL is used to set the operating voltage of the Click board™ to either 3.3V or 5V. GND and VCC rails can be used to provide the power supply for another node. Note that the VCC terminal is directly routed to either 3.3V or 5V rail of the mikroBUS™, depending on the VCC SEL jumper position. MikroElektronika provides a library that contains functions compatible with the MikroElektronika compilers, which can be used for working with the RS485 2 Click. The library also contains an example application, which demonstrates their use. This example application can be used as a reference for custom designs.

Features overview

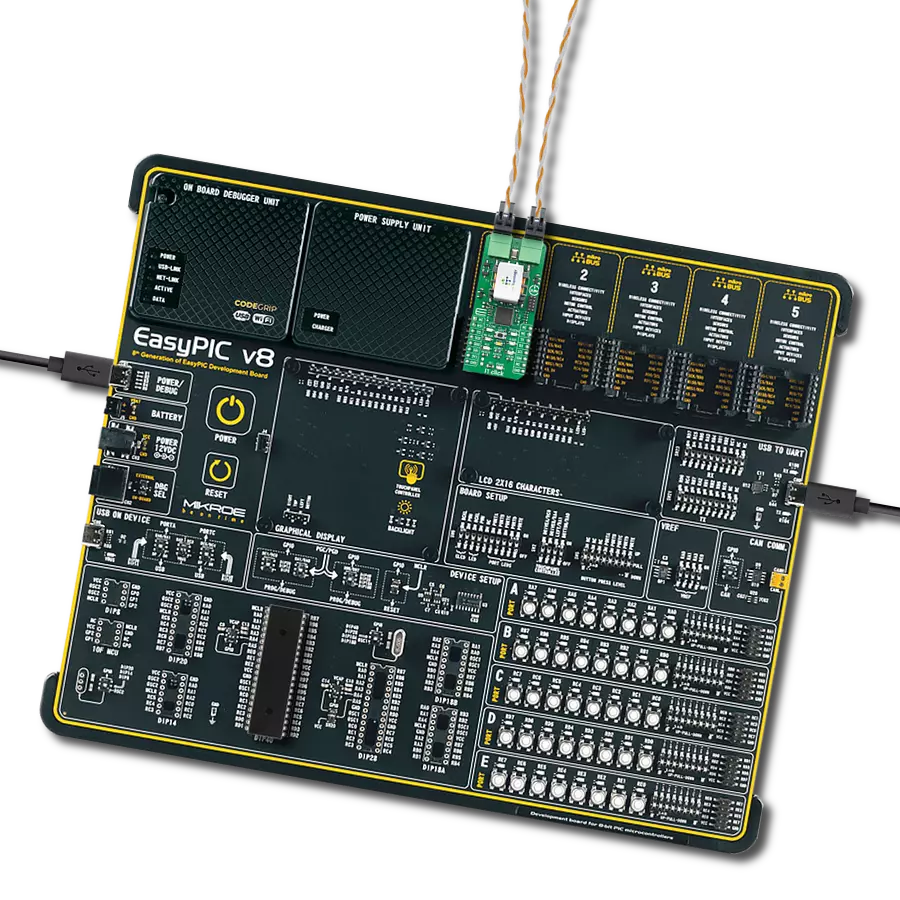

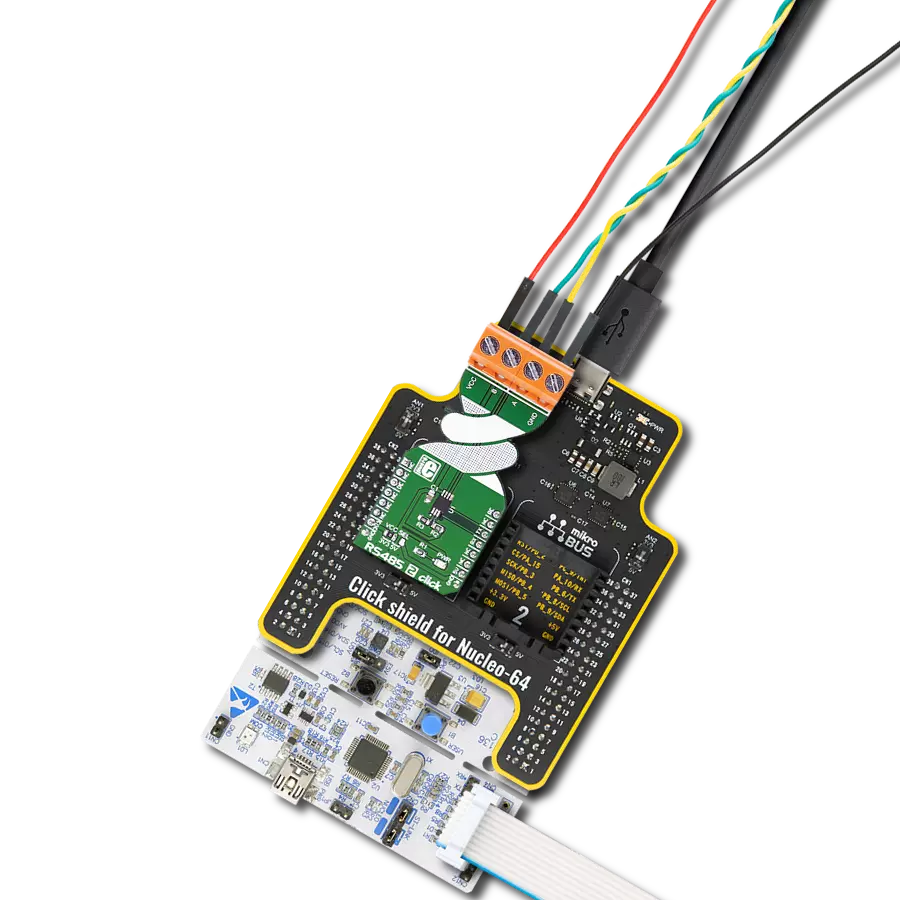

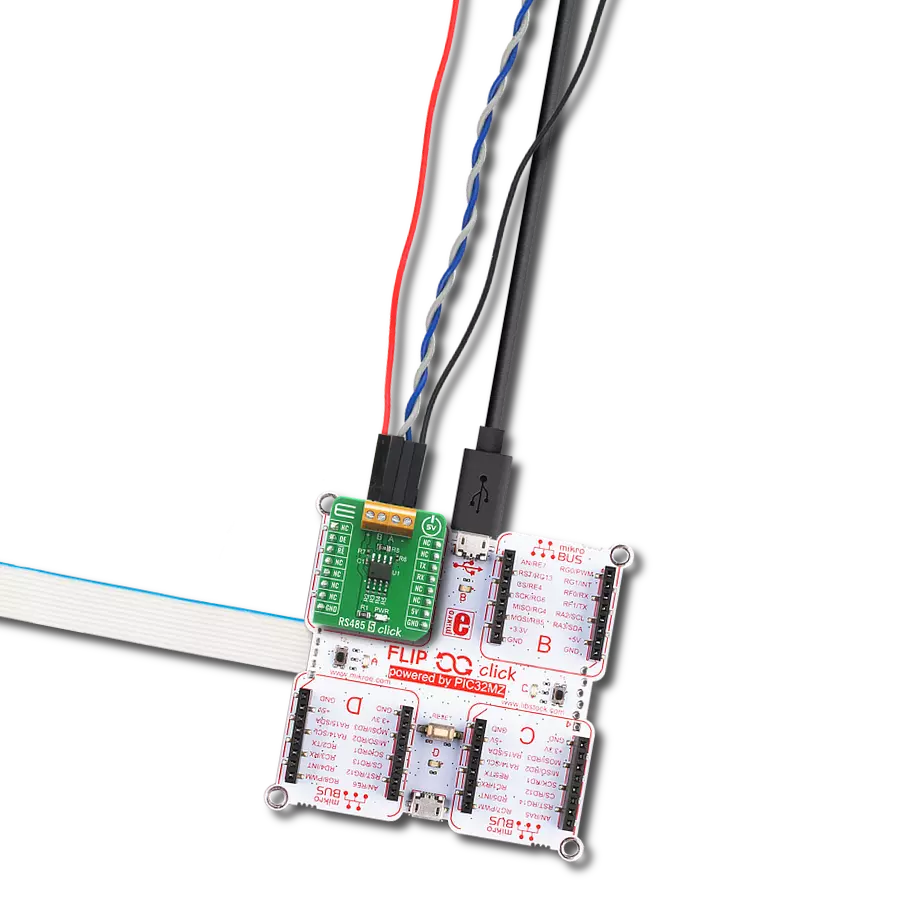

Development board

Clicker 2 for Kinetis is a compact starter development board that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit ARM Cortex-M4F microcontroller, the MK64FN1M0VDC12 from NXP Semiconductors, two mikroBUS™ sockets for Click board™ connectivity, a USB connector, LED indicators, buttons, a JTAG programmer connector, and two 26-pin headers for interfacing with external electronics. Its compact design with clear and easily recognizable silkscreen markings allows you to build gadgets with unique functionalities and

features quickly. Each part of the Clicker 2 for Kinetis development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the Clicker 2 for Kinetis programming method, using a USB HID mikroBootloader or an external mikroProg connector for Kinetis programmer, the Clicker 2 board also includes a clean and regulated power supply module for the development kit. It provides two ways of board-powering; through the USB Micro-B cable, where onboard voltage regulators provide the appropriate voltage levels to each component on the board, or

using a Li-Polymer battery via an onboard battery connector. All communication methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, reset button, and several user-configurable buttons and LED indicators. Clicker 2 for Kinetis is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

NXP

Pin count

121

RAM (Bytes)

262144

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

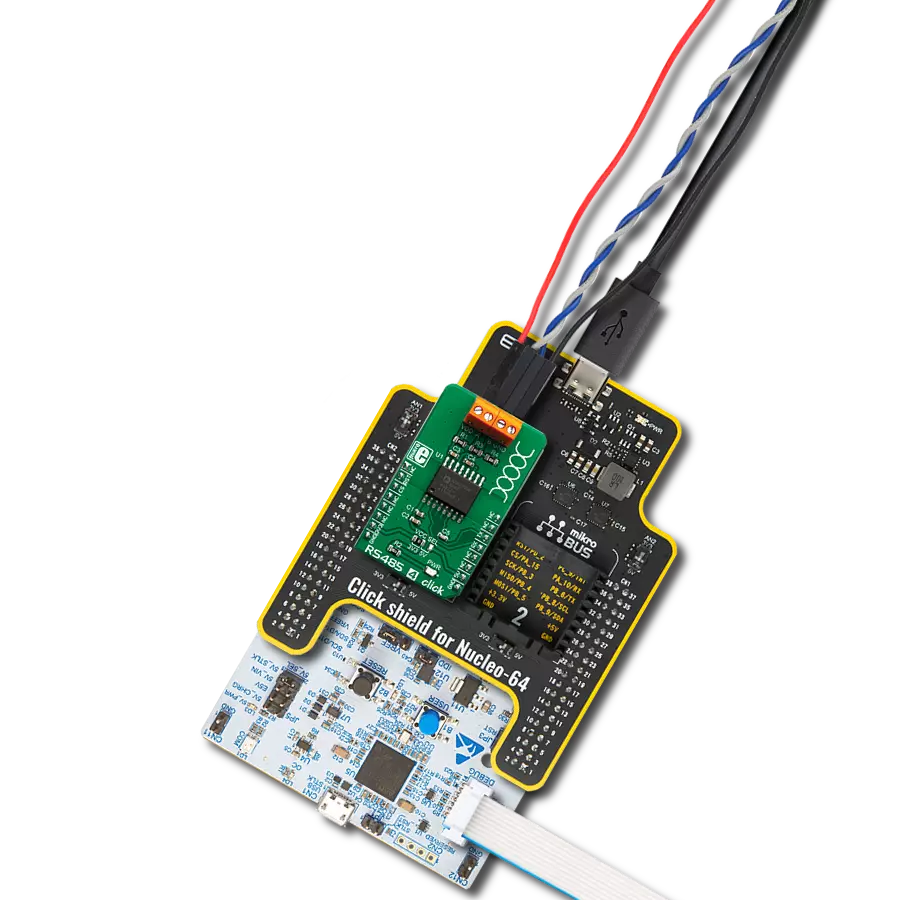

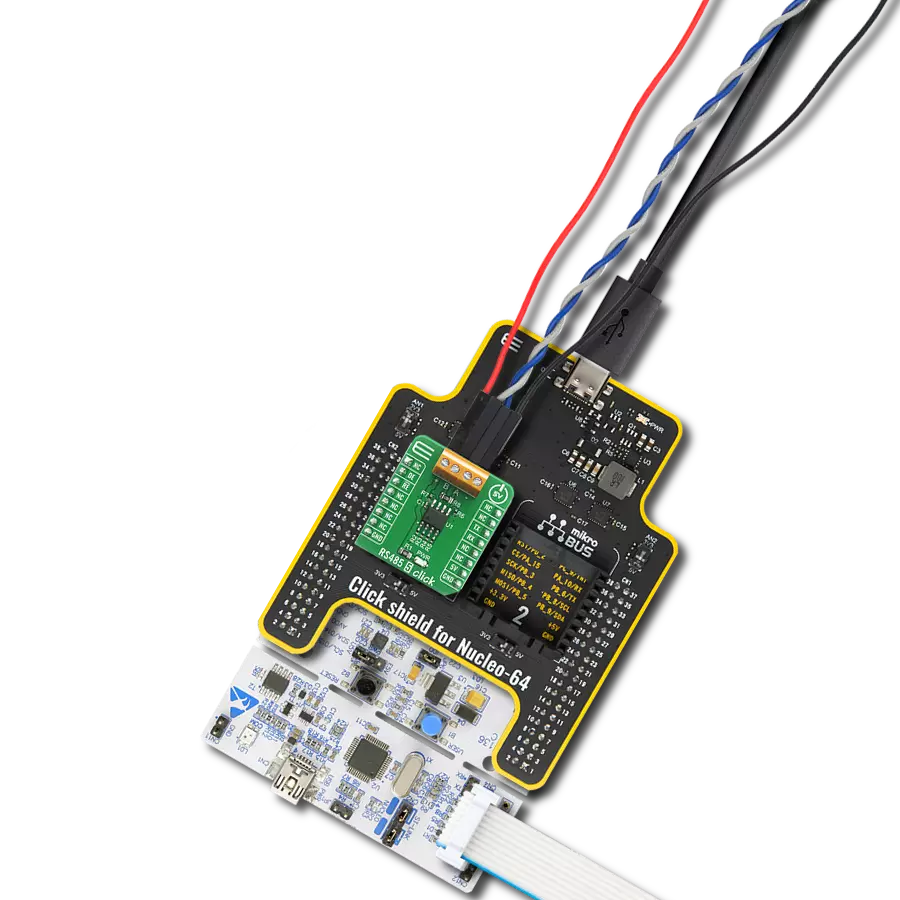

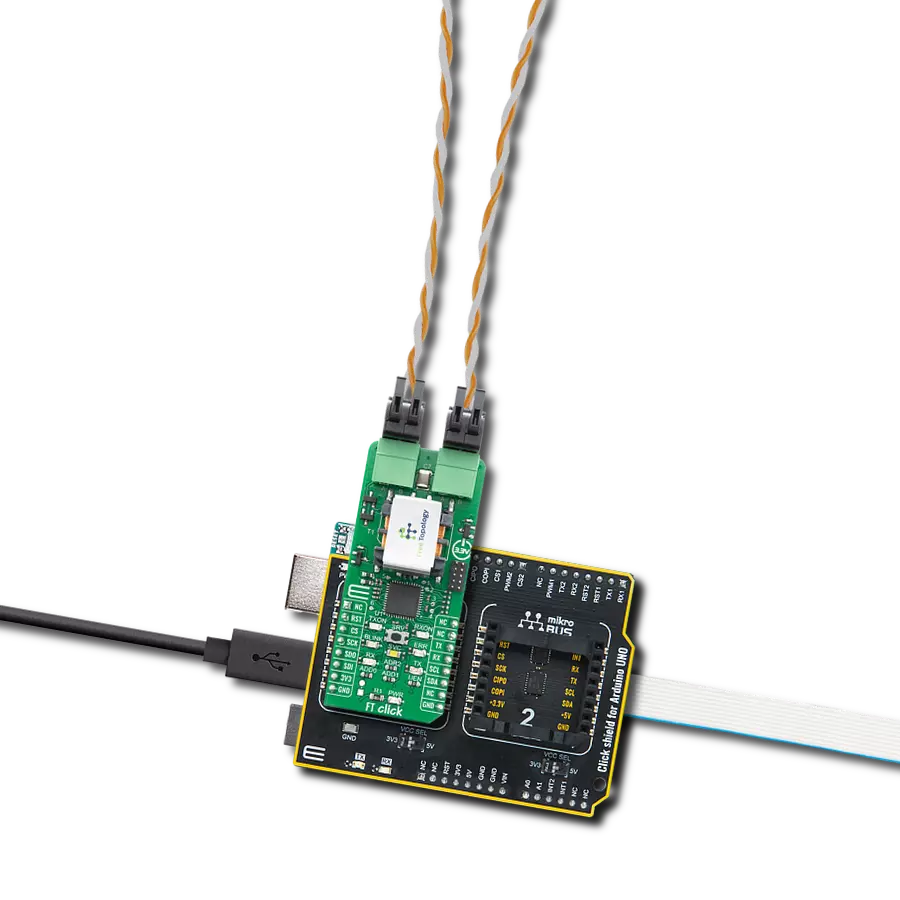

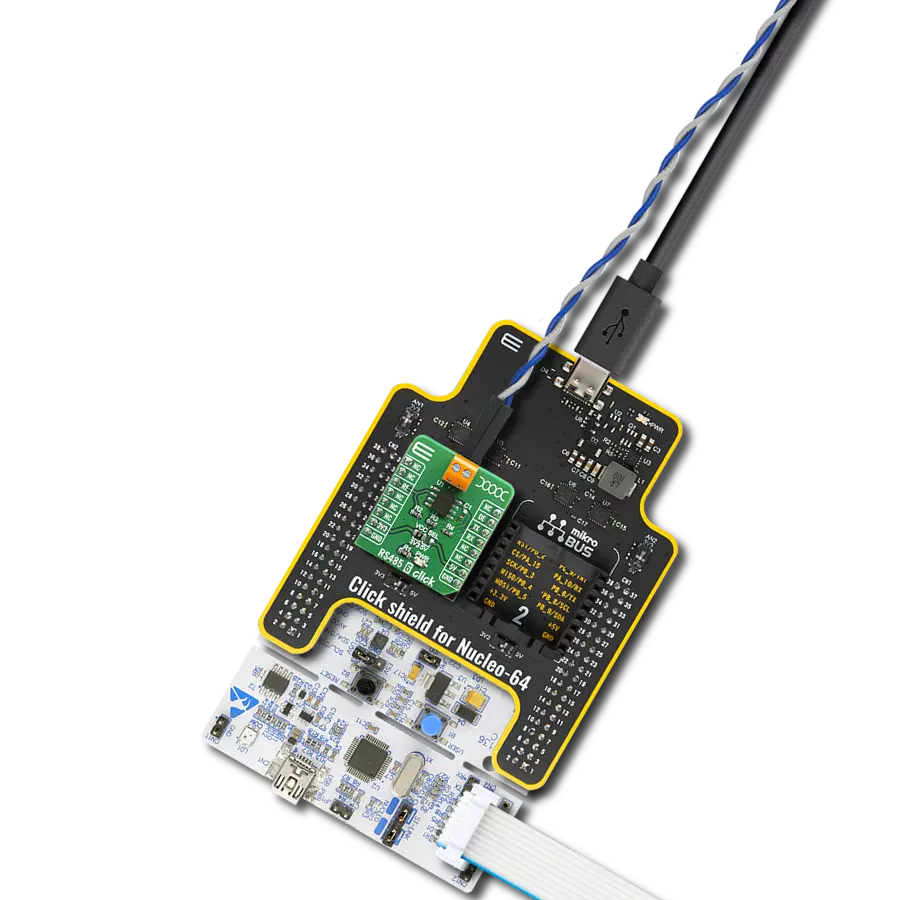

Project assembly

Software Support

Library Description

This library contains API for RS485 2 Click driver.

Key functions:

rs4852_generic_read- Generic read function.rs4852_generic_write- Generic write function.rs4852_set_de_pin- Set DE ( cs ) pin state.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Rs4852 Click example

*

* # Description

* This example reads and processes data from RS485 2 Clicks.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and enables the selected mode.

*

* ## Application Task

* Depending on the selected mode, it reads all the received data or sends the desired message

* every 2 seconds.

*

* ## Additional Function

* - rs4852_process ( ) - The general process of collecting the received data.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "rs4852.h"

#include "string.h"

#define PROCESS_RX_BUFFER_SIZE 500

#define TEXT_TO_SEND "MikroE - RS485 2 Click board\r\n"

// #define DEMO_APP_RECEIVER

#define DEMO_APP_TRANSMITTER

// ------------------------------------------------------------------ VARIABLES

static rs4852_t rs4852;

static log_t logger;

// ------------------------------------------------------- ADDITIONAL FUNCTIONS

static void rs4852_process ( void )

{

int32_t rsp_size;

char uart_rx_buffer[ PROCESS_RX_BUFFER_SIZE ] = { 0 };

uint8_t check_buf_cnt;

rsp_size = rs4852_generic_read( &rs4852, uart_rx_buffer, PROCESS_RX_BUFFER_SIZE );

if ( rsp_size > 0 )

{

for ( uint8_t cnt = 0; cnt < rsp_size; cnt++ )

{

log_printf( &logger, "%c", uart_rx_buffer[ cnt ] );

if ( uart_rx_buffer[ cnt ] == '\n' )

{

log_printf( &logger, "--------------------------------\r\n" );

}

}

}

}

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

rs4852_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

rs4852_cfg_setup( &cfg );

RS4852_MAP_MIKROBUS( cfg, MIKROBUS_1 );

rs4852_init( &rs4852, &cfg );

Delay_ms ( 100 );

#ifdef DEMO_APP_RECEIVER

rs4852_set_re_pin( &rs4852, RS4852_ENABLE_RE );

rs4852_set_de_pin( &rs4852, RS4852_DISABLE_DE );

log_info( &logger, "---- Receiver mode ----" );

#endif

#ifdef DEMO_APP_TRANSMITTER

rs4852_set_de_pin( &rs4852, RS4852_ENABLE_DE );

rs4852_set_re_pin( &rs4852, RS4852_DISABLE_RE );

log_info( &logger, "---- Transmitter mode ----" );

#endif

Delay_ms ( 100 );

}

void application_task ( void )

{

#ifdef DEMO_APP_RECEIVER

rs4852_process( );

#endif

#ifdef DEMO_APP_TRANSMITTER

rs4852_generic_write( &rs4852, TEXT_TO_SEND, strlen( TEXT_TO_SEND ) );

log_info( &logger, "---- Data sent ----" );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

#endif

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END