Say goodbye to low battery anxiety with our reliable charging solution

A

A

Hardware Overview

How does it work?

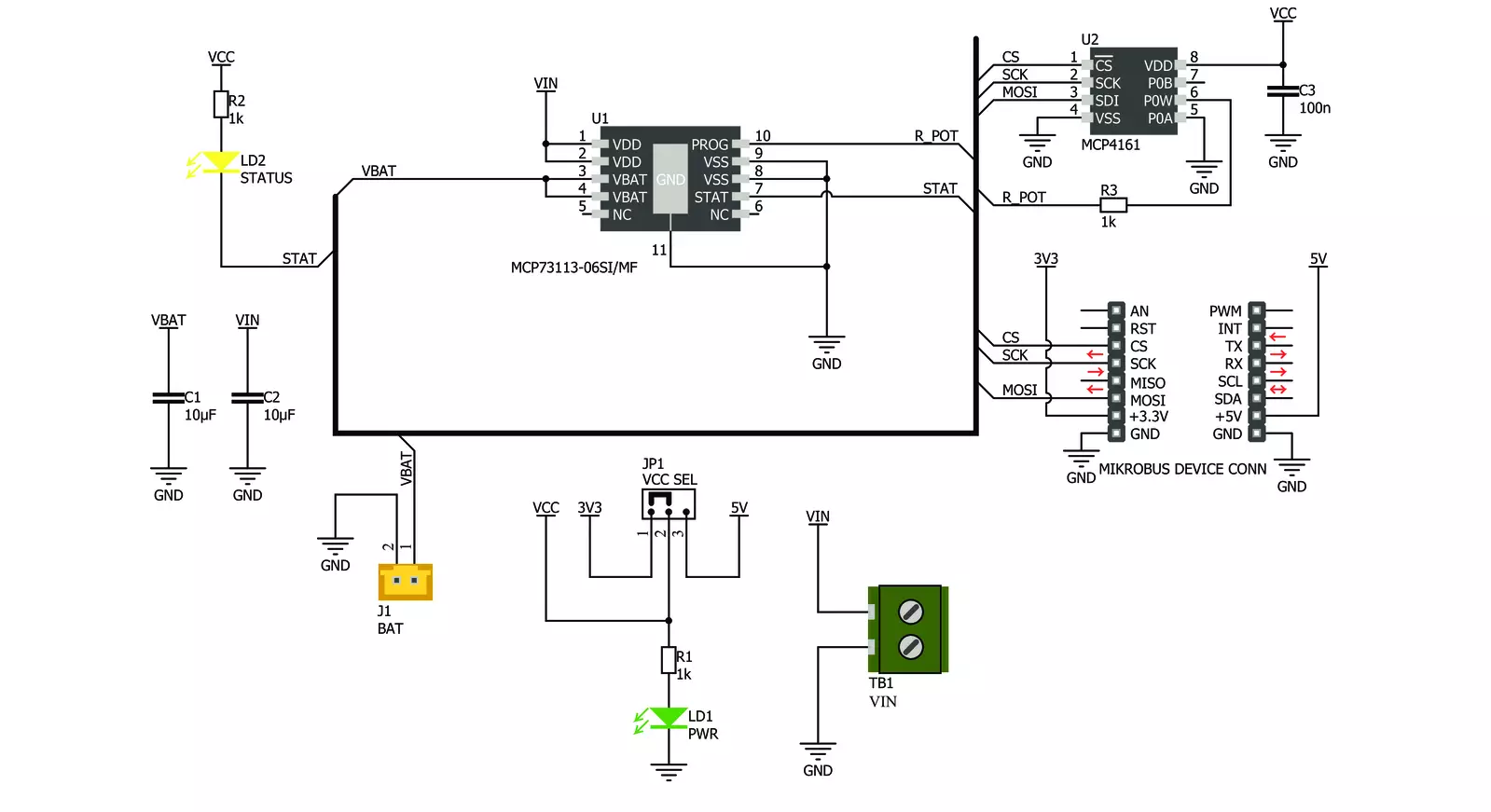

Charger 5 Click is based on the MCP73113, a single-cell Li-Po/Li-Ion battery charge from Microchip, along with the digital potentiometer chip labeled as MCP4161, from the same company. This click can easily and securely charge and fast-charge batteries on many devices that use 3.7V Li-Po/Li-Ion batteries. The constant charging current on the MCP73113 is set by a resistor connected between the PROG pin and the VCC; instead of using the conventional resistor, this board employs the MCP4161 digital potentiometer IC, which allows setting the constant charging current via the SPI interface. This way, the constant charging current can be set from 100mA to 950mA. The MCP73113 charger features several different battery charging protection and optimization schemes to keep the charging process safe and efficient. The undervoltage protection shuts the charger circuit down if the connected input voltage is below the threshold value.

The overvoltage protection will also put the device in shutdown mode if the input voltage exceeds the threshold value. Also, the connected input voltage should be 150mV greater than the battery voltage, or else it will remain in a power-down state. This prevents the battery from draining in case there's no input voltage. Therefore, the input voltage range should stay between 5V and 6.5V. The device is resistant to voltage spikes up to 18V on its input connector, but for proper operation, the input voltage should stay in the recommended voltage range. The connected battery voltage is constantly monitored. If it drops below the charging threshold and if all the other input voltage charging conditions are met, the charging process will start. When the battery is charged to the factory-set threshold, the charging will be stopped to prevent battery overcharging. The charging threshold for the MCP73113 charger IC used on this click is set to 4.2V.

If a Li-Ion battery is discharged below 3V, it must be pre-charged with around 10% of the full charge current. This means that the charging current, in this case, will be 10% of the fast charging current set by the MCP4161 digital potentiometer. Charger 5 click detects a short circuit on the battery connector. The short circuit is also reported in case of a faulty battery cell. If such an event occurs, the charger will enter the shutdown mode. The MCP73113 charger IC features thermal management too, which regulates the charging current, based on the die temperature. If the IC die is heated over 150°C, the device will be shut down. The onboard SMD jumper selector selects voltage for the digital potentiometer IC and SPI logic levels. There are also two onboard connectors. One connector is a screw terminal used to connect the external power supply (5V to 6.5V). The other connector is the Li-Po/Li-Ion battery 2.54mm header connector.

Features overview

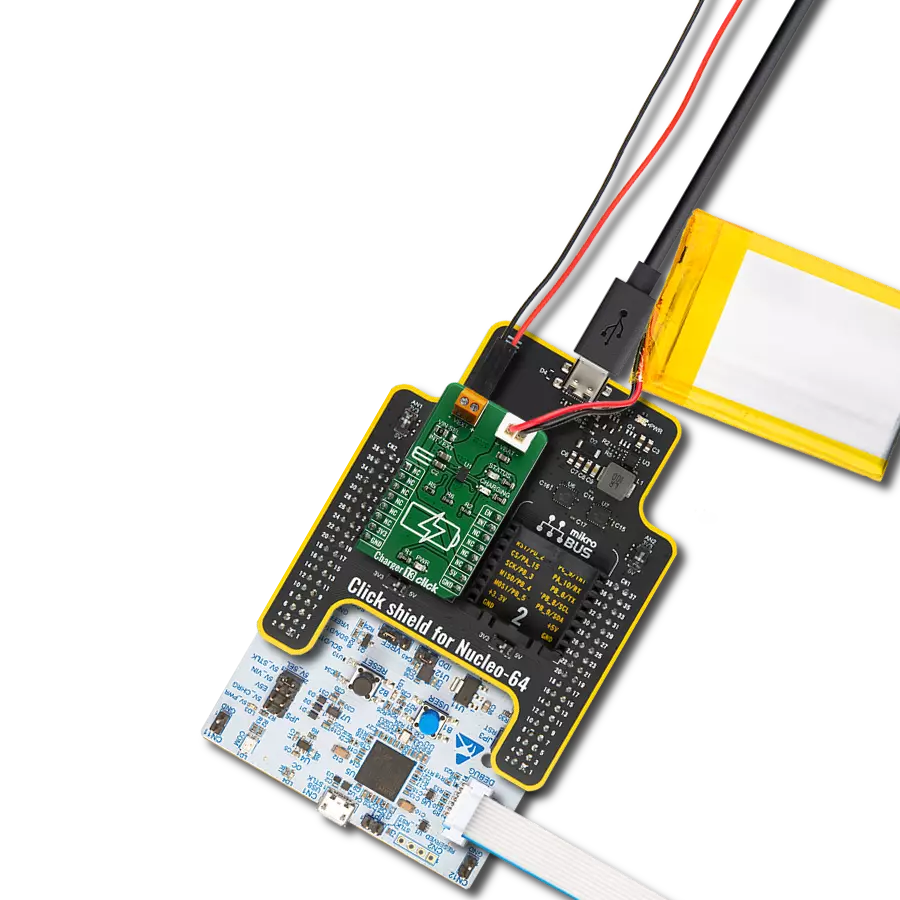

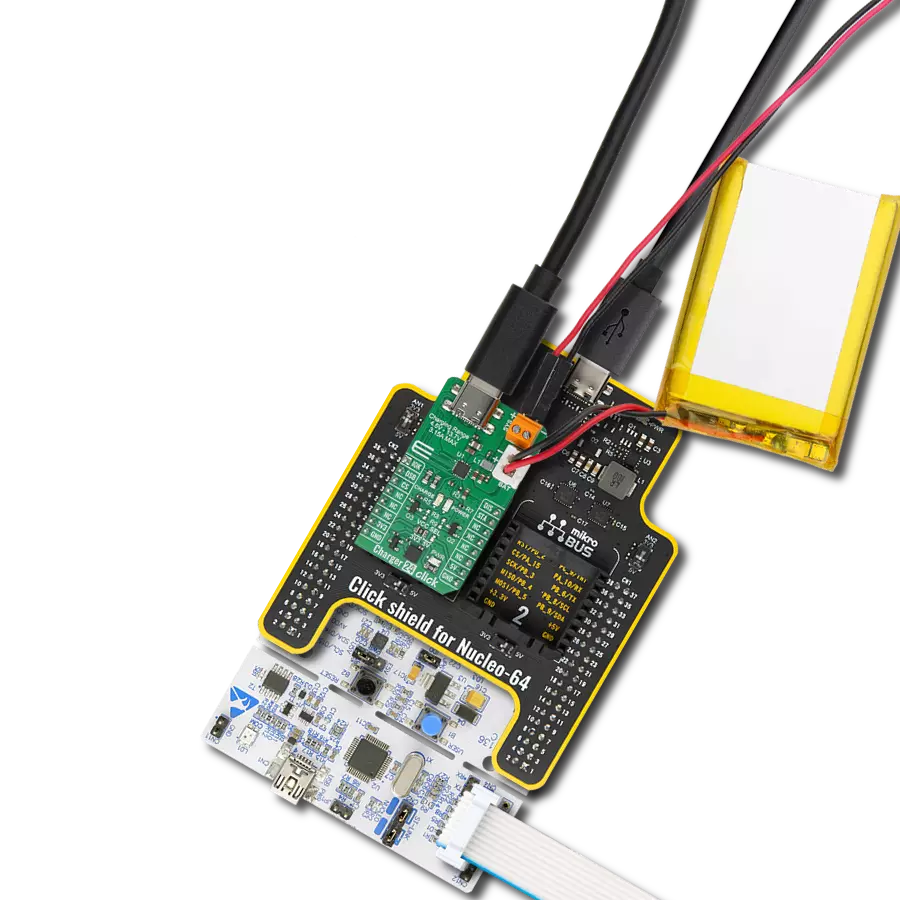

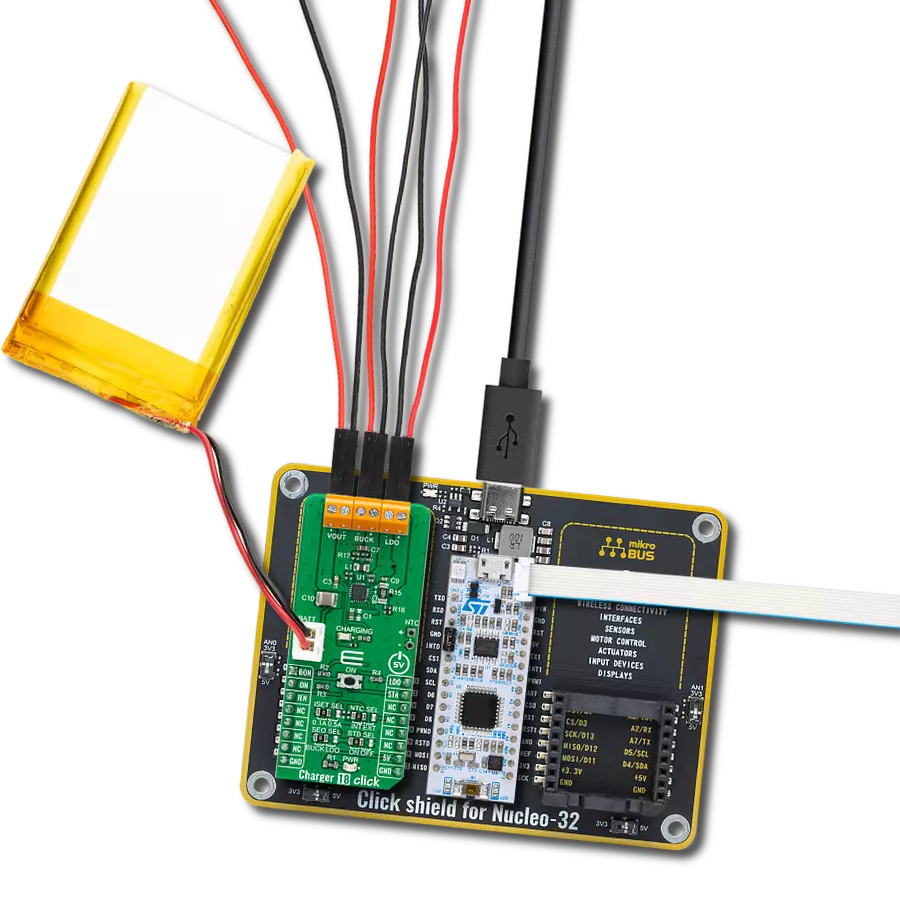

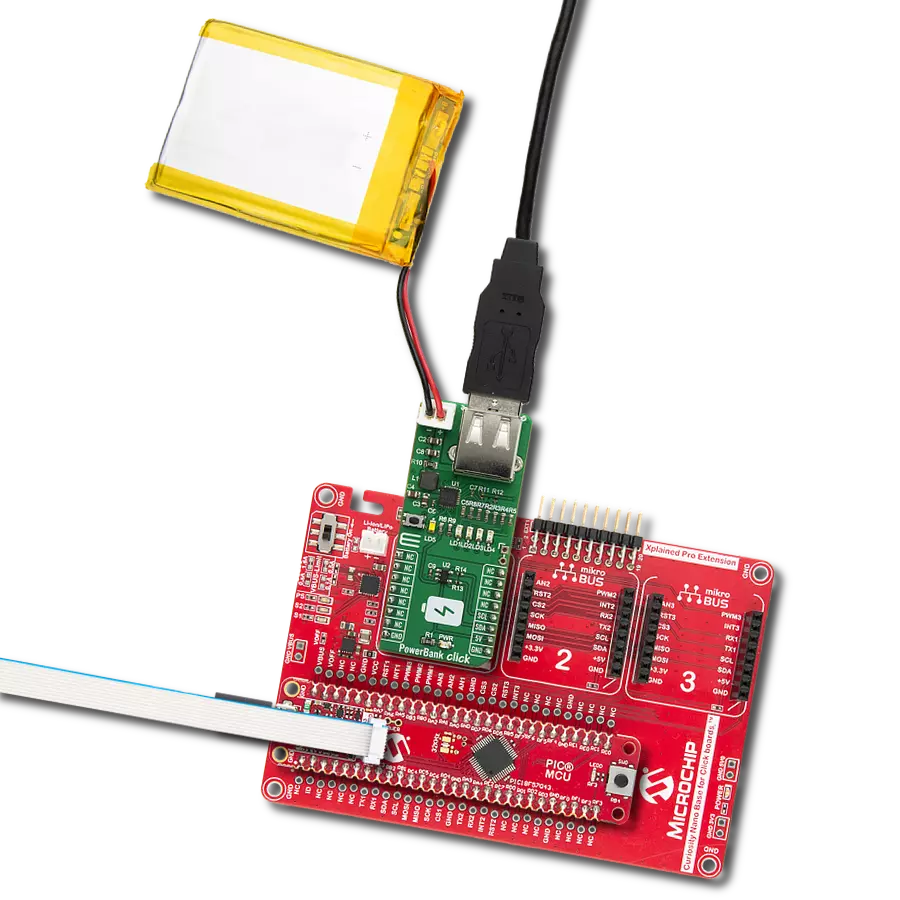

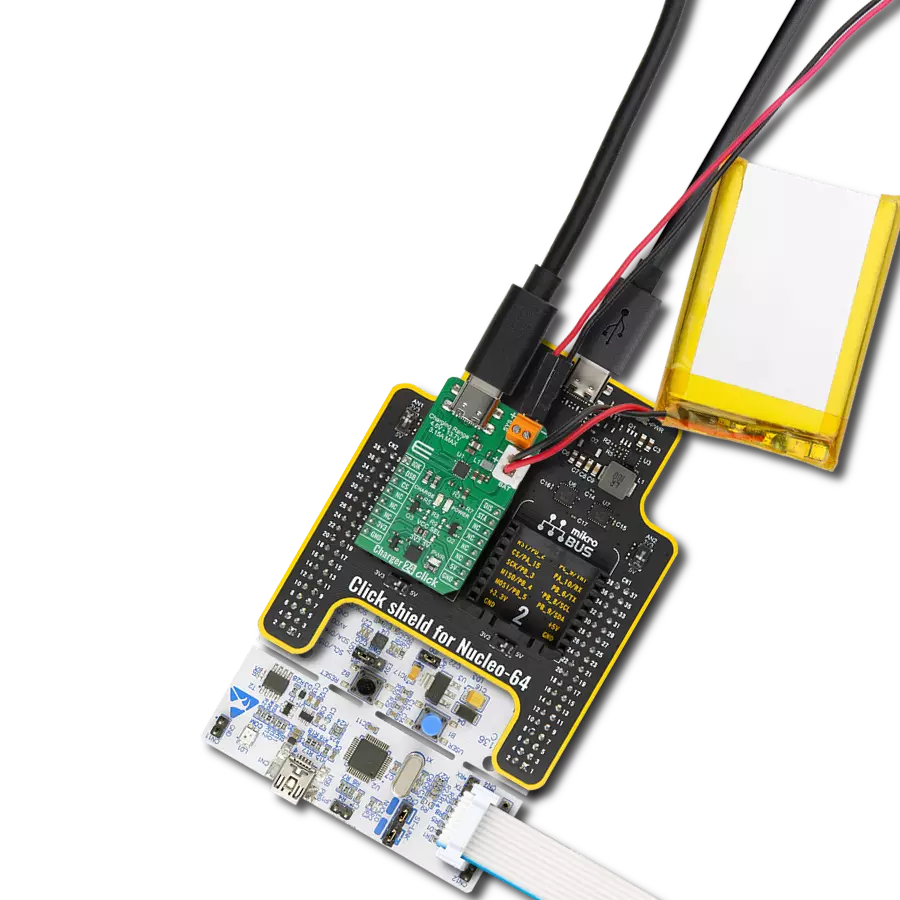

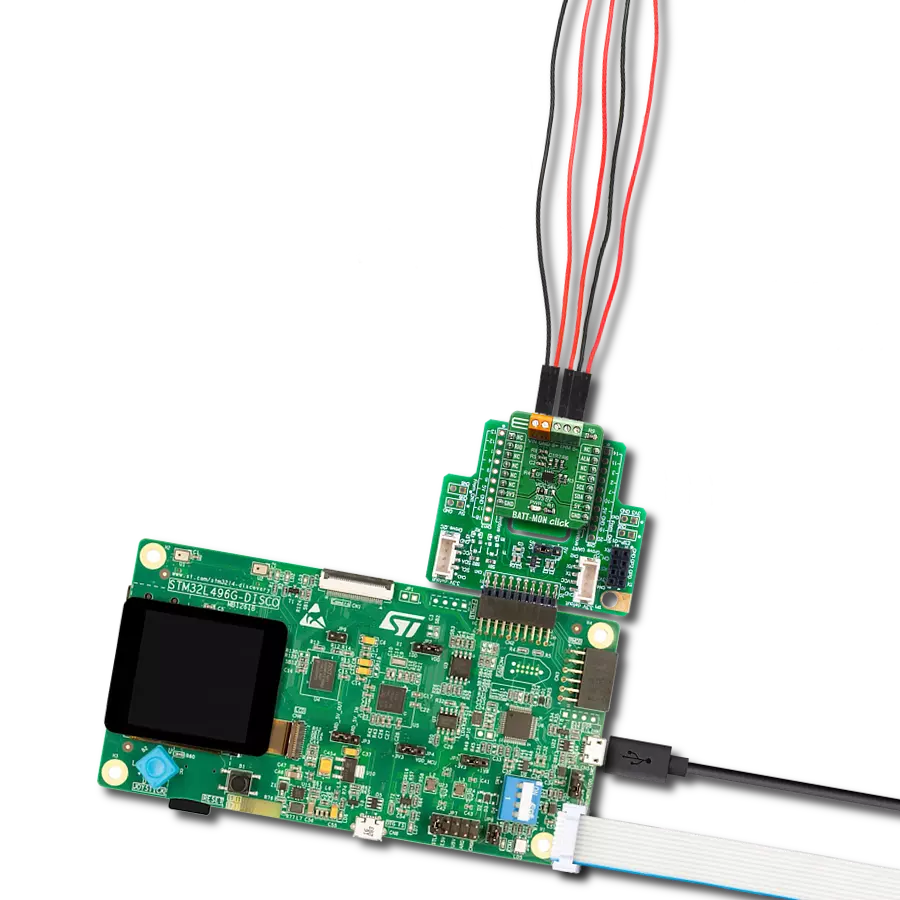

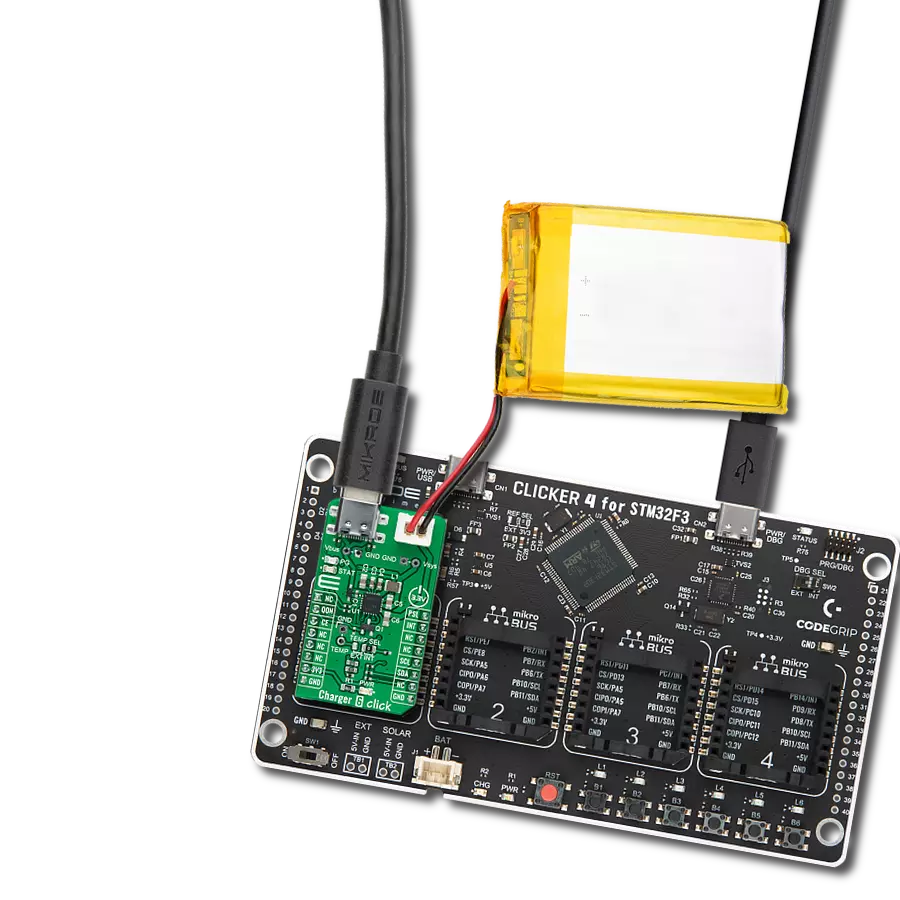

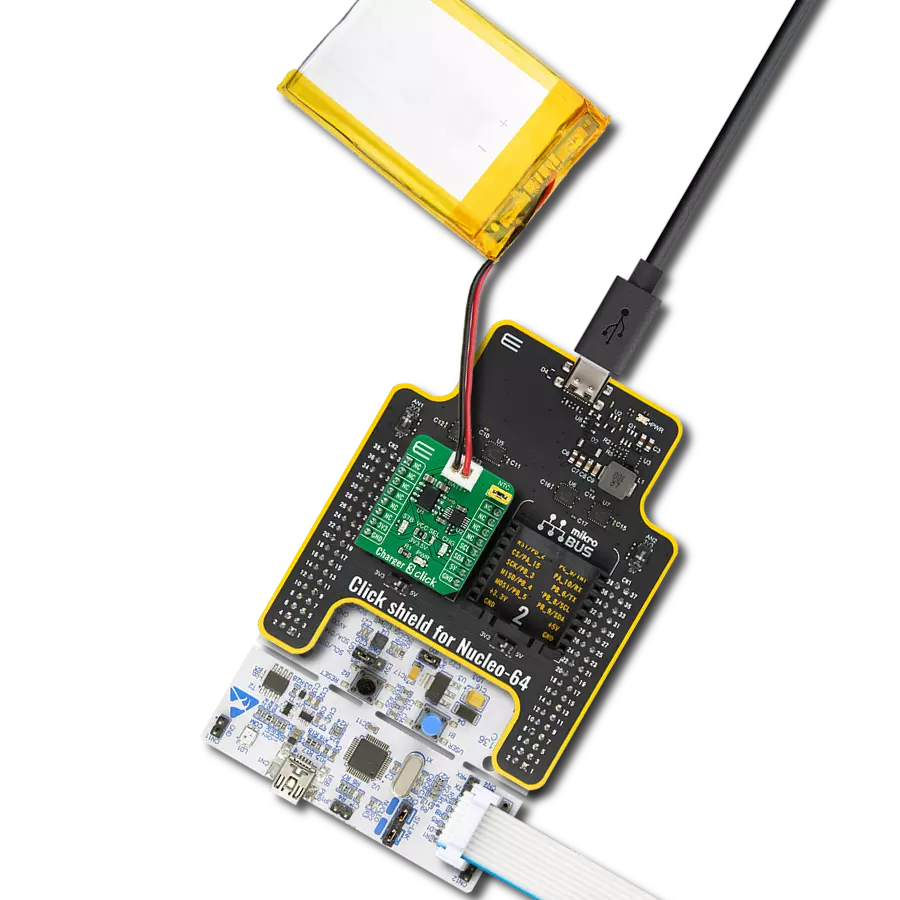

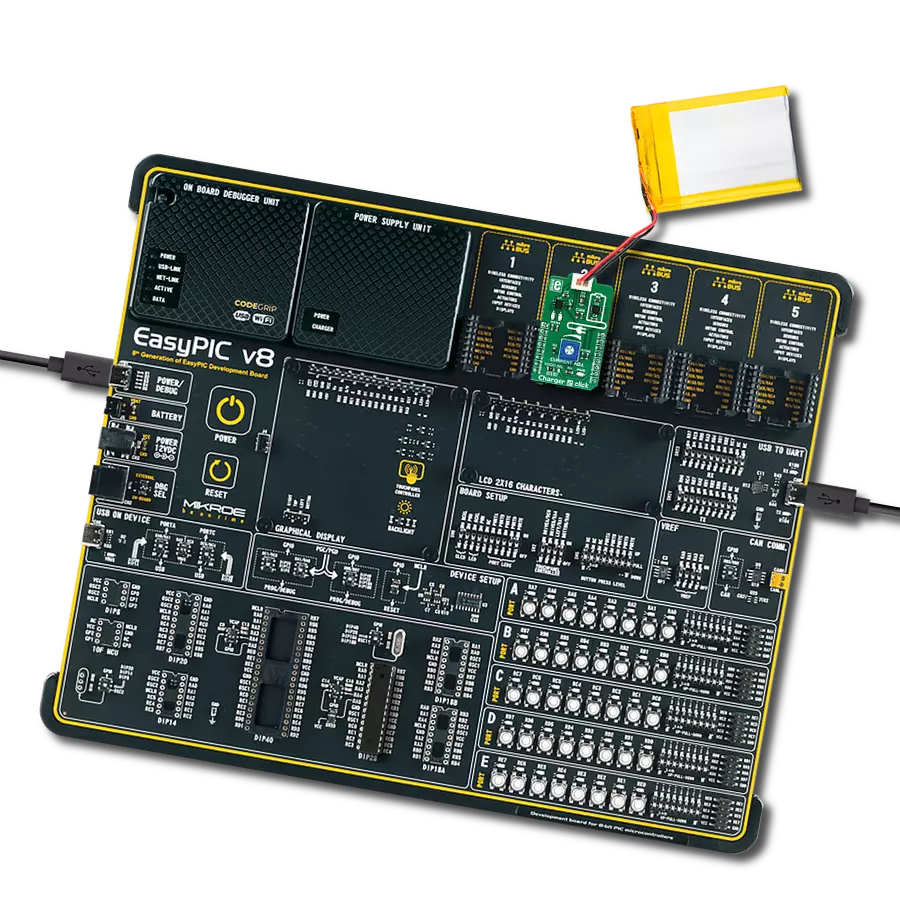

Development board

Clicker 2 for Kinetis is a compact starter development board that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit ARM Cortex-M4F microcontroller, the MK64FN1M0VDC12 from NXP Semiconductors, two mikroBUS™ sockets for Click board™ connectivity, a USB connector, LED indicators, buttons, a JTAG programmer connector, and two 26-pin headers for interfacing with external electronics. Its compact design with clear and easily recognizable silkscreen markings allows you to build gadgets with unique functionalities and

features quickly. Each part of the Clicker 2 for Kinetis development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the Clicker 2 for Kinetis programming method, using a USB HID mikroBootloader or an external mikroProg connector for Kinetis programmer, the Clicker 2 board also includes a clean and regulated power supply module for the development kit. It provides two ways of board-powering; through the USB Micro-B cable, where onboard voltage regulators provide the appropriate voltage levels to each component on the board, or

using a Li-Polymer battery via an onboard battery connector. All communication methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, reset button, and several user-configurable buttons and LED indicators. Clicker 2 for Kinetis is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

NXP

Pin count

121

RAM (Bytes)

262144

You complete me!

Accessories

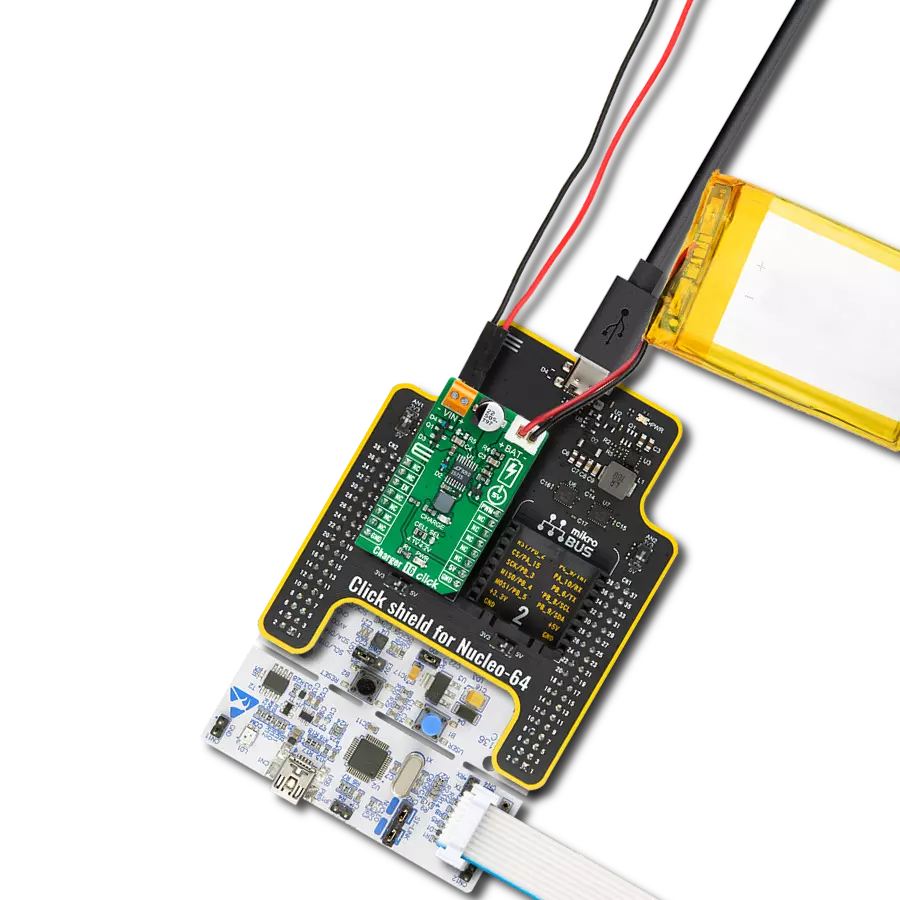

Li-Polymer Battery is the ideal solution for devices that demand a dependable and long-lasting power supply while emphasizing mobility. Its compatibility with mikromedia boards ensures easy integration without additional modifications. With a voltage output of 3.7V, the battery meets the standard requirements of many electronic devices. Additionally, boasting a capacity of 2000mAh, it can store a substantial amount of energy, providing sustained power for extended periods. This feature minimizes the need for frequent recharging or replacement. Overall, the Li-Polymer Battery is a reliable and autonomous power source, ideally suited for devices requiring a stable and enduring energy solution. You can find a more extensive choice of Li-Polymer batteries in our offer.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Charger 5 Click driver.

Key functions:

charger5_generic_write- Generic write functioncharger5_generic_read-Generic read functioncharger5_increment_wiper- Increment wiper function

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file main.c

* \brief Charger 5 Click example

*

* # Description

* This example demonstrates the use of the Charger 5 Click board.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes peripherals and pins used for the Charger 5 Click and prepares

* the Charger 5 Click for properly working.

*

* ## Application Task

* Demonstrates the use of driver functions. It will set charging current to

* 500 mA, then will increment that value by 10 steps, and after that will

* decrement it by 5 steps.

*

* ## Note

* Increment/decrement command can only be issued to volatile memory locations.

*

* \author Nemanja Medakovic

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "charger5.h"

// ------------------------------------------------------------------ VARIABLES

static charger5_t charger5;

static log_t console;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init( void )

{

charger5_cfg_t charger5_cfg;

log_cfg_t console_cfg;

// Click initialization.

charger5_cfg_setup( &charger5_cfg );

CHARGER5_MAP_MIKROBUS( charger5_cfg, MIKROBUS_1 );

charger5_init( &charger5, &charger5_cfg );

charger5_default_cfg( &charger5 );

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( console_cfg );

log_init( &console, &console_cfg );

log_printf( &console, "*** Charger 5 initialization done ***\r\n" );

log_printf( &console, "***************************************\r\n" );

}

void application_task( void )

{

charger5_generic_write( &charger5, CHARGER5_REG_WIPER0_VOL,

CHARGER5_CURRENT_500MA );

log_printf( &console, "Output current is set to 500 mA.\r\n" );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

charger5_increment_wiper( &charger5, CHARGER5_REG_WIPER0_VOL,

CHARGER5_STEPS_10 );

log_printf( &console, "Output current value is incremented by 10 steps.\r\n" );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

charger5_decrement_wiper( &charger5, CHARGER5_REG_WIPER0_VOL,

CHARGER5_STEPS_5 );

log_printf( &console, "Output current value is decremented by 5 steps.\r\n" );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Battery charger