Enhance logistics and automation processes by monitoring and optimizing the movement of goods, robots, and machinery, improving overall supply chain efficiency

A

A

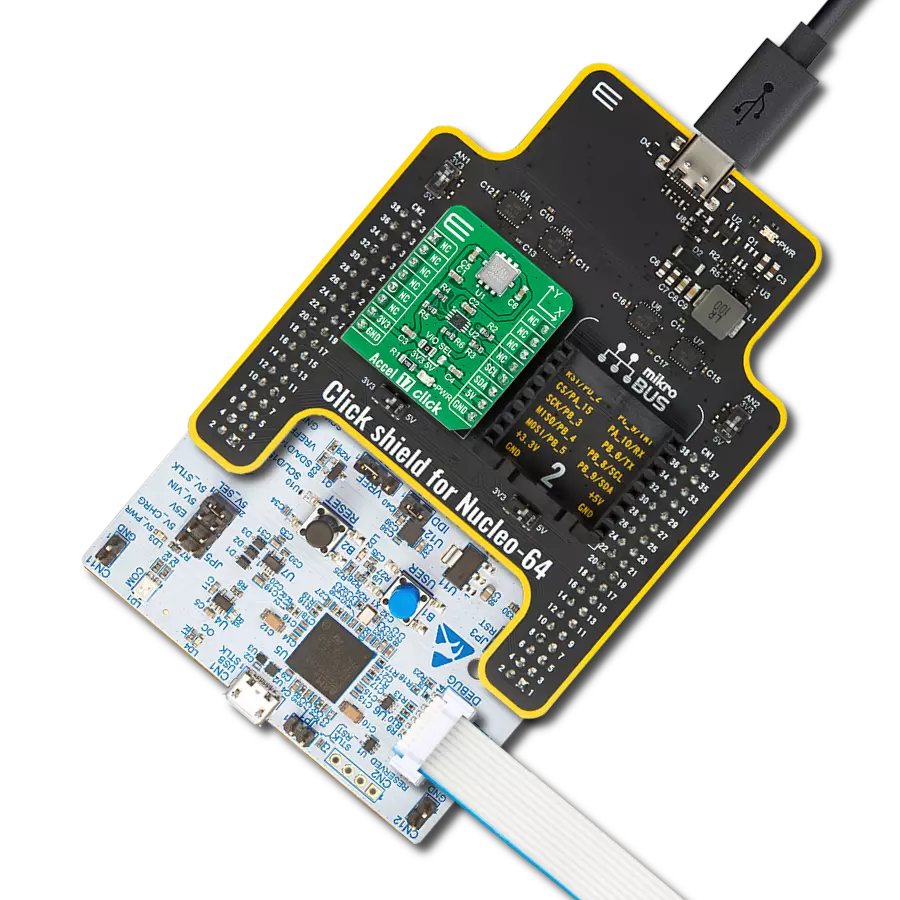

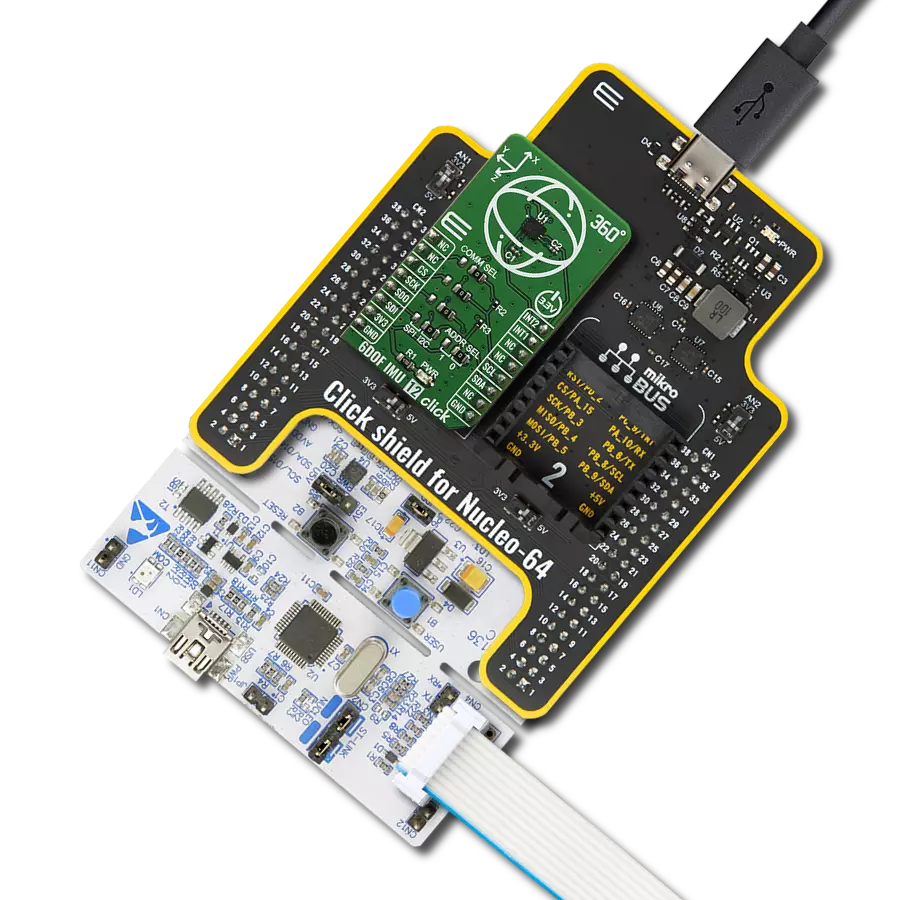

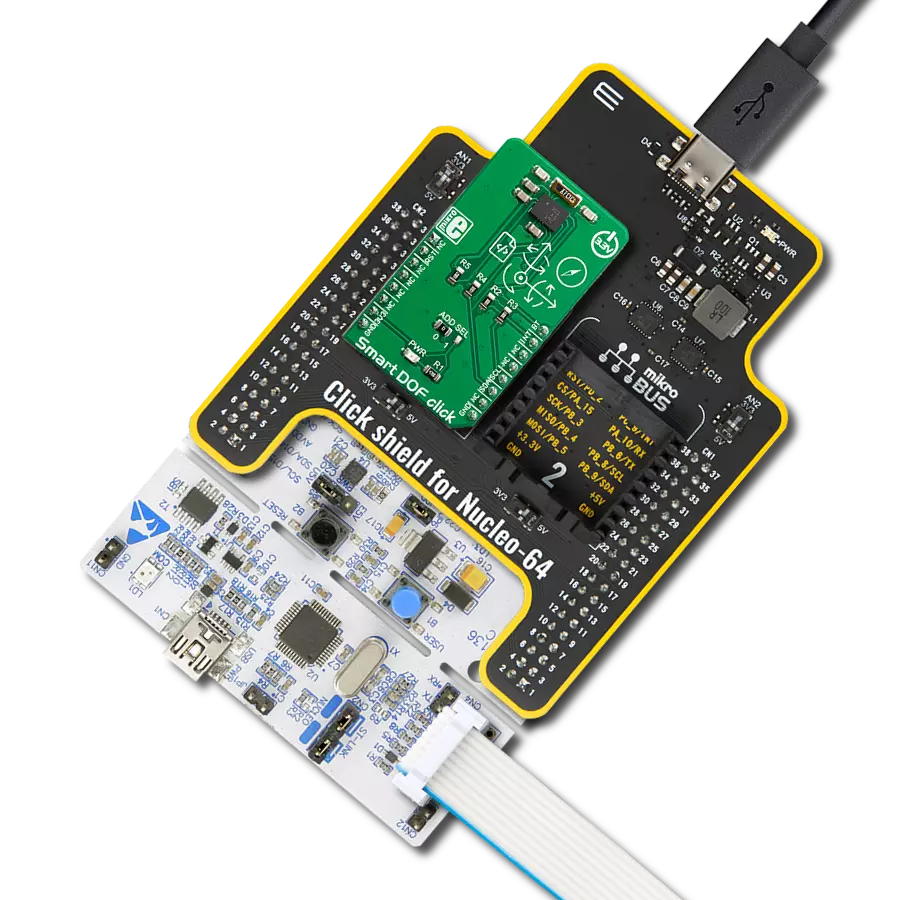

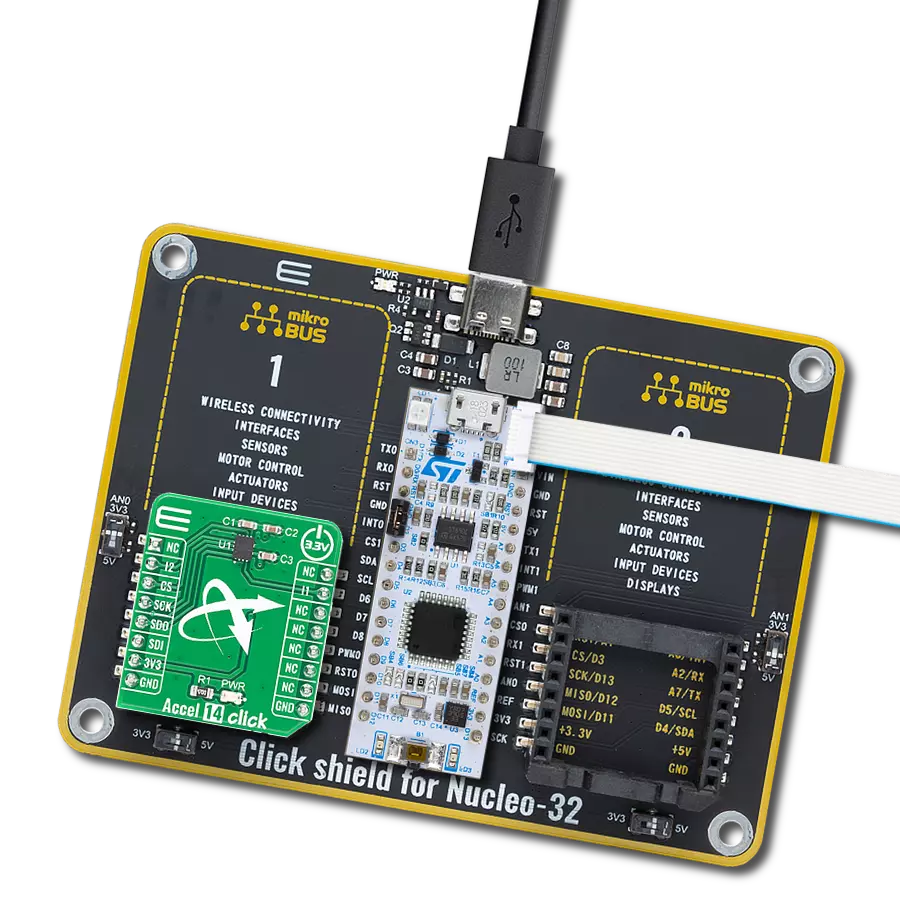

Hardware Overview

How does it work?

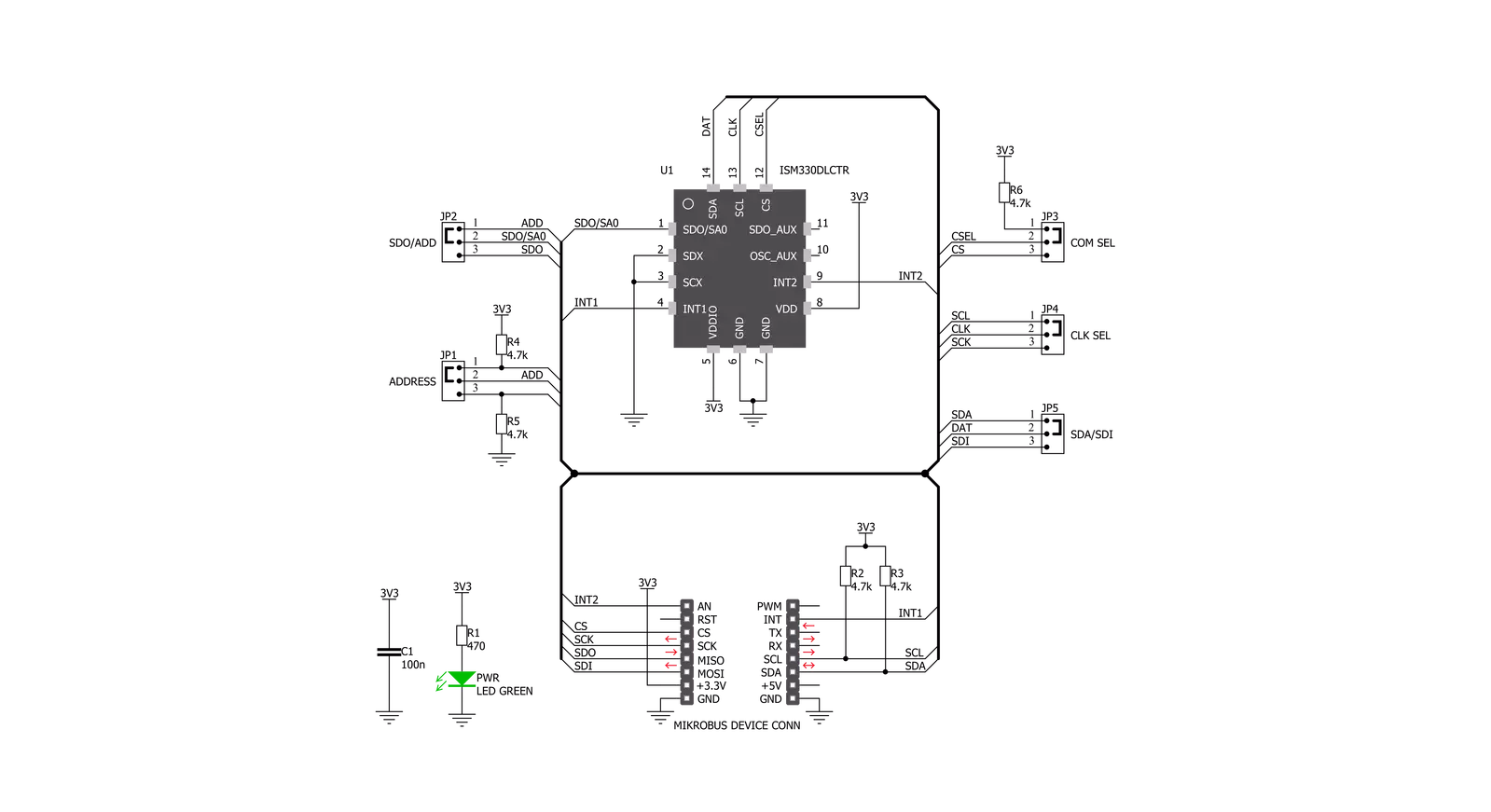

6DOF IMU 8 Click is based on the ISM330DLC, a 3D accelerometer and 3D gyroscope with digital output for industrial applications from STMicroelectronics. It is an advanced inertial module from iNEMO series, featuring an integrated microelectromechanical gyroscope and an accelerometer sensor (MEMS) within the same package. This device is designed with Industry 4.0 in mind, and produced using well-proven CMOS and MEMS fabrication processes, providing a high integration scale on a wafer level. This allows for a very good matching between the IC and the MEMS, offering very good robustness, mechanical shock immunity, and improved stability. Three-axis gyroscope MEMS can be programmed to measure the rotation about each axis, in five different ranges of angular speed (degrees per angle, dps): ±125, ±250, ±500, ±1000, and ±2000. Three-axis accelerometer MEMS can be programmed to measure the acceleration along each axis, in four different acceleration ranges: ±2g, ±4g, ±8g, and ±16g. The developer can select an optimal range for both properties, depending on the application requirements. The ISM330DLC incorporates a

powerful programmable interrupt engine with two dedicated interrupt pins. The interrupt engine can detect many different events, including free-fall, wakeup, 6D orientation, tap, and double-tap events, activity and inactivity recognition, as well as a tilt detection with two configurable event detection options: an average window and an average threshold. The function of these two interrupt pins is not limited to these events. They can also be used for FIFO buffer-related events, such as a buffer is full, the buffer is empty, watermark level is reached, and the buffer is overrun. Data Ready event can also be signaled for each of the two sensors (gyro and accel). The INT 1 pin is routed to the mikroBUS™ INT pin, while the INT 2 pin is routed to the mikroBUS™ AN pin. These pins are labeled as IT1 and IT2 on the Click board™, respectively. A FIFO buffer helps to reduce the communication bus traffic, processing load, and the power consumption, offering temporary storage for the output data. The ISM330DLC features a smart FIFO buffer with the capacity of 4096 bytes, which can be set to work in five different modes. The FIFO buffer is highly

configurable. It is possible to select the data to be stored from several sources (gyroscope, accelerometer, timestamp, temperature…). As already discussed, the FIFO buffer itself can trigger interrupt for several events, alerting the host MCU about its status. 6DOF IMU 8 click supports both SPI and I2C communication interfaces, allowing it to be used with a wide range of different MCUs. The communication interface can be selected by moving SMD jumpers grouped under the COM SEL to an appropriate position (SPI or I2C). The slave I2C address can also be configured by an SMD jumper when the Click board™ is operated in the I2C mode an SMD jumper labeled as ADD LSB is used to set the least significant bit (LSB) of the I2C address. When set to 1, the 7-bit I2C slave address becomes 0b1101011x. If set to 0, the address becomes 0b1101010x. The last digit (x) is the R/W bit. This Click Board™ uses both I2C and SPI communication interfaces. It is designed to be operated only with up to 3.3V logic levels. Proper conversion of logic voltage levels should be applied, before the Click board™ is used with MCUs operated at 5V.

Features overview

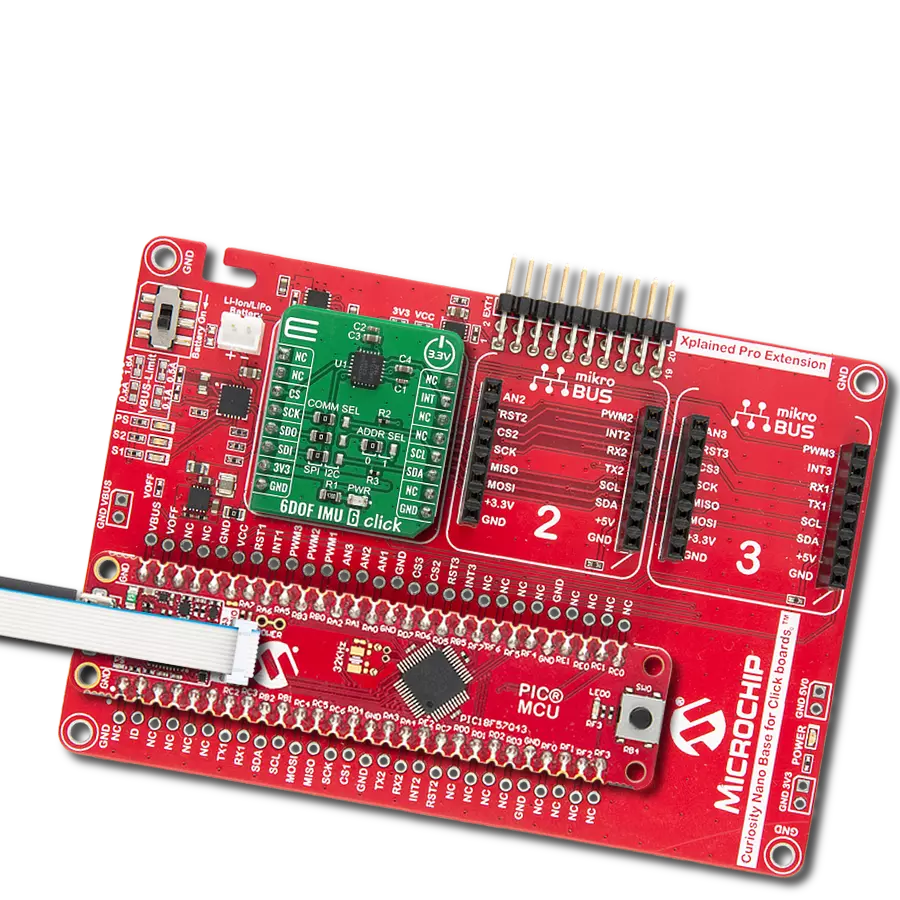

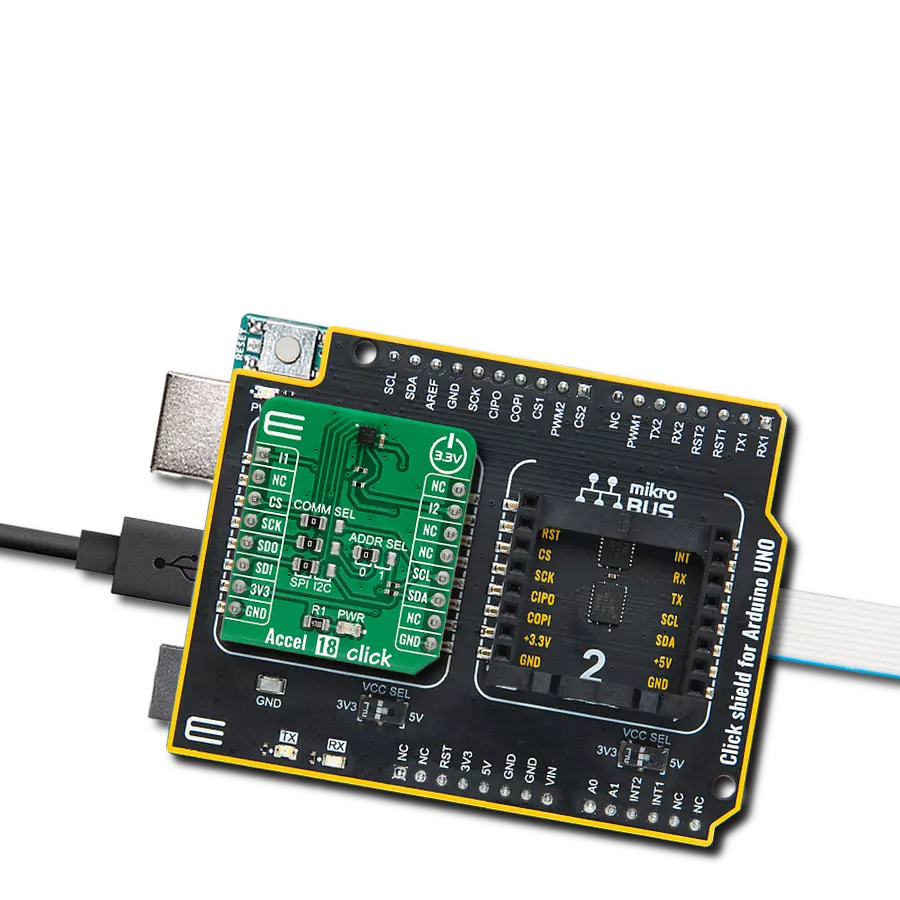

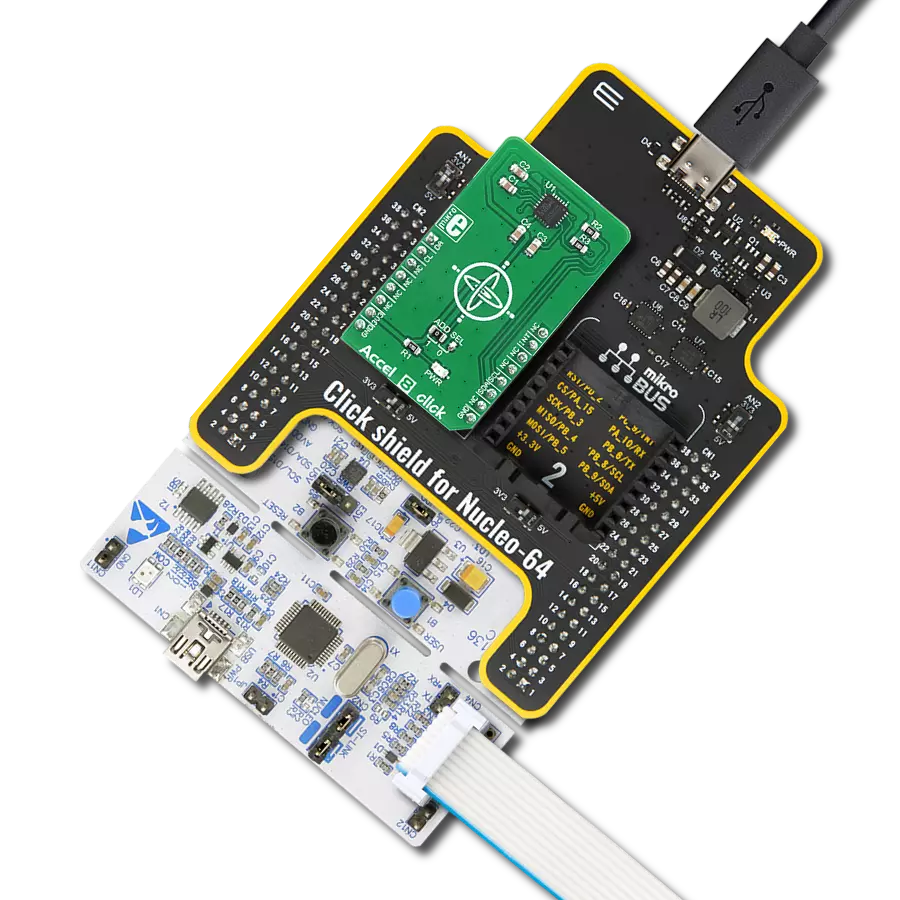

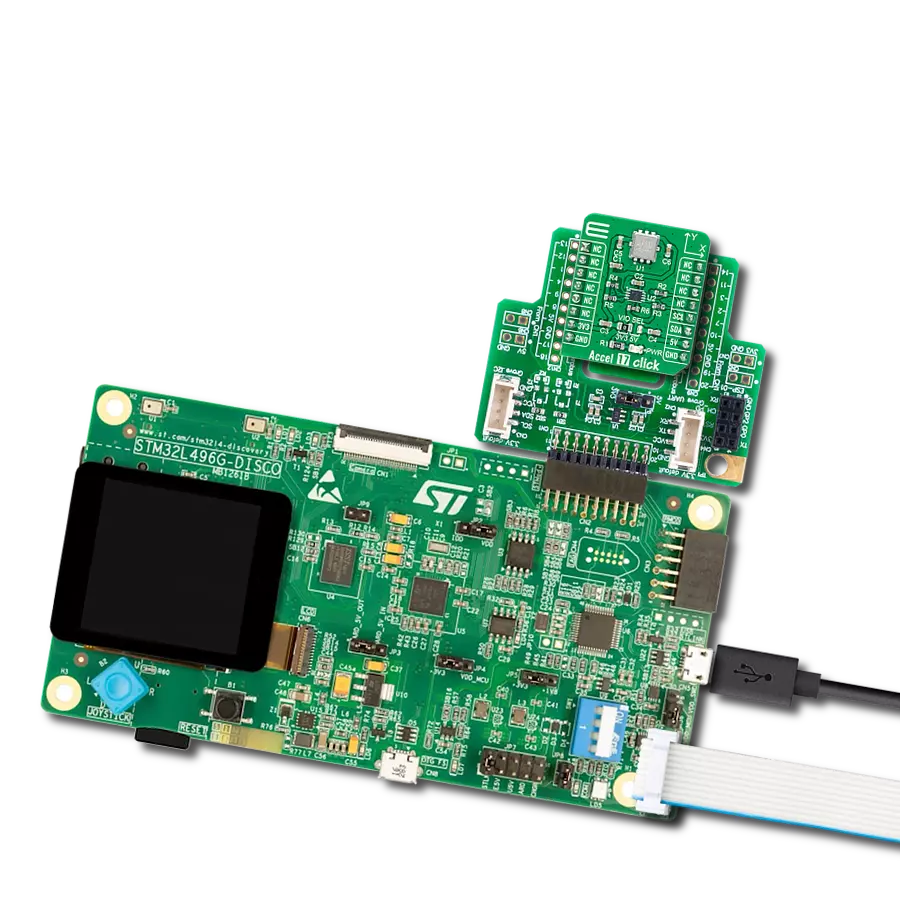

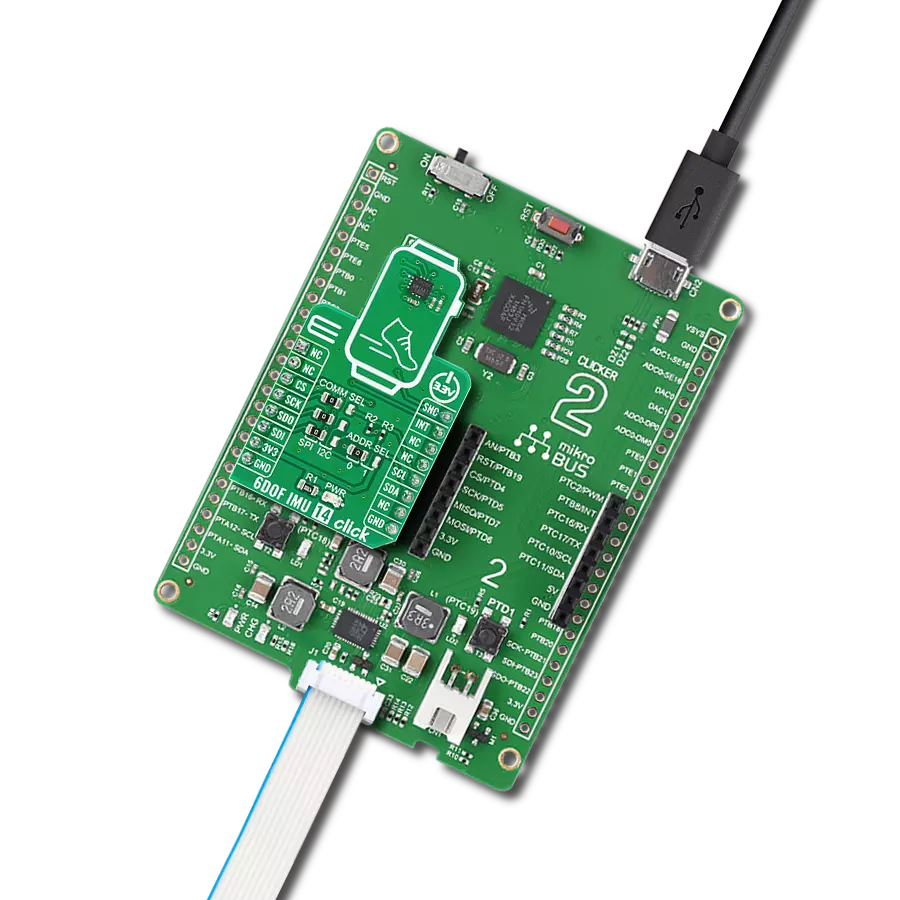

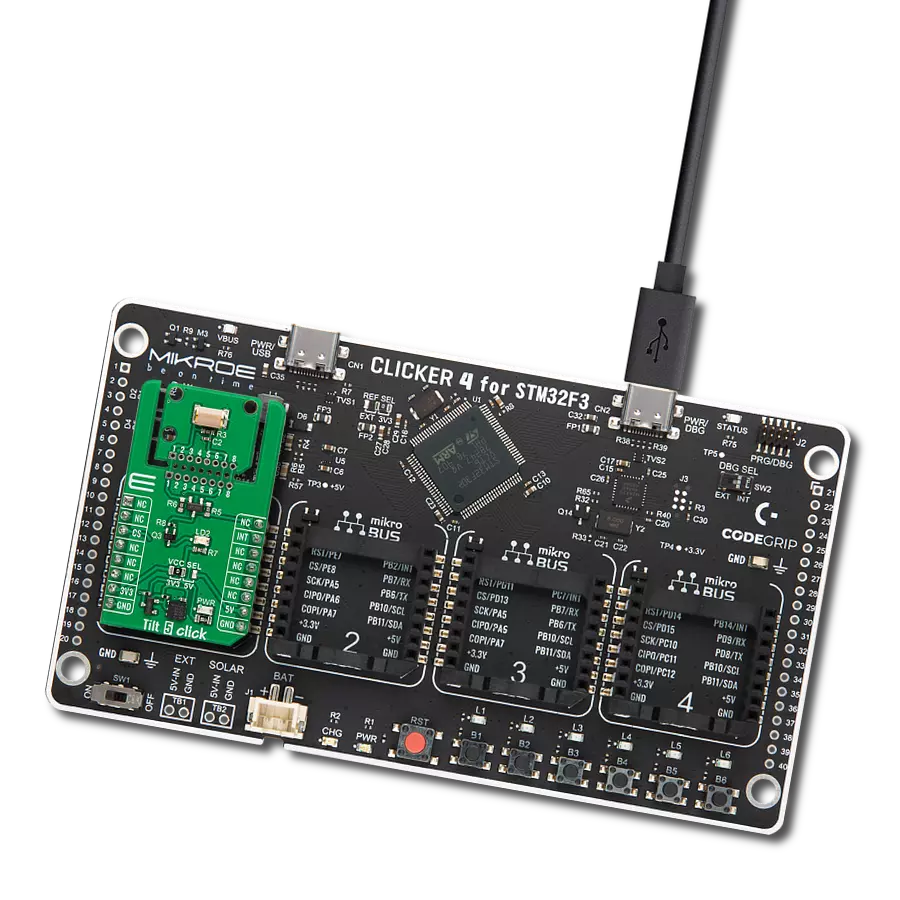

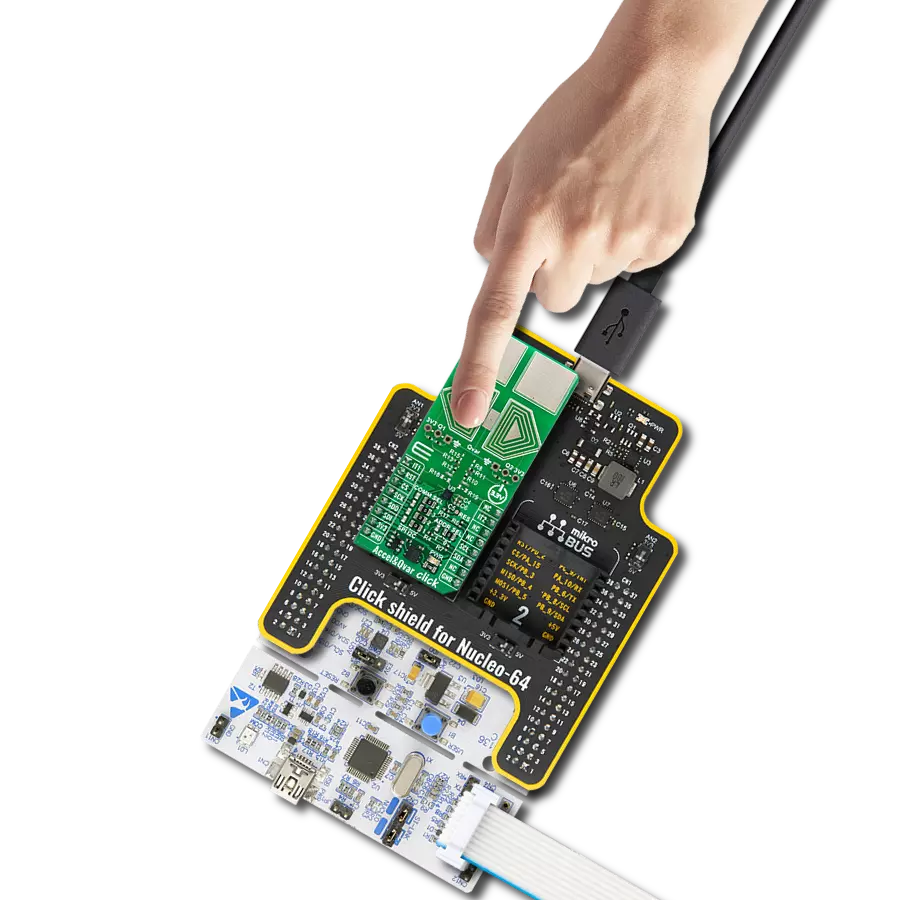

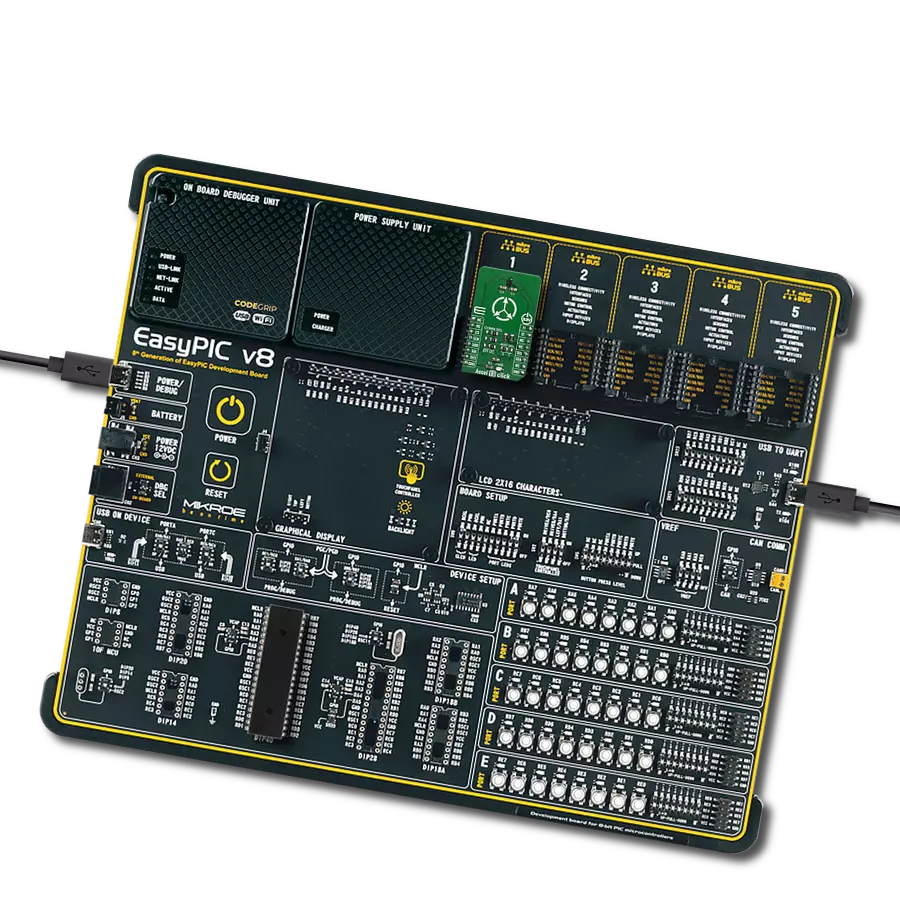

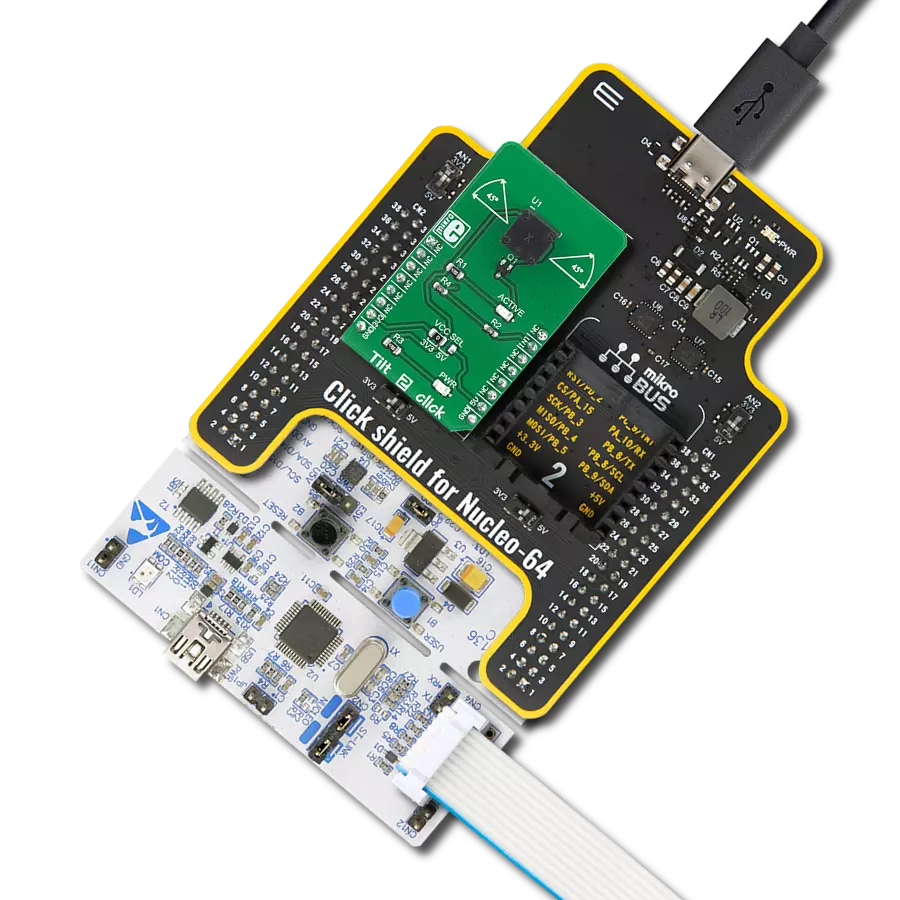

Development board

UNI Clicker is a compact development board designed as a complete solution that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It supports a wide range of microcontrollers, such as different ARM, PIC32, dsPIC, PIC, and AVR from various vendors like Microchip, ST, NXP, and TI (regardless of their number of pins), four mikroBUS™ sockets for Click board™ connectivity, a USB connector, LED indicators, buttons, a debugger/programmer connector, and two 26-pin headers for interfacing with external electronics. Thanks to innovative manufacturing technology, it allows you to build

gadgets with unique functionalities and features quickly. Each part of the UNI Clicker development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the UNI Clicker programming method, using a third-party programmer or CODEGRIP/mikroProg connected to onboard JTAG/SWD header, the UNI Clicker board also includes a clean and regulated power supply module for the development kit. It provides two ways of board-powering; through the USB Type-C (USB-C) connector, where onboard voltage regulators provide the appropriate voltage levels to each component on the board, or using a Li-Po/Li

Ion battery via an onboard battery connector. All communication methods that mikroBUS™ itself supports are on this board (plus USB HOST/DEVICE), including the well-established mikroBUS™ socket, a standardized socket for the MCU card (SiBRAIN standard), and several user-configurable buttons and LED indicators. UNI Clicker is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

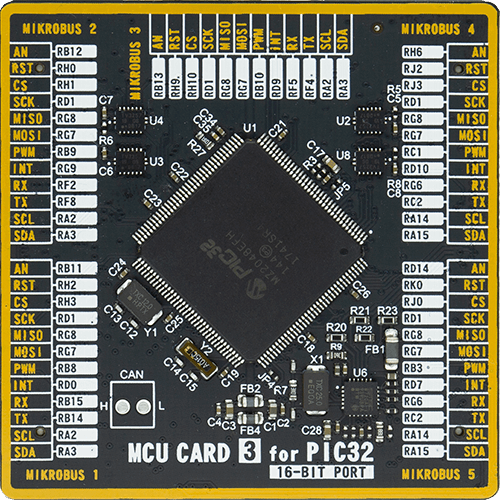

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

PIC32

MCU Memory (KB)

1024

Silicon Vendor

Microchip

Pin count

144

RAM (Bytes)

262144

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for 6DOF IMU 8 Click driver.

Key functions:

c6dofimu8_get_int_1_pin- This function checks does interrupt generated on the INT1 pinc6dofimu8_get_drdy_status- This function checks a data ready status for all measurementsc6dofimu8_get_magnetometer_data- This function performs a magnetometer data reading

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief c6DofImu8 Click example

*

* # Description

* This app gets three-axis gyroscope value, three-axis accelerometer value and temperature.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes device and performs a device software reset and configuration.

*

* ## Application Task

* Waits until any new data is entered to the data registers and then reads the accelerometer,

* gyroscope and temperature data which will be converted and calculated to the properly units each second.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "c6dofimu8.h"

// ------------------------------------------------------------------ VARIABLES

static c6dofimu8_t c6dofimu8;

static log_t logger;

// ------------------------------------------------------- ADDITIONAL FUNCTIONS

void log_axis ( t_c6dofimu8_axis *log_data )

{

log_printf( &logger, "* X-axis : %.3f \r\n", log_data->x );

log_printf( &logger, "* Y-axis : %.3f \r\n", log_data->y );

log_printf( &logger, "* Z-axis : %.3f \r\n", log_data->z );

}

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

c6dofimu8_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

c6dofimu8_cfg_setup( &cfg );

C6DOFIMU8_MAP_MIKROBUS( cfg, MIKROBUS_1 );

c6dofimu8_init( &c6dofimu8, &cfg );

Delay_ms ( 500 );

c6dofimu8_default_cfg( &c6dofimu8 );

log_printf( &logger, "** 6DOF IMU 8 is initialized **\r\n" );

Delay_ms ( 300 );

}

void application_task ( void )

{

uint8_t data_ready;

int8_t temperature;

t_c6dofimu8_axis accel_data;

t_c6dofimu8_axis gyro_data;

data_ready = c6dofimu8_get_drdy_status( &c6dofimu8, C6DOFIMU8_TEMP_DRDY_MASK |

C6DOFIMU8_G_DRDY_MASK |

C6DOFIMU8_XL_DRDY_MASK );

while ( data_ready == C6DOFIMU8_EVENT_NOT_DETECTED )

{

data_ready = c6dofimu8_get_drdy_status( &c6dofimu8, C6DOFIMU8_TEMP_DRDY_MASK |

C6DOFIMU8_G_DRDY_MASK |

C6DOFIMU8_XL_DRDY_MASK );

}

c6dofimu8_get_data( &c6dofimu8, &accel_data, &gyro_data, &temperature );

log_printf( &logger, "** Accelerometer values : \r\n" );

log_axis( &accel_data );

log_printf( &logger, "** Gyroscope values : \r\n" );

log_axis( &gyro_data );

log_printf( &logger, "** Temperature value : %d degC \r\n", ( int16_t )temperature );

log_printf( &logger, "-------------------------------------------------\r\n" );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END