Master the art of movement with our 3-axis accelerometer, where the future of precision opens doors to applications that demand accuracy and reliability

A

A

Hardware Overview

How does it work?

Accel 25 Click is based on the MXC4005XC, a highly reliable digital triaxial acceleration from MEMSIC. The MXC4005XC is highly configurable with a programmable acceleration range of ±2g, ±4g, or ±8g based on MEMSIC's proprietary thermal technology built with a 0.18μm standard CMOS process. It contains no moving sensor parts, eliminating field reliability and repeatability issues; no measurable resonance (immunity to vibration), stiction, or detectable hysteresis exists. The MXC4005XC also eliminates the "click" sounds typically heard in ball-based orientation sensors.

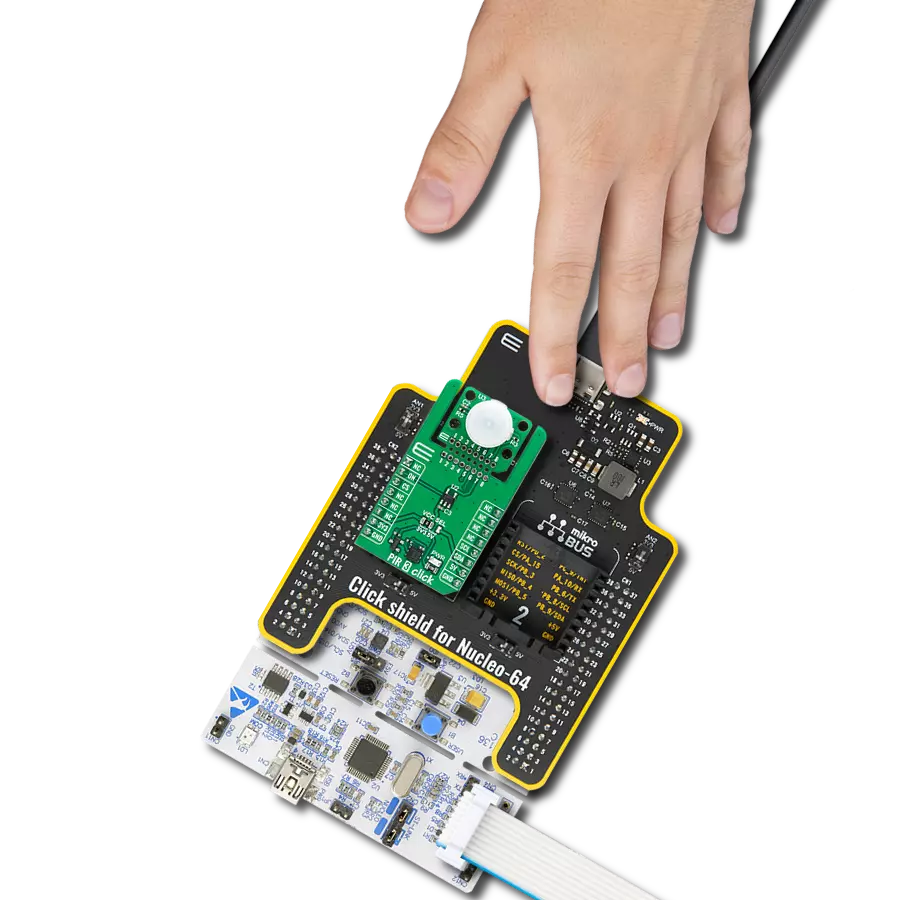

The shock survival of this MEMS sensing structure is greater than 200,000g. This sensor provides X/Y/Z axis acceleration signals with a low 0g offset and temperature signals with high accuracy. In addition, it also detects six orientation positions, X/Y shake, and shakes directions. Accel 25 Click communicates with MCU using the standard I2C 2-Wire interface to read data and configure settings capable of operating in a standard or fast mode of operation. The acceleration signal is provided in 12-bit output resolution. In addition to communication pins, this board also possesses an

additional interrupt pin, routed to the INT pin on the mikroBUS™ socket, for orientation and X/Y shake detections. The MXC4005XC allows users to be placed in a Power-Down mode enabled through the I2C interface. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, it comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

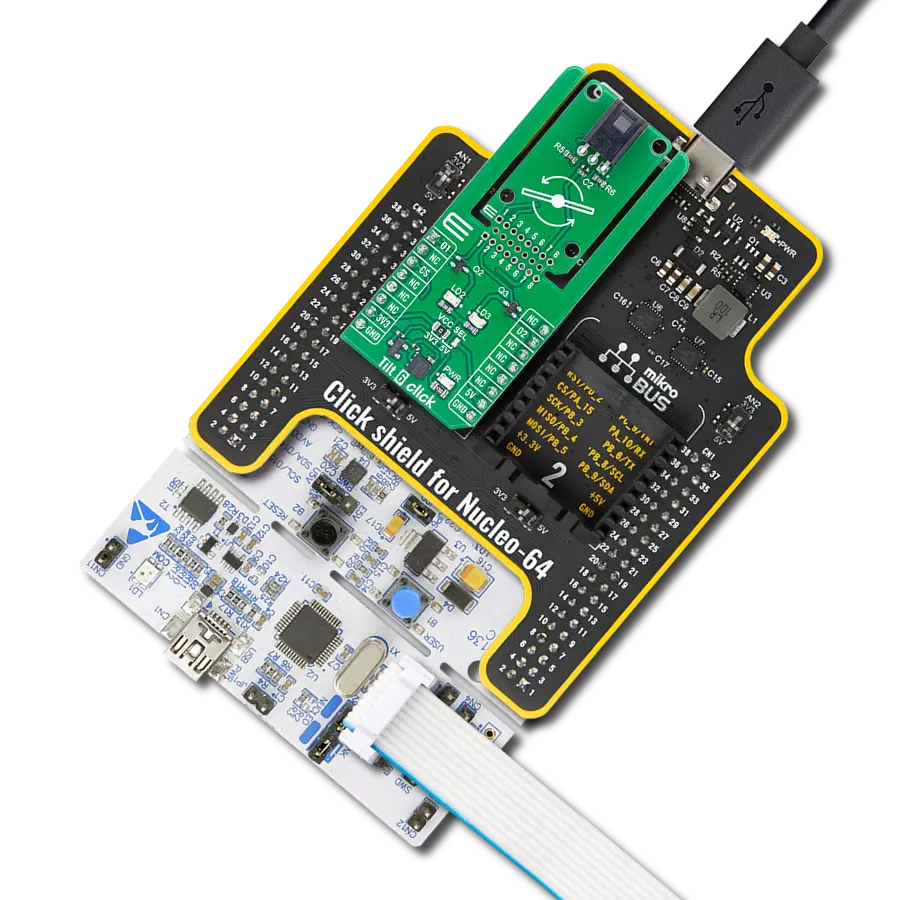

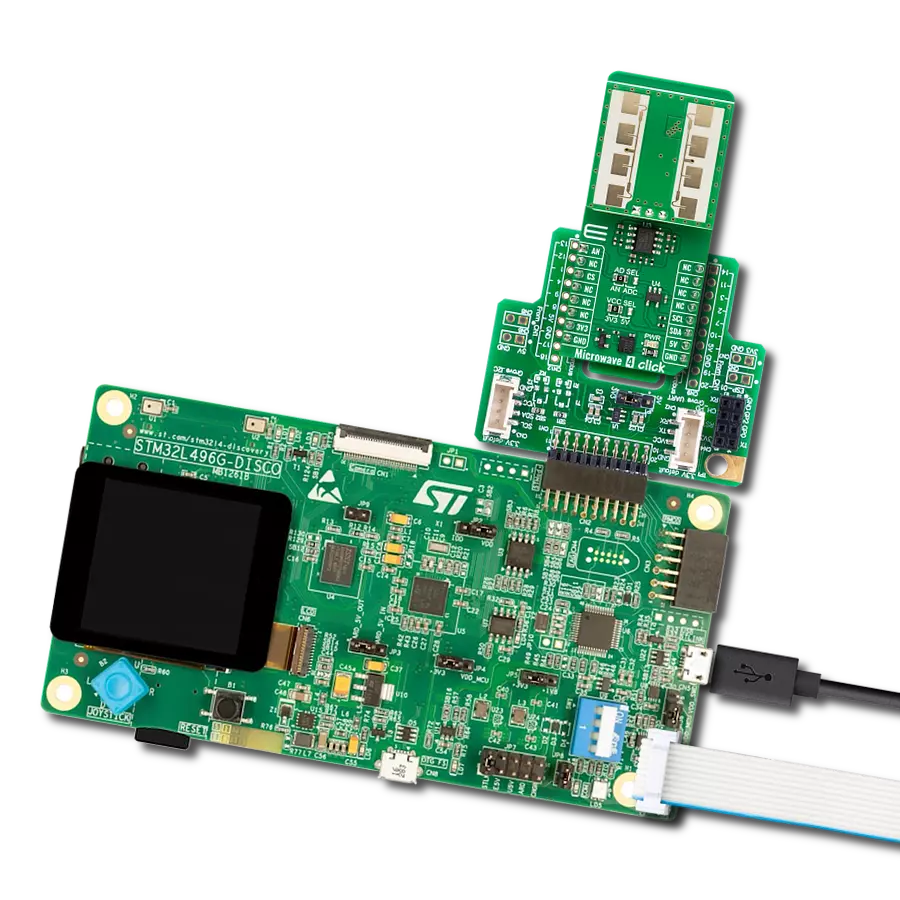

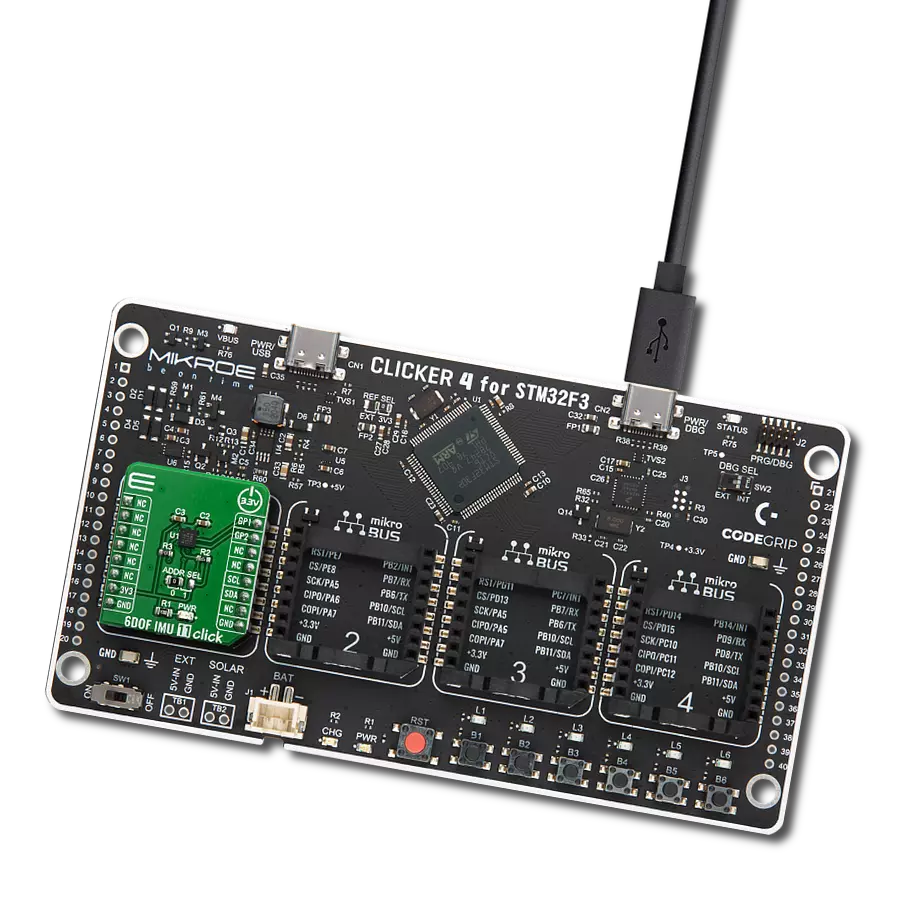

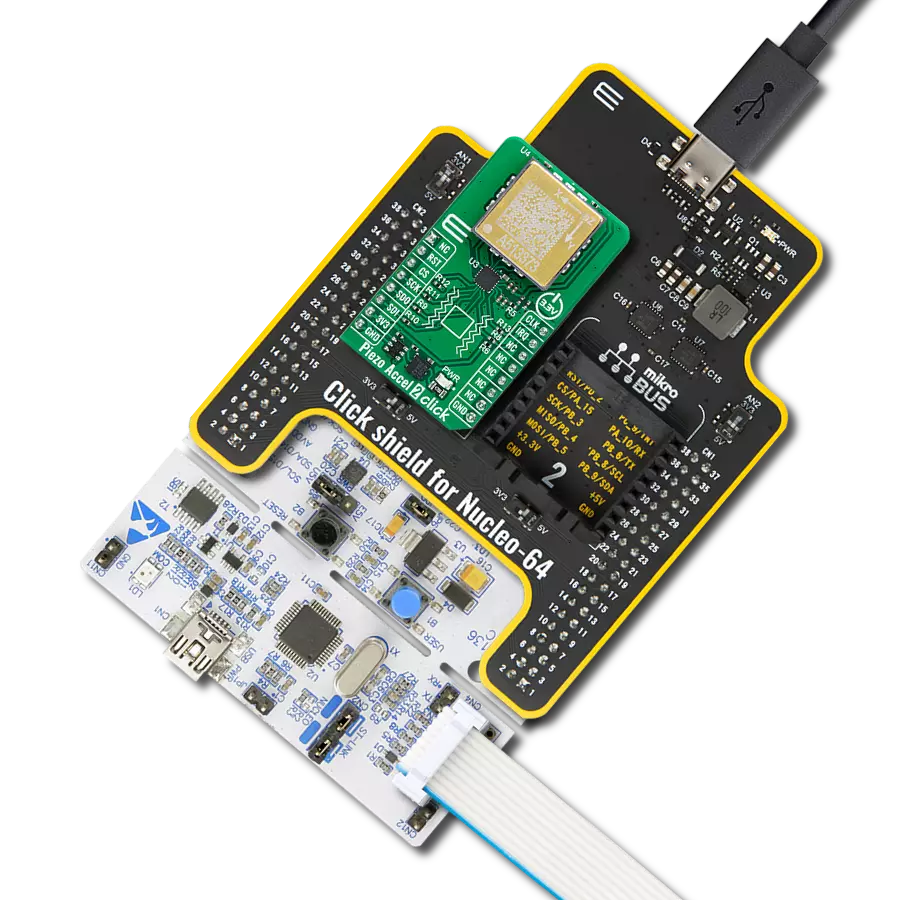

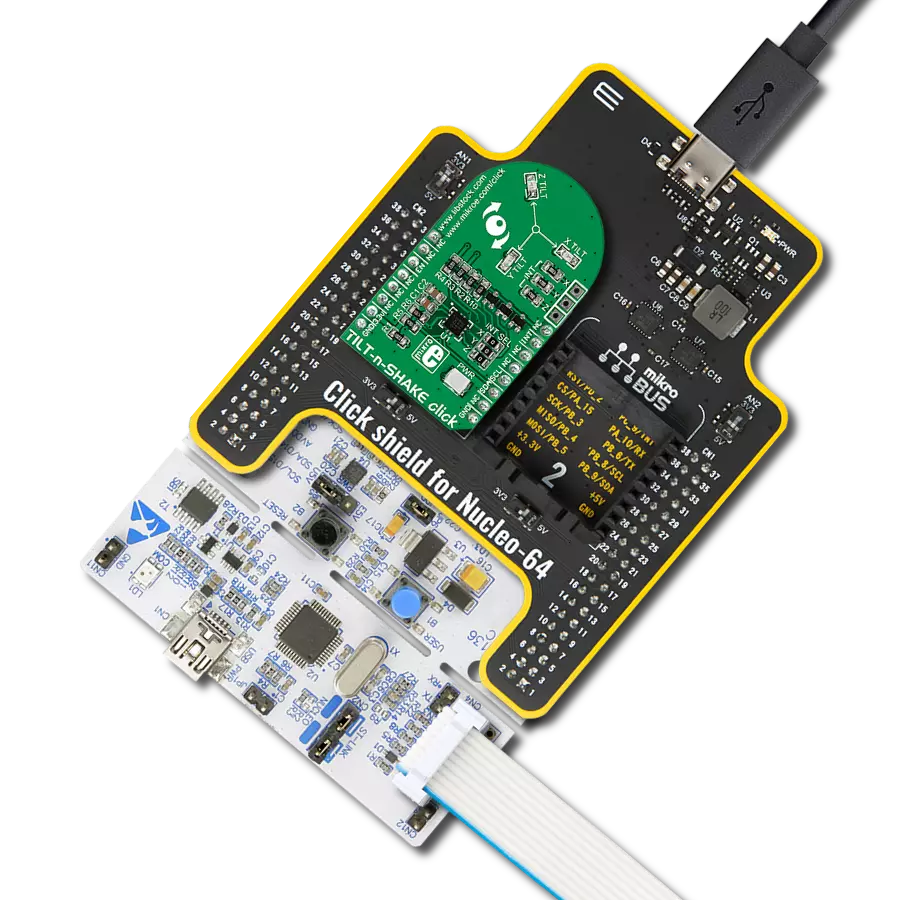

Development board

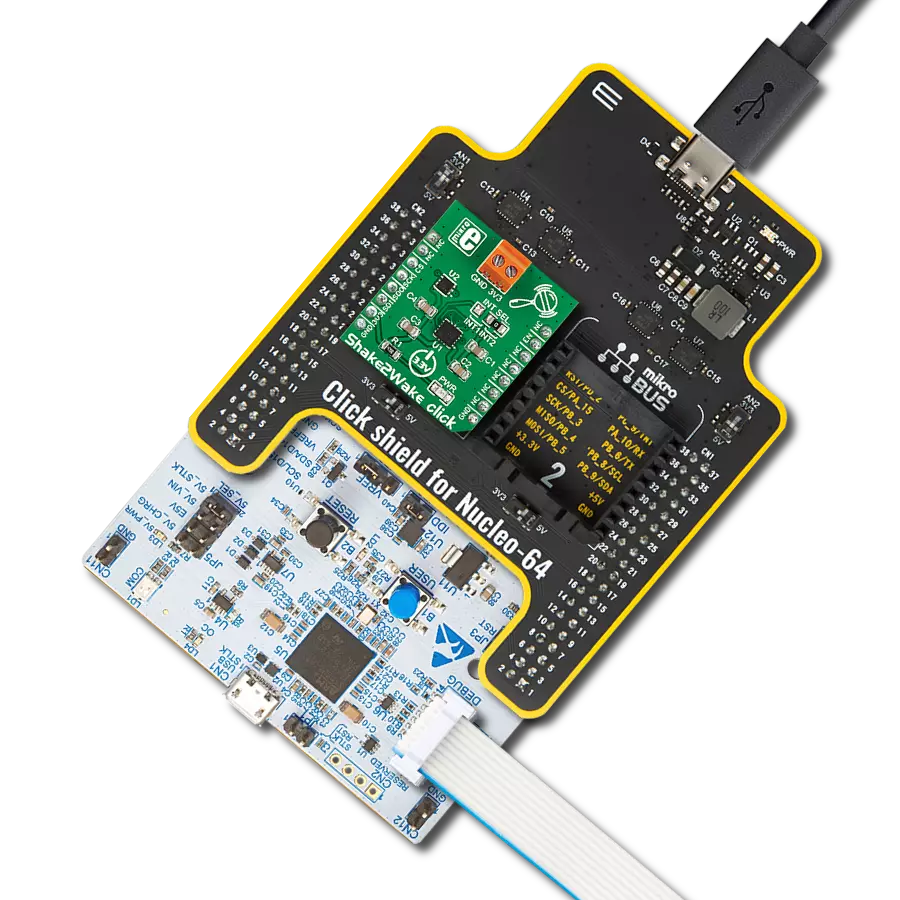

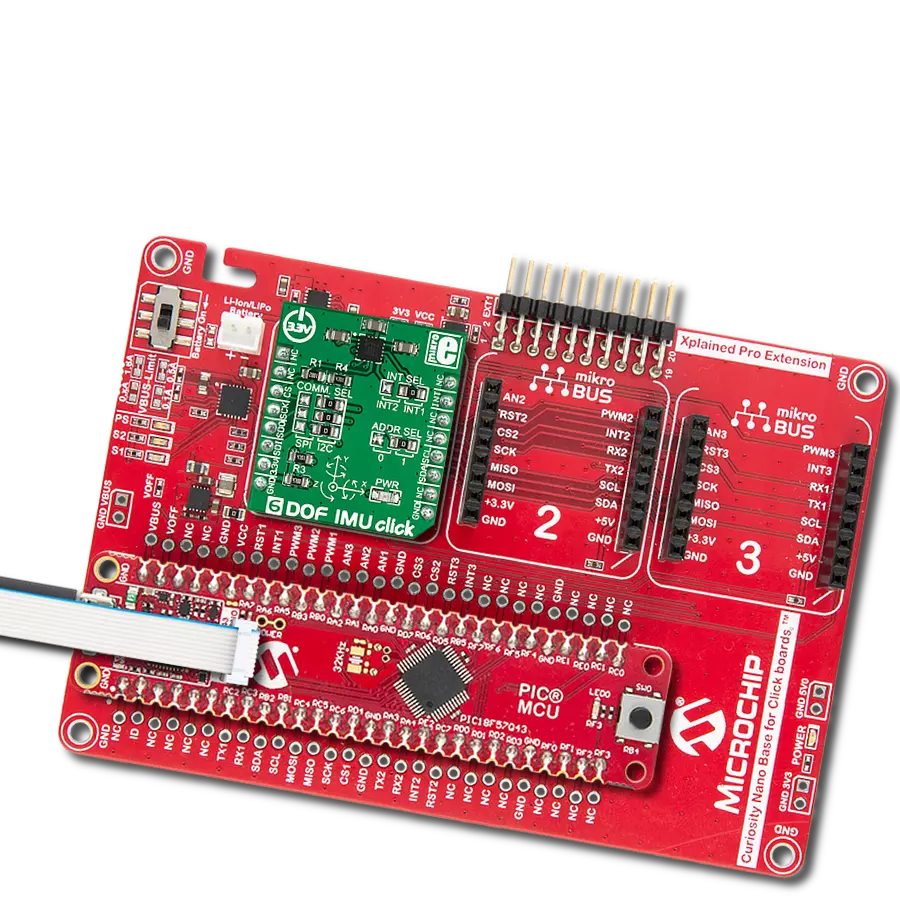

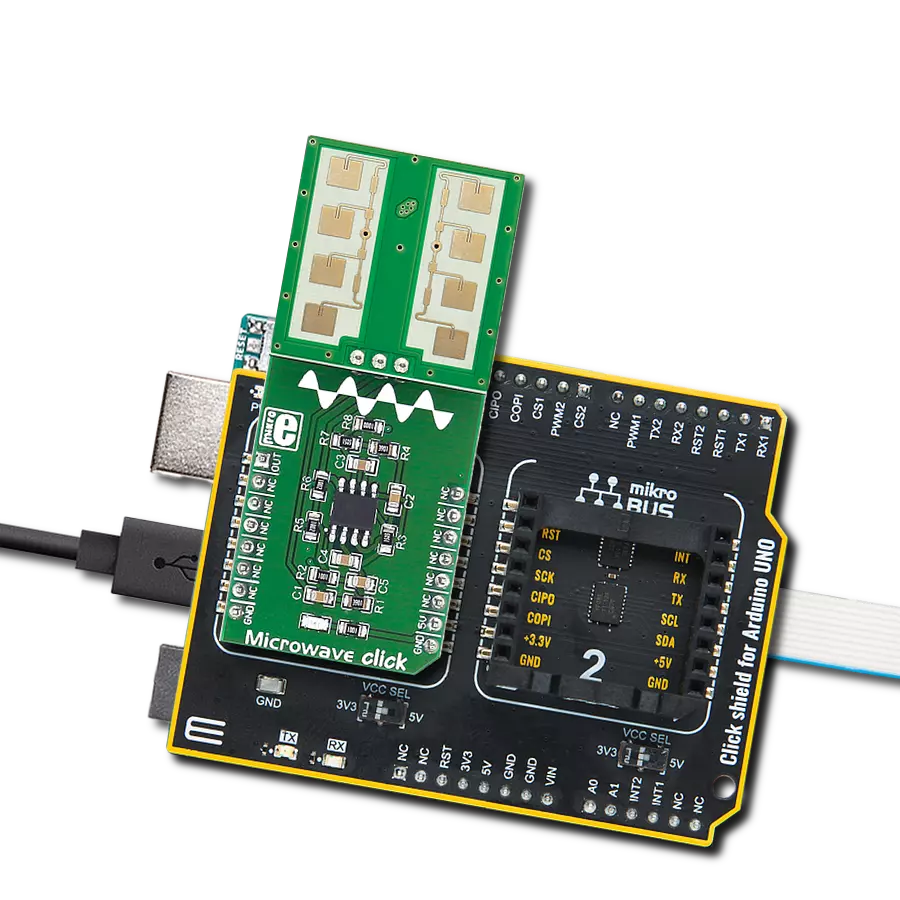

Flip&Click PIC32MZ is a compact development board designed as a complete solution that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit PIC32MZ microcontroller, the PIC32MZ2048EFH100 from Microchip, four mikroBUS™ sockets for Click board™ connectivity, two USB connectors, LED indicators, buttons, debugger/programmer connectors, and two headers compatible with Arduino-UNO pinout. Thanks to innovative manufacturing technology,

it allows you to build gadgets with unique functionalities and features quickly. Each part of the Flip&Click PIC32MZ development kit contains the components necessary for the most efficient operation of the same board. In addition, there is the possibility of choosing the Flip&Click PIC32MZ programming method, using the chipKIT bootloader (Arduino-style development environment) or our USB HID bootloader using mikroC, mikroBasic, and mikroPascal for PIC32. This kit includes a clean and regulated power supply block through the USB Type-C (USB-C) connector. All communication

methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, user-configurable buttons, and LED indicators. Flip&Click PIC32MZ development kit allows you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

2048

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

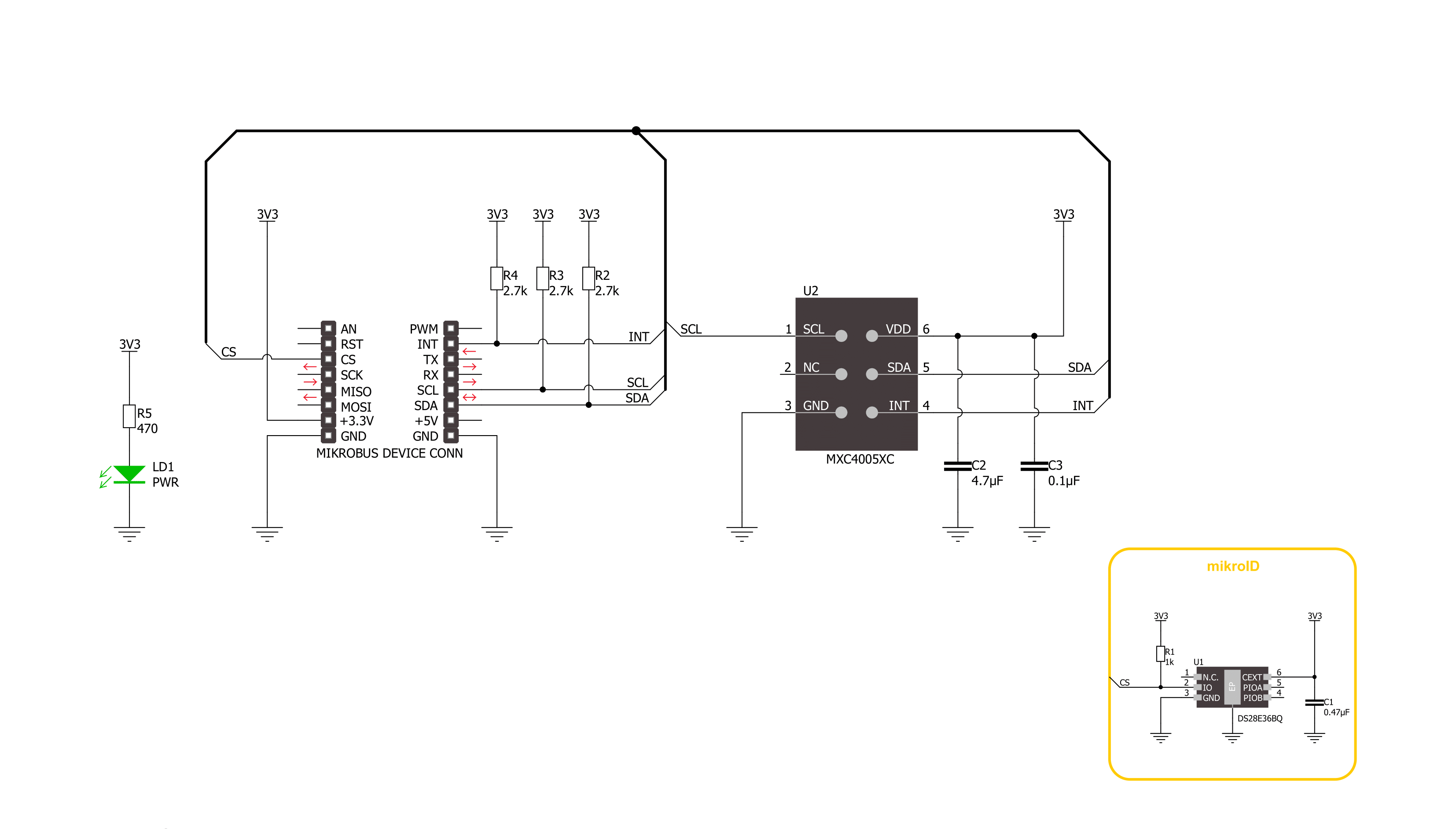

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Accel 25 Click driver.

Key functions:

accel25_soft_reset- Accel 25 soft reset functionaccel25_set_full_scale_range- Accel 25 set full scale range functionaccel25_read_data- Accel 25 read data function

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief Accel 25 Click example

*

* # Description

* This example demonstrates the use of Accel 25 Click board by reading and displaying

* accel data (X, Y, and Z axis) as well as temperature measurements on the USB UART.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and performs the Click default configuration.

*

* ## Application Task

* Reads and displays the accel data (X, Y, and Z axis) as well as temperature measurements

* on the USB UART every 100ms approximately.

*

* @author Stefan Ilic

*

*/

#include "board.h"

#include "log.h"

#include "accel25.h"

static accel25_t accel25;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

accel25_cfg_t accel25_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

accel25_cfg_setup( &accel25_cfg );

ACCEL25_MAP_MIKROBUS( accel25_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == accel25_init( &accel25, &accel25_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( ACCEL25_ERROR == accel25_default_cfg ( &accel25 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

accel25_data_t meas_data;

// Wait for data ready indication

if ( ACCEL25_PIN_STATE_LOW == accel25_get_int_pin ( &accel25 ) );

{

if ( ACCEL25_OK == accel25_read_data ( &accel25, &meas_data ) )

{

log_printf( &logger, " X: %.3f g\r\n", meas_data.x );

log_printf( &logger, " Y: %.3f g\r\n", meas_data.y );

log_printf( &logger, " Z: %.3f g\r\n", meas_data.z );

log_printf( &logger, " Temperature: %.2f degC\r\n", meas_data.temperature );

}

Delay_ms ( 100 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Motion