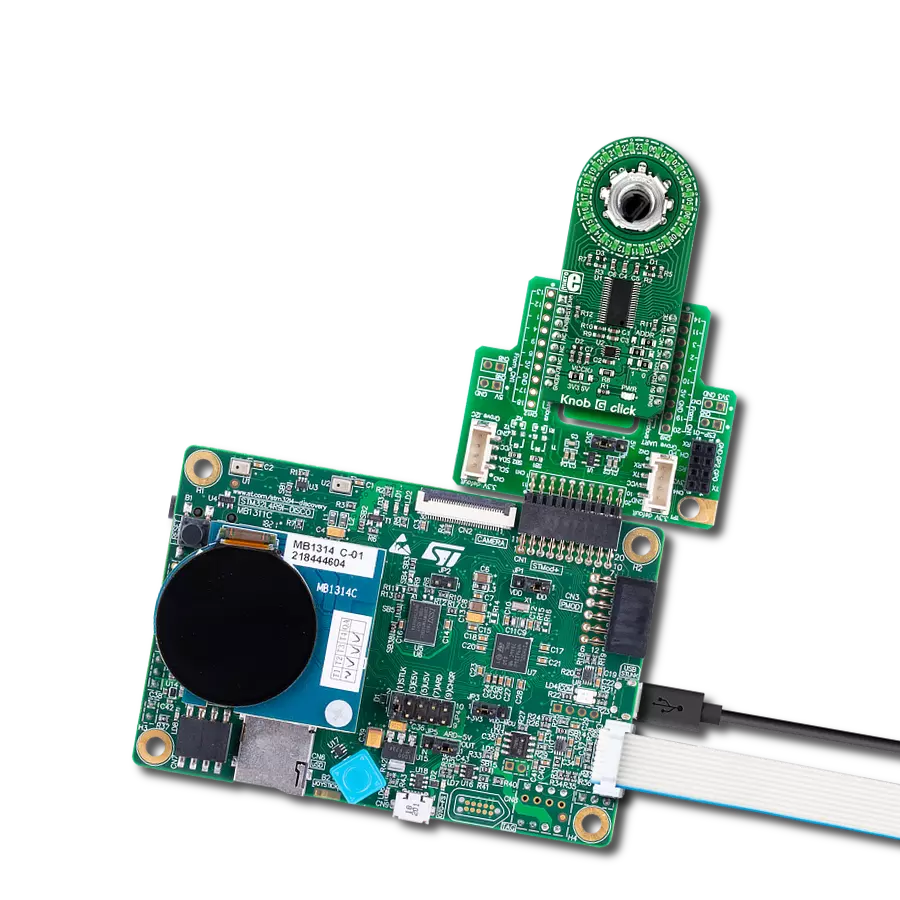

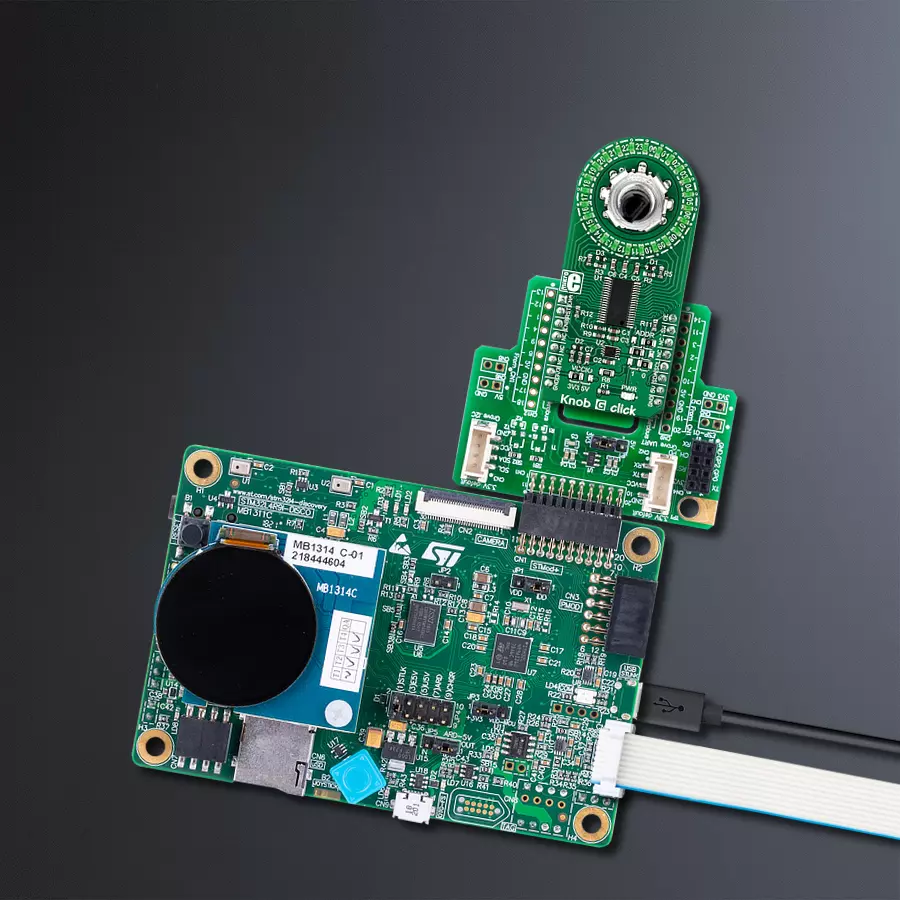

Discover the perfect fusion of precision and visual delight with our quadrature rotary encoder boasting a vibrant ring of 24 green LEDs

A

A

Hardware Overview

How does it work?

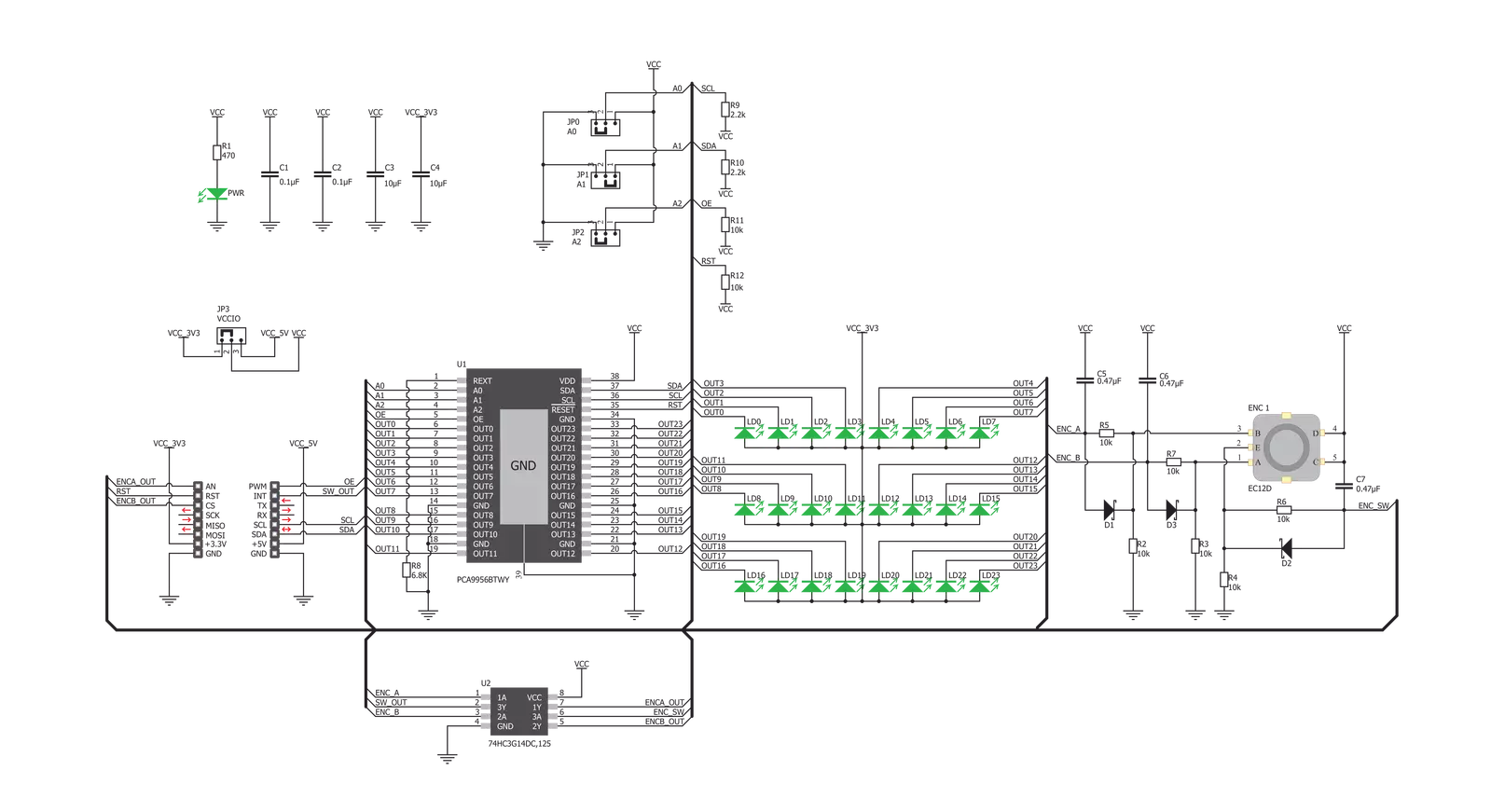

Knob G Click consists of two distinctive sections: the first section is the rotary quadrature encoder with its outputs routed to the GPIO pins of the mikroBUS. The encoder is debounced by a dedicated circuitry composed of passive elements and a triple inverting Schmitt trigger IC. The second section is the LED driver IC, with accompanying LEDs positioned in a form of a ring around the encoder, making them perfectly suited for encoder position indicators. This Click Board uses the EC12D, a 15-pulse incremental rotary encoder with a push-button, from ALPS. This encoder has very good mechanical specifications: debouncing time for its internal switches goes down to 2ms, and it can withstand a huge number of switching cycles, up to 30,000. The supporting debouncing circuitry allows contacts to fully settle before the output is triggered. When encoder contacts are closed, the capacitor will start to discharge through the resistor, via the contacts, and to the GND. The Schmitt trigger connected to the capacitor will output a LOW logic level when its low voltage threshold level is reached; and vice versa - when encoder contacts are open, the capacitor will start to charge through the resistor, and the Schmitt trigger will output a HIGH logic level, when its high voltage threshold level is reached. This allows reading the states of two encoder contacts and one push-button contact directly from the code, with no bulky software debouncing applied. This makes Knob G click usable directly within the the interrupt-on-change ISR, allowing an absolute accuracy and no skipped pulses (which might occur when a regular software polling technique is used). Output pins of the encoder contacts are labeled as ENA and ENB for the quadrature encoder contacts, and SW for the push-button contact. These pins are routed to the AN, CS, and INT pin of the Mirko BUS, respectively. The LED ring is composed of 24

individual green LEDs which are driven by the PCA9956B, an 8-bit, 24-channel, constant current LED driver, from NXP. This driver IC has many LED driving features, including constant current sinking capability, which greatly simplifies the design: maximum current through LEDs is determined by a single resistor. The PCA9956B has registers for controlling each channel individually, along with a single register which controls all channels at once. It supports PWM-mode dimming, as well as the current-mode dimming (by scaling down the maximum LED current). The PCA9956B can use a lower frequency signal from a secondary integrated PWM oscillator to modulate the PWM dimming signal. While the PWM frequency of the driver is fixed at 31.25kHz reducing the visible LED flickering completely, the modulating low-frequency signal can range from 0 to 122Hz, allowing interesting blinking effects to be produced without using the computing power of the microcontroller (MCU). The driver produces smooth dimming of LEDs, since the resolution of the PWM duty cycle is 8 bits. More details and features can be found found in the PCA9956B datasheet, in the download section, below. The OE pin of the PCA9956B is routed to the PWM pin of the mikroBUS. When a LOW logic level is applied to the OE pin, LED outputs will be enabled. This pin is pulled to a HIGH logic level by a resistor. The OE pin can also be driven by an external PWM signal, offering an alternative way of dimming all LEDs at once. LED driver IC can be reset by pulling the RST pin to a LOW logic level. This pin is pulled to a HIGH level by the resistor. The reset pulse can be very short (2.5 µs) but the device will not be ready for another 1.5 ms after the pulse. Besides the hardware reset, the PCA9956B also supports a software reset, which is required if the device is going to be operated in the fast I2C mode (including clock speed above 100kHz).

The datasheet of the PCA9956B offers a detailed explanation on performing the software reset and using the fast I2C mode (FM+). The PCA9956B IC uses the 3.3V rail of the mikroBUS as the LED power supply, so there is no significant voltage drop causing thermal dissipation. However, turning all LEDs ON at once with the maximum current set in the current registers, might cause the Knob G click to dissipate some heat. This is expected, as the thermal dissipation of each channel is adding up to the sum dissipation of the entire IC. The PCA9956B IC features thermal shutdown protection, along with the set of error reporting features. The PCA9956B can report both open-circuit event and short-circuit event for each LED. These errors will be written in the ERR registers, one for each LED channel. The datasheet explains how to interpret the values of these registers. Slave I2C address of the PCA9956B device can be selected by using three SMD jumpers, grouped under the ADDR label. The PCA9956B allows its slave I2C address to be selected from a wide range of 125 different values. Each of the address pins (A0 to A3) can be left floating, pulled up, pulled down and shorted to VCC or GND. However, some I2C addresses are reserved, so they should be used with care. The datasheet of the PCA9956B offers tables with resistor values for each state of the address pins and reserved I2C addresses. Knob G click uses three 0 Ω SMD jumpers to set the states of these address pins. The logic voltage level can be selected by the SMD jumper, labeled as VCCIO. This jumper determines levels for the logic signals from Schmitt triggers, as well as for the I2C interface of Knob G click. This allows it to be interfaced with a wide range of different MCUs, both compatible with 3.3V and 5V logic voltage levels.

Features overview

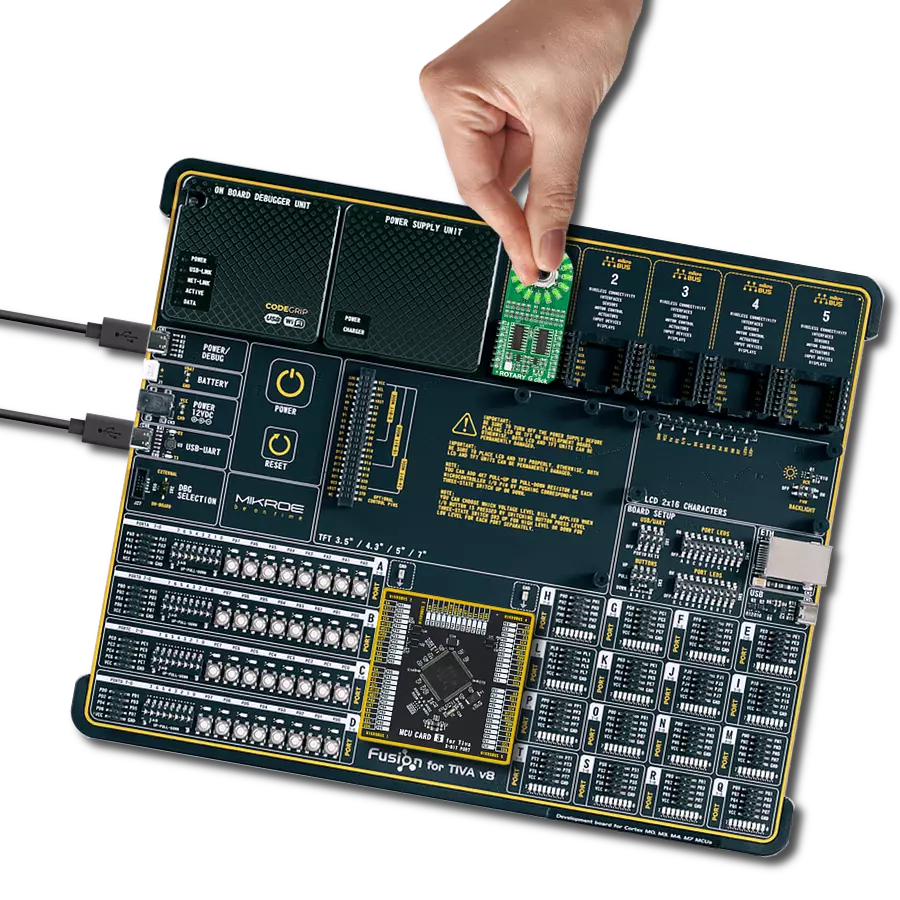

Development board

Discovery kit with STM32L4R9AI MCU is a complete demonstration and development platform for the STMicroelectronics Arm® Cortex®-M4 core-based STM32L4R9AI microcontroller. Leveraging the innovative ultra-low-power oriented features, 640 Kbytes of embedded RAM, graphics performance (Chrom-ART Accelerator™), and DSISM controller offered by the STM32L4R9AI, the 32L4R9IDISCOVERY kit enables users to easily prototype applications with state-of-the-art energy efficiency, as well as providing stunning audio and graphics rendering with direct support for an AMOLED DSI round display. For even more user friendliness, the on-board ST-LINK/V2-1 debugger provides out-of-the-box programming and

debugging capabilities. The STM32L4R9AI microcontroller features four I2Cs, five USARTs, one ULP UART, three SPIs, two SAIs, one SDIO, one USB 2.0 full-speed OTG, two CANs, one FMC parallel synchronous interface, one 12 bit ADC, one 12-bit DAC, two ULP analog comparators, two op-amps, one two data-lane DSI display, one digital filter for sigma-delta modulation and SWP interface, two Octo-SPI interfaces, an 8- to 14-bit camera interface, one touch-sensing controller interface, JTAG, and SWD debugging support. This Discovery board offers everything users need to get started quickly and develop applications easily. The hardware features on the board help to evaluate the following peripherals: USB OTG FS, microSD™

card, 8-bit camera interface, 16-Mbit PSRAM, PMOD, and STMod+ connectors, IDD measurement, full-duplex I2S with an audio codec and stereo headset jack including an analog microphone, DFSDM with a pair of MEMS digital microphones on board, 512-Mbit Octo-SPI Flash memory device, I2C extension connector, 1.2" AMOLED display using a one data-lane DSI interface with a capacitive touch panel. The ARDUINO® compatible connectors expand the functionality with a wide choice of specialized shields. The integrated ST-LINK/V2-1 provides an embedded in-circuit debugger and programmer for the STM32 MCU.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

2048

Silicon Vendor

STMicroelectronics

Pin count

169

RAM (Bytes)

655360

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Knob G Click driver.

Key functions:

knob_get_encoder_position- Functions for get Encoder positionknob_set_led_state- Functions for set led state(PWM on the LED)knob_get_sw_button_state- Functions for get SW pin(switch button) state

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Knob Click example

*

* # Description

* The demo application displays different types of LED controls and encoder position readings.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Configuring Clicks and log objects.

* Settings the Click in the default configuration.

*

* ## Application Task

* The Task application has 3 test modes:

* - The first example is setting BRIGHTNESS on all LEDs.

* - Other examples put the LED in the position read from the encoder.

* - The third example sets the LED to be read while the encoder registers the clockwise movement

* and turn off those LEDs that the encoder reads when moving in a counterclockwise direction.

* - The example is changed by pressing the SW button

*

* \author Katarina Perendic

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "knob.h"

// ------------------------------------------------------------------ VARIABLES

static knob_t knob;

static log_t logger;

static int32_t new_position = 0;

static int32_t old_position = 0;

static uint8_t sw_state = 0;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

knob_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

knob_cfg_setup( &cfg );

KNOB_MAP_MIKROBUS( cfg, MIKROBUS_1 );

knob_init( &knob, &cfg );

knob_reset( &knob );

Delay_ms ( 300 );

knob_default_cfg( &knob );

}

void application_task ( void )

{

uint8_t cnt;

uint8_t direction;

// Task implementation.

knob_get_encoder_position( &knob, &new_position, &direction );

if ( knob_get_sw_button_state( &knob ) == 0 )

{

sw_state++;

if ( sw_state >= 3 ) sw_state = 0;

knob_set_brightness( &knob, KNOB_BRIGHTNESS_ALL_LED, 0x00 );

Delay_ms ( 300 );

}

// Logs position

if ( new_position != old_position )

{

log_printf( &logger, "** EnCoder position : %d ", new_position );

}

old_position = new_position;

switch ( sw_state )

{

// Brightness

case 0:

{

cnt++;

if ( cnt > 127 )

{

cnt = 0;

}

knob_set_brightness( &knob, KNOB_BRIGHTNESS_ALL_LED, cnt );

Delay_ms ( 15 );

break;

}

// Encoder with one led

case 1:

{

if ( new_position > 24 )

{

knob_set_encoder_start_position( &knob, 1 );

}

if ( new_position < 1 )

{

knob_set_encoder_start_position( &knob, 24 );

}

if (direction == 1)

{

knob_set_led_state( &knob, new_position, KNOB_LED_ON );

knob_set_led_state( &knob, new_position - 1, KNOB_LED_OFF );

}

else

{

knob_set_led_state( &knob, new_position, KNOB_LED_ON );

knob_set_led_state( &knob, new_position + 1, KNOB_LED_OFF );

}

Delay_1ms();

break;

}

// Encoder with all led

case 2:

{

if ( new_position > 24 )

{

knob_set_encoder_start_position( &knob, 1 );

}

if ( new_position < 1 )

{

knob_set_encoder_start_position( &knob, 24 );

}

if ( direction == 1 )

{

knob_set_led_state( &knob, new_position, KNOB_LED_ON );

}

else

{

knob_set_led_state( &knob, new_position + 1, KNOB_LED_OFF);

}

Delay_1ms();

break;

}

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Rotary encoder