Manage and control different devices in industrial and automation setups, ensuring safety and flexibility in the process

A

A

Hardware Overview

How does it work?

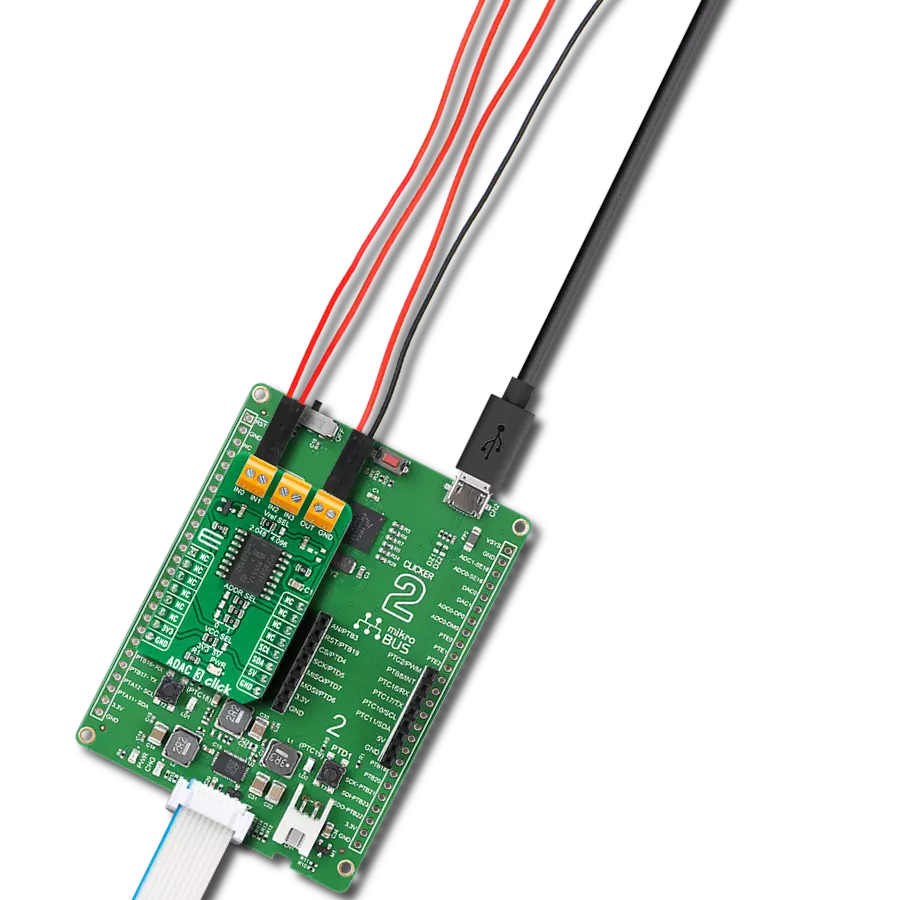

AD-SWIO 3 Click is based on the AD74115H, a single-channel, software-configurable input and output with HART mode, and ADP1034, a 3-channel isolated micropower management unit with seven digital isolators and programmable power control both from Analog Devices. The AD74115H has a single-channel input and output, which can be configured as voltage input, current input, voltage output, current output, digital input, digital output, 2/3/4-wire RTD measurement, or thermocouple measurement input. It features a 16-bit, Σ-Δ analog-to-digital converter (ADC) and a 14-bit digital-to-analog converter (DAC), with a high accuracy 2.5V on-chip reference that can be used both for ADC and DAC. You can connect the desired load to terminals labeled I/OP and I/ON for analog output, analog input, and digital input functions. To apply a stimulus to the two auxiliary high-voltage sense pins, use I/O EXT1 and I/O

EXT2 terminals. The resistance measurements can be made between those four terminals, depending on the number of wires RTD. For instance, take 2-wire resistance measurements between the I/OP and I/ON terminals. The integrated HART modem can transmit and receive signals to and from the I/OP terminal. For more info, check the datasheet. Four LEDs (GPIOA, GPIOB, GPIOC, GPIOD) can be configured in several ways to represent digital input, digital output, external or internal conditions, and more. An onboard thermistor is connected to the AD74115H, which can measure the board's temperature. The ADP1034 provides power and isolation to the AD74115H. A flyback regulator supply voltage of 24V can be applied over the VINP terminal. You can control the flyback regulator slew rate over the SLEW jumper between the slowest and normal as default. You can also choose the highest by leaving the SLEW pin open. The

ZA9644-AED, a flyback transformer from Coilcraft, is used for flyback regulator operation. AD-SWIO 3 Click uses a standard 4-wire SPI serial interface of the AD74115H through the isolation that provides the ADP1034 to communicate with the host MCU. You can reset the AD74115H over the RST pin. When a new sequence of ADC conversion is ready to be read, the RDY will be asserted. Also, the alert ALR pin will be asserted when the alert condition is met. All those lines pass through an isolation barrier of the ADP1034 on its way to the host MCU. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used for further development.

Features overview

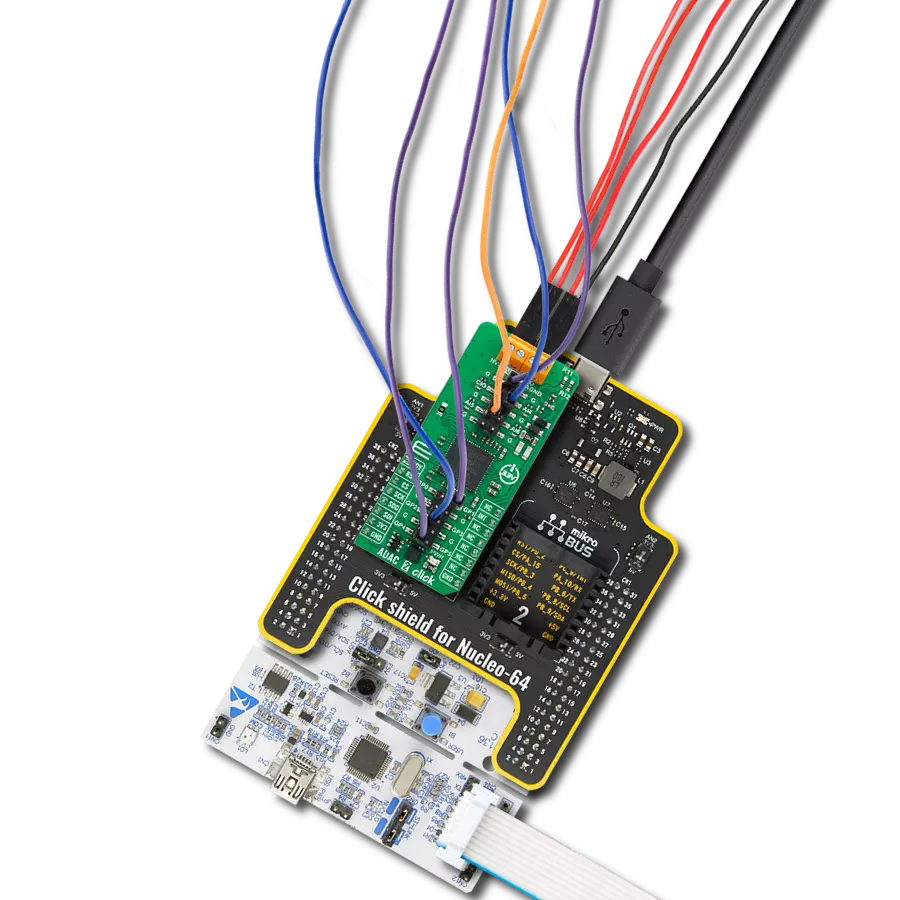

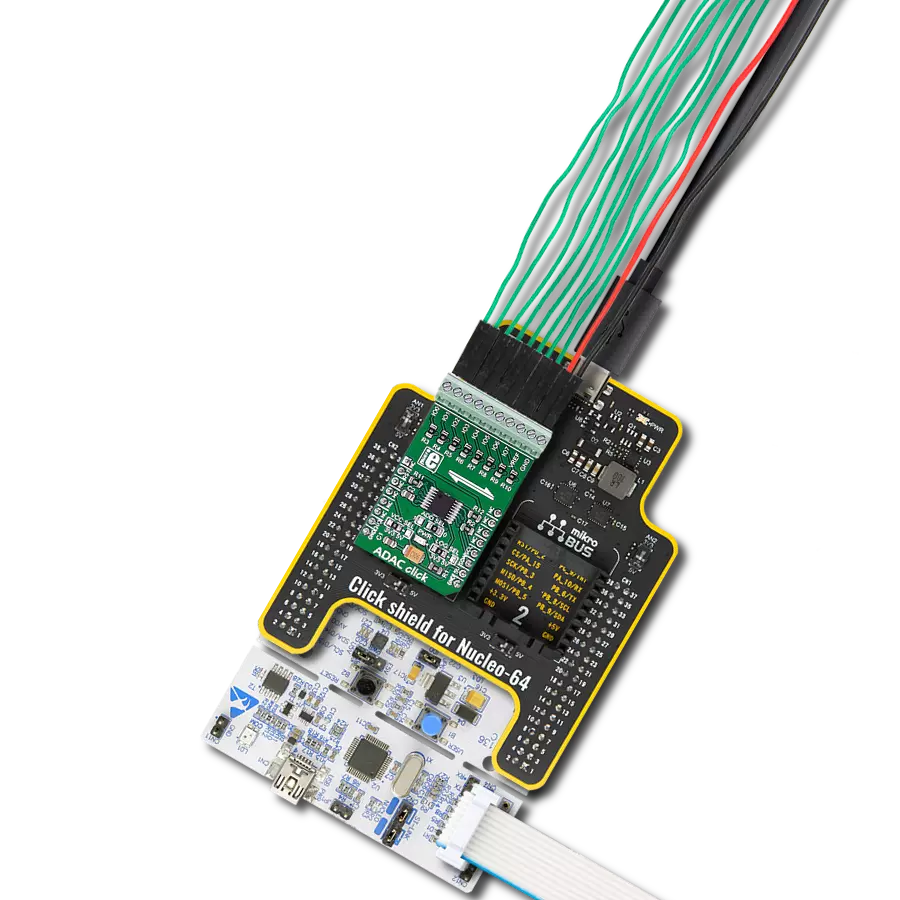

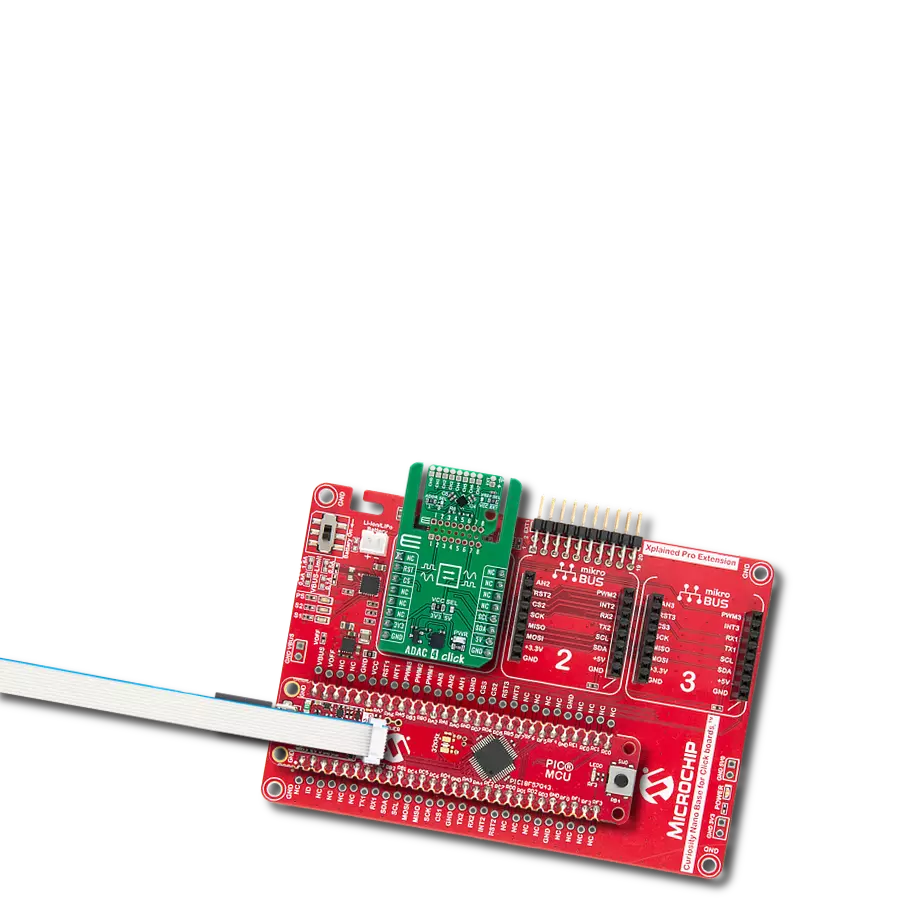

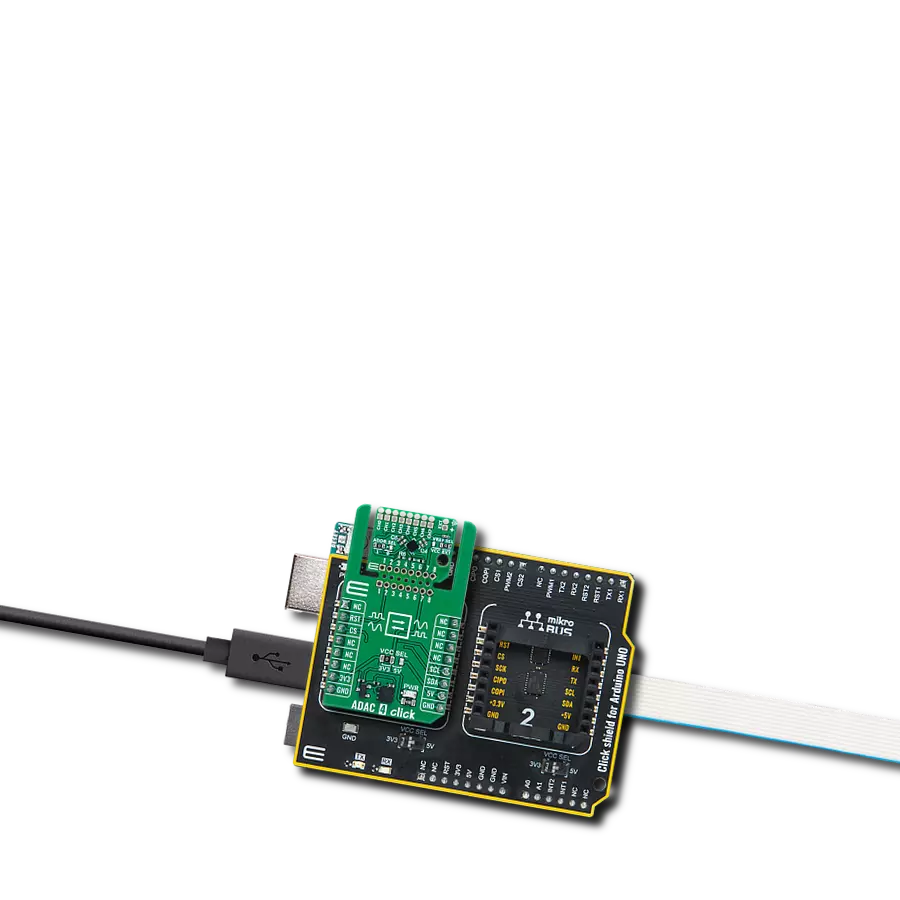

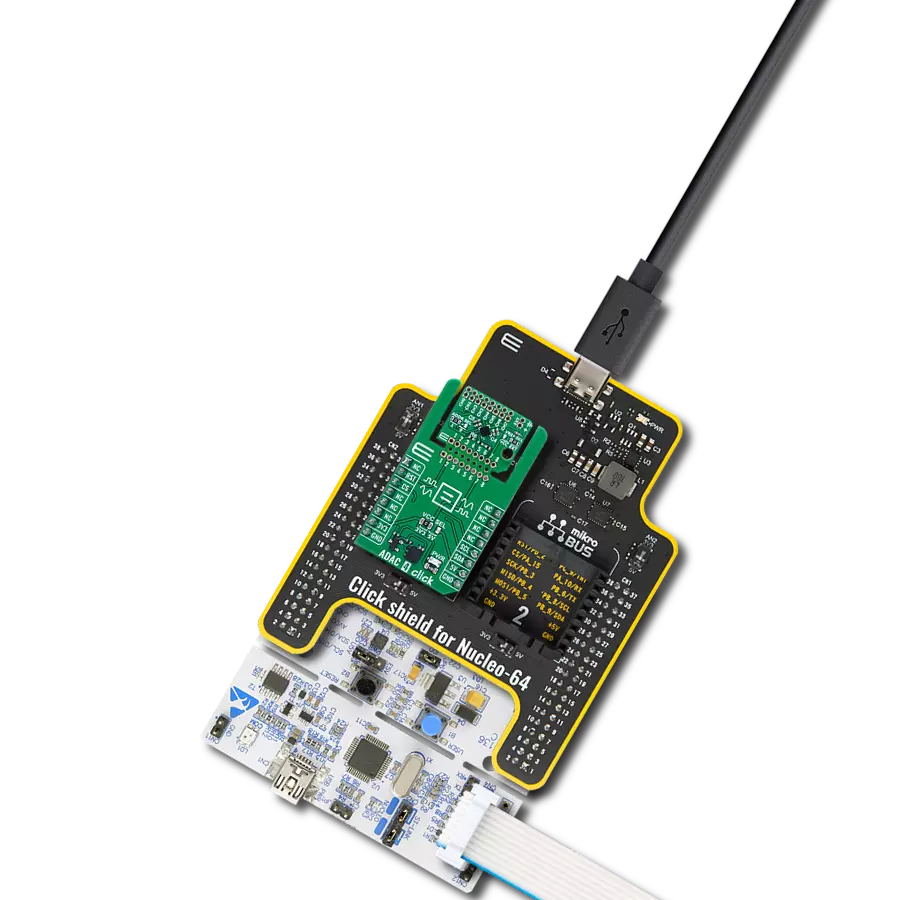

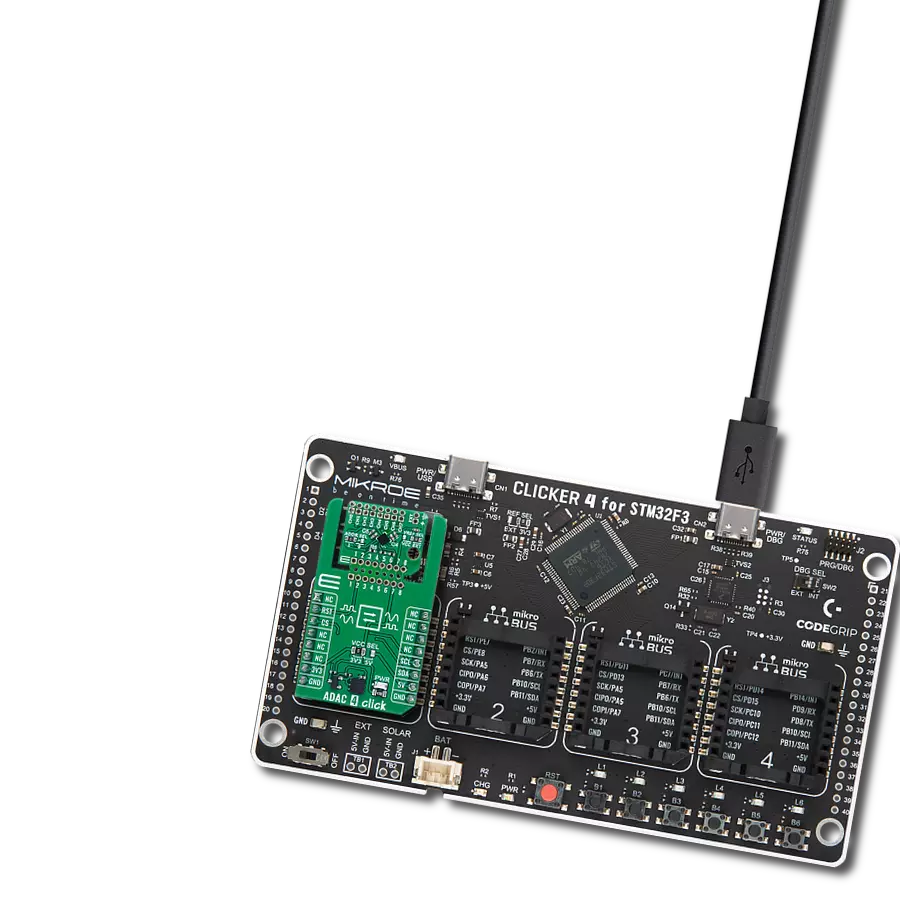

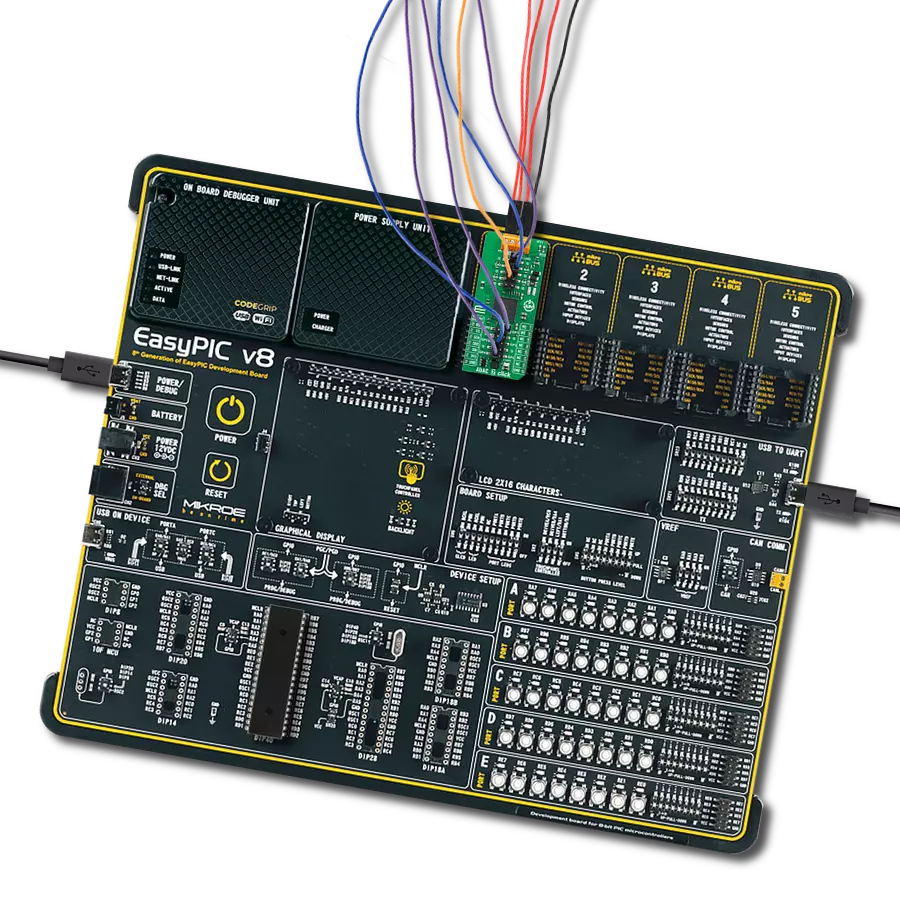

Development board

Curiosity PIC32 MZ EF development board is a fully integrated 32-bit development platform featuring the high-performance PIC32MZ EF Series (PIC32MZ2048EFM) that has a 2MB Flash, 512KB RAM, integrated FPU, Crypto accelerator, and excellent connectivity options. It includes an integrated programmer and debugger, requiring no additional hardware. Users can expand

functionality through MIKROE mikroBUS™ Click™ adapter boards, add Ethernet connectivity with the Microchip PHY daughter board, add WiFi connectivity capability using the Microchip expansions boards, and add audio input and output capability with Microchip audio daughter boards. These boards are fully integrated into PIC32’s powerful software framework, MPLAB Harmony,

which provides a flexible and modular interface to application development a rich set of inter-operable software stacks (TCP-IP, USB), and easy-to-use features. The Curiosity PIC32 MZ EF development board offers expansion capabilities making it an excellent choice for a rapid prototyping board in Connectivity, IOT, and general-purpose applications.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

2048

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for AD-SWIO 3 Click driver.

Key functions:

adswio3_get_voltage_input- This function reads the raw ADC value and converts them to a proportional voltage level measured by the voltage between the I/OP and I/ON screw terminals.adswio3_get_diag_res- This function is used to read the desired diagnostic conversion results.adswio3_set_adc_cnv- This function is used to control the ADC conversions that must be performed.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief AD-SWIO 3 Click example

*

* # Description

* This library contains API for the AD-SWIO 3 Click driver

* for measurements of the analog output, analog input, digital input,

* resistance temperature detector (RTD), and thermocouple measurements.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization of SPI and log UART.

* After driver initialization, the app executes a default configuration

* that enables and sets it to measure IOP/ION voltage input from 0V to 12V,

* with 4.8k SPS and enabled four diagnostics measurements (AVDD, VASS, VACC and LVIN).

*

* ## Application Task

* This example demonstrates the use of the AD-SWIO 3 Click board.

* The demo application reads and displays the voltage level input,

* measured by the voltage between the I/OP and I/ON screw terminals

* and NTC thermistor temperature in degrees Celsius.

* Results are being sent to the UART Terminal, where you can track their changes.

*

* @author Nenad Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "adswio3.h"

static adswio3_t adswio3;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

adswio3_cfg_t adswio3_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

adswio3_cfg_setup( &adswio3_cfg );

ADSWIO3_MAP_MIKROBUS( adswio3_cfg, MIKROBUS_1 );

if ( SPI_MASTER_ERROR == adswio3_init( &adswio3, &adswio3_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( ADSWIO3_ERROR == adswio3_default_cfg ( &adswio3 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

Delay_ms ( 100 );

for ( uint8_t n_cnt = ADSWIO3_GPIO_CONFIG_SEL_A; n_cnt <= ADSWIO3_GPIO_CONFIG_SEL_D; n_cnt ++ )

{

if ( ADSWIO3_ERROR == adswio3_set_gpio_config( &adswio3, n_cnt,

ADSWIO3_GPIO_CONFIG_GPO_DATA_HIGH,

ADSWIO3_GPIO_CONFIG_GP_WK_PD_DIS,

ADSWIO3_GPIO_CONFIG_MODE_OUT ) )

{

log_error( &logger, " Set GPIO configuration. " );

for ( ; ; );

}

Delay_ms ( 100 );

}

float diag_vtg = 0;

log_printf( &logger, "_________________________\r\n" );

log_printf( &logger, " > Diagnostic Voltages <\r\n" );

if ( ADSWIO3_OK == adswio3_get_diag_vtg( &adswio3, ADSWIO3_DIAG_RESULT_SEL_0, &diag_vtg ) )

{

log_printf( &logger, " AVDD: %.2f V\r\n", diag_vtg );

Delay_ms ( 100 );

}

if ( ADSWIO3_OK == adswio3_get_diag_vtg( &adswio3, ADSWIO3_DIAG_RESULT_SEL_1, &diag_vtg ) )

{

log_printf( &logger, " VASS: %.2f V\r\n", diag_vtg );

Delay_ms ( 100 );

}

if ( ADSWIO3_OK == adswio3_get_diag_vtg( &adswio3, ADSWIO3_DIAG_RESULT_SEL_2, &diag_vtg ) )

{

log_printf( &logger, " VACC: %.2f V\r\n", diag_vtg );

Delay_ms ( 100 );

}

if ( ADSWIO3_OK == adswio3_get_diag_vtg( &adswio3, ADSWIO3_DIAG_RESULT_SEL_3, &diag_vtg ) )

{

log_printf( &logger, " LVIN: %.2f V\r\n", diag_vtg );

Delay_ms ( 100 );

}

log_printf( &logger, "_________________________\r\n" );

Delay_ms ( 1000 );

}

void application_task ( void )

{

float ntc_temp = 0, iop_ion_vtg = 0;

if ( ADSWIO3_OK == adswio3_get_ntc_temp( &adswio3, ADSWIO3_DIAG_RESULT_SEL_3, &ntc_temp ) )

{

log_printf( &logger, " NTC Temperature: %.2f degC\r\n", ntc_temp );

Delay_ms ( 100 );

}

if ( ADSWIO3_OK == adswio3_get_voltage_input( &adswio3, 0, &iop_ion_vtg ) )

{

log_printf( &logger, "IOP/ION Voltage: %.3f V\r\n", iop_ion_vtg );

Delay_ms ( 100 );

}

log_printf( &logger, "_________________________\r\n" );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END