Our mission is to infuse your projects with the enchantment of 6-axis motion sensing, unlocking entirely new possibilities for them to interact seamlessly with the physical world

A

A

Hardware Overview

How does it work?

6DOF IMU 5 Click is based on the ICM-20789, a 6-axis inertial sensor (3-axis gyroscope and a 3-axis accelerometer), and ultra-low noise MEMS capacitive barometric pressure sensor from TDK InvenSense. ICM-20789 features a 4 KB FIFO that can lower the traffic on the serial bus interface. The digital output barometric pressure sensor is based on an ultra-low noise innovative MEMS capacitive technology that can measure pressure differences with an accuracy of ±1 Pa, an accuracy enabling altitude measurement differentials as small as 8.5 cm without the penalty of increased power consumption or reduced sensor throughput. The capacitive pressure sensor has a ±1 hPa absolute accuracy over its full range of 300 hPa -1100 hPa. The pressure sensor offers industry leading temperature stability of the pressure sensor with a temperature coefficient offset of ±0.5 Pa/°C, embedded temperature sensor and 400kHz I2C

bus for communication. The gyroscope has a programmable full-scale range of ±250 dps, ±500 dps, ±1000 dps, and ±2000 dps. The accelerometer has a user-programmable full-scale range of ±2g, ±4g, ±8g, and ±16g. Factory-calibrated initial sensitivity of both sensors reduces production-line calibration requirements. Other features include on-chip 16-bit ADCs, programmable digital filters, another embedded temperature sensor, and programmable interrupts. The device features I2C serial interface to access its registers at 400 kHz as well as at 8 MHz SPI. The onboard chip ICM-20789 requires stable voltage for power supply of input/output pins (VDDIO) at 1.8V which also supplies the pressure sensor. 6DOF IMU 5 click does all of the power supply regulations as well as the logic level translations needed for proper operation. The MCP1826, a 1000 mA Low Dropout (LDO) linear regulator provides high-current and

low-output voltage of 1.8V to all of the essential parts of the board, while TXB0106 and PCA9306 do the SPI and I2C signal level translations, respectively, between the MCU and the ICM-20789. Interacting with the 6-axis is possible through SPI communication protocol while the I2C bus allows access to pressure sensors 16-bit address space registers. This device is intended for implementation in Drones and Flying Toys, Motion-based gaming controllers, Virtual Reality Headsets & Controllers, Indoor/Outdoor Navigation (dead-reckoning, floor/elevation/step detection). This Click Board™ uses both I2C and SPI communication interfaces. It is designed to be operated only with 3.3V logic levels. A proper logic voltage level conversion should be performed before the Click board™ is used with MCUs with logic levels of 5V.

Features overview

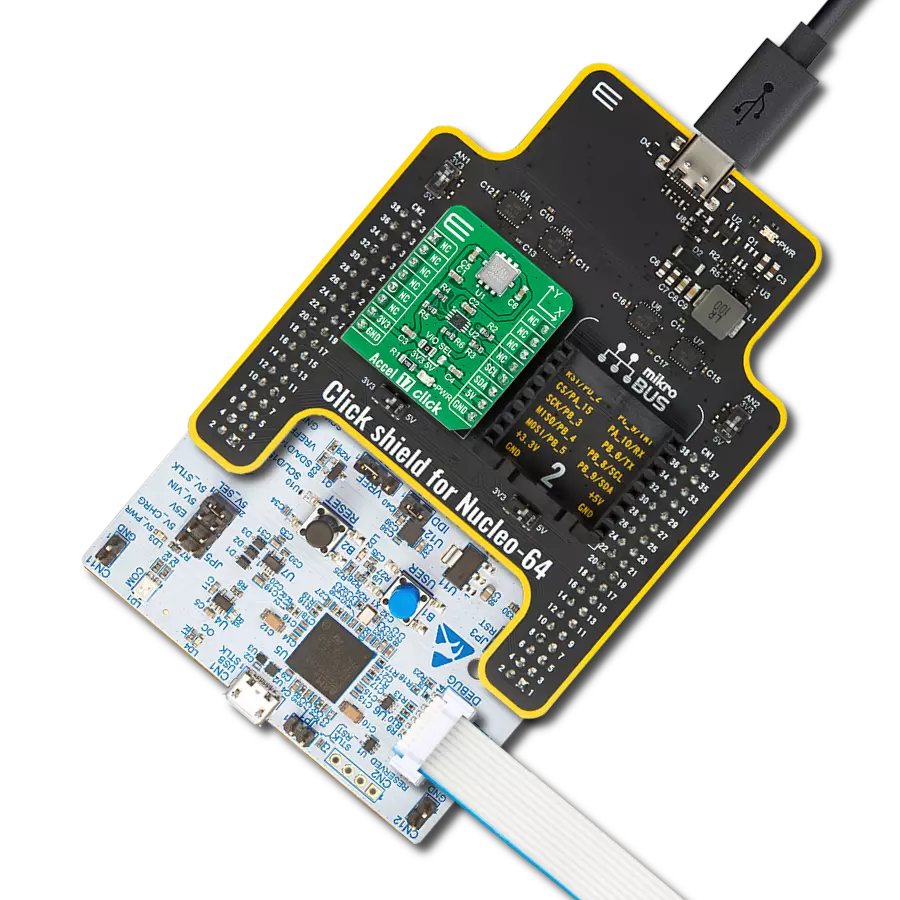

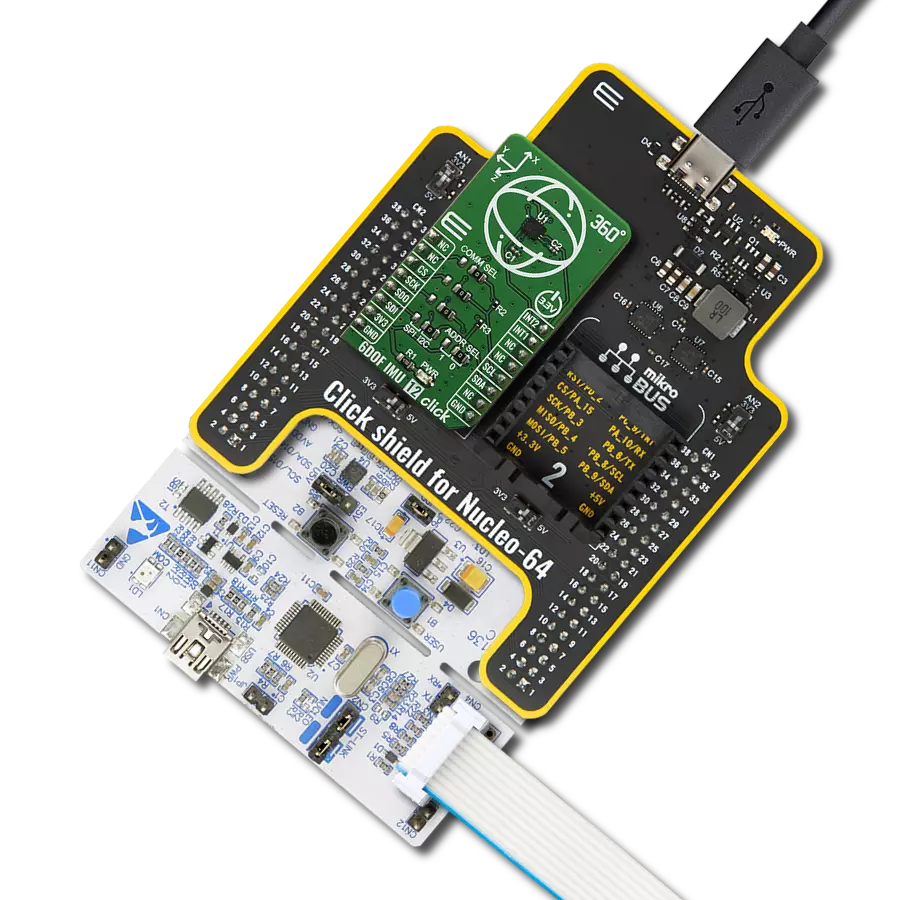

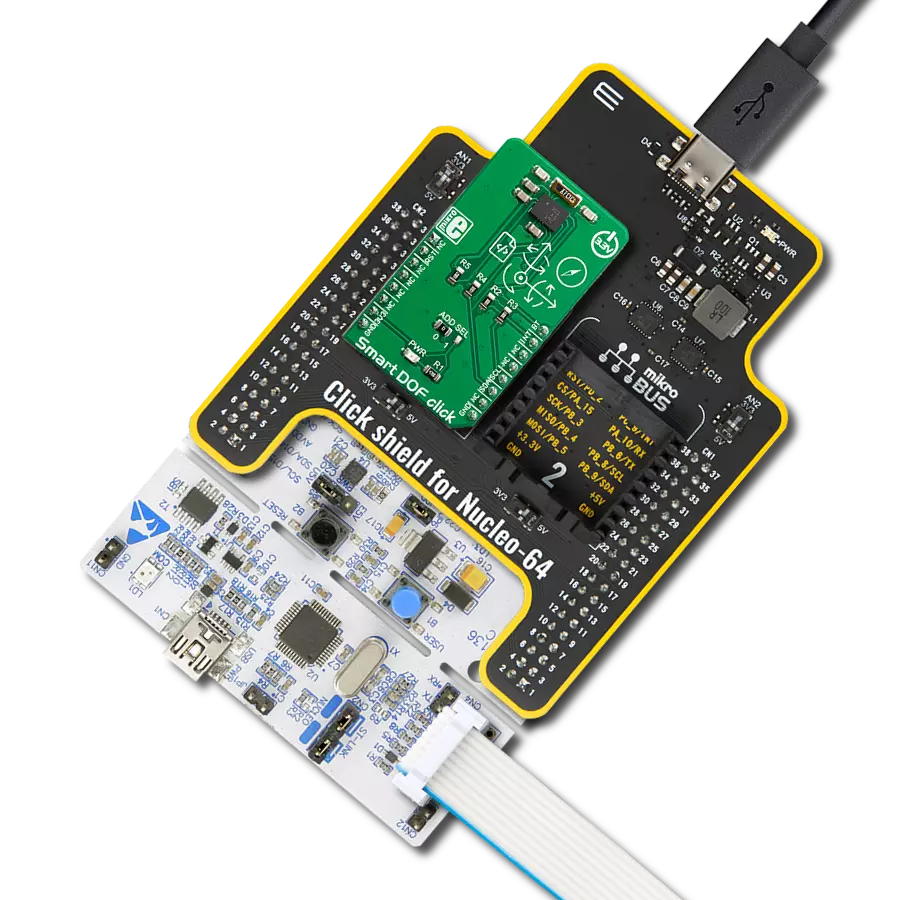

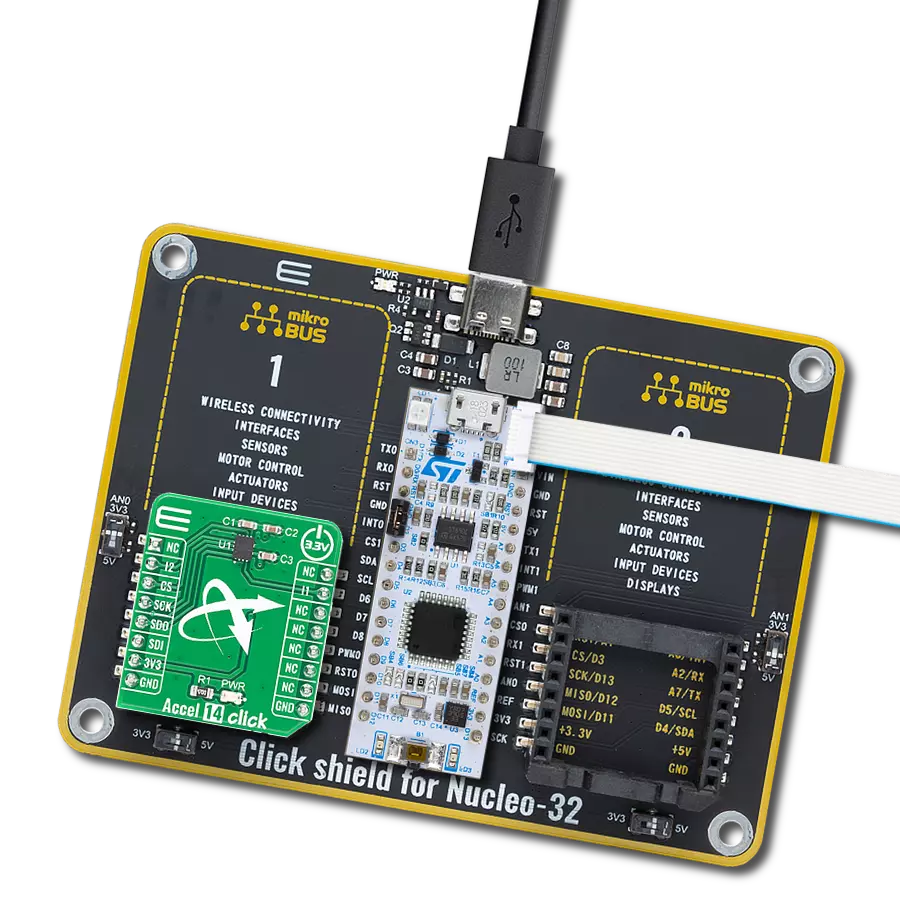

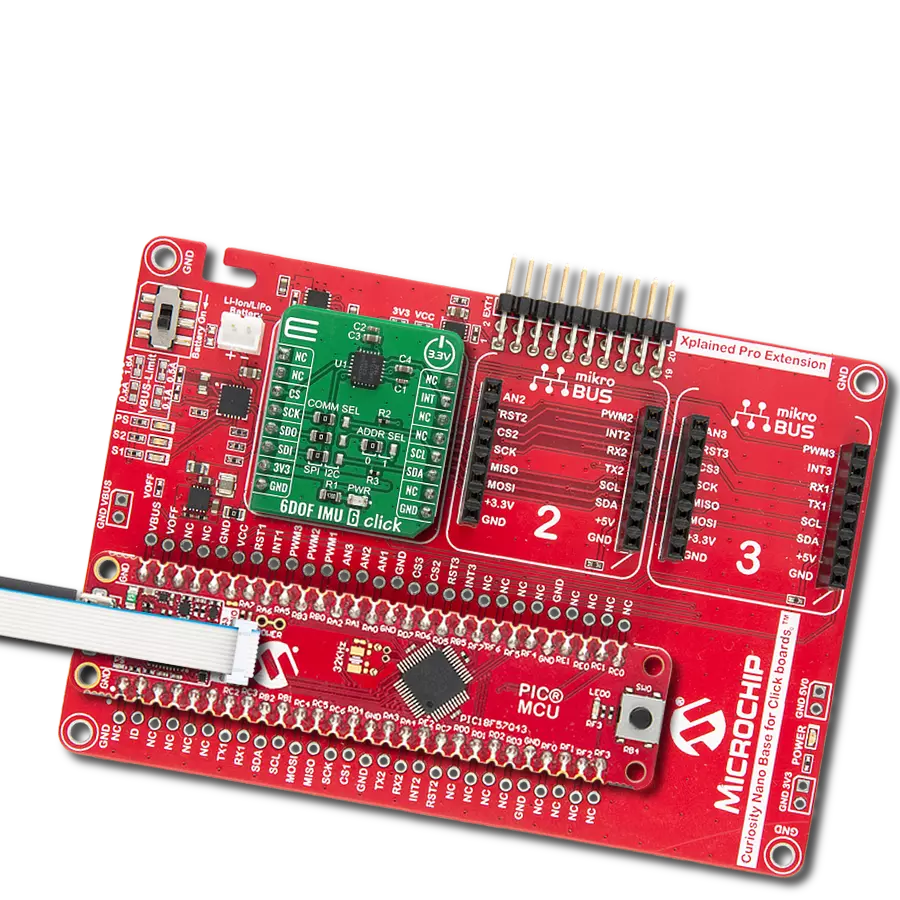

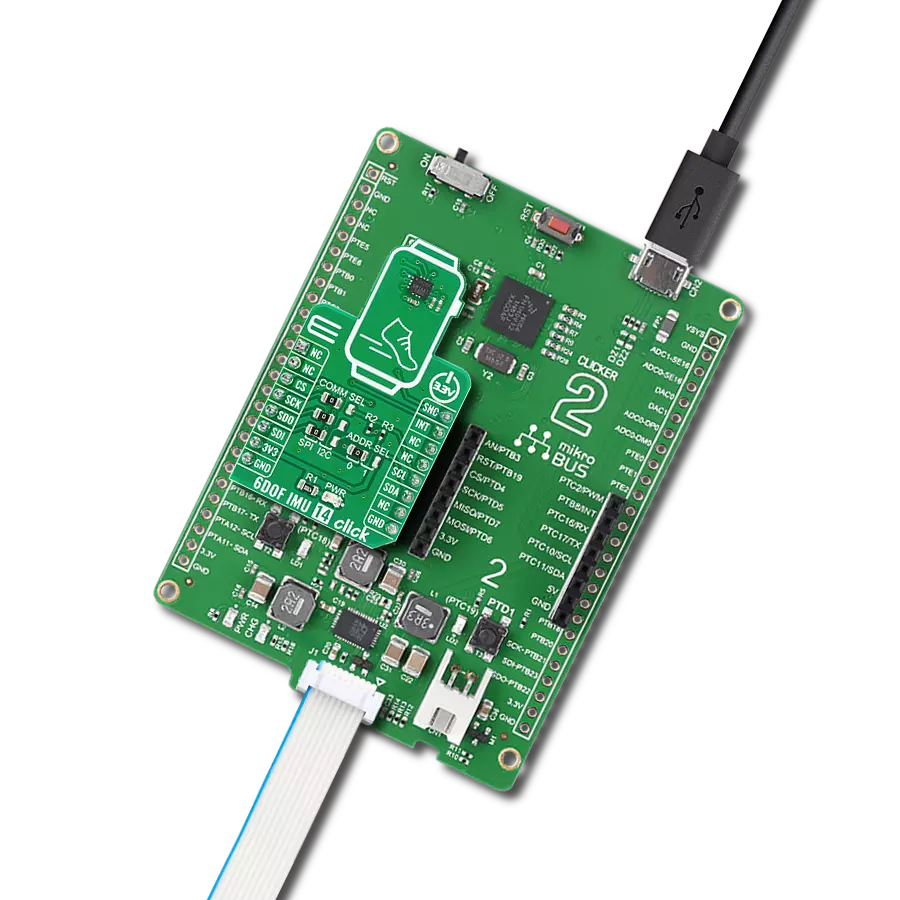

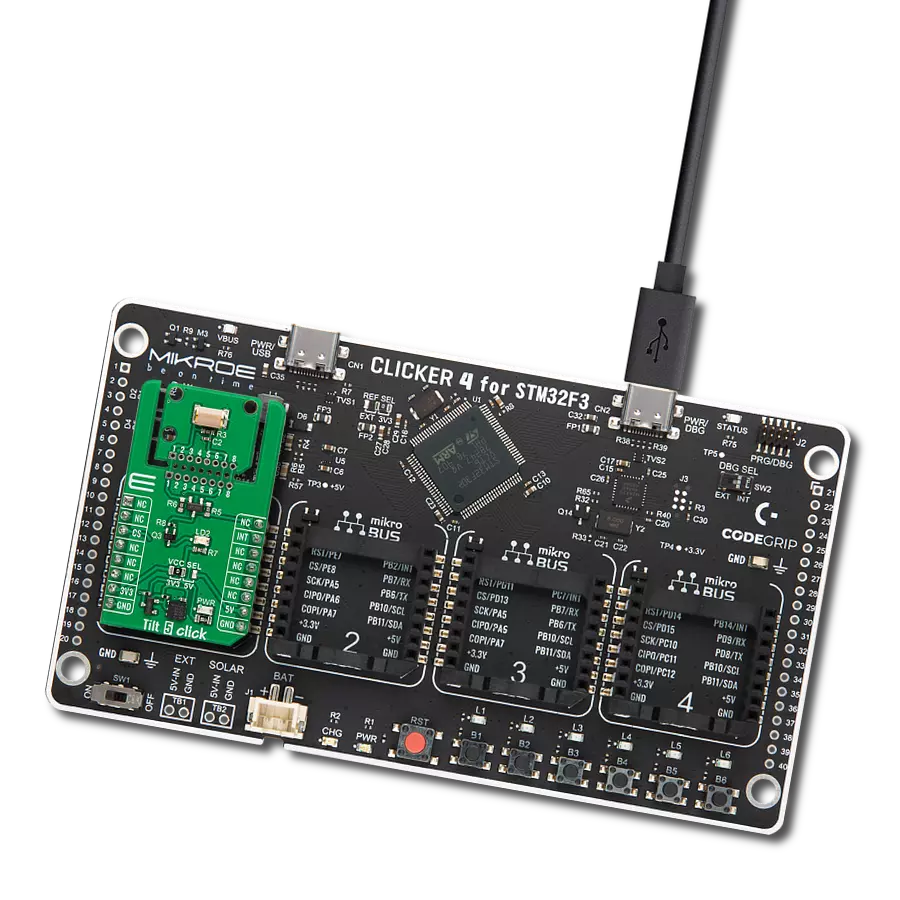

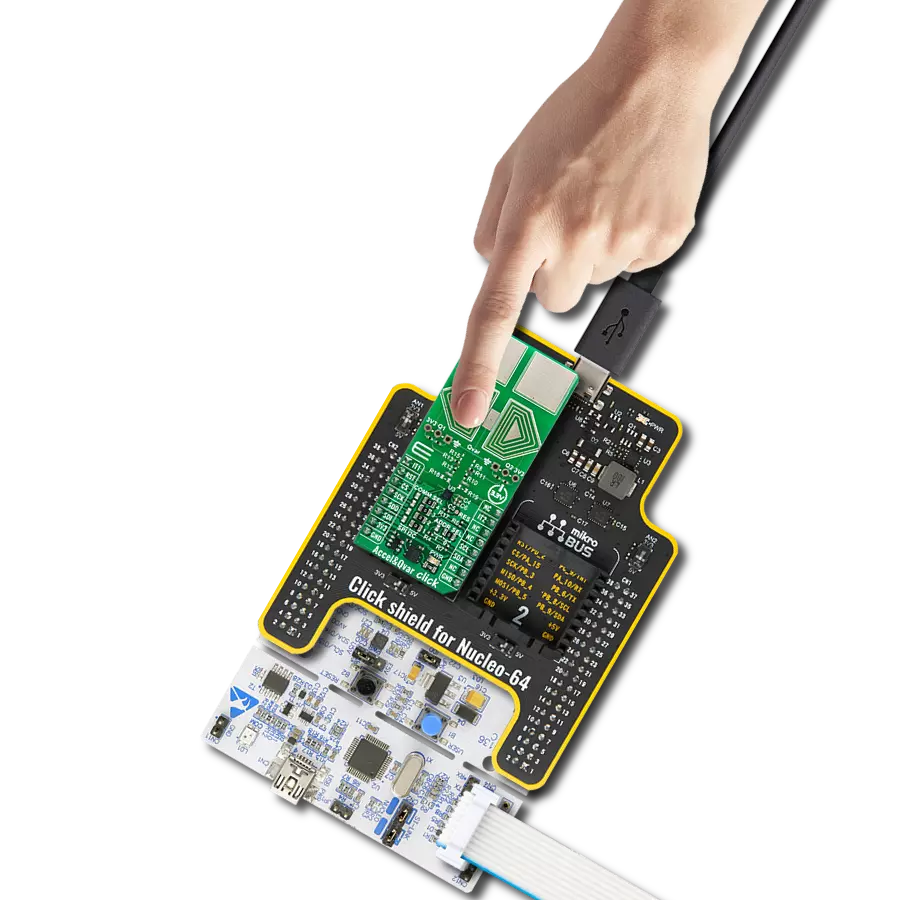

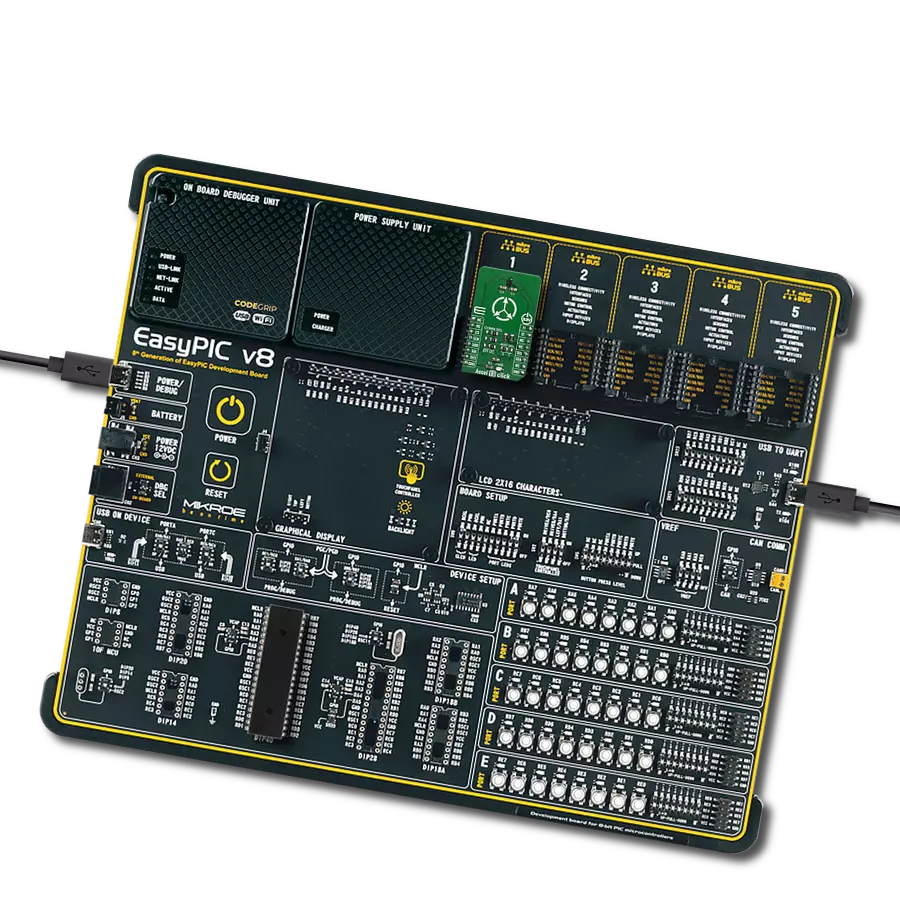

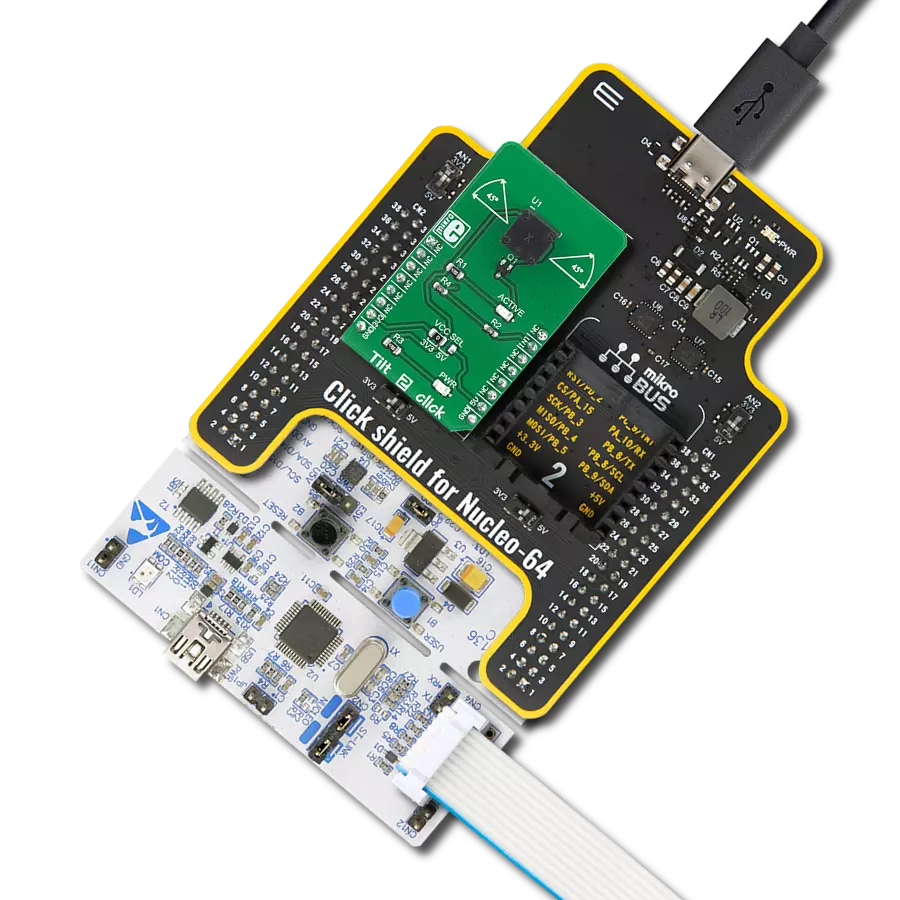

Development board

Curiosity PIC32 MZ EF development board is a fully integrated 32-bit development platform featuring the high-performance PIC32MZ EF Series (PIC32MZ2048EFM) that has a 2MB Flash, 512KB RAM, integrated FPU, Crypto accelerator, and excellent connectivity options. It includes an integrated programmer and debugger, requiring no additional hardware. Users can expand

functionality through MIKROE mikroBUS™ Click™ adapter boards, add Ethernet connectivity with the Microchip PHY daughter board, add WiFi connectivity capability using the Microchip expansions boards, and add audio input and output capability with Microchip audio daughter boards. These boards are fully integrated into PIC32’s powerful software framework, MPLAB Harmony,

which provides a flexible and modular interface to application development a rich set of inter-operable software stacks (TCP-IP, USB), and easy-to-use features. The Curiosity PIC32 MZ EF development board offers expansion capabilities making it an excellent choice for a rapid prototyping board in Connectivity, IOT, and general-purpose applications.

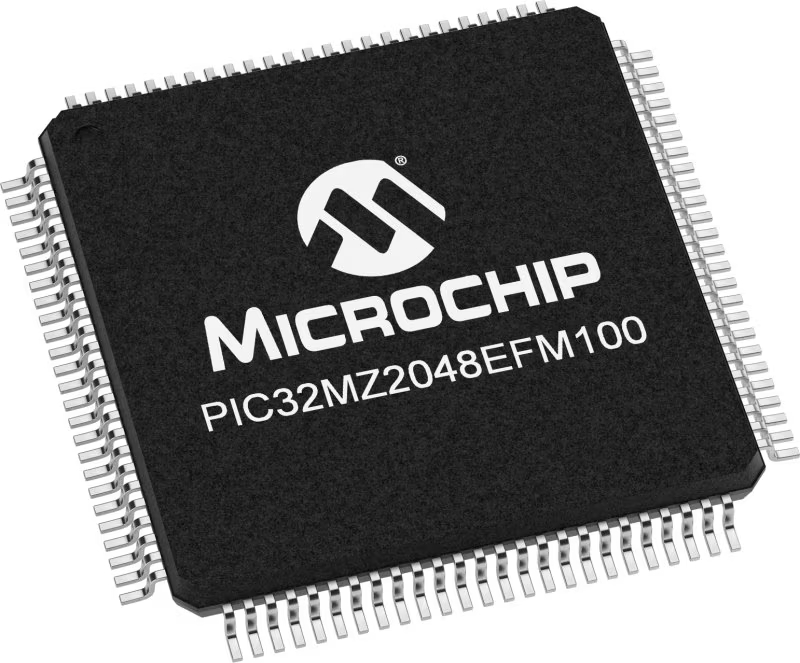

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

2048

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for 6DOF IMU 5 Click driver.

Key functions:

c6dofimu5_power- This function turns the device on or offc6dofimu5_read_gyroscope- This function is used to read gyroscope datac6dofimu5_read_accelerometer- This function is used to read accelerometer data

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief C6DofImu5 Click example

*

* # Description

* This example demonstrates the use of 6DOF IMU 5 Click board.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver, checks the communication and sets the device

* default configuration.

*

* ## Application Task

* Measures acceleration, gyroscope, temperature and pressure data and

* displays the results on USB UART each second.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "c6dofimu5.h"

// ------------------------------------------------------------------ VARIABLES

static c6dofimu5_t c6dofimu5;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

c6dofimu5_cfg_t cfg;

uint8_t id_val;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

c6dofimu5_cfg_setup( &cfg );

C6DOFIMU5_MAP_MIKROBUS( cfg, MIKROBUS_1 );

c6dofimu5_init( &c6dofimu5, &cfg );

c6dofimu5_read_bytes ( &c6dofimu5, C6DOFIMU5_WHO_AM_I, &id_val, 1 );

if ( id_val == C6DOFIMU5_WHO_AM_I_VAL )

{

log_printf( &logger, "-------------------------\r\n " );

log_printf( &logger, " 6DOF IMU 5 Click \r\n " );

log_printf( &logger, "-------------------------\r\n " );

c6dofimu5_power ( &c6dofimu5, C6DOFIMU5_POWER_ON );

}

else

{

log_printf( &logger, "-------------------------\r\n " );

log_printf( &logger, " FATAL ERROR!!! \r\n " );

log_printf( &logger, "-------------------------\r\n " );

for ( ; ; );

}

c6dofimu5_default_cfg( &c6dofimu5 );

c6dofimu5_baro_settings( &c6dofimu5 );

log_printf( &logger, " ---Initialised--- \r\n " );

log_printf( &logger, "-------------------------\r\n " );

Delay_ms ( 100 );

}

void application_task ( void )

{

float x_gyro;

float y_gyro;

float z_gyro;

float x_accel;

float y_accel;

float z_accel;

uint32_t raw_pres;

uint16_t raw_temp;

c6dofimu5_process_data_t process_data;

c6dofimu5_acceleration_rate( &c6dofimu5, &x_accel, &y_accel, &z_accel );

c6dofimu5_angular_rate( &c6dofimu5, &x_gyro, &y_gyro, &z_gyro );

log_printf( &logger, " Accel X: %.2f \t Gyro X: %.2f\r\n", x_accel, x_gyro );

log_printf( &logger, " Accel Y: %.2f \t Gyro Y: %.2f\r\n", y_accel, y_gyro );

log_printf( &logger, " Accel Z: %.2f \t Gyro Z: %.2f\r\n", z_accel, z_gyro );

log_printf( &logger, "-------------------------\r\n " );

c6dofimu5_read_raw_data( &c6dofimu5, &raw_pres, &raw_temp );

process_data.p_raw = raw_pres;

process_data.t_raw = raw_temp;

c6dofimu5_process_data( &c6dofimu5, &process_data );

log_printf( &logger, "Pressure: %.2f mBar\r\n " , process_data.pressure * 0.01 );

log_printf( &logger, "Temperature: %.2f Celsius\r\n " , process_data.temperature );

log_printf( &logger, "-------------------------\r\n" );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Motion