Our three-axis accelerometer is engineered to revolutionize motion sensing, providing accurate and real-time measurements for a multitude of applications

A

A

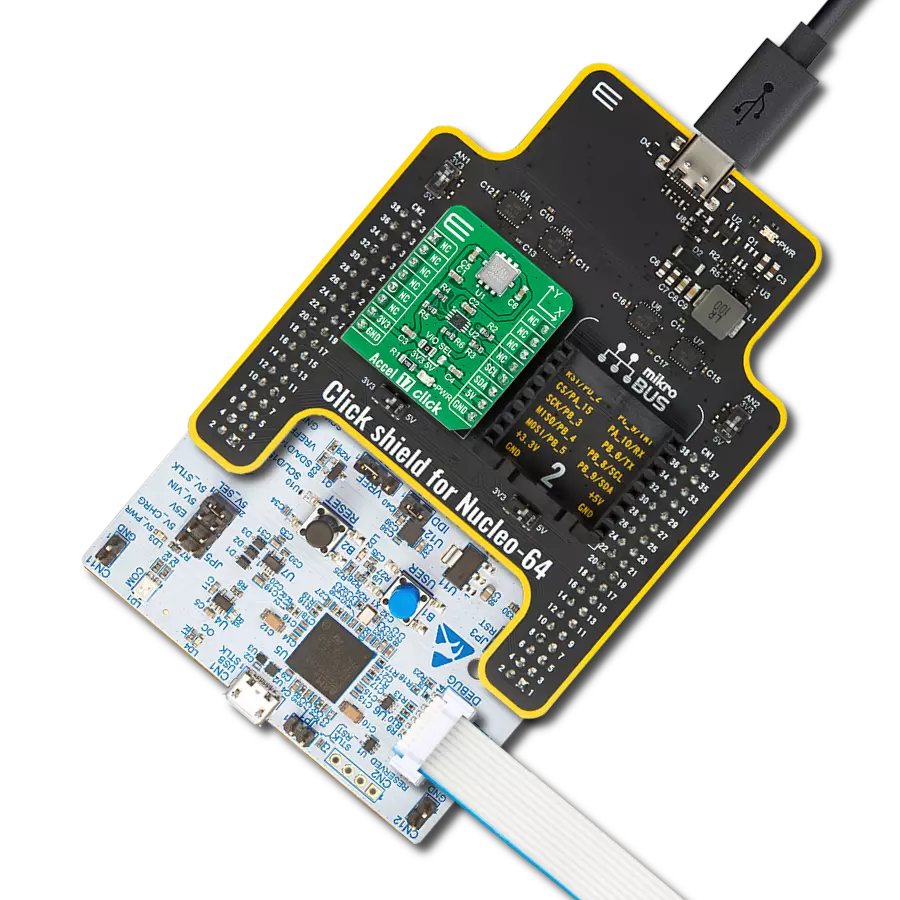

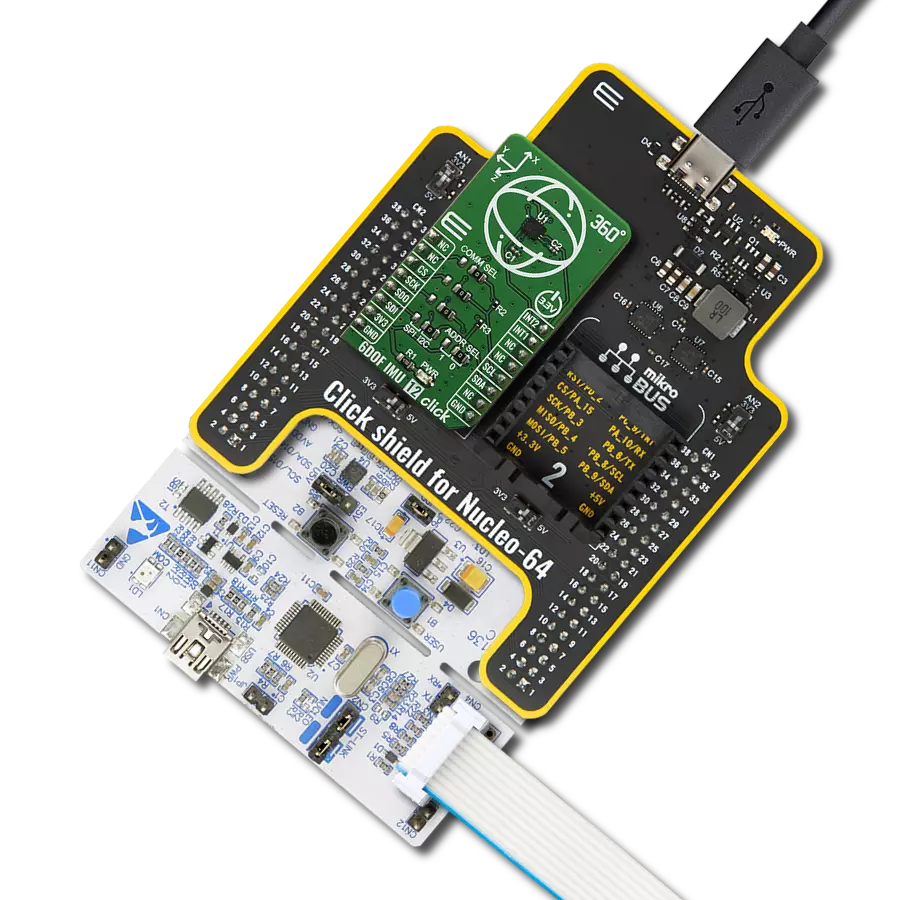

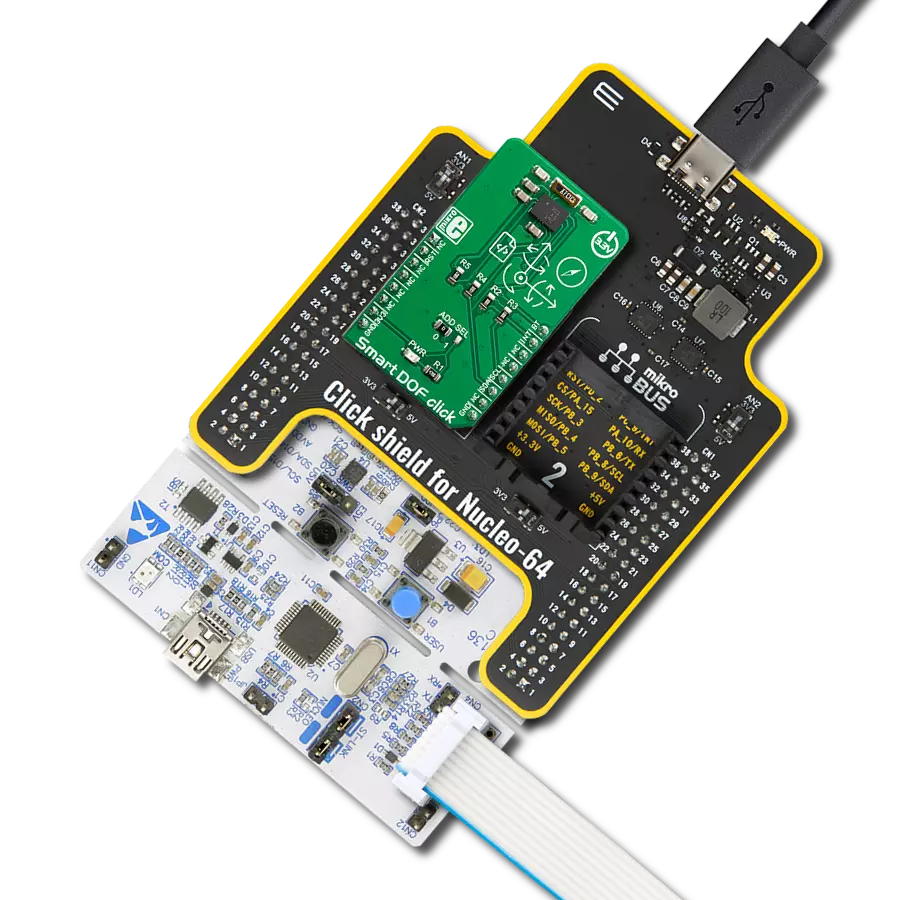

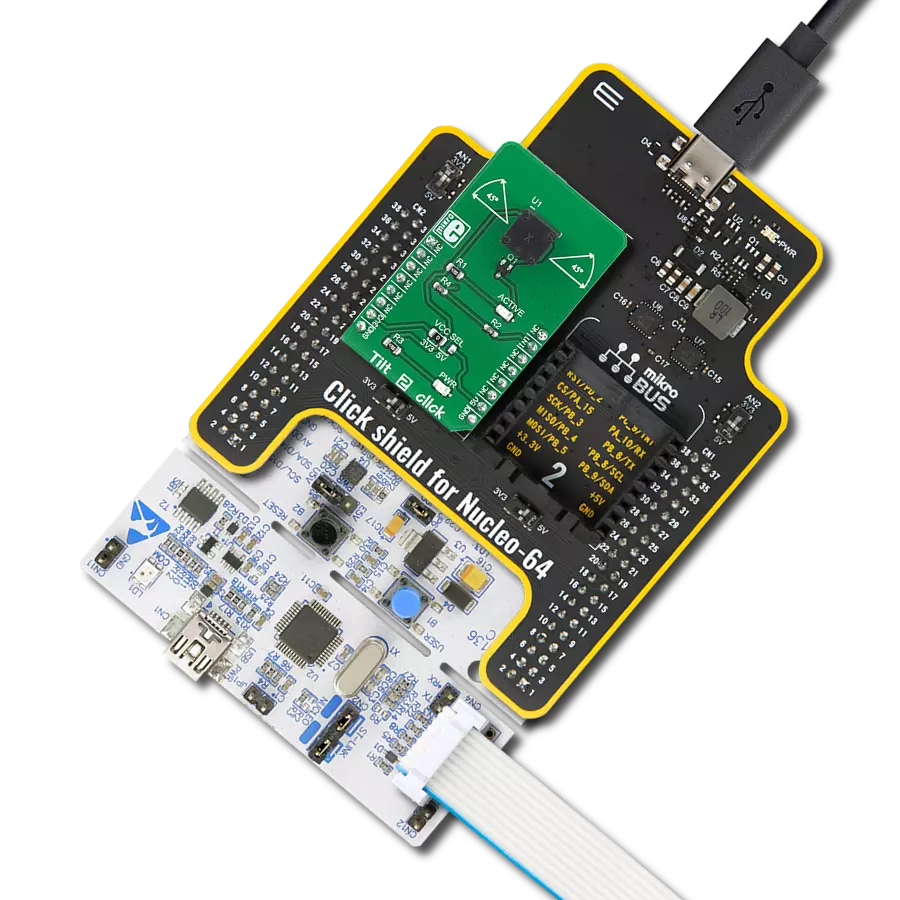

Hardware Overview

How does it work?

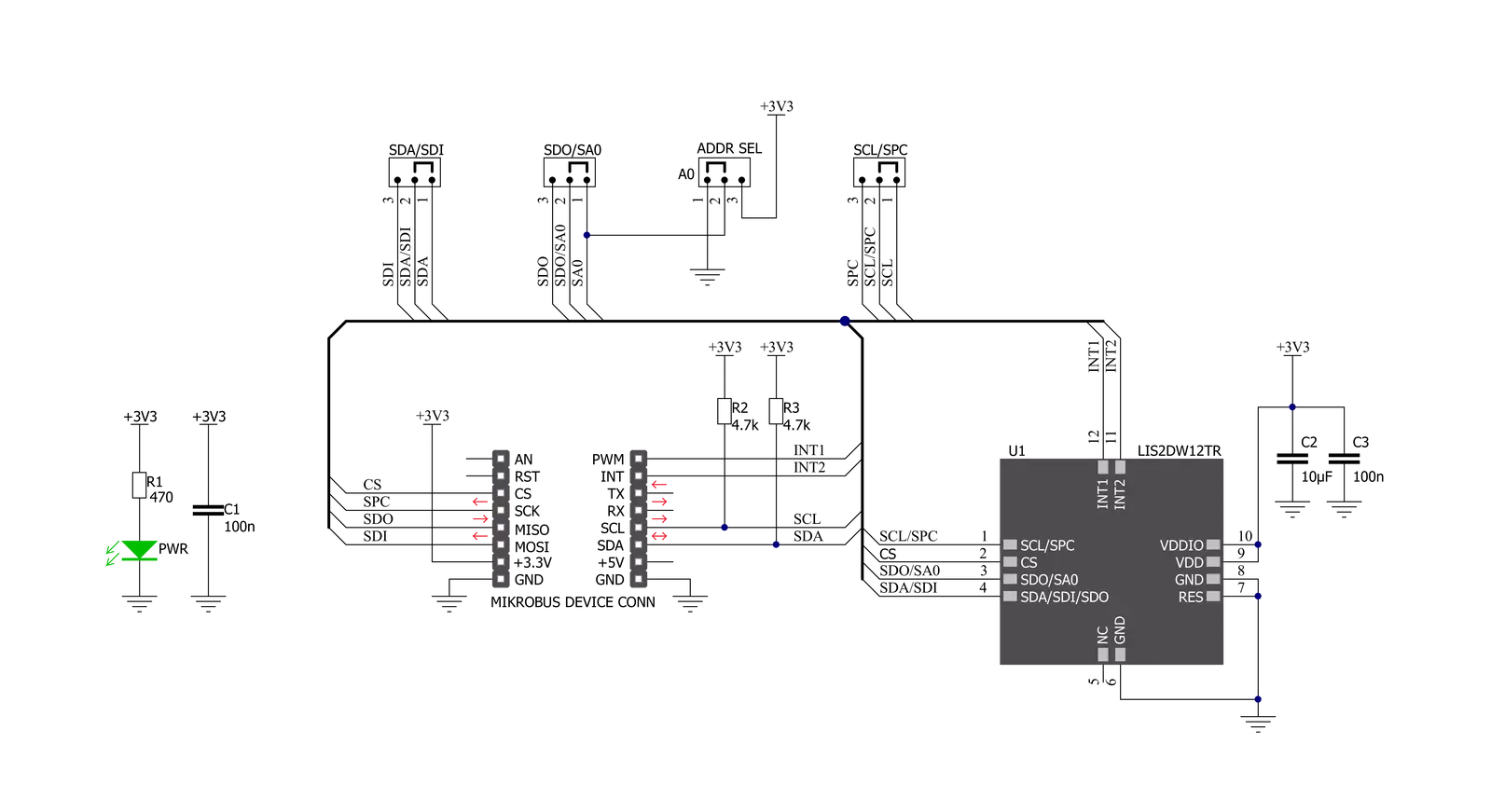

Accel 10 Click is based on the LIS2DW12TR, a high-performance ultra-low-power 3-axis "femto" accelerometer, from STMicroelectronics. This sensor has many features perfectly suited for wearables, handheld, and IoT applications, offering a good balance between the performance and the power consumption. One of its key features is its extremely low power consumption, which makes it perfectly suited for such applications. There are several power modes which the LIS2DW12TR device can use. While in Low Power mode, the device consumes only 0.38µA, but the access to some features is restricted. Having that in mind, accel 10 Click can be used for a rapid development and testing of various applications based on step counting, fitness applications, profile switching and display ON/OFF applications, angle measurement applications, and similar applications. More information can be found within the LIS2DW12TR datasheet. The LIS2DW12TR sensor can measure acceleration within ranges of ±2 g, ±4 g, ±8, and ±16 g. It can output the measurement data using the Output Data Rate (ODR) from 1.6Hz (Low Power mode), up to 1600Hz (Performance mode). A high-precision analog front end facilitates highly sensitive MEMS,

featuring a 14-bit A/D Converter. It allows very high accuracy of the output, even during very low amplitude changes. This makes the sensor particularly sensitive and accurate with movements that generate relatively low acceleration signals. However, using a highly sensitive MEMS makes the LIS2DW12TR prone to damage caused by extremely high g-forces (10,000 g for less than 200 µs). Acceleration data is available in 14-bit format from both the data registers and the internal FIFO buffer, which can can memorize 32 slots of X, Y and Z data. The FIFO buffer can be used for more complex calculations or timed readings, reducing the traffic on the communication interface. FIFO buffer allows optimization within the firmware that runs on the host MCU. Besides the acceleration MEMS and complementary analog front-end circuit, the LIS2DW12TR sensor also has an integrated temperature sensor. It is updated up to 25 times per second, and sampled to an 12-bit value (complement of 2’s format). Interrupts can be triggered for many different events. Some basic events include the data-ready interrupt event and aforementioned FIFO events, while so-called feature engines can trigger an interrupt for any of

the detected motion/movement events, including step detection/counter, activity recognition, tilt on wrist, tap/double tap, any/no motion, and error event interrupt. The extensive interrupt engine can use two programmable interrupt pins. Both of these pins can be assigned with any interrupt source and can be either LOW or HIGH on interrupt, depending on settings in appropriate registers. These two pins are routed to PWM and INT pin of the mikroBUS™, and are labeled as IT1 and IT2, respectively. Accel 10 Click offers two communication interfaces. It can be used with either I2C or SPI. The onboard SMD jumpers labeled as COMM SEL allow switching between the two interfaces. Note that all the jumpers have to be positioned either I2C or to SPI position. When I2C interface is selected, an additional SMD jumper labeled as ADDR SEL becomes available, determining the least significant bit of the LIS2DW12TR I2C address. This Click Board™ uses both I2C and SPI communication interfaces. It is designed to be operated only with 3.3V logic levels. A proper logic voltage level conversion should be performed before the Click board™ is used with MCUs with logic levels of 5V.

Features overview

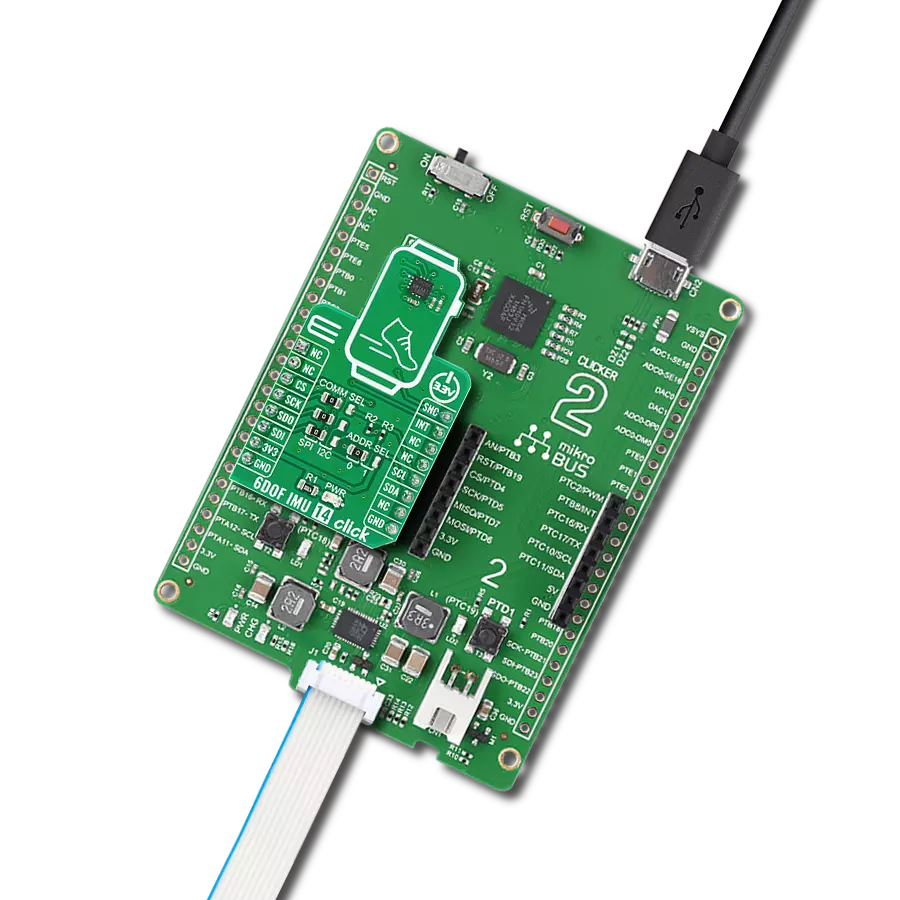

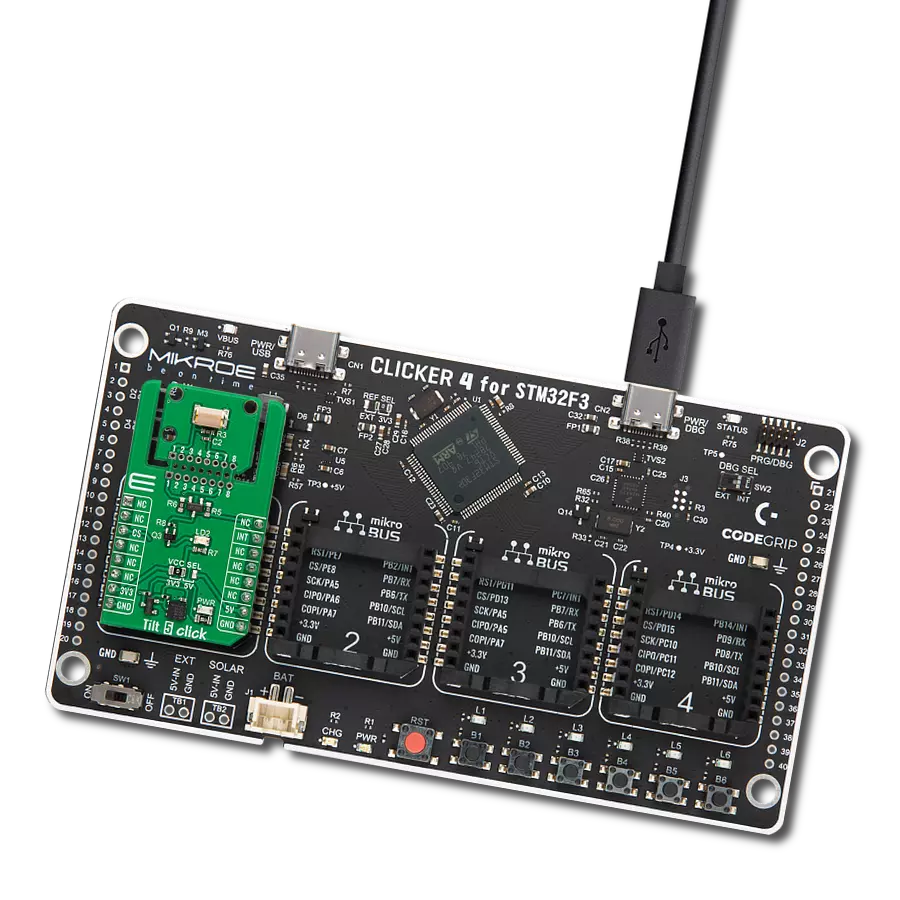

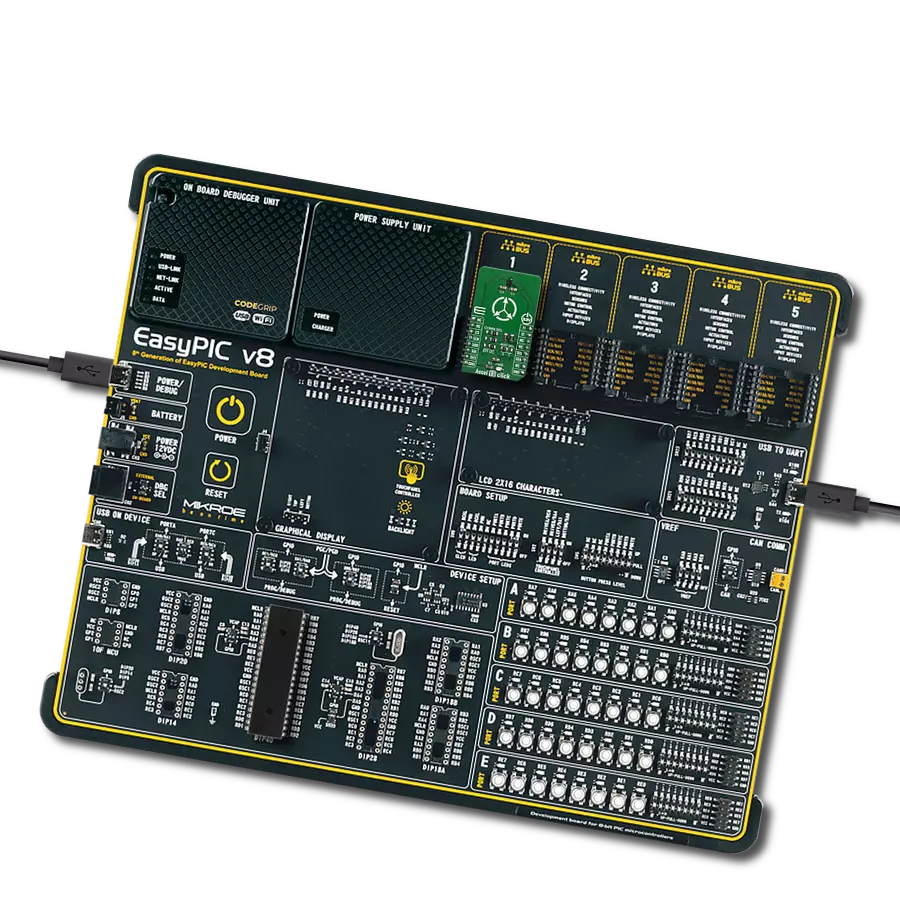

Development board

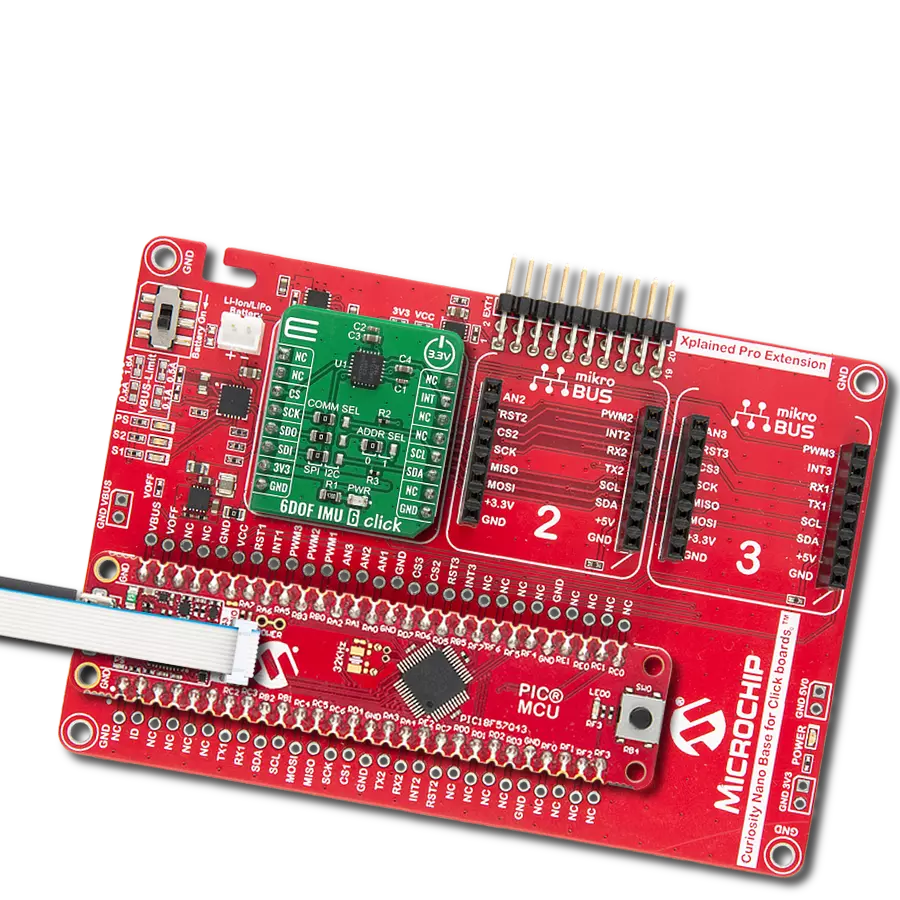

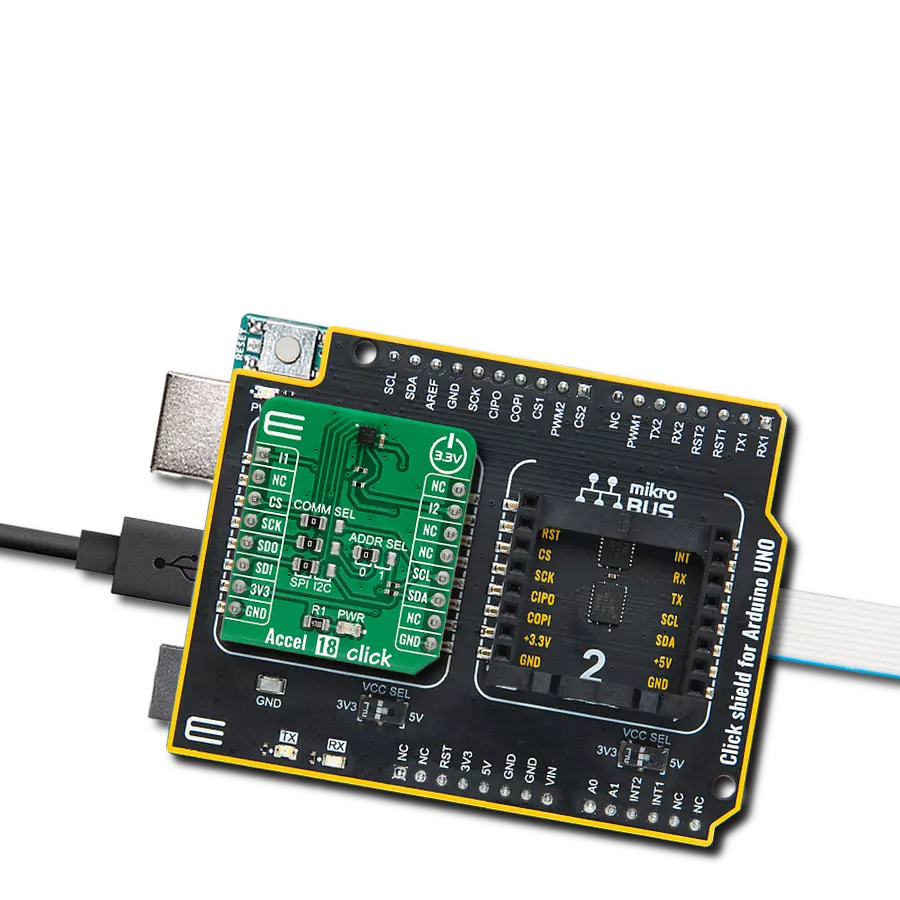

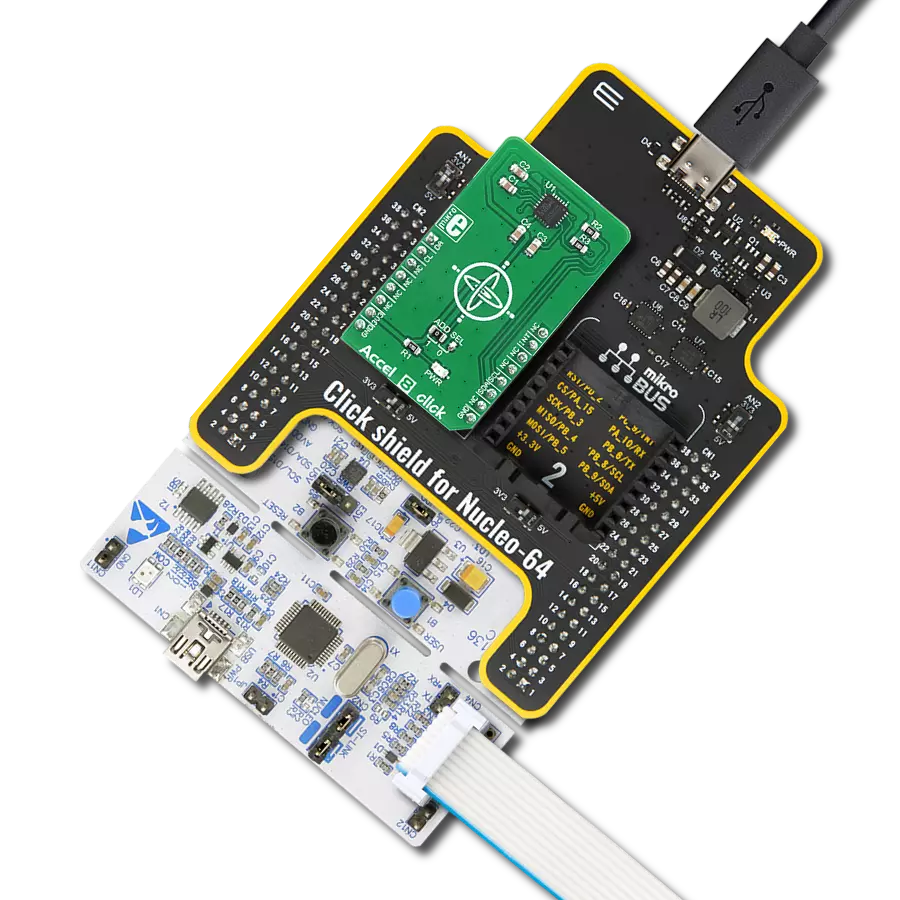

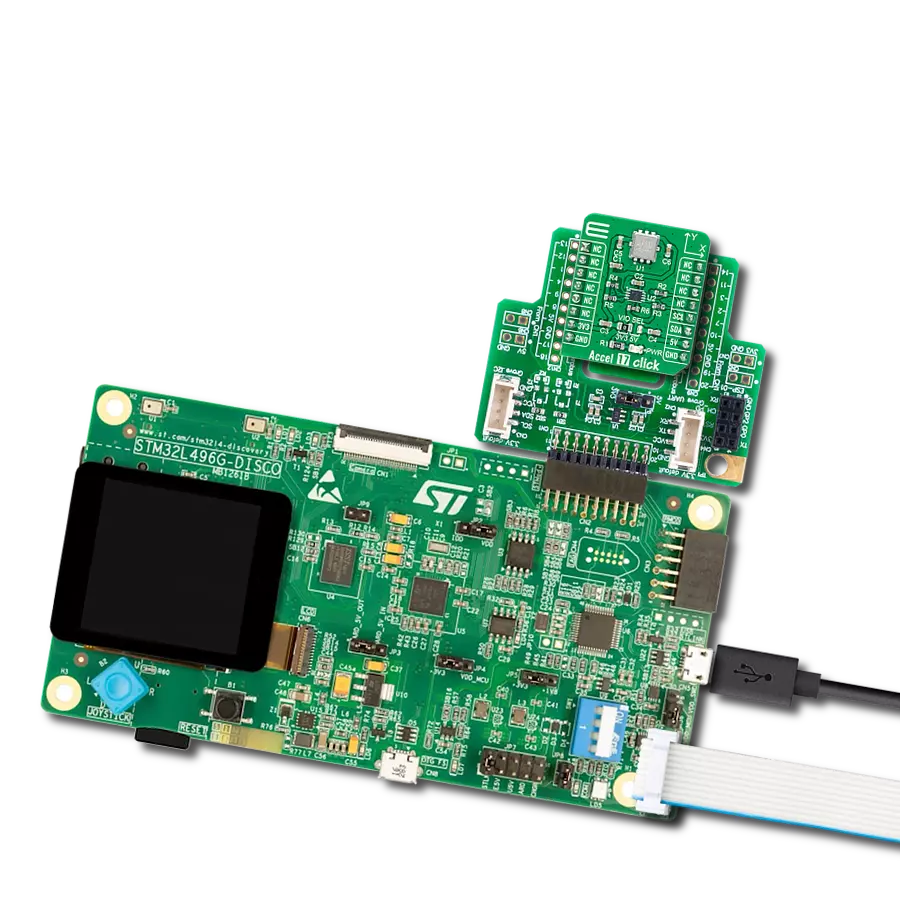

PIC18F57Q43 Curiosity Nano evaluation kit is a cutting-edge hardware platform designed to evaluate microcontrollers within the PIC18-Q43 family. Central to its design is the inclusion of the powerful PIC18F57Q43 microcontroller (MCU), offering advanced functionalities and robust performance. Key features of this evaluation kit include a yellow user LED and a responsive

mechanical user switch, providing seamless interaction and testing. The provision for a 32.768kHz crystal footprint ensures precision timing capabilities. With an onboard debugger boasting a green power and status LED, programming and debugging become intuitive and efficient. Further enhancing its utility is the Virtual serial port (CDC) and a debug GPIO channel (DGI

GPIO), offering extensive connectivity options. Powered via USB, this kit boasts an adjustable target voltage feature facilitated by the MIC5353 LDO regulator, ensuring stable operation with an output voltage ranging from 1.8V to 5.1V, with a maximum output current of 500mA, subject to ambient temperature and voltage constraints.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC

MCU Memory (KB)

128

Silicon Vendor

Microchip

Pin count

48

RAM (Bytes)

8196

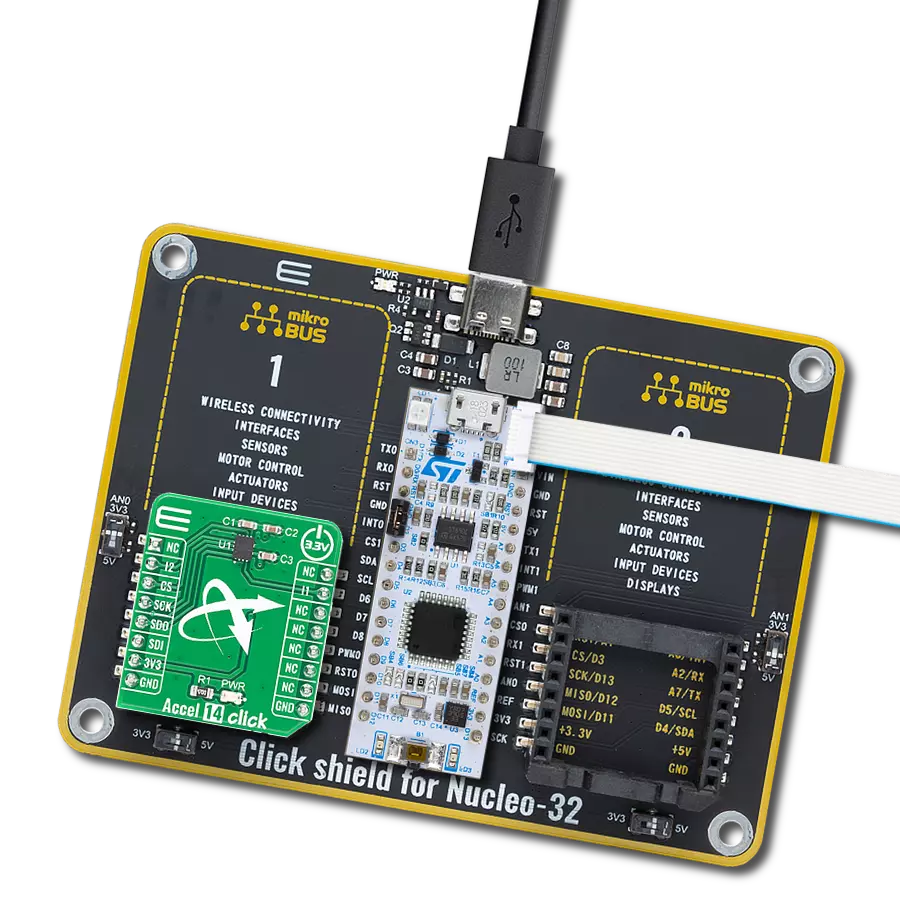

You complete me!

Accessories

Curiosity Nano Base for Click boards is a versatile hardware extension platform created to streamline the integration between Curiosity Nano kits and extension boards, tailored explicitly for the mikroBUS™-standardized Click boards and Xplained Pro extension boards. This innovative base board (shield) offers seamless connectivity and expansion possibilities, simplifying experimentation and development. Key features include USB power compatibility from the Curiosity Nano kit, alongside an alternative external power input option for enhanced flexibility. The onboard Li-Ion/LiPo charger and management circuit ensure smooth operation for battery-powered applications, simplifying usage and management. Moreover, the base incorporates a fixed 3.3V PSU dedicated to target and mikroBUS™ power rails, alongside a fixed 5.0V boost converter catering to 5V power rails of mikroBUS™ sockets, providing stable power delivery for various connected devices.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

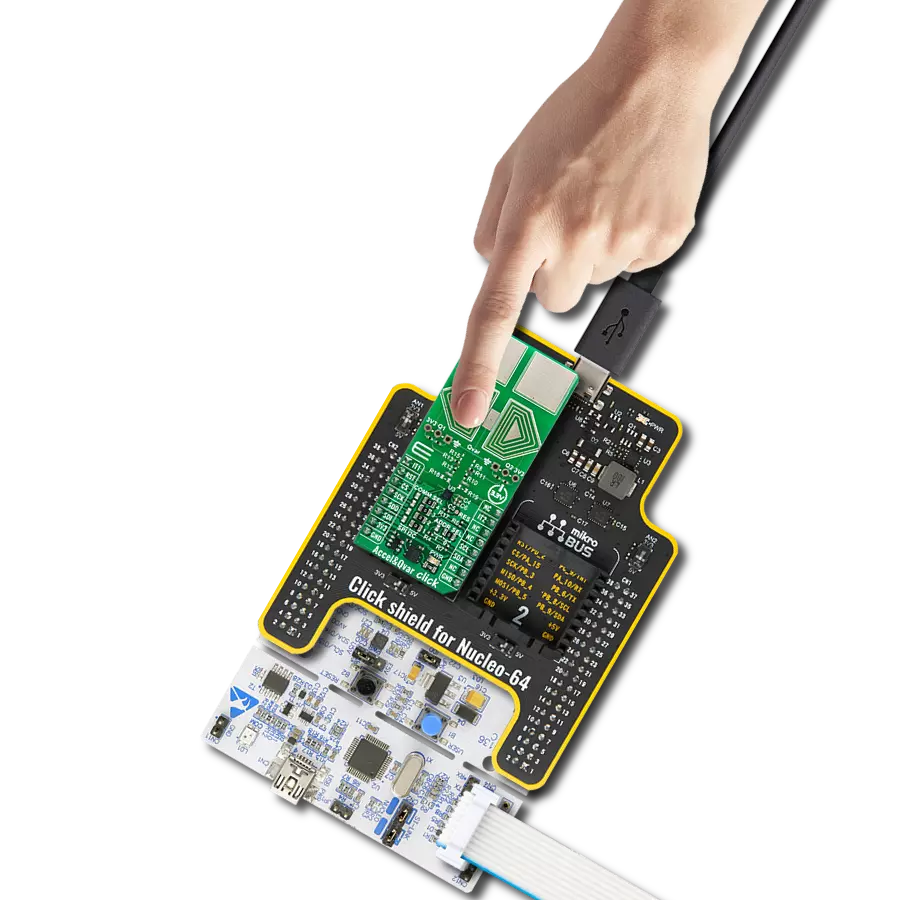

Step by step

Project assembly

Software Support

Library Description

This library contains API for Accel 10 Click driver.

Key functions:

accel10_check_data_ready- Check data ready functionaccel10_get_data- Read Accel data functionaccel10_read_temperature- Read temperature function

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Accel10 Click example

*

* # Description

* This example demonstrates the use of Accel 10 Click board.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and checks the communication by reading the device ID.

* After that, performs the Click default configuration.

*

* ## Application Task

* Reads the accel values for X, Y, and Z axis and also reads the temperature in Celsius

* and displays the results on the USB UART each second.

*

* \author Nenad Filipovic

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "accel10.h"

// ------------------------------------------------------------------ VARIABLES

static accel10_t accel10;

static log_t logger;

static accel10_data_t accel_data;

static int8_t temperature;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

accel10_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

accel10_cfg_setup( &cfg );

ACCEL10_MAP_MIKROBUS( cfg, MIKROBUS_1 );

accel10_init( &accel10, &cfg );

Delay_ms ( 500 );

log_printf( &logger, "---------------------\r\n" );

log_printf( &logger, " Accel 10 Click\r\n" );

log_printf( &logger, "---------------------\r\n" );

// Checking communication

if ( accel10_check_id( &accel10 ) == ACCEL10_SUCCESS )

{

log_printf( &logger, " Communication OK\r\n" );

log_printf( &logger, "---------------------\r\n" );

Delay_ms ( 100 );

}

else

{

log_printf( &logger, " Communication ERROR\r\n" );

log_printf( &logger, " Reset the device\r\n" );

log_printf( &logger, "---------------------\r\n" );

for ( ; ; );

}

accel10_default_cfg ( &accel10 );

log_printf( &logger, " Default config.\r\n" );

log_printf( &logger, "---------------------\r\n" );

Delay_ms ( 100 );

}

void application_task ( void )

{

if ( accel10_check_data_ready( &accel10 ) == ACCEL10_STATUS_DATA_READY )

{

accel10_get_data ( &accel10, &accel_data );

Delay_ms ( 10 );

log_printf( &logger, " Accel X : %d\r\n", accel_data.x );

log_printf( &logger, " Accel Y : %d\r\n", accel_data.y );

log_printf( &logger, " Accel Z : %d\r\n", accel_data.z );

temperature = accel10_read_temperature( &accel10 );

Delay_ms ( 10 );

log_printf( &logger, " Temperature : %d C\r\n", ( int16_t ) temperature );

log_printf( &logger, "---------------------\r\n" );

Delay_ms ( 1000 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Motion