Revolutionize your connectivity strategy and cut expenses by leveraging your existing electrical infrastructure for seamless communication.

A

A

Hardware Overview

How does it work?

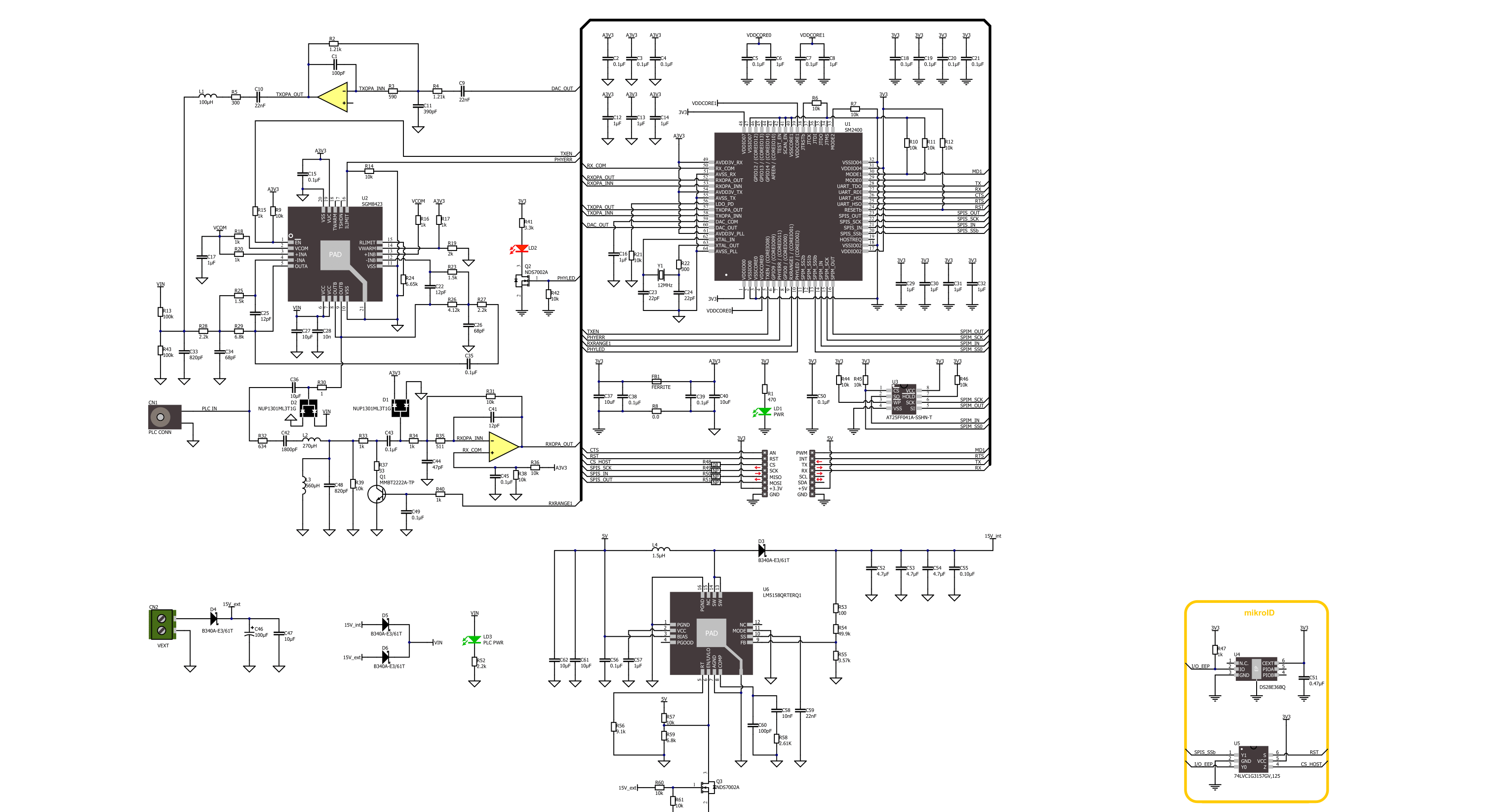

N-PLC Click is based on the SM2400, the ultimate Narrow-band Power Line Communication (N-PLC) modem from Semitech that combines cost-effective design optimized for PLC applications with a high level of programmability to address a multitude of communications schemes and evolving standards. The SM2400 system-on-chip (SoC) features a dual-core architecture for dedicated PHY signal processing and MAC layer functionality to guarantee superior communication performance while maintaining high flexibility and programmability for OFDM-based and other open standards and fully customized implementations. It has a set of firmware options implementing IEEE 1901.2 compliant PHY and MAC layers, a 6LoWPAN data link layer, PRIME, G3-PLC, and other special modes tailored for industrial IoT applications. The SM2400 combines the benefits of programmable architecture with power and efficiency by utilizing a DSP core configured specifically for N-PLC modulations and a dedicated 32-bit core that runs protocols. It contains a high-speed 256-bit AES-CCM engine to ensure standard compliance and secure communication, and all the necessary mixed-signal components, such as ADC, DAC, gain control and two OpAmp to deliver a cost-effective N-PLC system design for any application. In addition to the SM2400, this Click board™ also includes a PLC line driver, the SGM8423, a high efficiency, Class A/B, and a low distortion power line driver. It is optimized to accept a signal from a

Power Line Carrier modem, such as the SM2400, which is presented in the example code, where two such boards talk to each other in a transmitter/receiver configuration. Besides directly performing enable/shutdown control of the line driver, the SM2400 has one diagnostic signal that can indicate error conditions, such as overcurrent or overheating, reported by the line driver. In addition, it is also possible to supply high voltage (110/220VAC) as an input on the PLC CONN connector, which will be converted into a signal of the appropriate level via the N-PLC Wall Adapter, a simple yet very useful power line communication AC coupling circuit for safe and secure operation. The green PLC PWR LED signal that the N-PLC Wall Adapter is connected and powered. The SM2400 communicates with an MCU using the UART interface as its main one, with commonly used UART RX and TX pins and the optional hardware flow control pins UART CTS and RTS (Clear to Send and Ready to Send). The UART interface serves as the primary interface to a host, which can be an MCU or a converter, such as serial-to-USB. As an alternative to the UART interface, users also have at their disposal the lines of the SPI serial interface (to use this interface, it is necessary to populate the appropriate 0Ω resistors to activate the SPI lines). The SM2400 executes its firmware from internal memory, with the loaded code at a boot time. The SM2400 can boot either from an external SPI flash, the AT25FF041A, or from a host MCU via UART interface depending on

the logic state of the MD1 pin of the mikroBUS™ socket (0 - boot over UART interface that allows direct firmware download (boot from the host), 1 – boot from external SPI flash memory), with the host MCU being the Master. In addition, the SM2400 provides the possibility of a reset via the RST pin of the mikroBUS™ socket (asserting this pin causes full chip reset and reboot), as well as visual detection of the communication status via the red PHY LED, which is asserted when an incoming packet is detected. The power supply of this Click board™ is performed very simply, without any additional hardware configuration (depending on the power supply capability and the desired range). It is possible to power the board in two ways: internally and externally. By default, the board power will be provided internally over the LM5158 boost converter in the value of 15V, which is obtained from the 5V mikroBUS™ power rail. When applying an external power supply of 15VDC on the VEXT terminal, the N-PLC Click will automatically be powered from the external source thanks to the protection of the converter, which automatically recognizes the presence of the external power supply and gives it priority. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, it comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

Development board

PIC18F57Q43 Curiosity Nano evaluation kit is a cutting-edge hardware platform designed to evaluate microcontrollers within the PIC18-Q43 family. Central to its design is the inclusion of the powerful PIC18F57Q43 microcontroller (MCU), offering advanced functionalities and robust performance. Key features of this evaluation kit include a yellow user LED and a responsive

mechanical user switch, providing seamless interaction and testing. The provision for a 32.768kHz crystal footprint ensures precision timing capabilities. With an onboard debugger boasting a green power and status LED, programming and debugging become intuitive and efficient. Further enhancing its utility is the Virtual serial port (CDC) and a debug GPIO channel (DGI

GPIO), offering extensive connectivity options. Powered via USB, this kit boasts an adjustable target voltage feature facilitated by the MIC5353 LDO regulator, ensuring stable operation with an output voltage ranging from 1.8V to 5.1V, with a maximum output current of 500mA, subject to ambient temperature and voltage constraints.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC

MCU Memory (KB)

128

Silicon Vendor

Microchip

Pin count

48

RAM (Bytes)

8196

You complete me!

Accessories

Curiosity Nano Base for Click boards is a versatile hardware extension platform created to streamline the integration between Curiosity Nano kits and extension boards, tailored explicitly for the mikroBUS™-standardized Click boards and Xplained Pro extension boards. This innovative base board (shield) offers seamless connectivity and expansion possibilities, simplifying experimentation and development. Key features include USB power compatibility from the Curiosity Nano kit, alongside an alternative external power input option for enhanced flexibility. The onboard Li-Ion/LiPo charger and management circuit ensure smooth operation for battery-powered applications, simplifying usage and management. Moreover, the base incorporates a fixed 3.3V PSU dedicated to target and mikroBUS™ power rails, alongside a fixed 5.0V boost converter catering to 5V power rails of mikroBUS™ sockets, providing stable power delivery for various connected devices.

An assortement of compatible AC plugs for all parts of the world are also sold. Reliability is paramount when it comes to power supply units. That's why we opted to carry Sunny Power Supply units. Note that power supply units are sold without AC plugs. Depending on where you are in the world, or where you plan to be, we also offer a wide selection of compatible AC plugs.

MIKROE offers a wide range of AC plugs for our Wall Power Supply units compatible with standards from Europe, the USA, the UK, India, China, Brazil, Australia, South Africa, Korea, and Argentina.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for N-PLC Click driver.

Key functions:

nplc_set_mode- This function sets operation mode to command or data.nplc_generic_write- This function writes a desired number of data bytes by using UART serial interface.nplc_generic_read- This function reads a desired number of data bytes by using UART serial interface.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief N-PLC Click Example.

*

* # Description

* This example demonstrates the use of an N-PLC click boards by showing

* the communication between the two click boards configured as a receiver and transmitter.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver, resets the click board to default config, displays the firmware version

* and switches to data operation mode. After that displays the selected application mode

* and sends an initial message in case of transmitter mode.

*

* ## Application Task

* Reads all the received data and echoes them back to the transmitter. The received and echoed messages

* will be displayed on the USB UART.

*

* @note

* Once both devices are programmed, one as a receiver and the other as a transmitter, you will need to reset

* the transmitter board in order to start the communication by sending an initial message.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "nplc.h"

// Comment out the line below in order to switch the application mode to receiver

// #define DEMO_APP_TRANSMITTER

#define DEMO_TEXT_MESSAGE "MikroE - N-PLC click board"

#define PROCESS_BUFFER_SIZE 200

#define RSP_TIMEOUT_MS 20000

static nplc_t nplc;

static log_t logger;

static char app_buf[ PROCESS_BUFFER_SIZE ] = { 0 };

static int32_t app_buf_len = 0;

/**

* @brief N-PLC clearing application buffer.

* @details This function clears memory of application buffer and reset its length and counter.

* @note None.

*/

static void nplc_clear_app_buf ( void );

/**

* @brief N-PLC data reading function.

* @details This function reads data from device and concatenates data to application buffer.

* @return @li @c 0 - Read some data.

* @li @c -1 - Nothing is read or buffer overflow error.

* See #err_t definition for detailed explanation.

* @note None.

*/

static err_t nplc_process ( void );

/**

* @brief N-PLC display response function.

* @details This function checks if any data is received from device and displays it on the USB UART.

* @return @li @c 0 - Read some data.

* @li @c -1 - Timeout error.

* See #err_t definition for detailed explanation.

* @note None.

*/

static err_t nplc_display_rsp ( void );

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

nplc_cfg_t nplc_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

nplc_cfg_setup( &nplc_cfg );

NPLC_MAP_MIKROBUS( nplc_cfg, MIKROBUS_1 );

if ( UART_ERROR == nplc_init( &nplc, &nplc_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

nplc_process( );

nplc_clear_app_buf( );

log_printf( &logger, " - HW reset -\r\n" );

nplc_hw_reset ( &nplc );

nplc_display_rsp ( );

log_printf( &logger, " - Go to command mode -\r\n" );

nplc_set_mode ( &nplc, NPLC_MODE_COMMAND );

nplc_display_rsp ( );

log_printf( &logger, " - Factory reset -\r\n" );

nplc_factory_reset ( &nplc );

nplc_display_rsp ( );

log_printf( &logger, " - Reboot -\r\n" );

nplc_sw_reset ( &nplc );

nplc_display_rsp ( );

log_printf( &logger, " - Go to command mode -\r\n" );

nplc_set_mode ( &nplc, NPLC_MODE_COMMAND );

nplc_display_rsp ( );

log_printf( &logger, " - Show firmware version -\r\n" );

nplc_firmware_version ( &nplc );

nplc_display_rsp ( );

log_printf( &logger, " - Go to data mode -\r\n" );

nplc_set_mode ( &nplc, NPLC_MODE_DATA );

#ifdef DEMO_APP_TRANSMITTER

log_printf( &logger, " Application Mode: Transmitter\r\n" );

log_printf( &logger, " Sending initial message: %s", ( char * ) DEMO_TEXT_MESSAGE );

nplc_generic_write( &nplc, DEMO_TEXT_MESSAGE, strlen ( DEMO_TEXT_MESSAGE ) );

log_printf( &logger, "\r\n--------------------------------\r\n" );

Delay_ms( 1000 );

#else

log_printf( &logger, " Application Mode: Receiver\r\n" );

#endif

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

nplc_process ( );

if ( app_buf_len > 0 )

{

Delay_ms( 500 );

nplc_process( );

log_printf( &logger, " Received message: %s", app_buf );

log_printf( &logger, "\r\n--------------------------------\r\n" );

Delay_ms( 500 );

log_printf( &logger, " Sending echo response: %s", app_buf );

nplc_generic_write( &nplc, app_buf, app_buf_len );

log_printf( &logger, "\r\n--------------------------------\r\n\n" );

nplc_clear_app_buf( );

Delay_ms( 1000 );

}

}

void main ( void )

{

application_init( );

for ( ; ; )

{

application_task( );

}

}

static void nplc_clear_app_buf ( void )

{

memset( app_buf, 0, app_buf_len );

app_buf_len = 0;

}

static err_t nplc_process ( void )

{

int32_t rx_size;

char rx_buff[ PROCESS_BUFFER_SIZE ] = { 0 };

Delay_ms ( 1 );

rx_size = nplc_generic_read( &nplc, rx_buff, PROCESS_BUFFER_SIZE );

Delay_ms ( 1 );

if ( rx_size > 0 )

{

int32_t buf_cnt = 0;

if ( ( app_buf_len + rx_size ) > PROCESS_BUFFER_SIZE )

{

nplc_clear_app_buf( );

return NPLC_ERROR;

}

else

{

buf_cnt = app_buf_len;

app_buf_len += rx_size;

}

for ( int32_t rx_cnt = 0; rx_cnt < rx_size; rx_cnt++ )

{

if ( rx_buff[ rx_cnt ] )

{

app_buf[ ( buf_cnt + rx_cnt ) ] = rx_buff[ rx_cnt ];

}

else

{

app_buf_len--;

buf_cnt--;

}

}

return NPLC_OK;

}

return NPLC_ERROR;

}

static err_t nplc_display_rsp ( void )

{

uint32_t timeout = RSP_TIMEOUT_MS;

while ( timeout-- )

{

nplc_process( );

if ( app_buf_len > 0 )

{

Delay_ms( 100 );

nplc_process( );

for ( int32_t buf_cnt = 0; buf_cnt < app_buf_len; buf_cnt++ )

{

log_printf( &logger, "%c", app_buf[ buf_cnt ] );

}

nplc_clear_app_buf( );

log_printf( &logger, "\r\n--------------------------------\r\n" );

return NPLC_OK;

}

}

return NPLC_ERROR;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Interface