Choose Qi RX for a smarter, wireless power solution that transforms the way you charge, streamlining your energy supply with unprecedented accuracy.

A

A

Hardware Overview

How does it work?

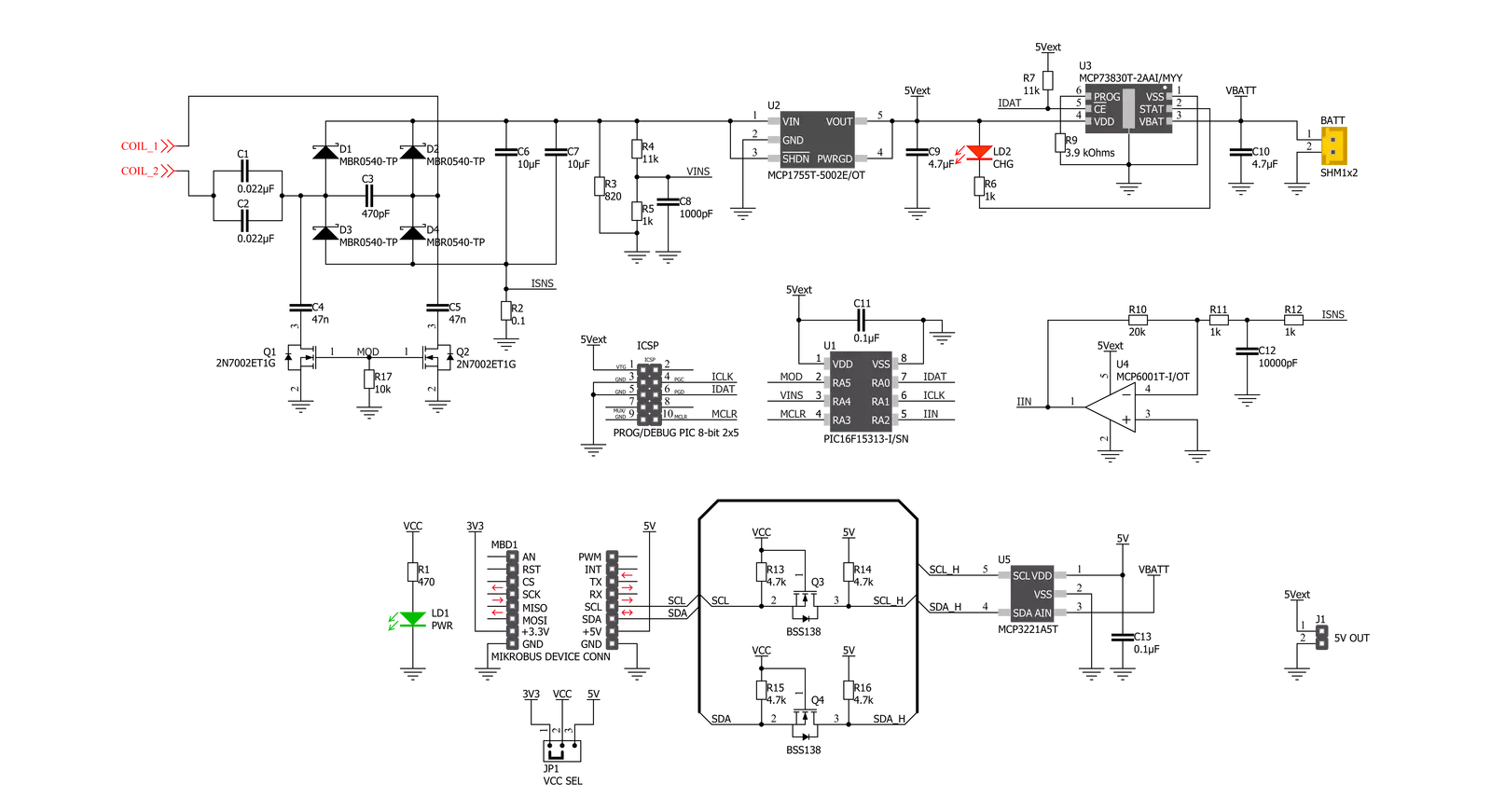

Qi RX Click is based on the PIC16F15313, a general-purpose 8-bit MCU that makes a flexible, low-cost alternative to wireless charging solutions based on ASICs from Microchip. The Qi RX Click allows users to quickly add wireless charging functionality to their projects without dealing with complex specific protocols or state machines. It is implemented using a general-purpose 8-bit MCU compatible with the Qi 1.1 (5W) standard. It can be used with any Qi 1.1 compatible wireless charging transmitter with the added functionality of a fully-featured Li-Ion charging controller. Wireless charging uses the principle of magnetic induction to transfer power, similar to a conventional AC transformer, where the receiver and the transmitter coils represent the transformer windings. The high-frequency signal of the Receiver Coil is rectified by a simple full-bridge rectifier implemented with four Schottky diodes (D1-D4), which output voltage is then monitored by the PIC16F15313 through a simple resistive divider R4 and R5. The communication with the

base transmitter is implemented using Amplitude Shift Keying (ASK), as recommended by the Qi 1.1 standard, with two low-power MOSFETs (Q1 and Q2) and two capacitors (C4 and C5) used to modulate the absorbed power. The rectified voltage is also applied at the input of the MCP1755, a low drop-out voltage regulator from Microchip that supplies the 5V voltage for the battery charger and the PIC16F15313 up to 300mA. This LDO is associated with the charge LED indicator labeled CHG, which will indicate the charging progress and turn off once the battery charging is finished. The battery charging functionality is provided by the MCP73830, a single-cell Li-Ion/Li-Polymer battery charge management controller from Microchip. The input current is measured by the PIC16F15313 using a shunt resistor R2 and the MCP6001, a single general-purpose OpAmp offering rail-to-rail input and output up to 6V from Microchip. The gain of this amplifier is set to 10. Measurement of the input current is necessary to accurately calculate input power and implement

the Foreign Object Detection (FOD) function using the power loss method. Qi RX Click communicates with MCU using the MCP3221, a successive approximation A/D converter with a 12-bit resolution from Microchip. This device provides one single-ended input with very low power consumption, a low maximum conversion current, and a Standby current of 250 μA and 1 μA. Data can be transferred at rates of up to 100 kbit/s in the Standard and 400 kbit/s in the Fast Mode. Also, maximum sample rates of 22.3 kSPS with the MCP3221 are possible in a Continuous-Conversion Mode with a clock rate of 400 kHz. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

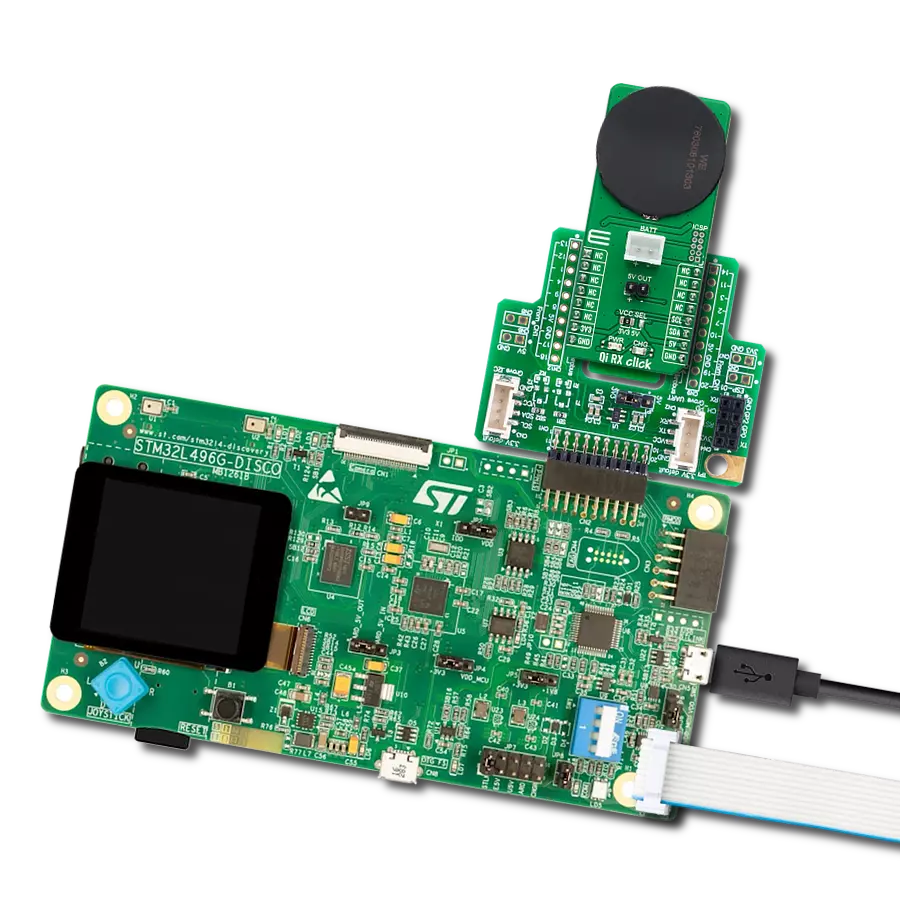

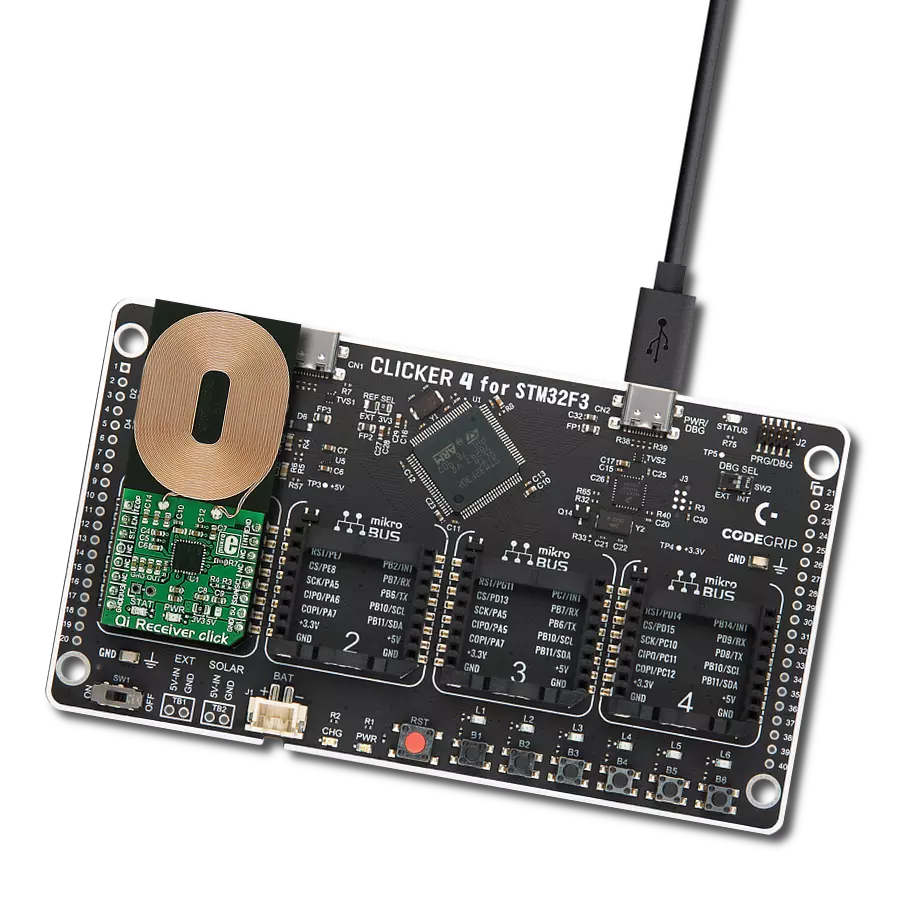

Development board

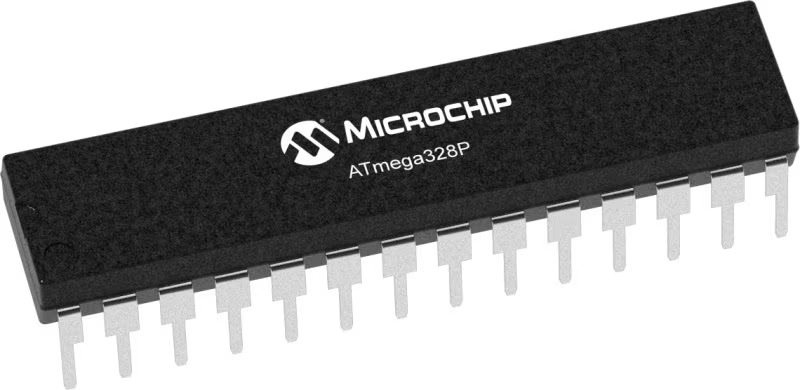

Arduino UNO is a versatile microcontroller board built around the ATmega328P chip. It offers extensive connectivity options for various projects, featuring 14 digital input/output pins, six of which are PWM-capable, along with six analog inputs. Its core components include a 16MHz ceramic resonator, a USB connection, a power jack, an

ICSP header, and a reset button, providing everything necessary to power and program the board. The Uno is ready to go, whether connected to a computer via USB or powered by an AC-to-DC adapter or battery. As the first USB Arduino board, it serves as the benchmark for the Arduino platform, with "Uno" symbolizing its status as the

first in a series. This name choice, meaning "one" in Italian, commemorates the launch of Arduino Software (IDE) 1.0. Initially introduced alongside version 1.0 of the Arduino Software (IDE), the Uno has since become the foundational model for subsequent Arduino releases, embodying the platform's evolution.

Microcontroller Overview

MCU Card / MCU

Architecture

AVR

MCU Memory (KB)

32

Silicon Vendor

Microchip

Pin count

28

RAM (Bytes)

2048

You complete me!

Accessories

Click Shield for Arduino UNO has two proprietary mikroBUS™ sockets, allowing all the Click board™ devices to be interfaced with the Arduino UNO board without effort. The Arduino Uno, a microcontroller board based on the ATmega328P, provides an affordable and flexible way for users to try out new concepts and build prototypes with the ATmega328P microcontroller from various combinations of performance, power consumption, and features. The Arduino Uno has 14 digital input/output pins (of which six can be used as PWM outputs), six analog inputs, a 16 MHz ceramic resonator (CSTCE16M0V53-R0), a USB connection, a power jack, an ICSP header, and reset button. Most of the ATmega328P microcontroller pins are brought to the IO pins on the left and right edge of the board, which are then connected to two existing mikroBUS™ sockets. This Click Shield also has several switches that perform functions such as selecting the logic levels of analog signals on mikroBUS™ sockets and selecting logic voltage levels of the mikroBUS™ sockets themselves. Besides, the user is offered the possibility of using any Click board™ with the help of existing bidirectional level-shifting voltage translators, regardless of whether the Click board™ operates at a 3.3V or 5V logic voltage level. Once you connect the Arduino UNO board with our Click Shield for Arduino UNO, you can access hundreds of Click boards™, working with 3.3V or 5V logic voltage levels.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Qi RX Click driver.

Key functions:

qirx_read_data- Read data function.qirx_read_voltage- Read voltage function.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief QiRX Click example

*

* # Description

* This is an example that demonstrates the use of the Qi RX Click board.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initalizes I2C driver and makes an initial log.

*

* ## Application Task

* This example shows the capabilities of the Qi RX Click by measuring voltage of the connected

* battery. In order to get correct calculations user should change "v_ref" value

* to his own power supply voltage.

*

* @author Stefan Ilic

*

*/

#include "board.h"

#include "log.h"

#include "qirx.h"

static qirx_t qirx;

static log_t logger;

uint16_t voltage;

uint16_t v_ref = 5058;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

qirx_cfg_t qirx_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

qirx_cfg_setup( &qirx_cfg );

QIRX_MAP_MIKROBUS( qirx_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == qirx_init( &qirx, &qirx_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

log_printf( &logger, "----------------------- \r\n" );

log_printf( &logger, " Qi RX Click \r\n" );

log_printf( &logger, "----------------------- \r\n" );

log_info( &logger, " Application Task " );

log_printf( &logger, "----------------------- \r\n" );

}

void application_task ( void )

{

voltage = qirx_read_voltage( &qirx, v_ref );

log_printf( &logger, " Battery voltage: %d mV \r\n", voltage );

log_printf( &logger, "----------------------- \r\n" );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Wireless Charging