We aim to empower your projects with the precision of three-axis acceleration technology, allowing you to measure, analyze, and excel in motion-related tasks

A

A

Hardware Overview

How does it work?

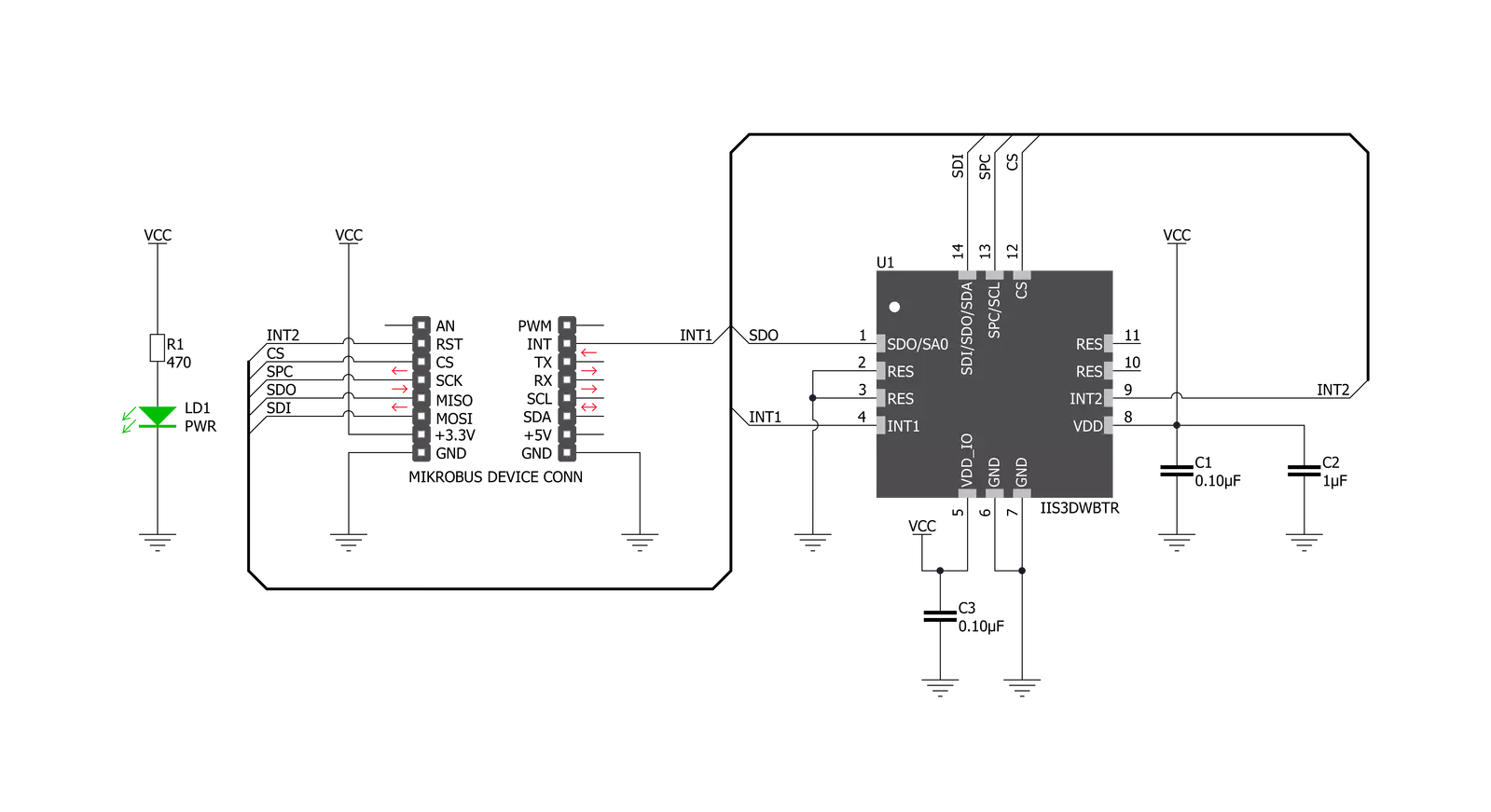

Accel 14 Click is based on the IIS3DWB, an ultra-wide bandwidth, low-noise, 3-axis digital vibration sensor from STMicroelectronics. The wide bandwidth, low noise, and very stable and repeatable sensitivity, together with the capability of operating over an extended temperature range, make this device particularly suitable for vibration monitoring in industrial applications. The IIS3DWB has a selectable full-scale acceleration range of ±2/±4/±8/±16 g and is capable of measuring accelerations with a bandwidth of up to 6 kHz with an output data rate of 26.7 kHz. A 3 kB first-in, first-out (FIFO) buffer is integrated into the device to avoid any data loss and limit the host processor's intervention. Accel 14 Click offers two possible operating configurations: Power-Down and Normal Mode. IIS3DWB has a voltage supply range from 2.1V to 3.6V. To avoid potential conflicts, it is recommended to set the lines connected to the device IO pins to a high-impedance state on the

host side during the power-on sequence. Furthermore, to guarantee the proper power-off of the device, it is recommended to maintain the duration of the VDD line to GND for at least 100 μs. After the power supply is applied, the IIS3DWB performs a 10 ms boot procedure to load the trimming parameters. After the boot is completed, the accelerometer is automatically configured in Power-Down mode. When the sensor is in Power-Down mode, almost all internal blocks of the device are switched off. The SPI digital interface remains active to allow communication with the device. The content of the configuration registers is preserved, and the output data registers are not updated, keeping the last data sampled in memory before going into Power-Down mode. When Accel 14 Click is set in Normal Mode, all three axes (X, Y, Z) are simultaneously active, and acceleration data can be read from the sensor concurrently for the 3-axis. The sensor provides

acceleration data at an output data rate of 26.667kHz. The IIS3DWB has been specifically designed to provide a wide bandwidth with a very flat frequency response in the passband and very high attenuation in the stopband to eliminate any frequency aliasing virtually. The device's functionality and measured acceleration data are accessible through the SPI interface. Also, the user can completely program functions such as the threshold and the timing of the two interrupt pins through the SPI digital interface. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, it comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

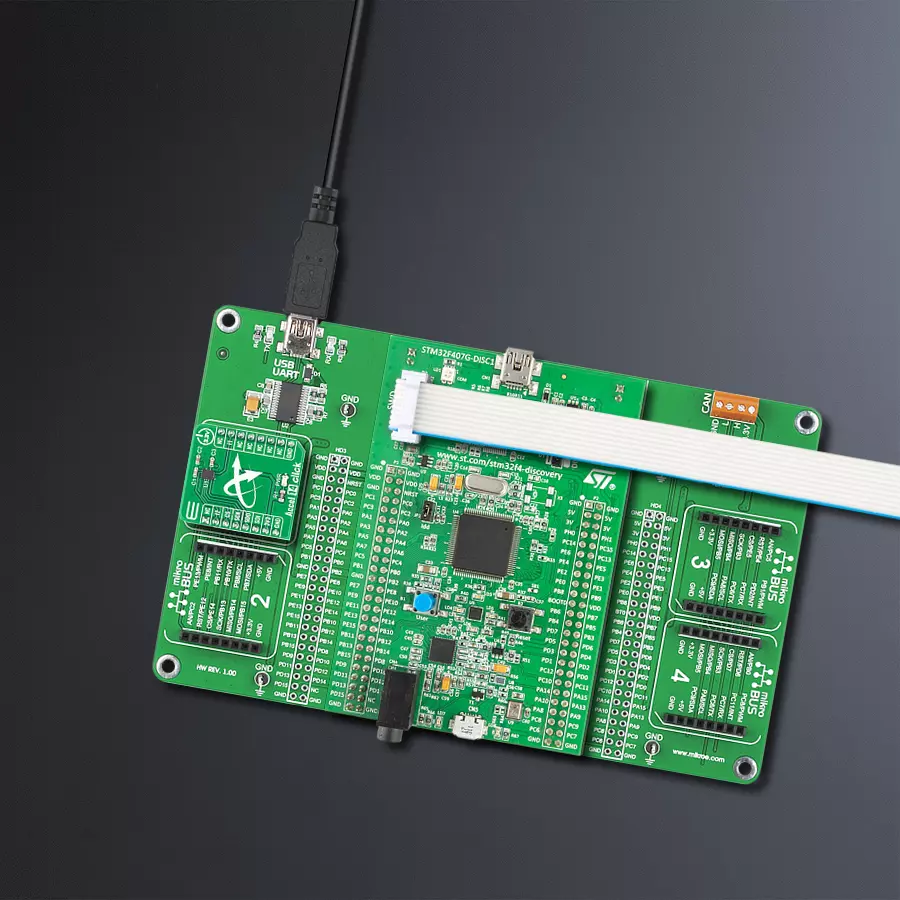

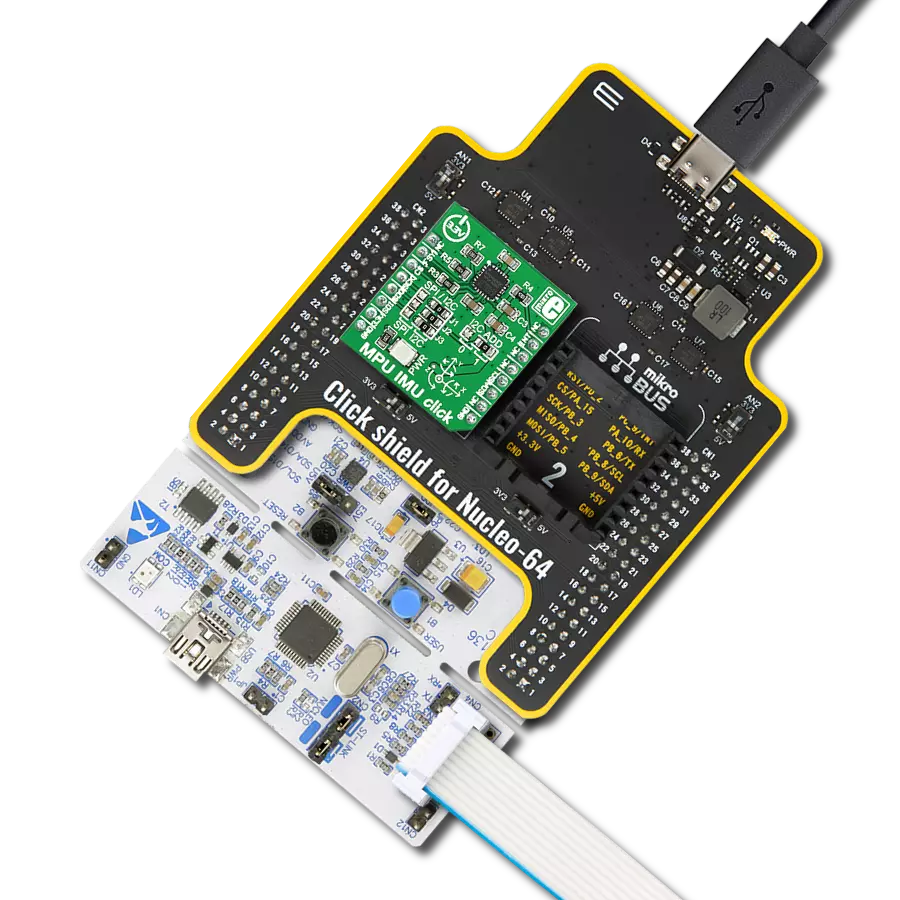

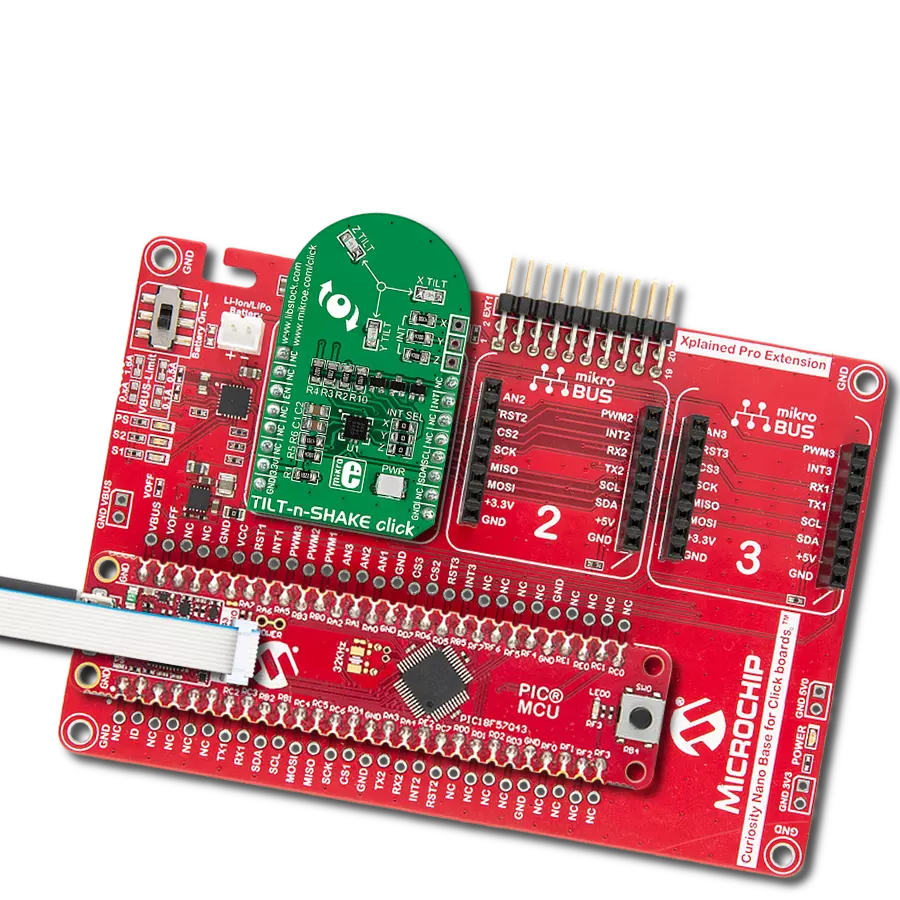

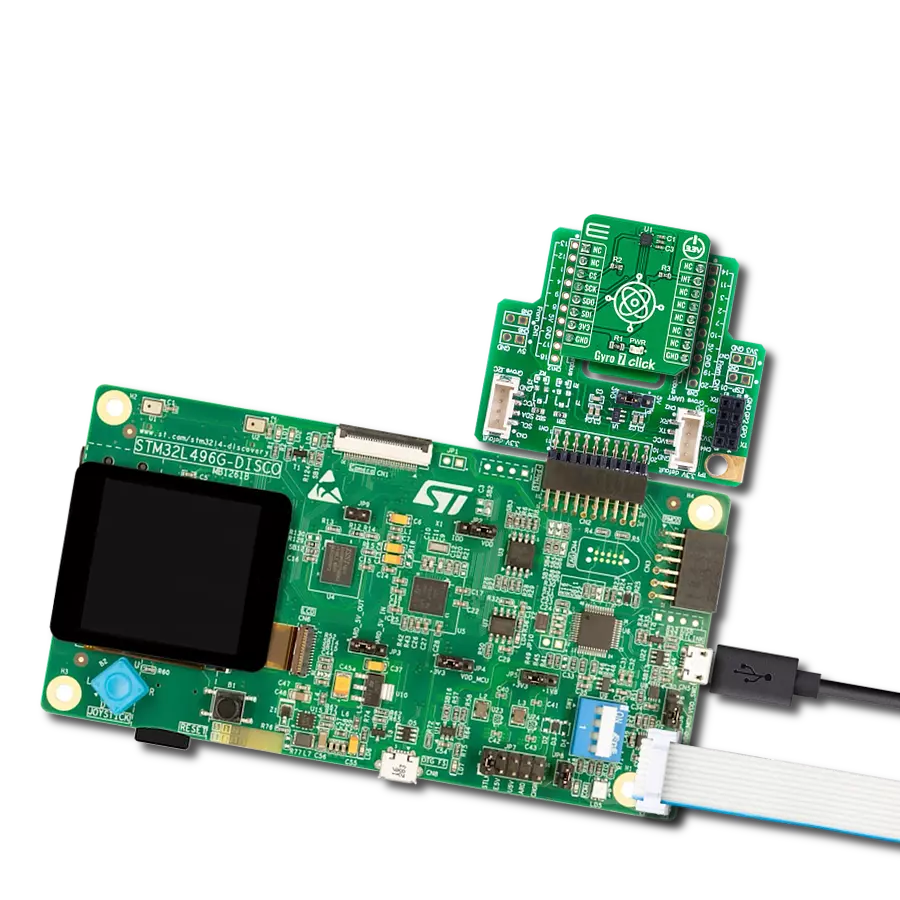

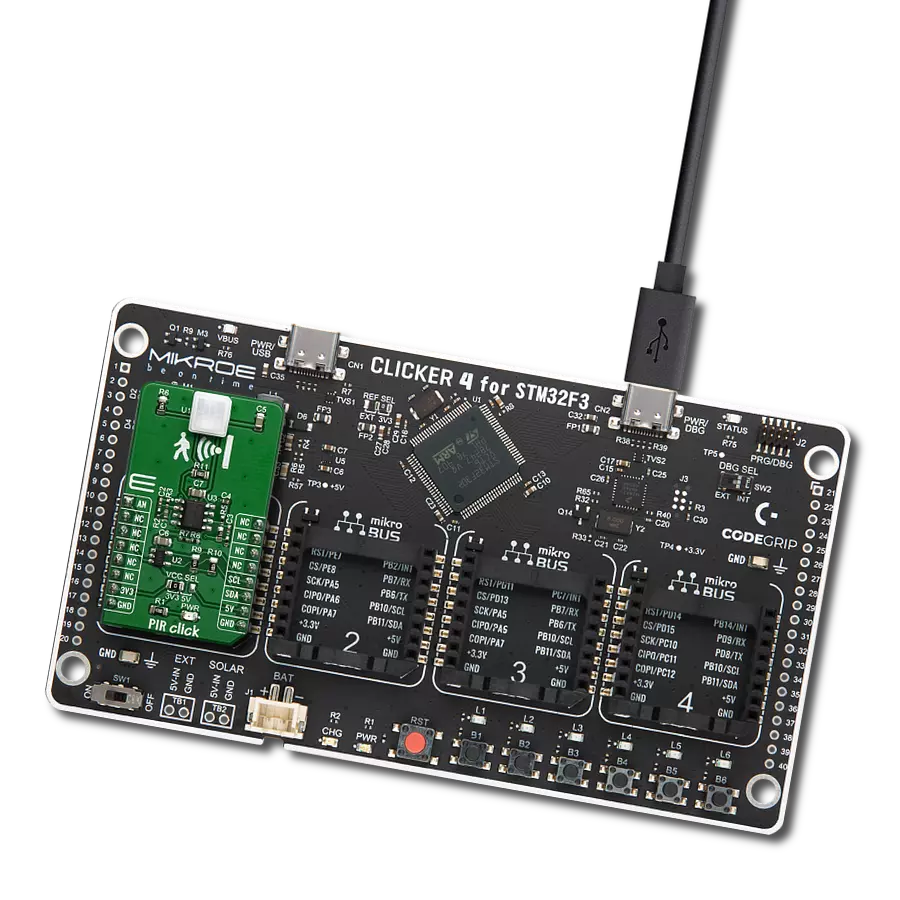

Development board

Discovery kit with STM32F407VG MCU, powered by the STM32F407 microcontroller, simplifies audio application development. It offers a robust platform with features like the ST-LINK/V2-A debugger, STMEMS digital accelerometer, digital microphone, and integrated audio DAC with a class D speaker driver. It has LEDs, push buttons, and a USB OTG

Micro-AB connector for versatile connectivity. The STM32F407VGT6 MCU boasts a 32-bit Arm Cortex-M4 with FPU, 1MB Flash memory, and 192KB RAM, housed in an LQFP100 package. Equipped with USB OTG FS, MEMS accelerometer, omnidirectional digital microphone, and user-friendly buttons, it ensures seamless operation.

The board accommodates various add-ons via extension headers while offering flexible power supply options, including ST-LINK, USB VBUS, or external sources. Supported by comprehensive free software and a range of IDEs, it empowers developers with flexibility and ease of use, making it an ideal choice for audio-centric projects.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

10

Silicon Vendor

STMicroelectronics

Pin count

100

RAM (Bytes)

100

You complete me!

Accessories

STM32F4 Discovery Shield is the perfect extension for your STM32F4 Discovery Board from STMicroelectronics. This versatile shield features four mikroBUS™ host sockets, a USB-UART module, and a CAN transceiver, expanding the capabilities of your Discovery board. Acting as a docking station, the STM32F4 Discovery Shield enables you to effortlessly transform your board into various applications, whether it's an RFID lock, SMS-triggered control switch, GPS tracking device, full-blown weather station, or any other idea you have in mind. With its seamless integration and enhanced functionality, this shield empowers you to explore endless possibilities and quickly bring your projects to life.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Accel 14 Click driver.

Key functions:

accel14_check_accel_data_ready- Check accel data ready functionaccel14_get_temperature- Get temperature functionaccel14_read_accel- Read Accel data function

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Accel14 Click example

*

* # Description

* This application measures accelermeter data.

*

* The demo application is composed of two sections :

*

* ## Application Init

* SPI, check device ID, sets default configuration, also write log.

*

* ## Application Task

* This is an example which demonstrates the use of Accel 14 Click board.

* Measured and display Acceleration data for X-axis, Y-axis and Z-axis.

* Results are being sent to the Usart Terminal where you can track their changes.

* All data logs write on USB uart changes for every 1 sec.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "accel14.h"

// ------------------------------------------------------------------ VARIABLES

static accel14_t accel14;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

accel14_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

accel14_cfg_setup( &cfg );

ACCEL14_MAP_MIKROBUS( cfg, MIKROBUS_1 );

accel14_init( &accel14, &cfg );

Delay_ms ( 100 );

log_printf( &logger, " Driver init done \r\n" );

log_printf( &logger, "--------------------- \r\n" );

log_printf( &logger, " Communication check \r\n" );

if ( accel14_check_communication( &accel14 ) == ACCEL14_CHECK_ID_SUCCESS )

{

log_printf( &logger, " SUCCESS \r\n" );

log_printf( &logger, "--------------------- \r\n" );

}

else

{

log_printf( &logger, " ERROR \r\n" );

log_printf( &logger, " Reset the device \r\n" );

log_printf( &logger, "--------------------- \r\n" );

for ( ; ; );

}

log_printf( &logger, " Set default config. \r\n" );

log_printf( &logger, "--------------------- \r\n" );

accel14_default_cfg( &accel14 );

Delay_ms ( 100 );

log_printf( &logger, " Acceleration data: \r\n" );

log_printf( &logger, "--------------------- \r\n" );

}

void application_task ( void )

{

accel14_accel_t accel_data;

uint8_t data_ready_flag;

data_ready_flag = accel14_check_accel_data_ready( &accel14 );

Delay_ms ( 10 );

if ( data_ready_flag == ACCEL14_NEW_DATA_AVAILABLE )

{

accel14_get_data ( &accel14, &accel_data );

log_printf( &logger, " Accel X : %d \r\n", accel_data.x );

log_printf( &logger, " Accel Y : %d \r\n", accel_data.y );

log_printf( &logger, " Accel Z : %d \r\n", accel_data.z );

log_printf( &logger, "--------------------- \r\n" );

Delay_ms ( 1000 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Motion