Enhance augmented reality (AR) experiences by accurately tracking user movements and surroundings, providing more realistic and interactive applications

A

A

Hardware Overview

How does it work?

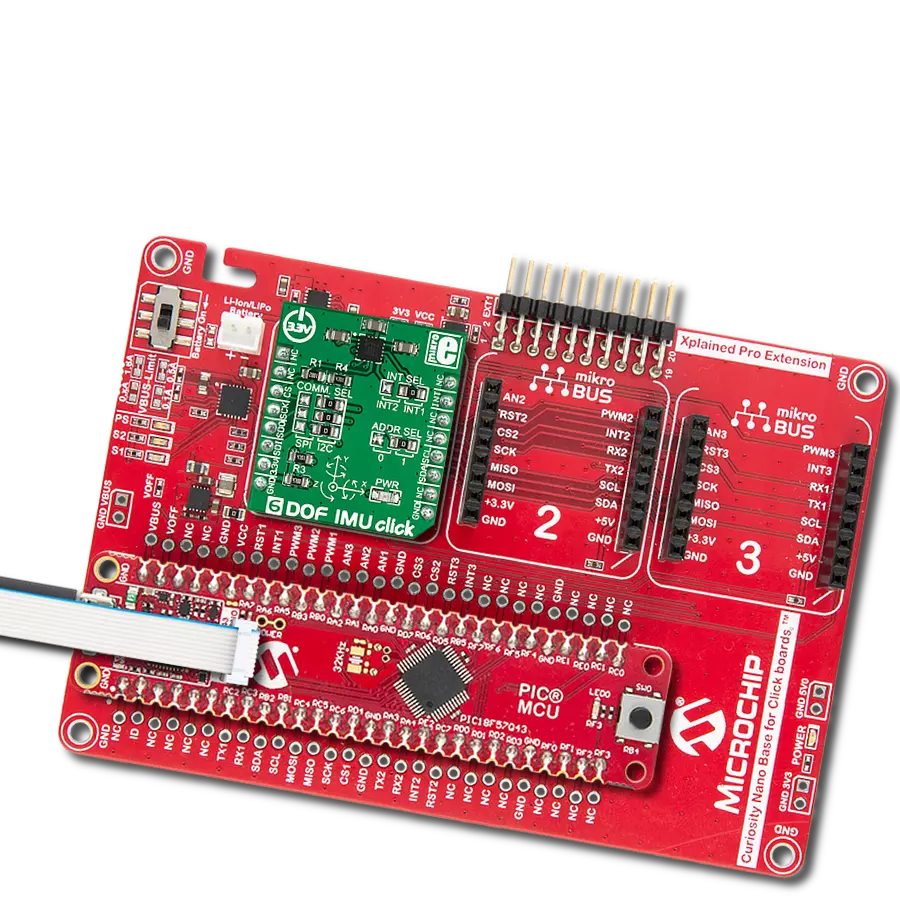

6DOF IMU 7 Click is based on the ICM-20649, a high-performance, 6-axis MEMS MotionTracking™ from TDK InvenSense. It is an advanced, integrated microelectromechanical gyroscope and accelerometer sensor (MEMS). This allows very high integration and very small dimensions, at an affordable cost. The IC contains a MEMS structure hermetically sealed and bonded at wafer level. The ICM-20649 is the world’s first wide-range 6-axis MotionTracking device for Sports and other High Impact applications. It is available in a 3x3x0.9 mm 24-pin QFN package. Many of today’s wearable and sports solutions, which analyze the motion of a user’s golf or tennis swings, soccer ball kicks, or basketball activities, require higher than currently available ±2000 dps (degrees per second) FSR for gyroscope and ±16g FSR for accelerometer to better insure that critical data is not lost at the point of high impact or high speed rotation. The

ICM-20649 - 6-axis inertial sensor used on the 6DOF IMU 7 click offers the smallest size, lowest profile and lowest power in conjunction with industry leading high FSR. With an extended FSR range of ±4000 dps for gyroscope and ±30g for accelerometer, it enables precise analysis of contact sports applications providing continuous motion sensor data before, during and after impact providing more accurate feedback. ICM-20649 devices, with their 6-axis integration, on-chip DMP, and run-time calibration firmware, enable manufacturers to eliminate the costly and complex selection, qualification, and system level integration of discrete devices, guaranteeing optimal motion performance for consumers. The gyroscope has a programmable full-scale range up to ±4000 dps. The accelerometer has a user-programmable accelerometer full-scale range up to ±30g. Factory-calibrated initial sensitivity of

both sensors reduces production-line calibration requirements. Other key features include on-chip 16-bit ADCs, programmable digital filters, an embedded temperature sensor, and programmable interrupts. The embedded Digital Motion Processor (DMP) within the ICM-20649 offloads computation of motion processing algorithms from the host processor. The DMP acquires data from accelerometers, gyroscopes, and additional third party sensors such as magnetometers, and processes the data. The resulting data can be read from the 512 bytes FIFO that is accessible via the I2C Serial Interface. The FIFO configuration register determines which data is written into the FIFO. The interrupt function may be used to determine when new data is available.

Features overview

Development board

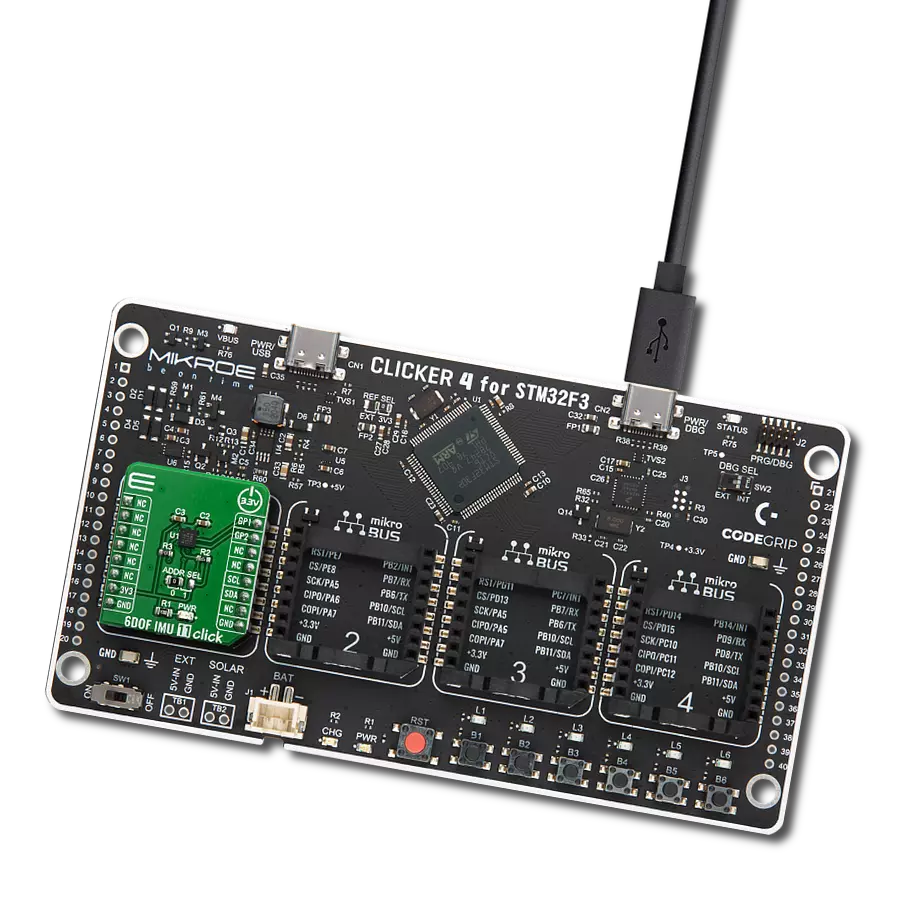

Nucleo 32 with STM32F031K6 MCU board provides an affordable and flexible platform for experimenting with STM32 microcontrollers in 32-pin packages. Featuring Arduino™ Nano connectivity, it allows easy expansion with specialized shields, while being mbed-enabled for seamless integration with online resources. The

board includes an on-board ST-LINK/V2-1 debugger/programmer, supporting USB reenumeration with three interfaces: Virtual Com port, mass storage, and debug port. It offers a flexible power supply through either USB VBUS or an external source. Additionally, it includes three LEDs (LD1 for USB communication, LD2 for power,

and LD3 as a user LED) and a reset push button. The STM32 Nucleo-32 board is supported by various Integrated Development Environments (IDEs) such as IAR™, Keil®, and GCC-based IDEs like AC6 SW4STM32, making it a versatile tool for developers.

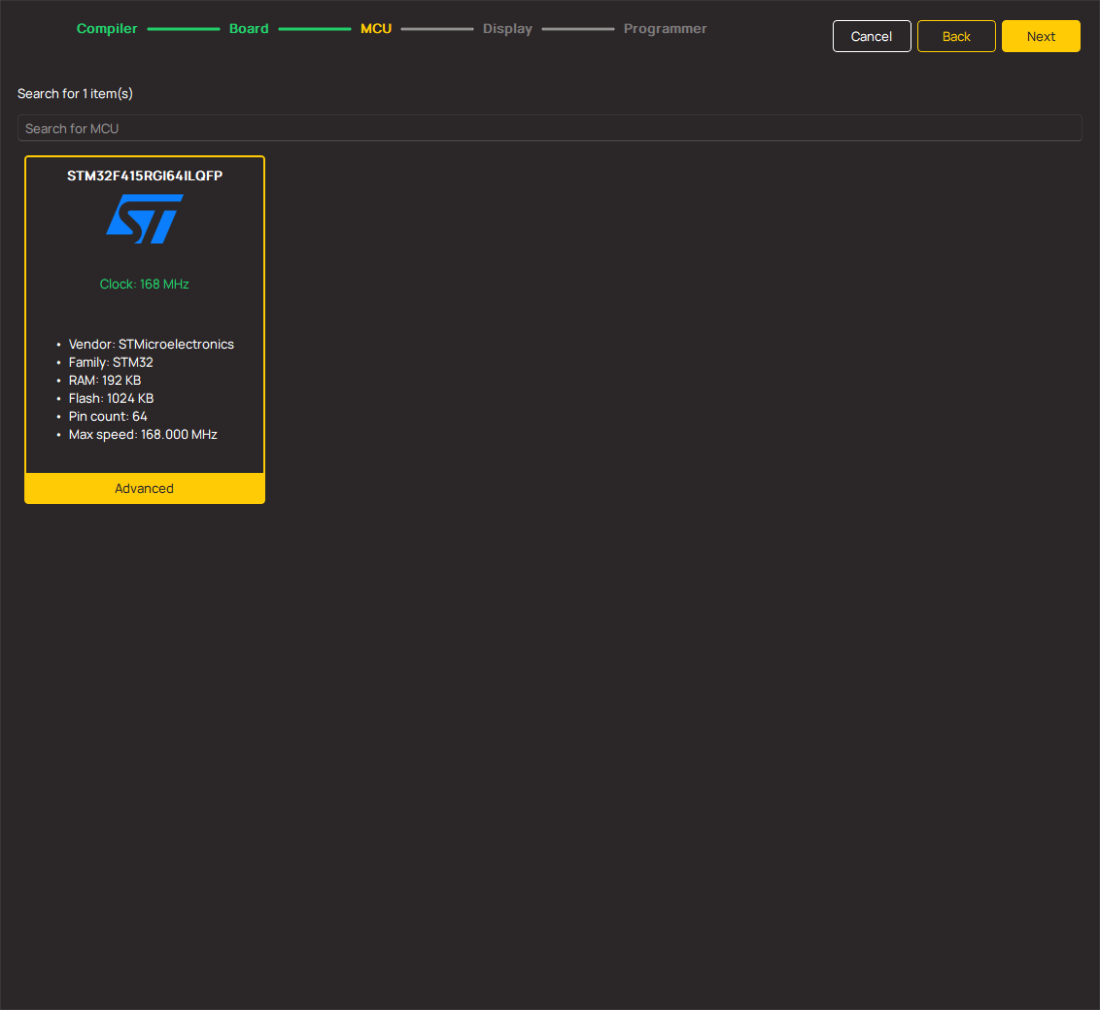

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M0

MCU Memory (KB)

32

Silicon Vendor

STMicroelectronics

Pin count

32

RAM (Bytes)

4096

You complete me!

Accessories

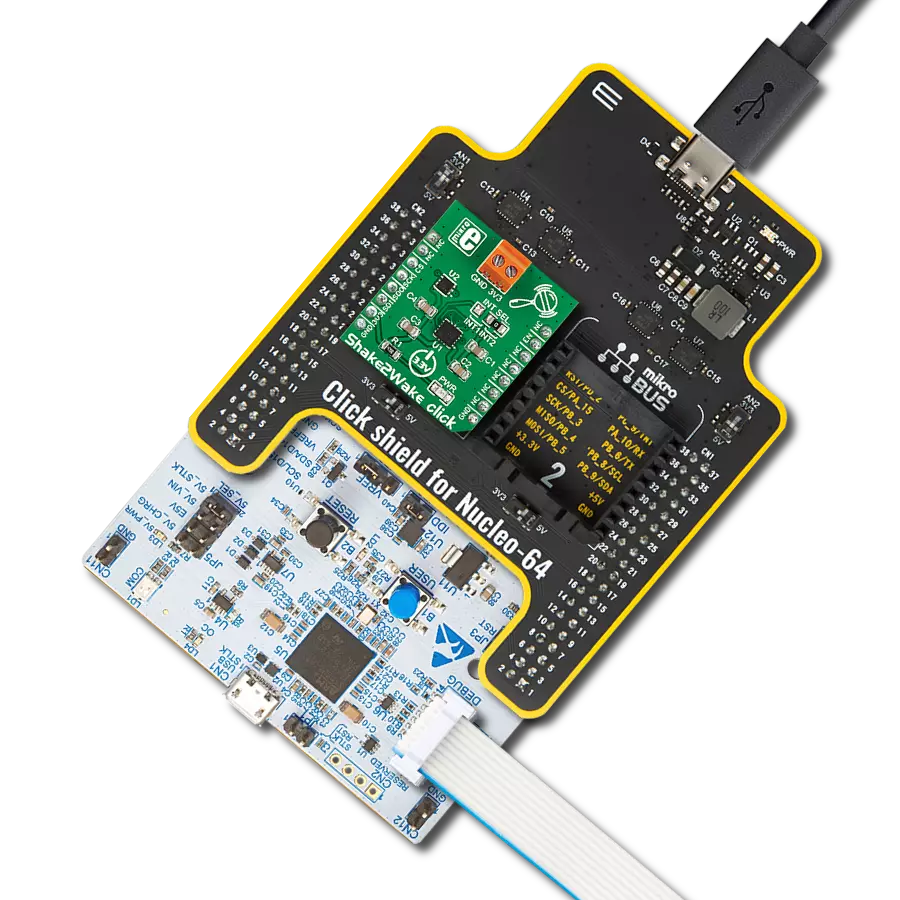

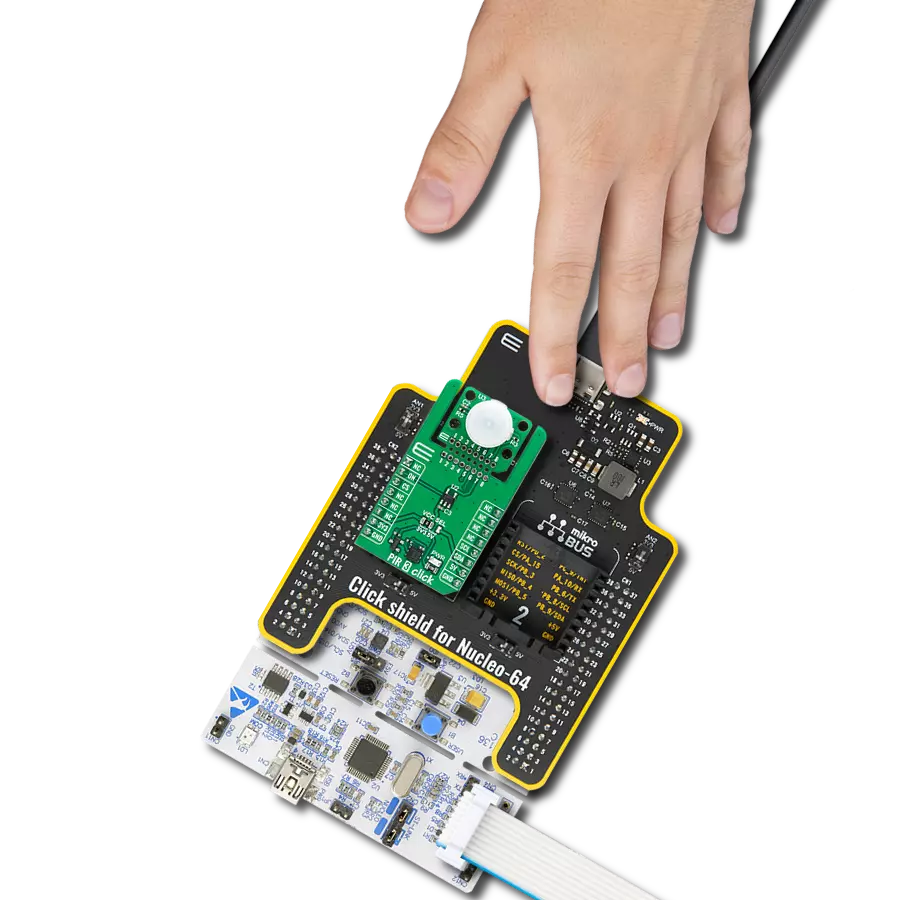

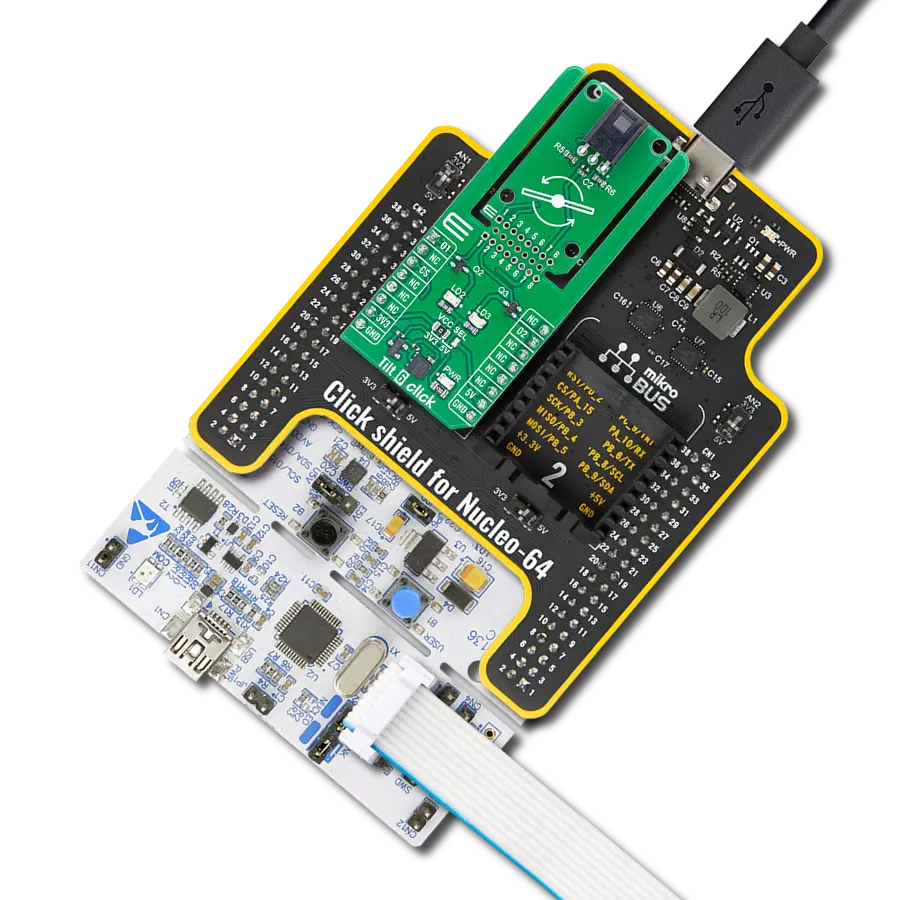

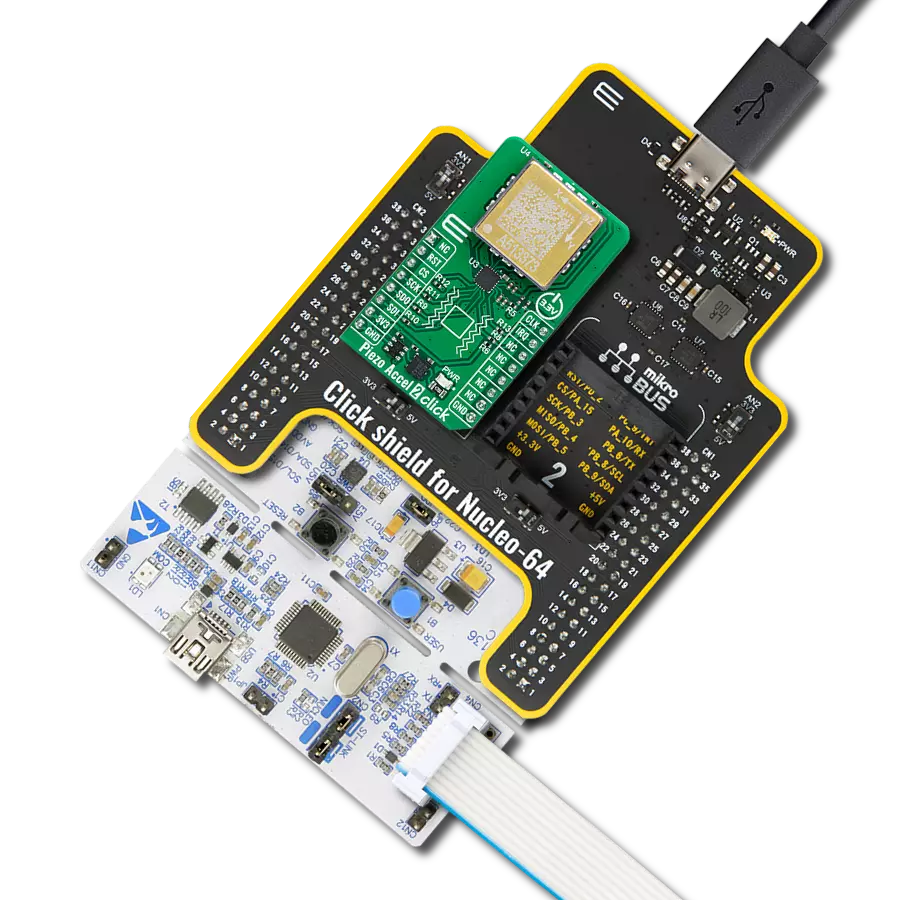

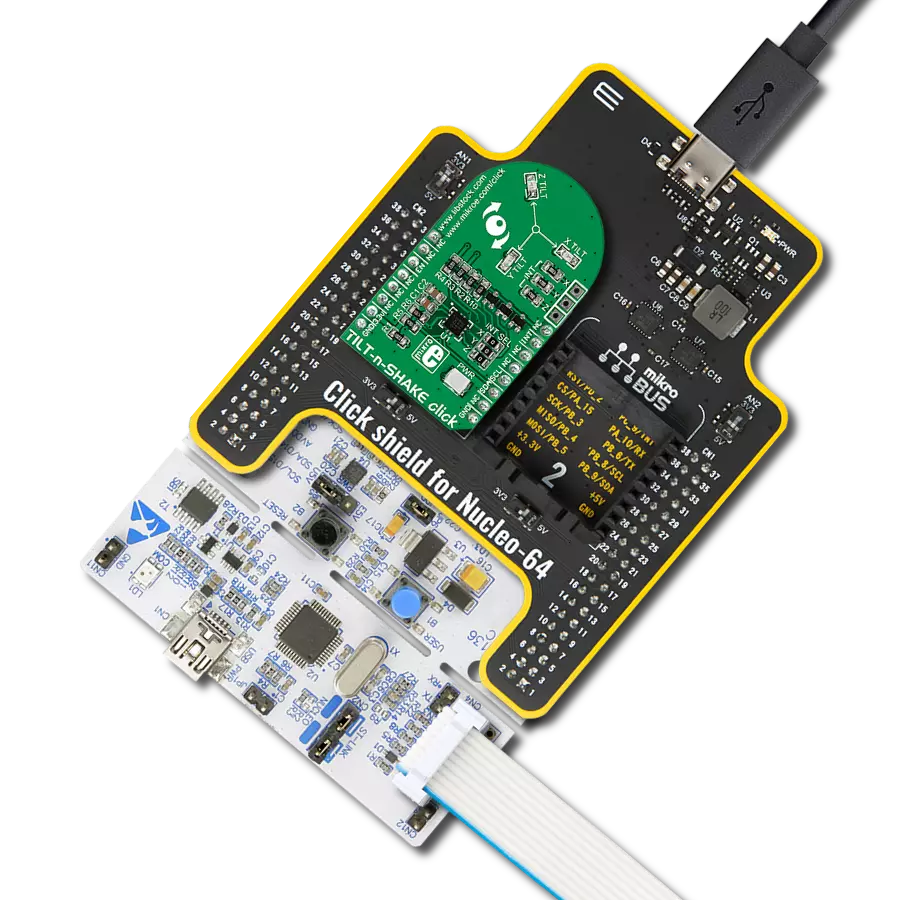

Click Shield for Nucleo-32 is the perfect way to expand your development board's functionalities with STM32 Nucleo-32 pinout. The Click Shield for Nucleo-32 provides two mikroBUS™ sockets to add any functionality from our ever-growing range of Click boards™. We are fully stocked with everything, from sensors and WiFi transceivers to motor control and audio amplifiers. The Click Shield for Nucleo-32 is compatible with the STM32 Nucleo-32 board, providing an affordable and flexible way for users to try out new ideas and quickly create prototypes with any STM32 microcontrollers, choosing from the various combinations of performance, power consumption, and features. The STM32 Nucleo-32 boards do not require any separate probe as they integrate the ST-LINK/V2-1 debugger/programmer and come with the STM32 comprehensive software HAL library and various packaged software examples. This development platform provides users with an effortless and common way to combine the STM32 Nucleo-32 footprint compatible board with their favorite Click boards™ in their upcoming projects.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for 6DOF IMU 7 Click driver.

Key functions:

c6dofimu7_get_gyro_data- This function reads gyroscope axis data and configures the gyro axis structc6dofimu7_get_accel_data- This function reads accelerometer axis data and configures the accel axis structc6dofimu7_get_temp_data- This function reads and returns temperature data

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief 6DofImu7 Click example

*

* # Description

* This example showcases how to initialize and configure the logger and Click modules and read

* and display temperature measurements and axis data from the gyroscope and accelerometer.

*

* The demo application is composed of two sections :

*

* ## Application Init

* This function initializes and configures the logger and Click modules.

*

* ## Application Task

* This function reads and displays accelerometer, gyroscope and temperature data every second.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "c6dofimu7.h"

// ------------------------------------------------------------------ VARIABLES

static c6dofimu7_t c6dofimu7;

static log_t logger;

static c6dofimu7_axis_t gyro;

static c6dofimu7_axis_t accel;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( )

{

log_cfg_t log_cfg;

c6dofimu7_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

c6dofimu7_cfg_setup( &cfg );

C6DOFIMU7_MAP_MIKROBUS( cfg, MIKROBUS_1 );

c6dofimu7_init( &c6dofimu7, &cfg );

c6dofimu7_default_cfg( &c6dofimu7 );

}

void application_task ( )

{

float temperature;

c6dofimu7_get_gyro_data( &c6dofimu7, &gyro, C6DOFIMU7_GYRO_SENSITIVITY );

log_printf( &logger, " * Gyro_X: %.5f * \r\n", gyro.x_axis );

log_printf( &logger, " * Gyro_Y: %.5f * \r\n", gyro.y_axis );

log_printf( &logger, " * Gyro_Z: %.5f * \r\n", gyro.z_axis );

log_printf( &logger, " ---------------------------- \r\n" );

c6dofimu7_get_accel_data( &c6dofimu7, &accel, C6DOFIMU7_ACCEL_SENSITIVITY );

log_printf( &logger, " * Accel_X: %.5f * \r\n", accel.x_axis );

log_printf( &logger, " * Accel_Y: %.5f * \r\n", accel.y_axis );

log_printf( &logger, " * Accel_Z: %.5f * \r\n", accel.z_axis );

log_printf( &logger, " ---------------------------- \r\n" );

temperature = c6dofimu7_get_temp_data( &c6dofimu7, C6DOFIMU7_TEMPERATURE_SENSITIVITY,

C6DOFIMU7_TEMPERATURE_OFFSET );

log_printf( &logger, " * Temperature: %.5f C * \r\n\r\n", temperature );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Motion