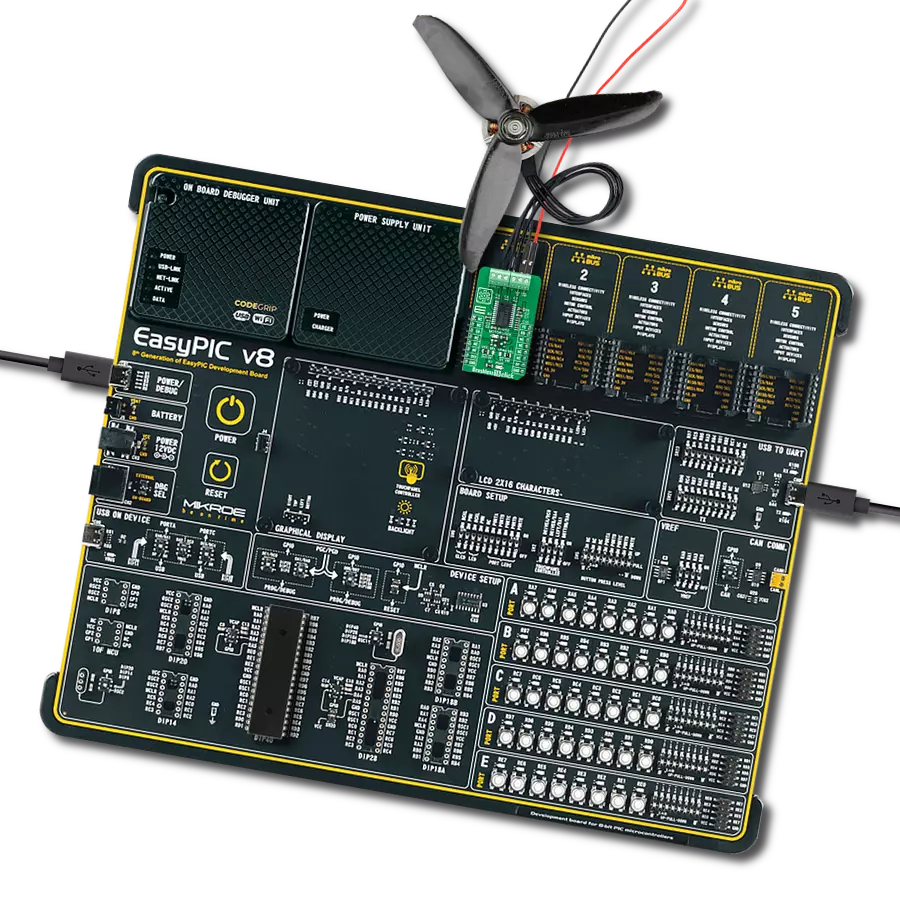

Our BLDC solution empowers you to achieve unparalleled motor performance, increasing efficiency and productivity

A

A

Hardware Overview

How does it work?

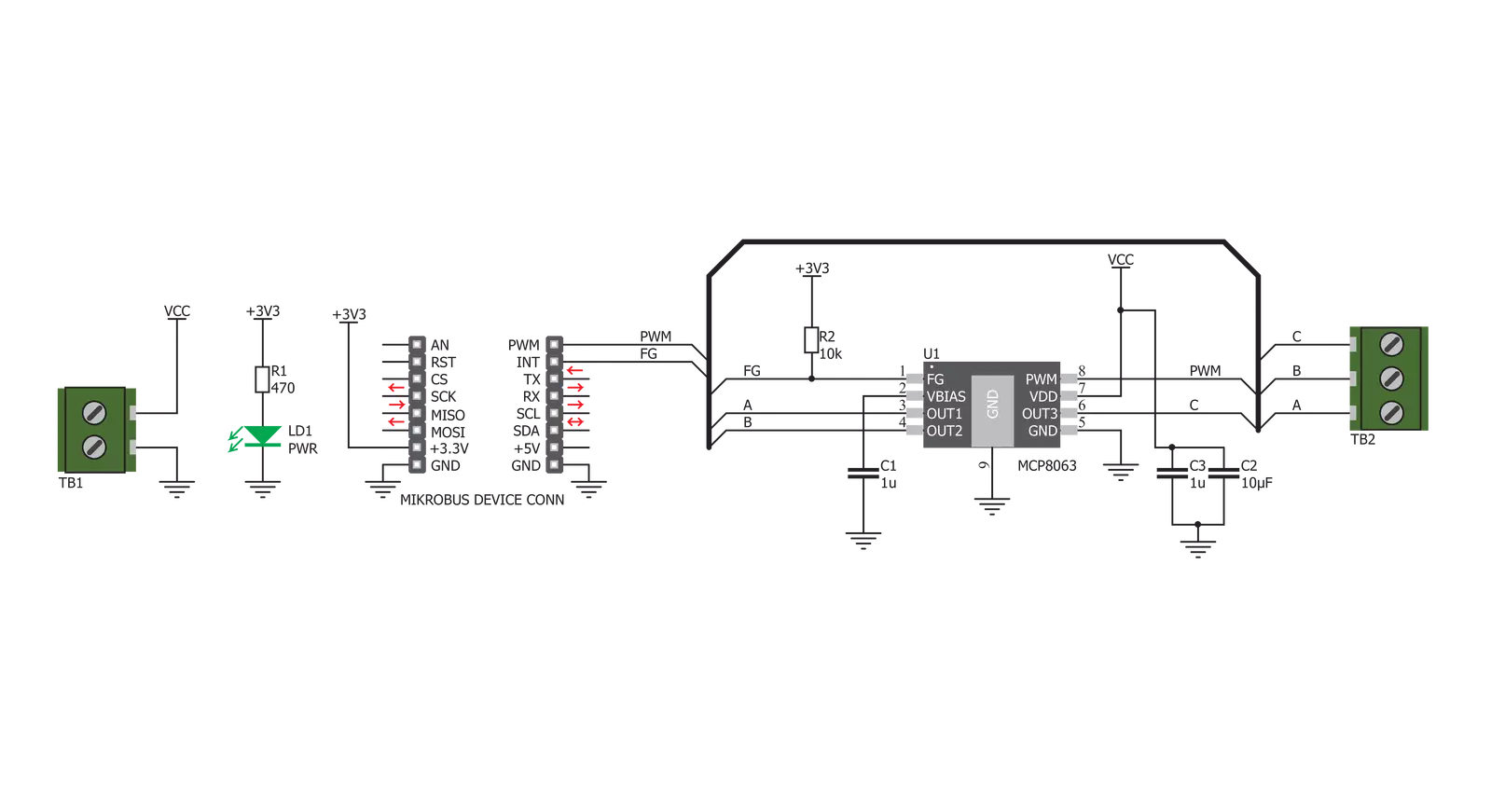

Brushless 4 Click is based on the MCP8063, a 3-phase brushless sinusoidal sensorless motor driver from Microchip. This IC has many features that make it a perfect choice for driving a wide range of small to medium BLDC motors. The MCP8063 requires a low count of external components due to its high degree of integration. It provides the rotor position digital output via the FG pin, routed to the mikroBUS™ INT pin, also labeled as FG on the Click board™ itself. The rotation speed control is implemented via the PWM pin of the mikroBUS™, routed to the PWM input pin of the IC. One of the most distinctive features of the Brushless 4 click is the 180° sinusoidal drive, which provides more torque and better efficiency than the more commonly used 120° driver topology. As mentioned above, the PWM signal can be used to control the motor speed. The duty cycle controls the rotor's speed, while the PWM signal's frequency doesn't affect the rotation speed and can vary between 20 Hz and 100 kHz. When the PWM input is at the HIGH logic level, the motor's rotational speed will be at a maximum. When the PWM input stays at the LOW logic level, the motor is stopped. Toggling between HIGH and LOW logic

states will result in the rotor turning at a specific speed, which depends on the duration of the HIGH logic level state. The PWM pin is routed to the same named pin of the mikroBUS™, conveniently allowing the MCU to provide the required PWM signal. Another method of controlling the motor speed can be implemented by varying the voltage of the motor power supply, which is connected via the input screw terminal, labeled as VBAT. This voltage can range from 2V up to 14V. The power supply has to be connected to the input terminal, as this terminal provides power for both the output stage of the MCP8063, as well as for the internal logic circuit (through the internal voltage regulator). The motor's rotational speed and phase can be determined using the FG pin. This pin acts like the Hall-effect sensor output, providing information about the motor's speed and phase to the host MCU via the mikroBUS™. The FC pin is pulled up with the onboard resistor. When the lock-up or desync condition appears, this pin is set to a high impedance mode, which is pulled to a HIGH logic level - because of the pull-up resistor. When the rotor is blocked, or it loses synchronization, an internal lock-up section

detects this condition and ties the coils to GND, effectively discharging the rotor with minimal self-heating. After a time-out, another attempt is made to run the rotor. If it is still blocked, another lock-up event is detected, and another time-out period is initiated. This way, the rotor is protected from overheating. As already mentioned, the MCP8063 IC features current limit protection. The maximum current is internally limited to 1.5A. This limitation prevents overheating of the motor coils and protects the output stage transistors. A good practice is always keeping the power consumption lower than the maximum specified, ensuring enough overhead. The thermal protection protects the IC when it reaches 170°C, with a hysteresis of 25°C before the restart is attempted, meaning that the IC has to be cooled down to 145°C. The output three-pole screw terminal is used to connect the motor phases. It is labeled with A, B, and C, allowing connecting of the three poles BLDC motors which do not require more than 1.5A (when the internal overcurrent limit is triggered). Brushless 4 Click supports only 3.3V MCUs and is not intended to be connected or controlled via the 5V MCU without proper level shifting circuitry.

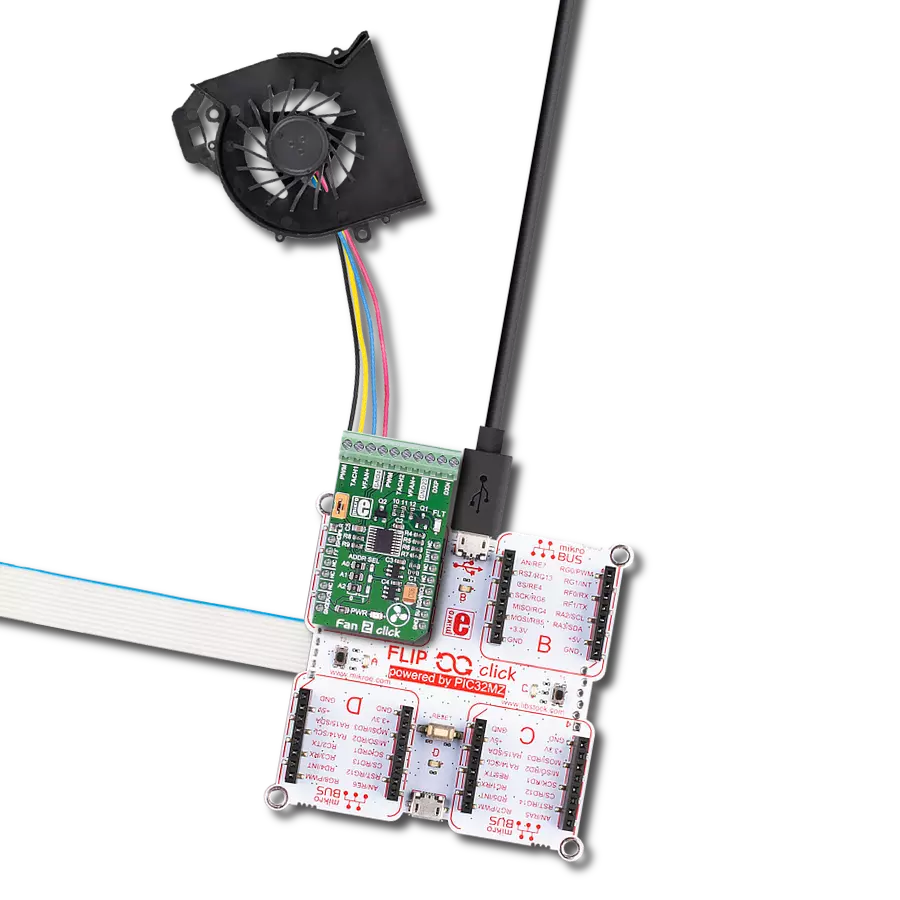

Features overview

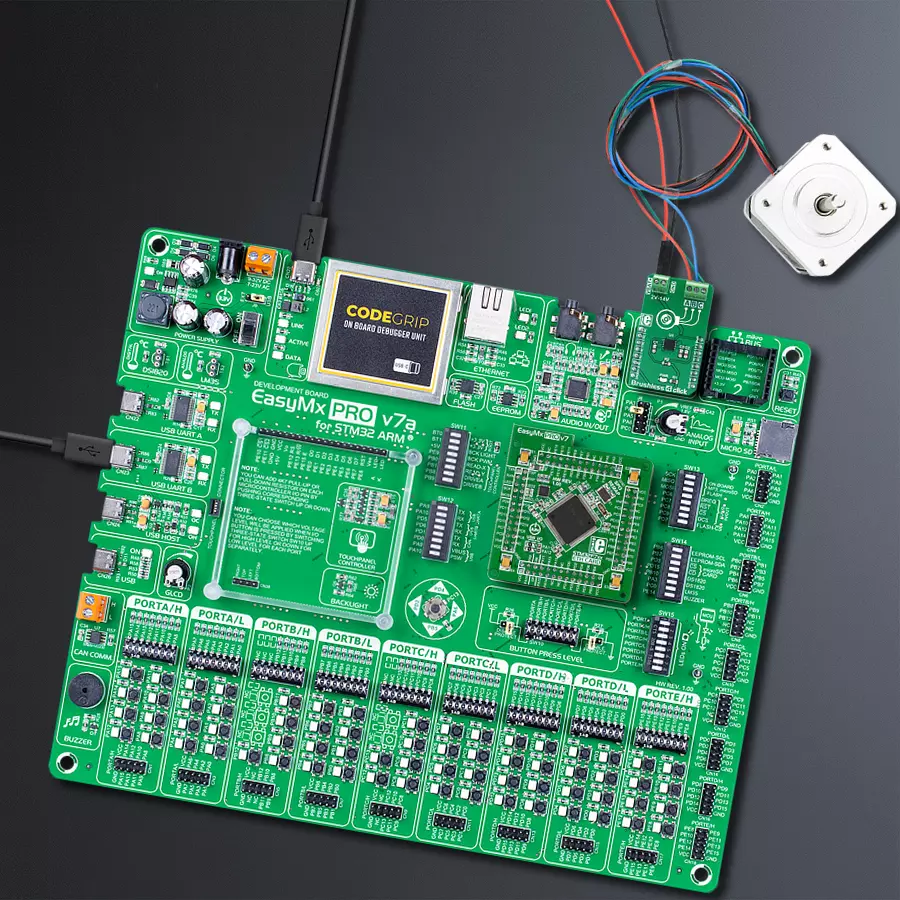

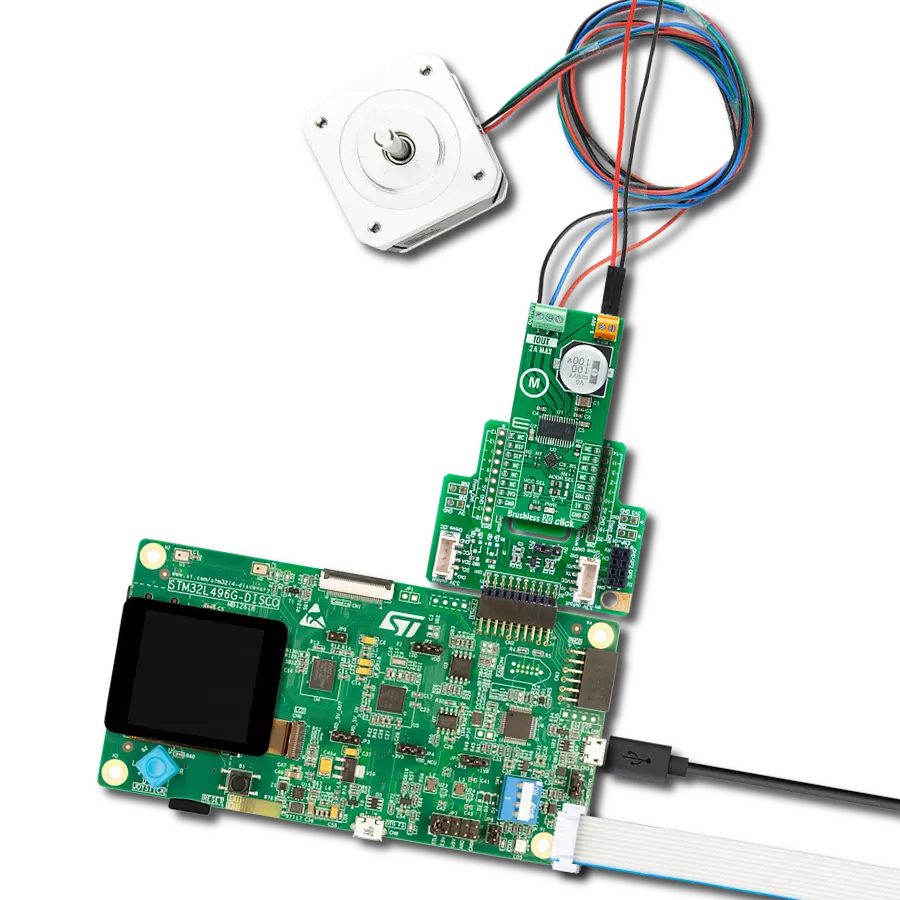

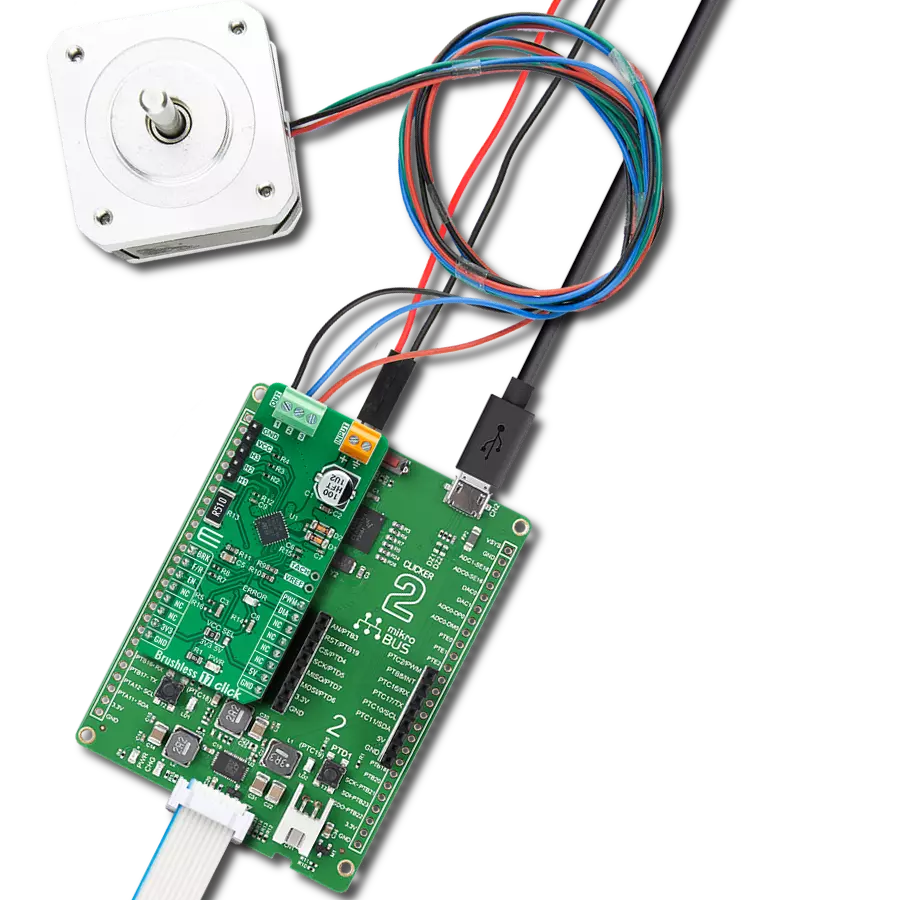

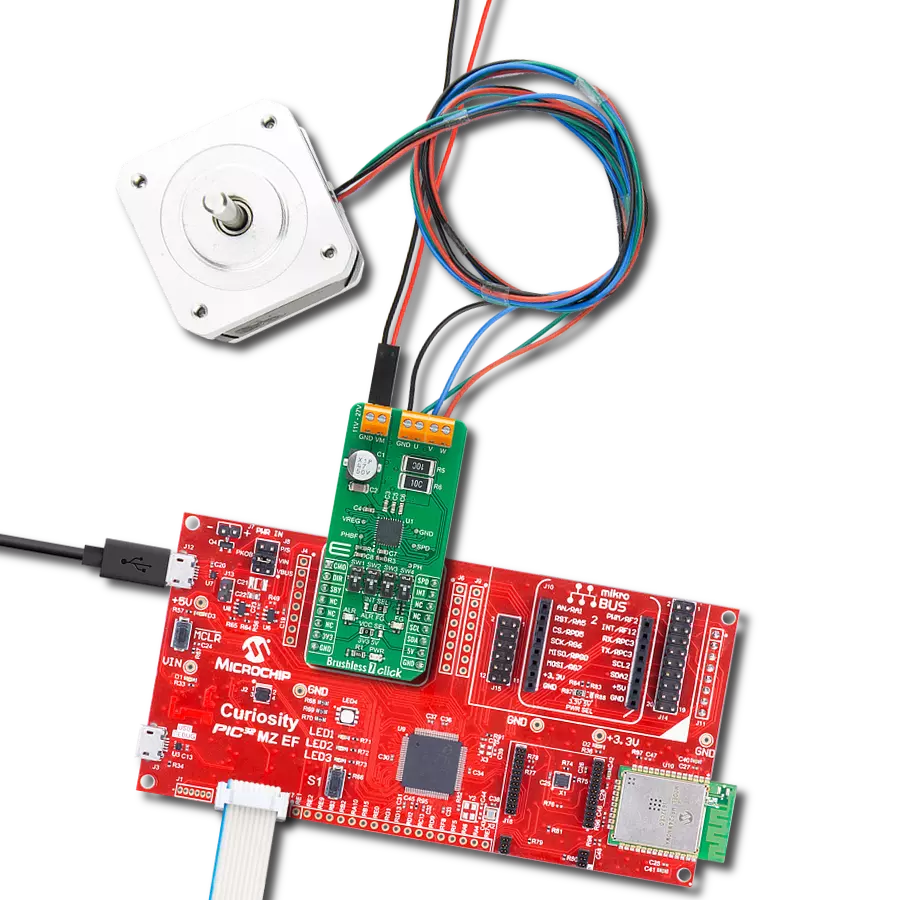

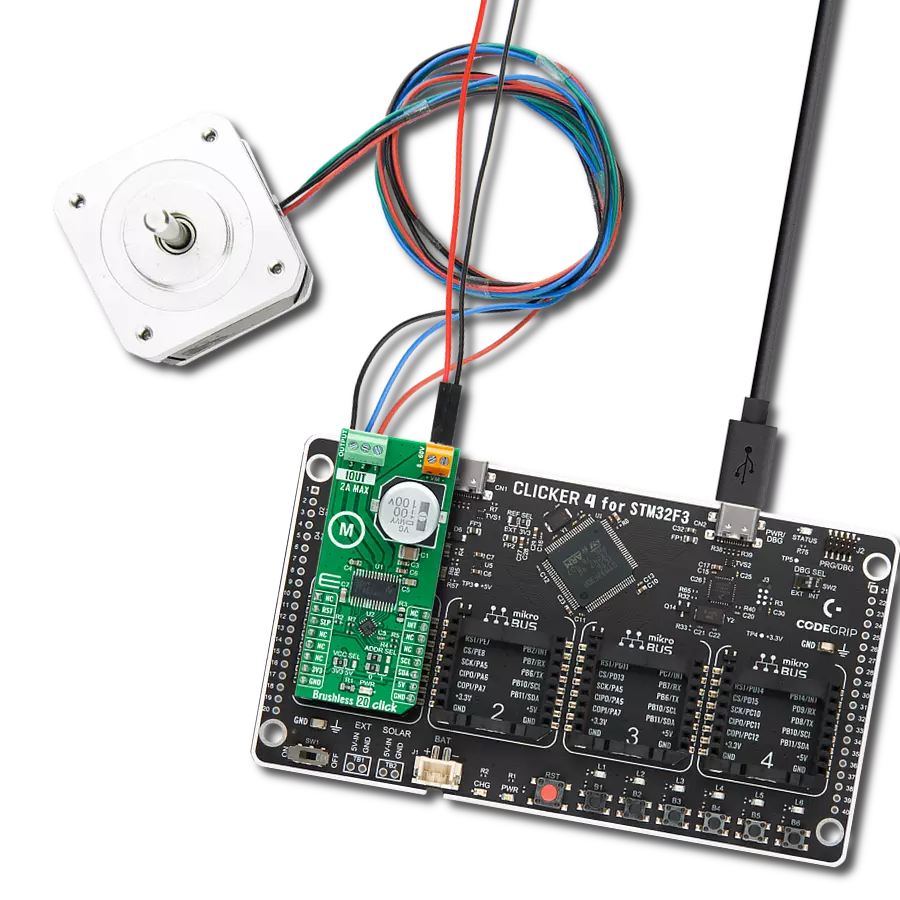

Development board

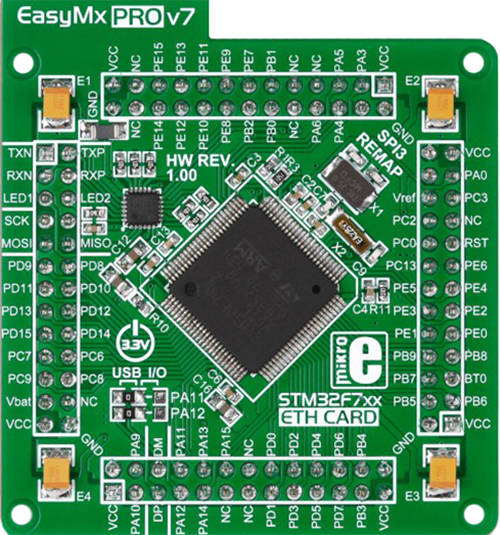

EasyMx PRO v7a for STM32 is the seventh generation of ARM development boards specially designed to develop embedded applications rapidly. It supports a wide range of 32-bit ARM microcontrollers from STMicroelectronics and a broad set of unique functions, such as the first-ever embedded debugger/programmer over USB-C. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. With two different connectors for each port, EasyMx PRO v7afor STM32 allows you to connect accessory boards, sensors, and custom electronics more efficiently than ever. Each part of the EasyMx

PRO v7a for STM32 development board contains the components necessary for the most efficient operation of the same board. In addition to the advanced integrated CODEGRIP programmer/debugger module, which offers many valuable programming/debugging options and seamless integration with the Mikroe software environment, the board also includes a clean and regulated power supply block for the development board. It can use a wide range of external power sources, including an external 12V power supply, 7-23V AC or 9-32V DC via DC connector/screw terminals, and a power source via the USB Type-C (USB-C) connector. Communication options such as USB-UART, USB-HOST/DEVICE, CAN, and

Ethernet are also included, including the well-established mikroBUS™ standard, one display option for the TFT board line of products, and a standard TQFP socket for the seventh-generation MCU cards. This socket covers 32-bit ARM MCUs like STM32 Cortex-M3, -M7, and -M4 MCUs. EasyMx PRO v7afor STM32 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Type

7th Generation

Architecture

ARM Cortex-M4

MCU Memory (KB)

10

Silicon Vendor

STMicroelectronics

Pin count

100

RAM (Bytes)

192k

You complete me!

Accessories

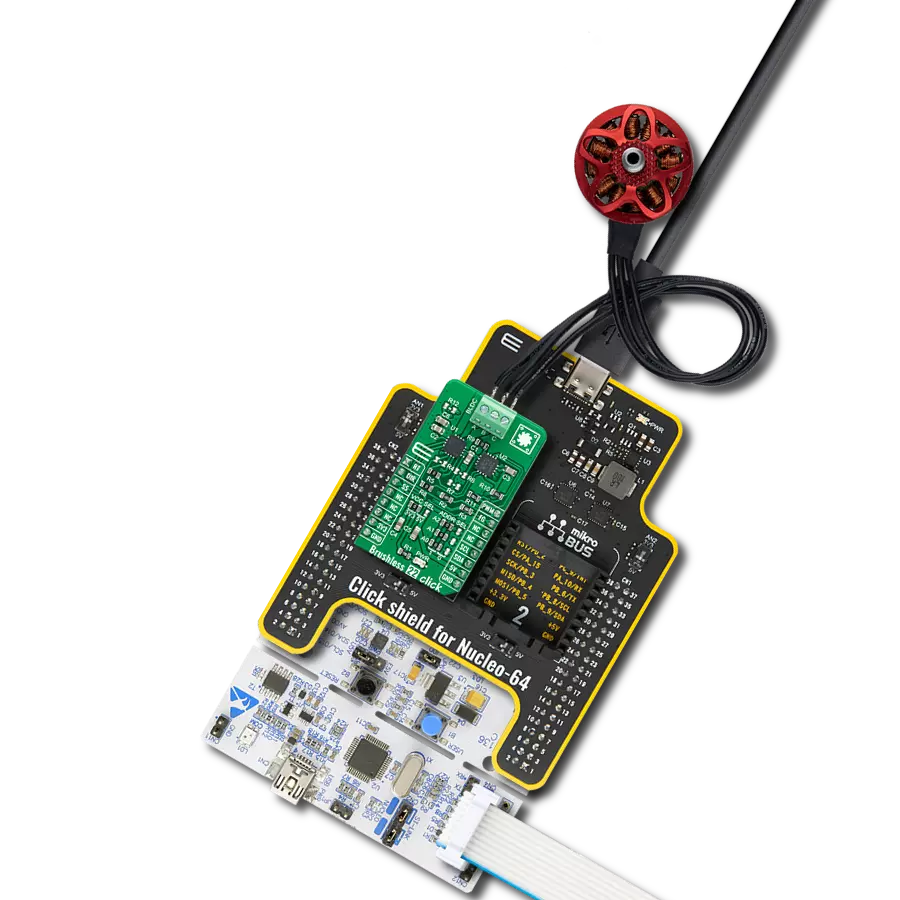

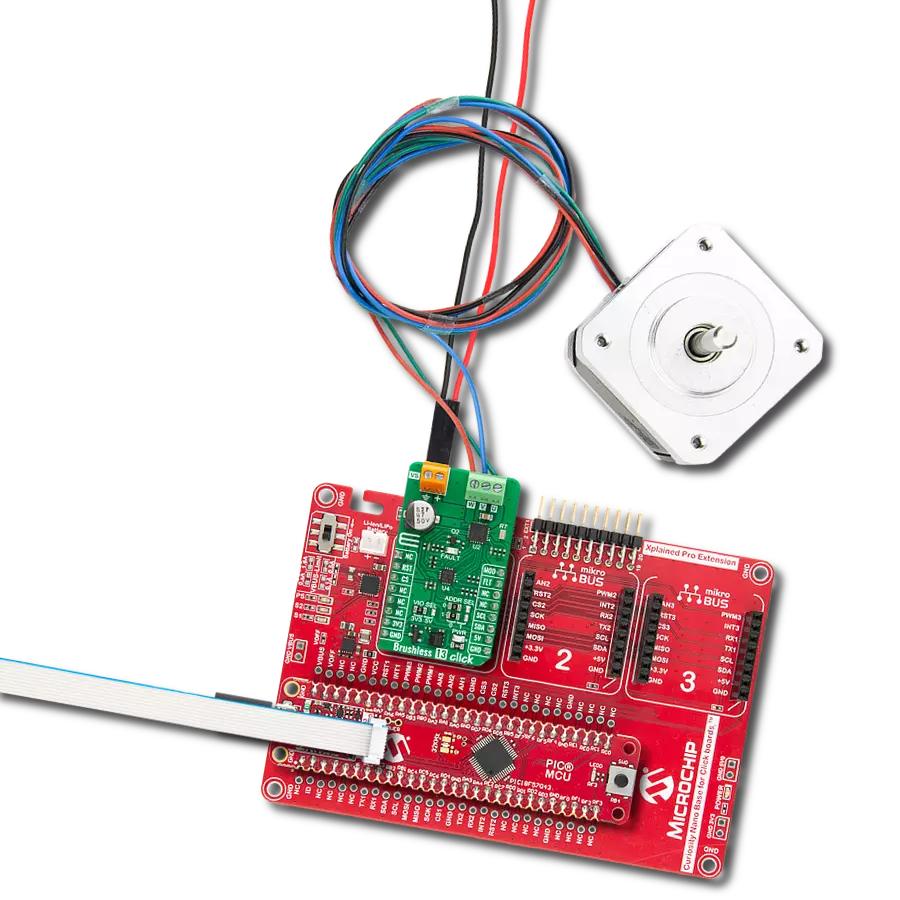

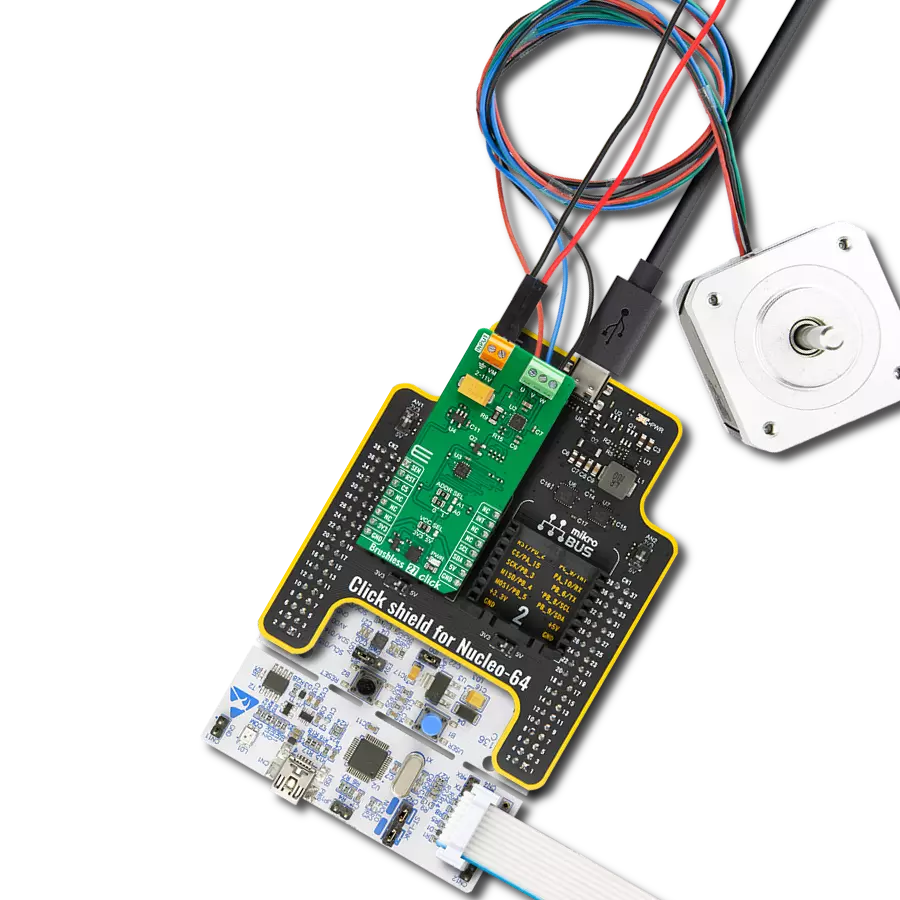

Brushless DC (BLDC) Motor with a Hall sensor represents a high-performance motor from the 42BLF motor series. This motor, wired in a star configuration, boasts a Hall Effect angle of 120°, ensuring precise and reliable performance. With a compact motor length of 47mm and a lightweight design tipping the scales at just 0.29kg, this BLDC motor is engineered to meet your needs. Operating flawlessly at a voltage rating of 24VDC and a speed range of 4000 ± 10% RPM, this motor offers consistent and dependable power. It excels in a normal operational temperature range from -20 to +50°C, maintaining efficiency with a rated current of 1.9A. Also, this product seamlessly integrates with all Brushless Click boards™ and those that require BLDC motors with Hall sensors.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Brushless 4 Click driver.

Key functions:

brushless4_set_duty_cycle- This function sets the PWM duty cyclebrushless4_pwm_start- This function starts PWM modulebrushless4_pwm_pin- This function sets the state of the PWM pin

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file

* @brief Brushless 4 Click example

*

* # Description

* This Click has many features for driving a wide range of small to medium BLDC motors.

* It provides the rotor position digital output, via the FG pin, routed to the mikroBUS INT pin.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the GPIO driver

* and configures the PWM peripheral for controlling the speed of the motor.

*

* ## Application Task

* This is an example that demonstrates the use of a Brushless 4 Click board.

* Brushless 4 Click communicates with the register via the PWM interface.

* Increases and decreasing the speed of the motor demonstrate speed control.

* Results are being sent to the Usart Terminal where you can track their changes.

*

*

* @author Nikola Peric

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "brushless4.h"

// ------------------------------------------------------------------ VARIABLES

static brushless4_t brushless4;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

brushless4_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

brushless4_cfg_setup( &cfg );

BRUSHLESS4_MAP_MIKROBUS( cfg, MIKROBUS_1 );

brushless4_init( &brushless4, &cfg );

brushless4_set_duty_cycle ( &brushless4, 0.0 );

brushless4_pwm_start( &brushless4 );

log_info( &logger, "---- Application Task ----" );

Delay_ms ( 1000 );

}

void application_task ( void )

{

static int8_t duty_cnt = 1;

static int8_t duty_inc = 1;

float duty = duty_cnt / 10.0;

brushless4_set_duty_cycle ( &brushless4, duty );

log_printf( &logger, "Duty: %d%%\r\n", ( uint16_t )( duty_cnt * 10 ) );

Delay_ms ( 500 );

if ( 10 == duty_cnt )

{

duty_inc = -1;

log_printf( &logger, " Slowing down... \r\n" );

}

else if ( 0 == duty_cnt )

{

duty_inc = 1;

log_printf( &logger, " Increasing the motor speed... \r\n" );

}

duty_cnt += duty_inc;

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Brushless