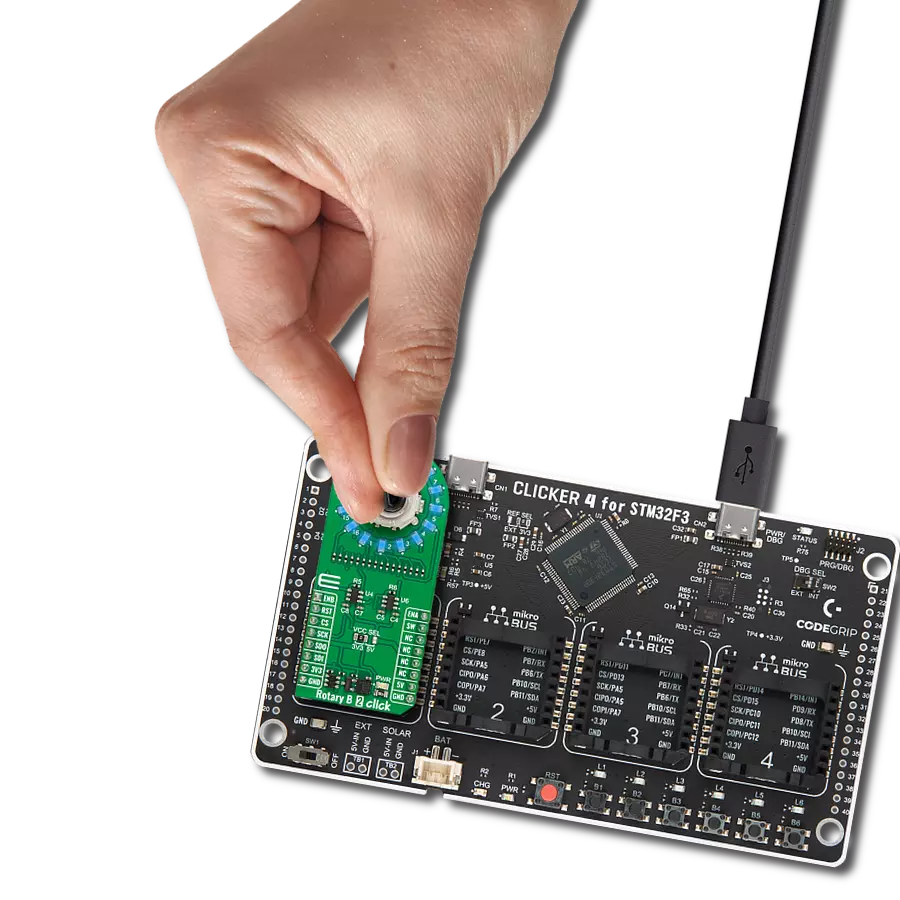

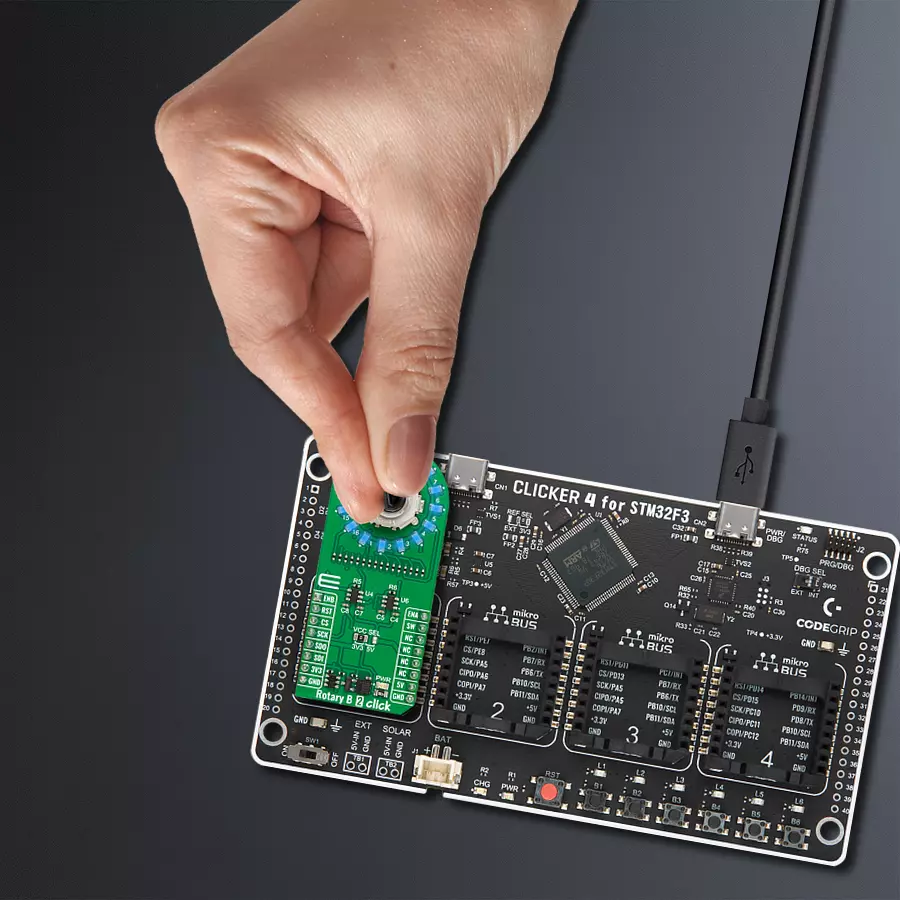

通过添加简单的旋钮和清晰的视觉效果,使您的项目更易于使用,从而实现更好的交互。

A

A

硬件概览

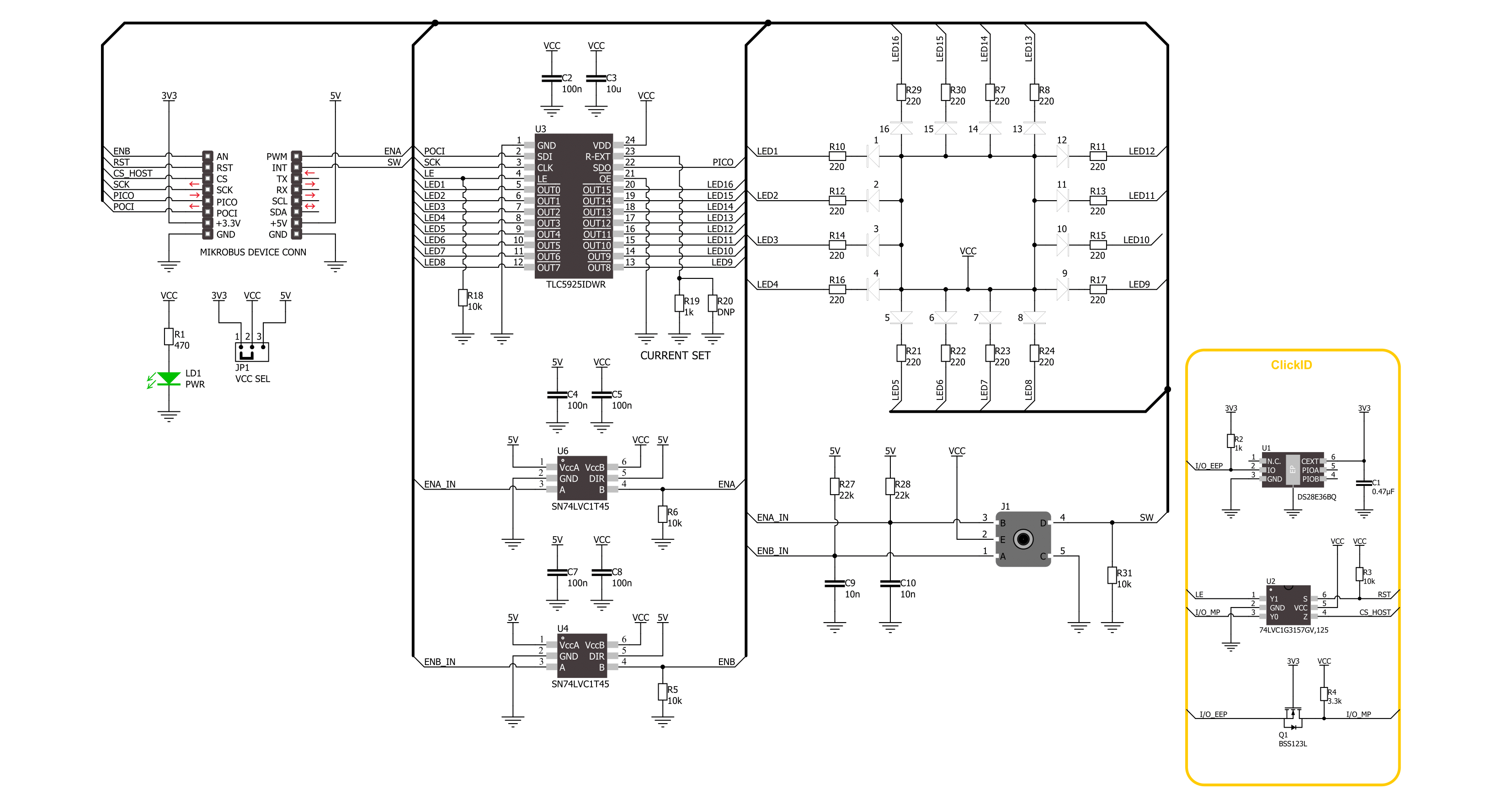

它是如何工作的?

Rotary B 2 Click基于德州仪器的TLC5925,这是一款低功耗的16通道恒流LED沉降驱动器,结合了ALPS的高品质旋转编码器EC12D1564402,使您可以在设计中添加精密输入旋钮。EC12D1564402增量旋转编码器被环绕着16个蓝色LED的环,其中单个旋转被分成15个离散步骤(与电位器相反,旋转编码器可以连续旋转)。驱动器可以单独控制每个LED,允许编程各种照明效果。编码器在两个mikroBUS™线上输出A和B信号(相位不同),同

时具有旋钮按键功能,该功能通过中断线输出。EC12D1564402是一个带有推按钮的15脉冲增量旋转编码器。此编码器具有独特的机械规格(其内部开关的去抖动时间可降至2ms),并且可以经受大量的开关周期,高达30,000次。支持去抖动电路允许在完全触发输出之前使接点稳定。Rotary B 2 Click使用TLC5925 LED驱动器的标准4线SPI串行接口与主机MCU通信,支持最高30MHz的时钟频率。旋转编码器输出A和B信号(相位不同)在两个mikroBUS™

线上,ENA和ENB引脚通过mikroBUS™插座输出,以及通过SW引脚(中断线)输出的按键接触。使用两个德州仪器的SN74LVC1T45单位双供电总线收发器进行逻辑电平转换。此Click board™可以通过VCC SEL跳线选择3.3V或5V逻辑电压电平运行。这样,既支持3.3V又支持5V的MCU可以正确使用通信线路。此外,该Click board™配备有一个包含易于使用的函数和示例代码的库,可用作进一步开发的参考。

功能概述

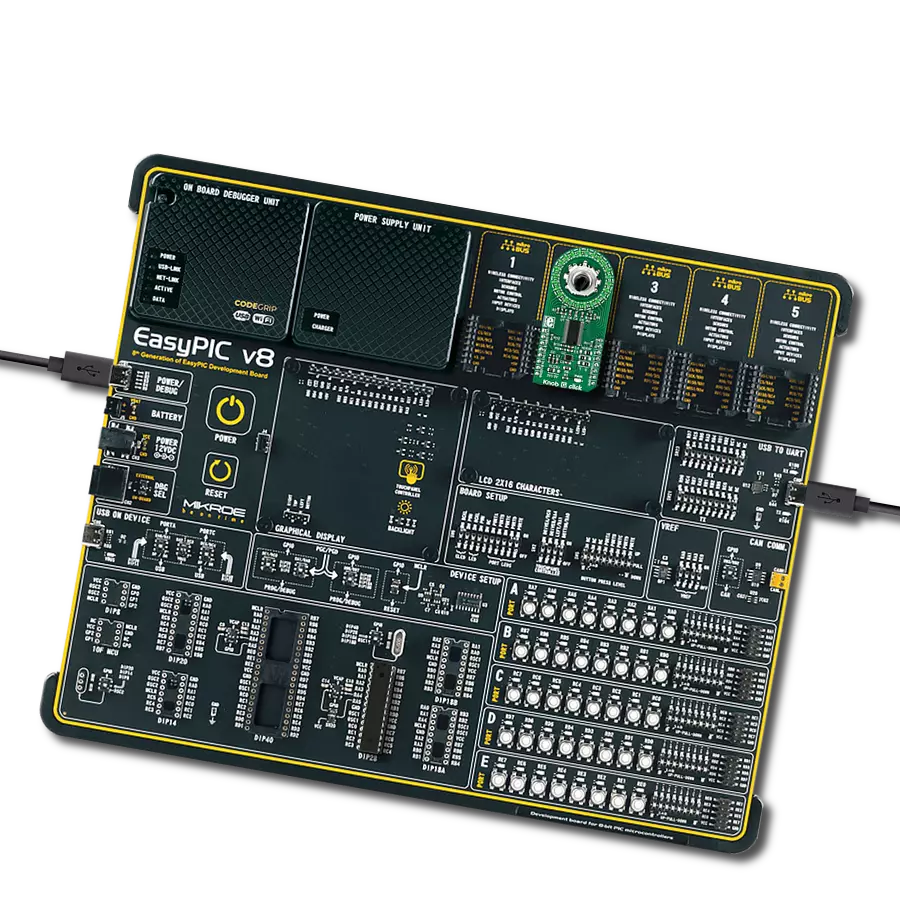

开发板

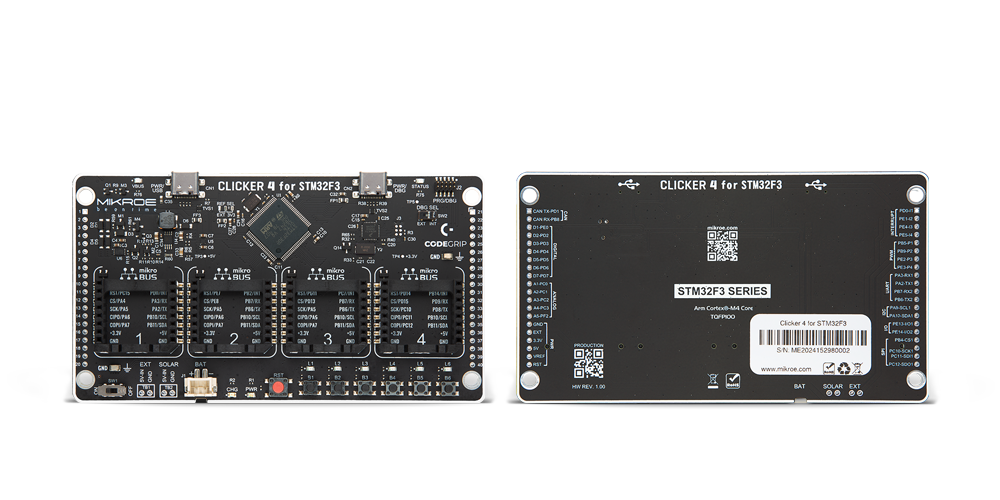

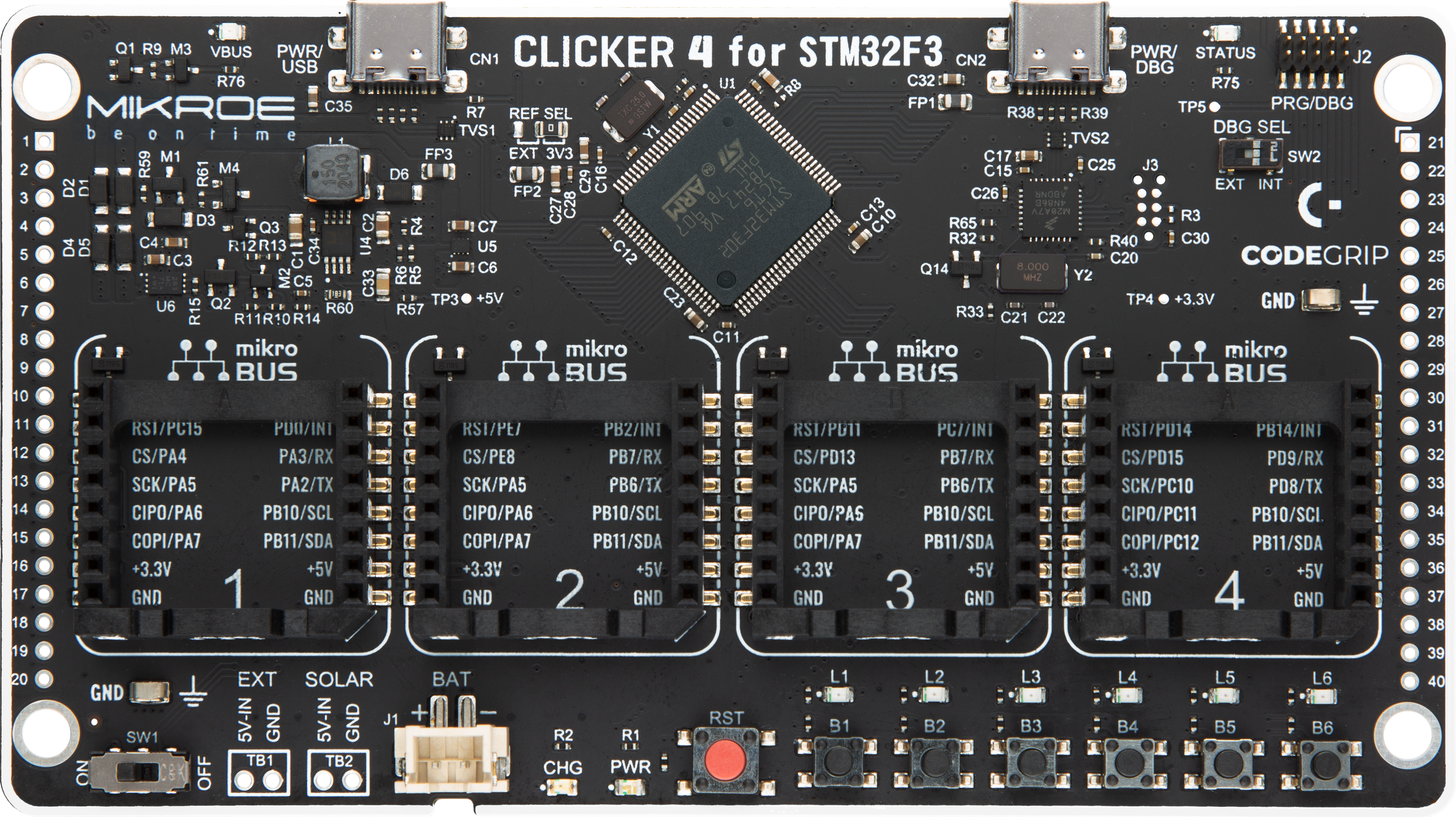

Clicker 4 for STM32F3 是一款紧凑型开发板,作为完整的解决方案而设计,可帮助用户快速构建具备独特功能的定制设备。该板搭载 STMicroelectronics 的 STM32F302VCT6 微控制器,配备四个 mikroBUS™ 插槽用于连接 Click boards™、完善的电源管理功能以及其他实用资源,是快速开发各类应用的理想平台。其核心 MCU STM32F302VCT6 基于高性能

Arm® Cortex®-M4 32 位处理器,运行频率高达 168MHz,处理能力强大,能够满足各种高复杂度任务的需求,使 Clicker 4 能灵活适应多种应用场景。除了两个 1x20 引脚排针外,板载最显著的连接特性是四个增强型 mikroBUS™ 插槽,支持接入数量庞大的 Click boards™ 生态系统,该生态每日持续扩展。Clicker 4 各功能区域标识清晰,界面直观简洁,极大

提升使用便捷性和开发效率。Clicker 4 的价值不仅在于加速原型开发与应用构建阶段,更在于其作为独立完整方案可直接集成至实际项目中,无需额外硬件修改。四角各设有直径 4.2mm(0.165")的安装孔,便于通过螺丝轻松固定。对于多数应用,只需配套一个外壳,即可将 Clicker 4 开发板转化为完整、实用且外观精美的定制系统。

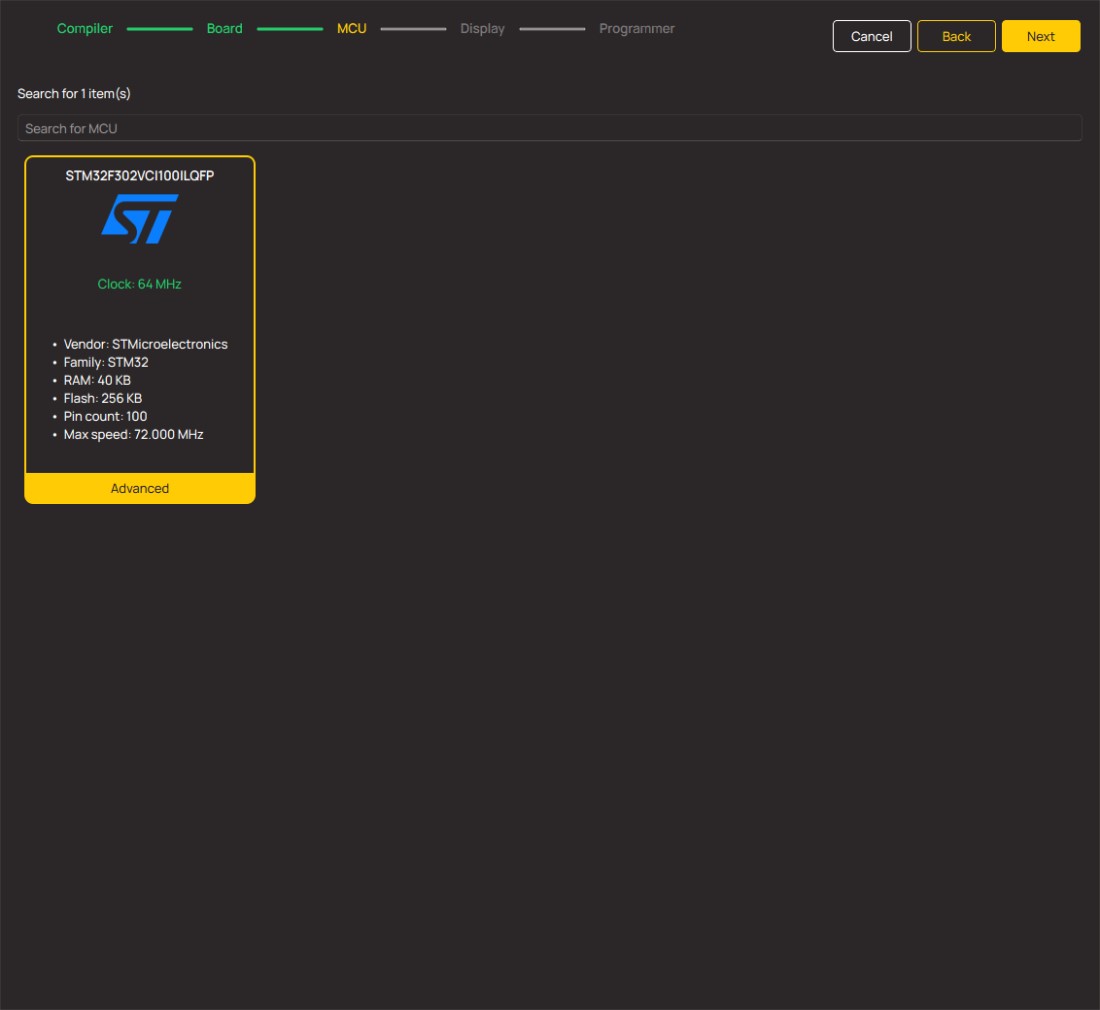

微控制器概述

MCU卡片 / MCU

建筑

ARM Cortex-M4

MCU 内存 (KB)

256

硅供应商

STMicroelectronics

引脚数

100

RAM (字节)

40960

使用的MCU引脚

mikroBUS™映射器

“仔细看看!”

Click board™ 原理图

一步一步来

项目组装

实时跟踪您的结果

应用程序输出

1. 应用程序输出 - 在调试模式下,“应用程序输出”窗口支持实时数据监控,直接提供执行结果的可视化。请按照提供的教程正确配置环境,以确保数据正确显示。

2. UART 终端 - 使用UART Terminal通过USB to UART converter监视数据传输,实现Click board™与开发系统之间的直接通信。请根据项目需求配置波特率和其他串行设置,以确保正常运行。有关分步设置说明,请参考提供的教程。

3. Plot 输出 - Plot功能提供了一种强大的方式来可视化实时传感器数据,使趋势分析、调试和多个数据点的对比变得更加直观。要正确设置,请按照提供的教程,其中包含使用Plot功能显示Click board™读数的分步示例。在代码中使用Plot功能时,请使用以下函数:plot(insert_graph_name, variable_name);。这是一个通用格式,用户需要将“insert_graph_name”替换为实际图表名称,并将“variable_name”替换为要显示的参数。

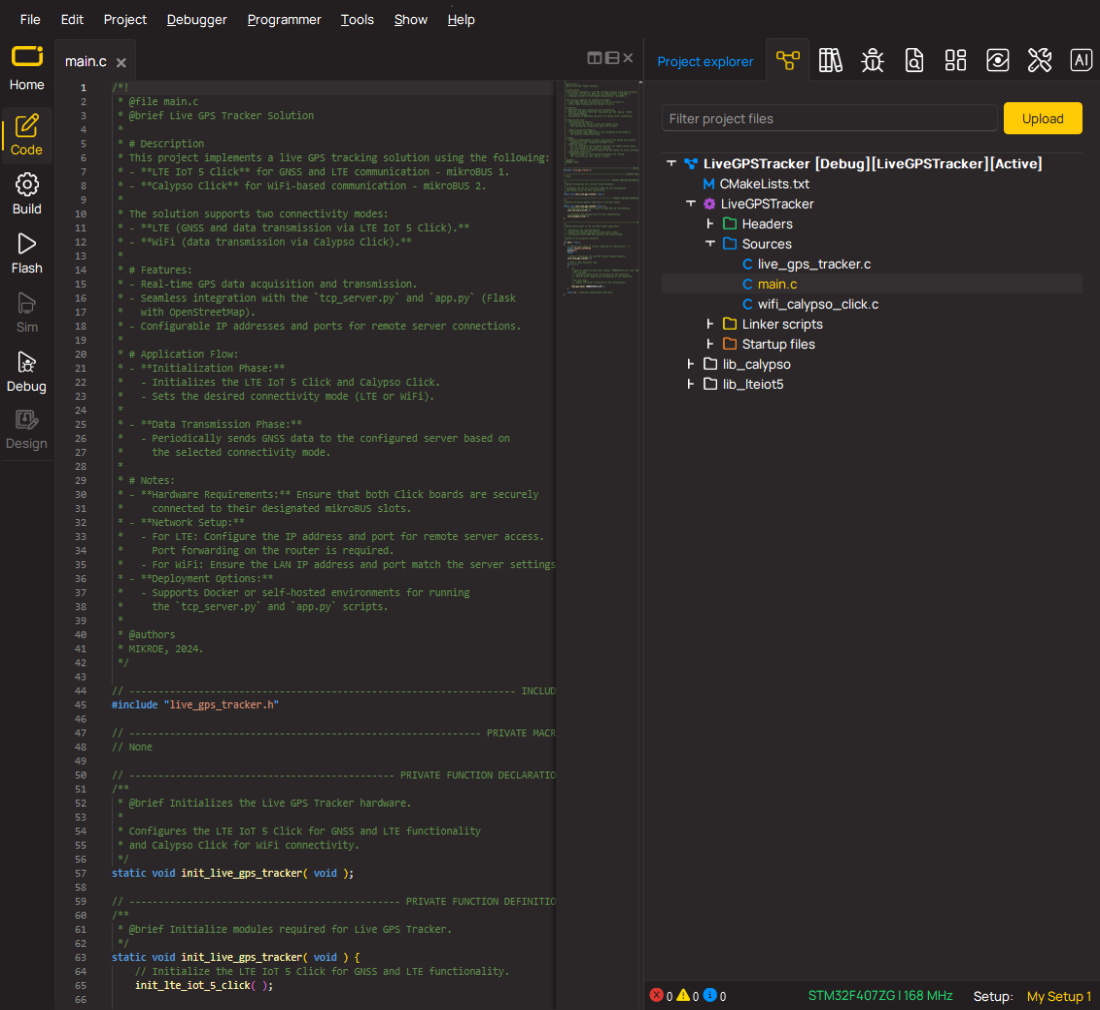

软件支持

库描述

该库包含 Rotary B 2 Click 驱动程序的 API。

关键功能:

rotaryb2_set_led_pos- 该函数打开所选LED位置的LED。rotaryb2_set_led_data- 该函数使用SPI串行接口写入所需的16位数据。rotaryb2_get_state_switch- 该函数返回旋转编码器开关信号,SW(INT)的状态。

开源

代码示例

完整的应用程序代码和一个现成的项目可以通过NECTO Studio包管理器直接安装到NECTO Studio。 应用程序代码也可以在MIKROE的GitHub账户中找到。

/*!

* @file main.c

* @brief Rotary B 2 Click example

*

* # Description

* This library contains the API for the Rotary B 2 Click driver

* to control LEDs states and a rotary encoder position readings.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization of SPI module and log UART.

* After the driver init, the app executes a default configuration and turn off all LEDs.

*

* ## Application Task

* This example demonstrates the use of the Rotary B 2 Click board.

* The demo example shows the functionality of a rotary encoder used to control LEDs.

*

* @author Nenad Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "rotaryb2.h"

#define ROTARYB2_ONE_LED ROTARYB2_SET_LED_DATA_1

#define ROTARYB2_TWO_LED ROTARYB2_SET_LED_DATA_1 | ROTARYB2_SET_LED_DATA_9

#define ROTARYB2_FOUR_LED ROTARYB2_SET_LED_DATA_1 | ROTARYB2_SET_LED_DATA_5 | \

ROTARYB2_SET_LED_DATA_9 | ROTARYB2_SET_LED_DATA_13

#define ROTARYB2_EIGHT_LED ROTARYB2_SET_LED_DATA_1 | ROTARYB2_SET_LED_DATA_3 | \

ROTARYB2_SET_LED_DATA_5 | ROTARYB2_SET_LED_DATA_7 | \

ROTARYB2_SET_LED_DATA_9 | ROTARYB2_SET_LED_DATA_11 | \

ROTARYB2_SET_LED_DATA_13 | ROTARYB2_SET_LED_DATA_15

#define ROTARYB2_EIGHT_LED_INV ROTARYB2_SET_LED_DATA_2 | ROTARYB2_SET_LED_DATA_4 | \

ROTARYB2_SET_LED_DATA_6 | ROTARYB2_SET_LED_DATA_8 | \

ROTARYB2_SET_LED_DATA_10 | ROTARYB2_SET_LED_DATA_12 | \

ROTARYB2_SET_LED_DATA_14 | ROTARYB2_SET_LED_DATA_16

static rotaryb2_t rotaryb2;

static log_t logger;

static uint8_t start_rot_status = 0;

static uint8_t led_demo_state = 0;

static uint8_t old_state = 0;

static uint8_t new_state = 1;

static uint8_t old_rot_state = 0;

static uint8_t new_rot_state = 1;

static uint16_t led_data = 1;

/**

* @brief Rotary B 2 select LED demo data function.

* @details This function selects one of the four LED demo data

* based on the current state of the LED demo.

* @return LED demo data:

* @li @c 0x0001 (ROTARYB2_ONE_LED) - Turn ON LED[1],

* @li @c 0x0101 (ROTARYB2_TWO_LED) - Turn ON LED[1,9],

* @li @c 0x0101 (ROTARYB2_FOUR_LED) - Turn ON LED[1,5,9,13],

* @li @c 0x5555 (ROTARYB2_EIGHT_LED) - Turn ON LED[1,3,5,7,9,11,13,15].

*/

static uint16_t rotaryb2_sel_led_demo_data ( uint8_t led_demo_state );

/**

* @brief Rotary B 2 switch detection function.

* @details This function is used for the switch state detection.

* @return Nothing.

*/

static void rotaryb2_switch_detection ( void );

/**

* @brief Rotary B 2 encoder mechanism function.

* @details This function is used to control the state of the LEDs

* by detecting the rotation direction of the rotary encoder.

* @return Nothing.

*/

static void rotaryb2_encoder_mechanism ( void );

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

rotaryb2_cfg_t rotaryb2_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

rotaryb2_cfg_setup( &rotaryb2_cfg );

ROTARYB2_MAP_MIKROBUS( rotaryb2_cfg, MIKROBUS_1 );

if ( SPI_MASTER_ERROR == rotaryb2_init( &rotaryb2, &rotaryb2_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( ROTARYB2_ERROR == rotaryb2_default_cfg ( &rotaryb2 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

if ( ROTARYB2_OK == rotaryb2_set_led_data( &rotaryb2, led_data ) )

{

rotaryb2_switch_detection( );

rotaryb2_encoder_mechanism( );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

static uint16_t rotaryb2_sel_led_demo_data ( uint8_t led_demo_state )

{

switch ( led_demo_state )

{

case 0:

{

return ROTARYB2_ONE_LED;

break;

}

case 1:

{

return ROTARYB2_TWO_LED;

break;

}

case 2:

{

return ROTARYB2_FOUR_LED;

break;

}

case 3:

{

return ROTARYB2_EIGHT_LED;

break;

}

default:

{

return ROTARYB2_ONE_LED;

break;

}

}

}

static void rotaryb2_switch_detection ( void )

{

if ( rotaryb2_get_state_switch( &rotaryb2 ) )

{

new_state = 1;

if ( ( 1 == new_state ) && ( 0 == old_state ) )

{

old_state = 1;

led_demo_state = ( led_demo_state + 1 ) % 5;

if ( 4 == led_demo_state )

{

for ( uint8_t n_cnt = 0; n_cnt < 10; n_cnt++ )

{

rotaryb2_set_led_data( &rotaryb2, ROTARYB2_EIGHT_LED_INV );

Delay_ms ( 100 );

rotaryb2_set_led_data( &rotaryb2, ROTARYB2_EIGHT_LED );

Delay_ms ( 100 );

}

for ( uint8_t led_p = ROTARYB2_SET_LED_POS_1; led_p <= ROTARYB2_SET_LED_POS_16; led_p++ )

{

rotaryb2_set_led_pos( &rotaryb2, led_p );

Delay_ms ( 100 );

}

led_demo_state = 0;

led_data = rotaryb2_sel_led_demo_data( led_demo_state );

}

else

{

led_data = rotaryb2_sel_led_demo_data( led_demo_state );

}

}

}

else

{

old_state = 0;

}

}

static void rotaryb2_encoder_mechanism ( void )

{

if ( rotaryb2_get_state_ena( &rotaryb2 ) == rotaryb2_get_state_enb( &rotaryb2 ) )

{

old_rot_state = 0;

start_rot_status = rotaryb2_get_state_ena( &rotaryb2 ) && rotaryb2_get_state_enb( &rotaryb2 );

}

else

{

new_rot_state = 1;

if ( new_rot_state != old_rot_state )

{

old_rot_state = 1;

if ( start_rot_status != rotaryb2_get_state_ena( &rotaryb2 ) )

{

led_data = ( led_data << 1 ) | ( led_data >> 15 );

}

else

{

led_data = ( led_data >> 1 ) | ( led_data << 15 );

}

}

}

}

// ------------------------------------------------------------------------ END

额外支持

资源

类别:旋转编码器