Fast absolute angle measurement over a full 360-degree range

A

A

Hardware Overview

How does it work?

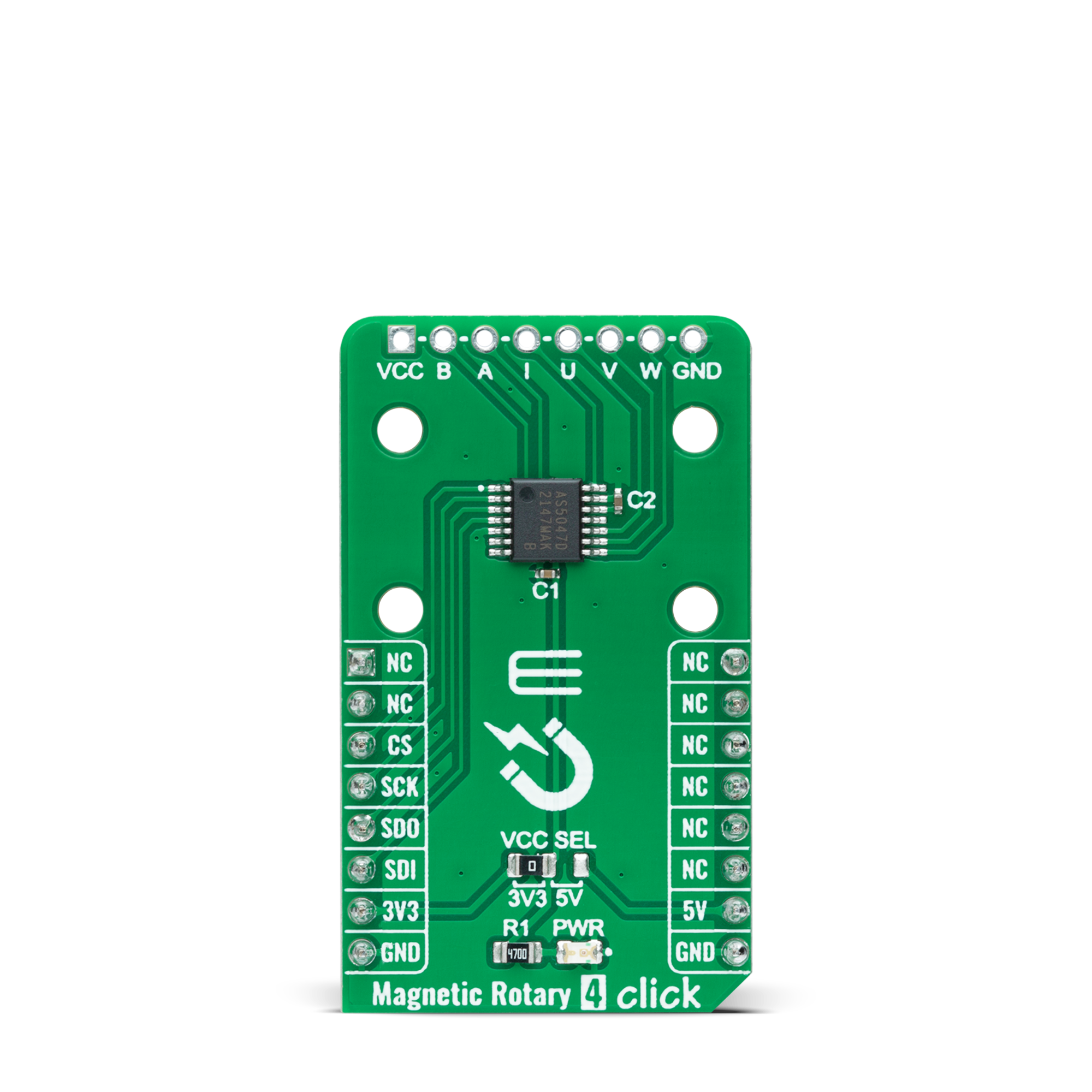

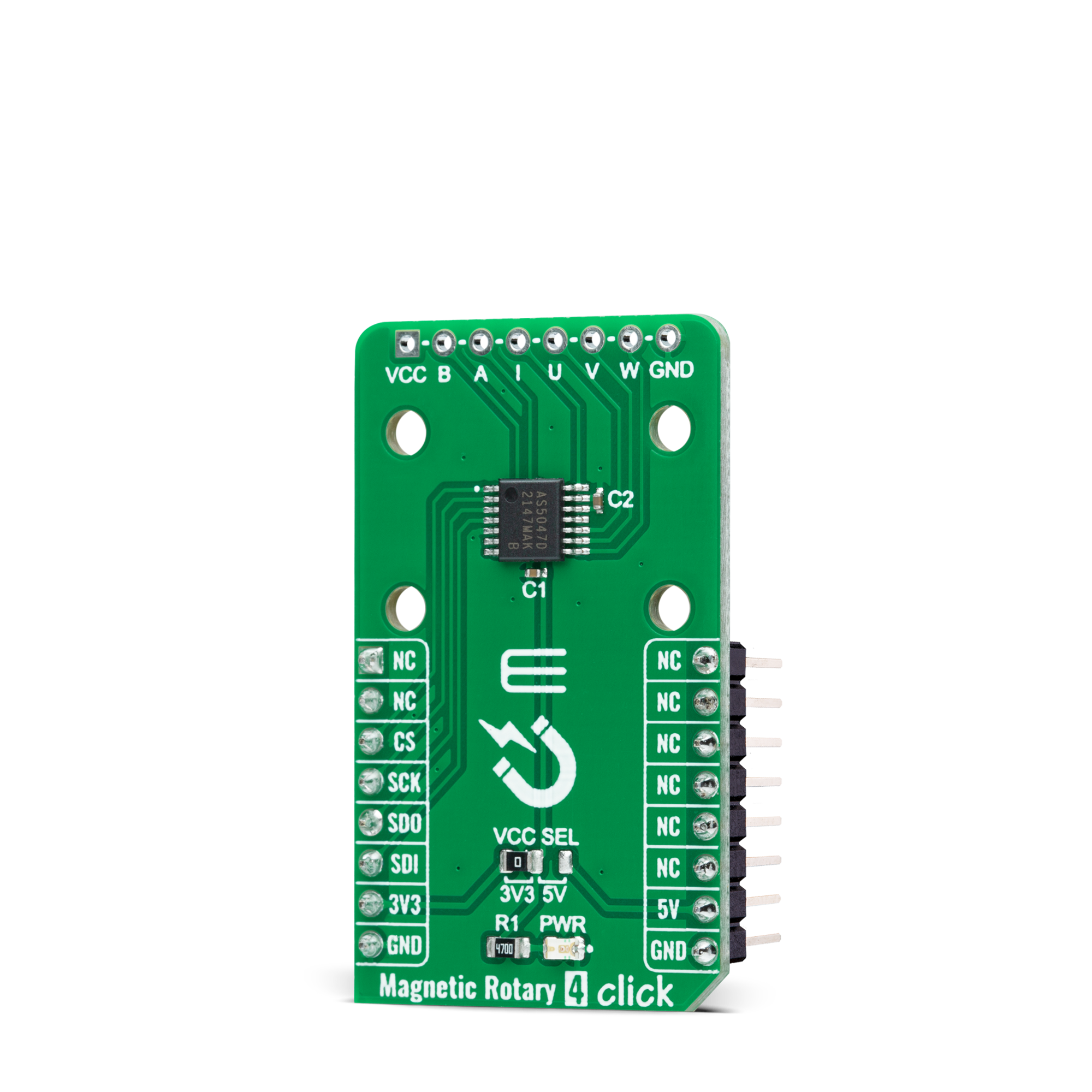

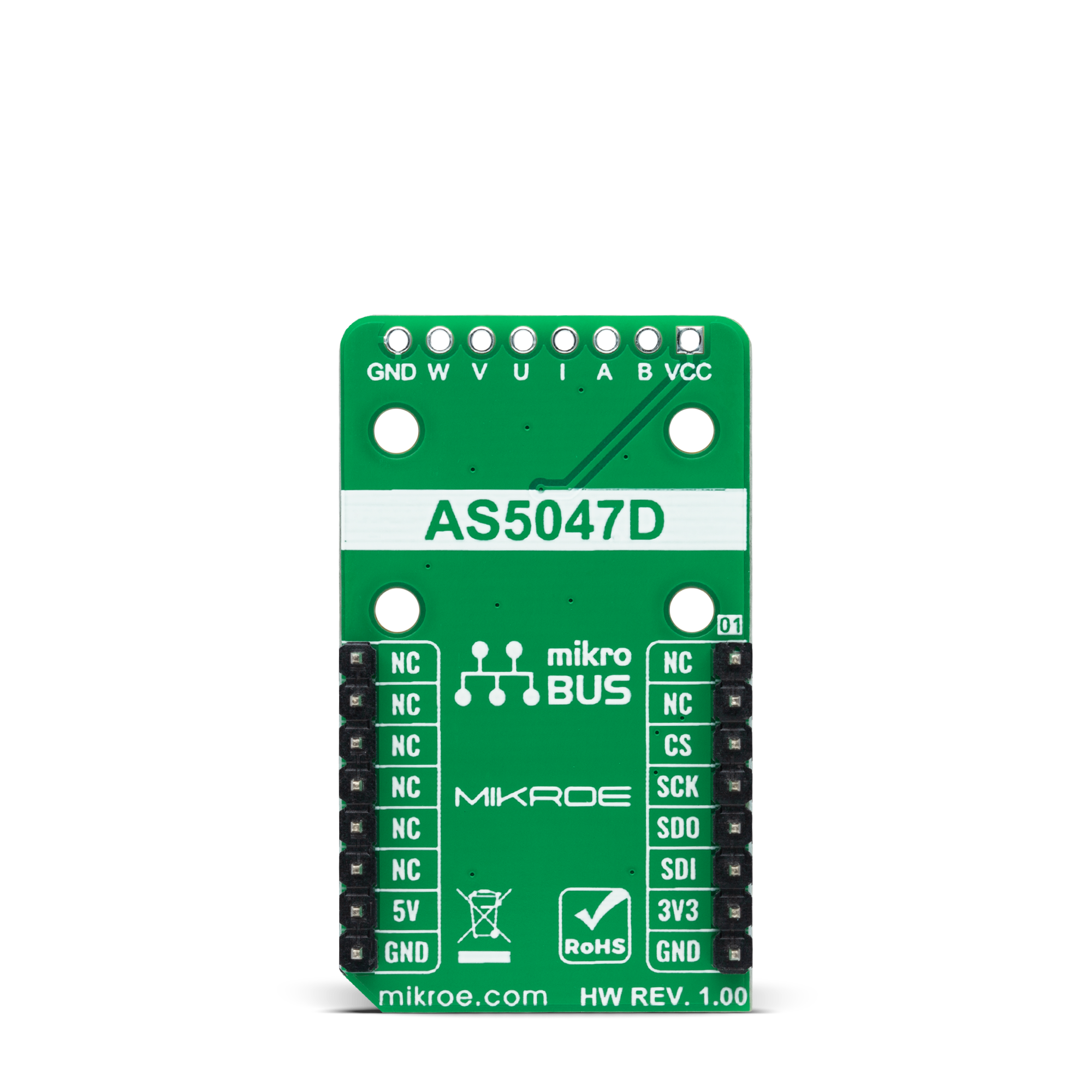

Magnetic Rotary 4 Click is based on the AS5047D, a high-resolution rotary position sensor for fast absolute angle measurement over a full 360-degree range from ams AG. The core of the AS5047D represents a CMOS technology Hall-effect magnetic sensor that converts the magnetic field component perpendicular to the surface of the chip into a digital value. It allows a host MCU to read 14-bit absolute angle position data from the AS5047D and to program non-volatile settings without a dedicated programmer. It is also equipped with a Dynamic Angle Error Compensation block that corrects the calculated angle regarding latency by using a linear prediction calculation algorithm. The signals from internal Hall sensors are amplified and filtered before their conversion by the ADC and then processed by the CORDIC block to compute the angle and magnitude of the magnetic field vector. The intensity of the magnetic field is used by the automatic gain control (AGC) to adjust the

amplification level to compensate for temperature and magnetic field variations. Magnetic Rotary 4 Click communicates with MCU through a standard SPI interface supporting the common SPI mode, SPI Mode 1. This Click board™ also comes with an onboard header reserved for incremental and commutation signals of their respective A/B/I and U/V/W signals alongside embedded self-diagnostics. Incremental movements are indicated on a set of ABI signals with a maximum resolution of 2000 steps / 500 pulses per revolution in decimal mode and 2048 steps / 512 pulses per revolution in binary mode. The resolution of the ABI signal is programmable and can be reduced to 32 or 8 pulses per revolution. Brushless DC (BLDC) motors are also controllable through a standard UVW commutation interface with a programmable number of pole pairs from 1 to 7. At constant rotation speed, the latency time is internally compensated by the AS5047D, reducing the

dynamic angle error at the SPI, ABI, and UVW outputs, while at higher speeds, the interpolator fills in the missing ABI pulses and generates the UVW signals with no loss of resolution. The AS5047D allows selection between a UVW output interface and a PWM-encoded interface on the W pin, which can be seen as an absolute angle position. Also, unique addition to this board is a position for a rotary magnet holder designed to be used alongside a magnetic rotary position sensor allowing fast prototyping and quick measurements during development. This Click board™ can only be operated from a 3.3V logic voltage level. Therefore, the board must perform appropriate logic voltage conversion before using MCUs with different logic levels. However, the Click board™ comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

Development board

PIC32MZ Clicker is a compact starter development board that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit PIC32MZ microcontroller with FPU from Microchip, a USB connector, LED indicators, buttons, a mikroProg connector, and a header for interfacing with external electronics. Thanks to its compact design with clear and easy-recognizable silkscreen markings, it provides a fluid and immersive working experience, allowing access anywhere and under

any circumstances. Each part of the PIC32MZ Clicker development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the PIC32MZ Clicker programming method, using USB HID mikroBootloader, or through an external mikroProg connector for PIC, dsPIC, or PIC32 programmer, the Clicker board also includes a clean and regulated power supply module for the development kit. The USB Micro-B connection can provide up to 500mA of current, which is more than enough to operate all onboard

and additional modules. All communication methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, reset button, and several buttons and LED indicators. PIC32MZ Clicker is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

1024

Silicon Vendor

Microchip

Pin count

64

RAM (Bytes)

524288

You complete me!

Accessories

Rotary Magnetic Holder is an addition designed for use alongside a magnetic rotary position sensor. It comes with a plastic stand measuring 22x16x10 millimeters (L x W x H), as well as an adjustable shaft with a 6mm diameter magnet. The plastic frame has four round feet that fit into holes in the board near the magnetic rotary position sensor, with a 6mm diameter hole on top to match the adjustable shaft that carries the magnet. This shaft has a height adjustment screw on it, allowing the user to adjust it between 18 and 22 millimeters. This way, fast prototyping and quick measurements of the magnet characteristics are allowed during development.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

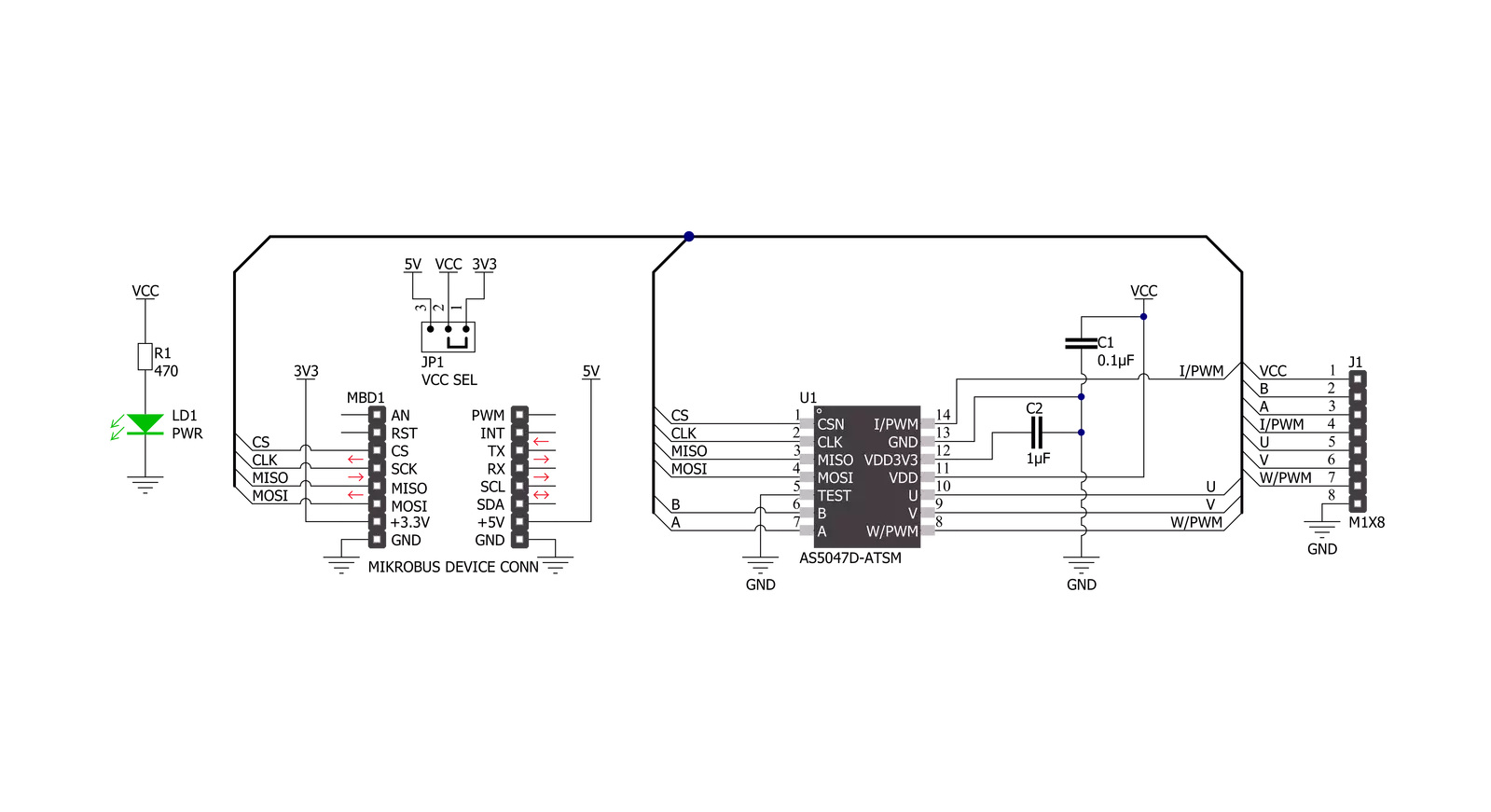

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Magnetic Rotary 4 Click driver.

Key functions:

magneticrotary4_set_rotation_directionThis function sets the magnet rotation direction to clockwise or counter-clockwise.magneticrotary4_calibrate_zero_positionThis function calibrates the sensor to zero Angle position.magneticrotary4_get_angleThis function reads the absolute position raw data and converts it to degrees (Angle).

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief MagneticRotary4 Click example

*

* # Description

* This example demonstrates the use of Magnetic Rotary 4 click board by reading

* and displaying the magnet (potentiometer) angular position in degrees.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver, sets the rotation direction, and calibrates the sensor

* for potentiometer zero position.

*

* ## Application Task

* Reads the magnet (potentiometer) angular position in degrees every 100ms

* and displays the results on the USB UART.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "magneticrotary4.h"

static magneticrotary4_t magneticrotary4;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

magneticrotary4_cfg_t magneticrotary4_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

magneticrotary4_cfg_setup( &magneticrotary4_cfg );

MAGNETICROTARY4_MAP_MIKROBUS( magneticrotary4_cfg, MIKROBUS_1 );

if ( SPI_MASTER_ERROR == magneticrotary4_init( &magneticrotary4, &magneticrotary4_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( MAGNETICROTARY4_ERROR == magneticrotary4_set_rotation_direction ( &magneticrotary4, MAGNETICROTARY4_DIRECTION_CW ) )

{

log_error( &logger, " Set rotation direction." );

for ( ; ; );

}

if ( MAGNETICROTARY4_ERROR == magneticrotary4_calibrate_zero_position ( &magneticrotary4 ) )

{

log_error( &logger, " Calibrate zero position." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

float angle;

if ( MAGNETICROTARY4_OK == magneticrotary4_get_angle ( &magneticrotary4, &angle ) )

{

log_printf( &logger, " Angle: %.1f degrees\r\n\n", angle );

Delay_ms ( 100 );

}

}

void main ( void )

{

application_init( );

for ( ; ; )

{

application_task( );

}

}

// ------------------------------------------------------------------------ END