Get reliable and high-resolution force data for your sensitive applications

A

A

Hardware Overview

How does it work?

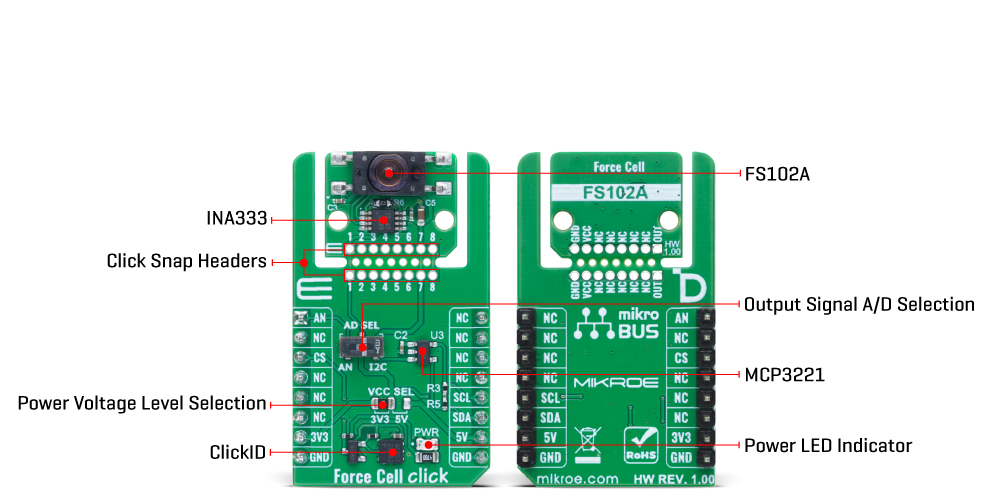

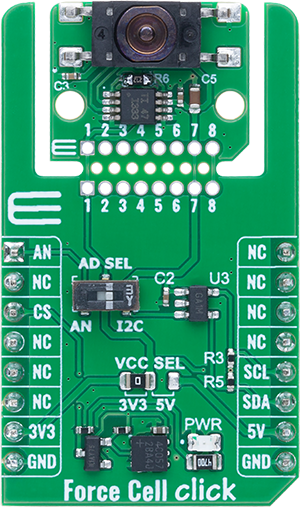

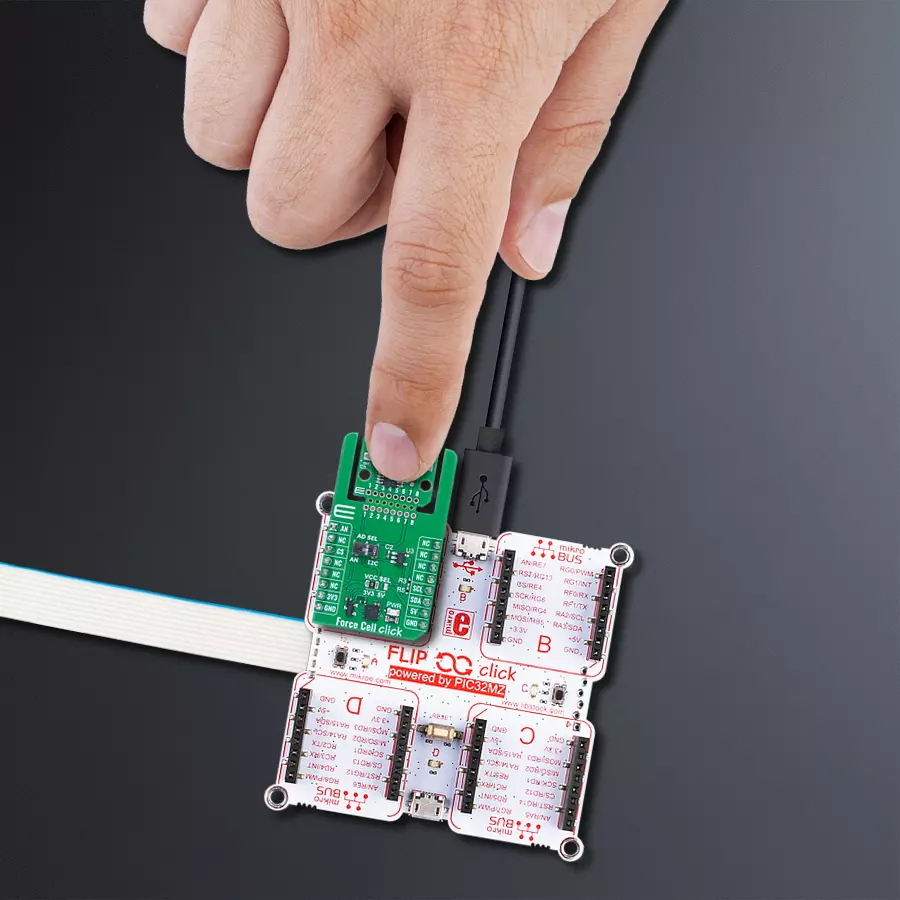

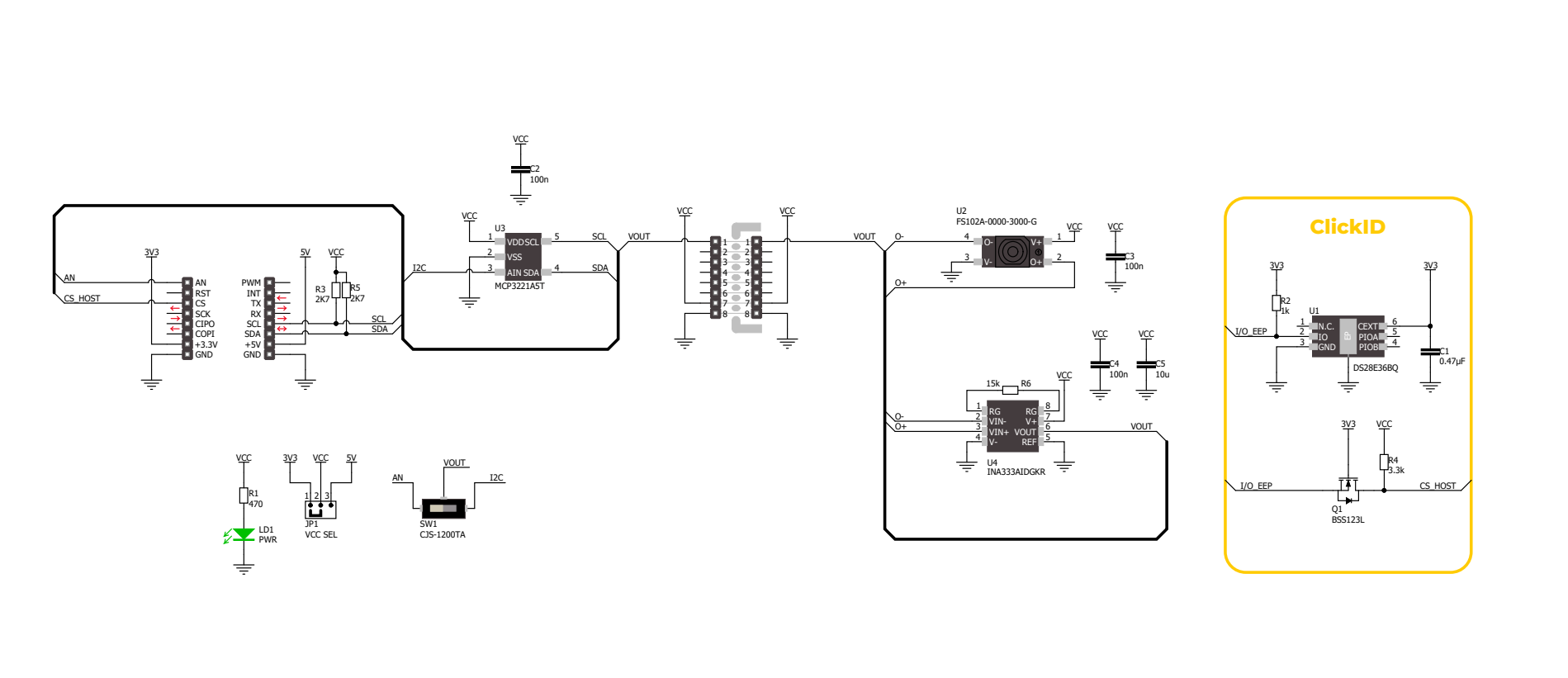

Force Cell Click is based on the FS102A-0000-3000-G, a miniature compression load cell from TE Connectivity’s FS10 series, designed to provide highly precise force measurement capabilities for embedded applications. The FS102A-0000-3000-G sensor features a sensitivity of 20mV/V and is capable of measuring forces up to 3000 grams, equivalent to 30 Newtons, making it suitable for a wide range of applications that require accurate force sensing. Using TE Connectivity’s high-reliability Microfused technology, this sensor delivers excellent span and zero stability, superior resolution, outstanding cycle life, and high over-range capability, ensuring long-term operational consistency even under demanding conditions. The FS102A-0000-3000-G’s innovative design incorporates a high-resistance pin-molded plastic housing that connects directly with the strain gauge signal, eliminating the need for internal PCBs and providing enhanced performance stability, particularly during exposure to high-temperature processes. Optimized for integration into embedded systems, Force Cell Click is ideal for use in wearable medical devices, industrial and consumer appliances, as well as robotics applications, where

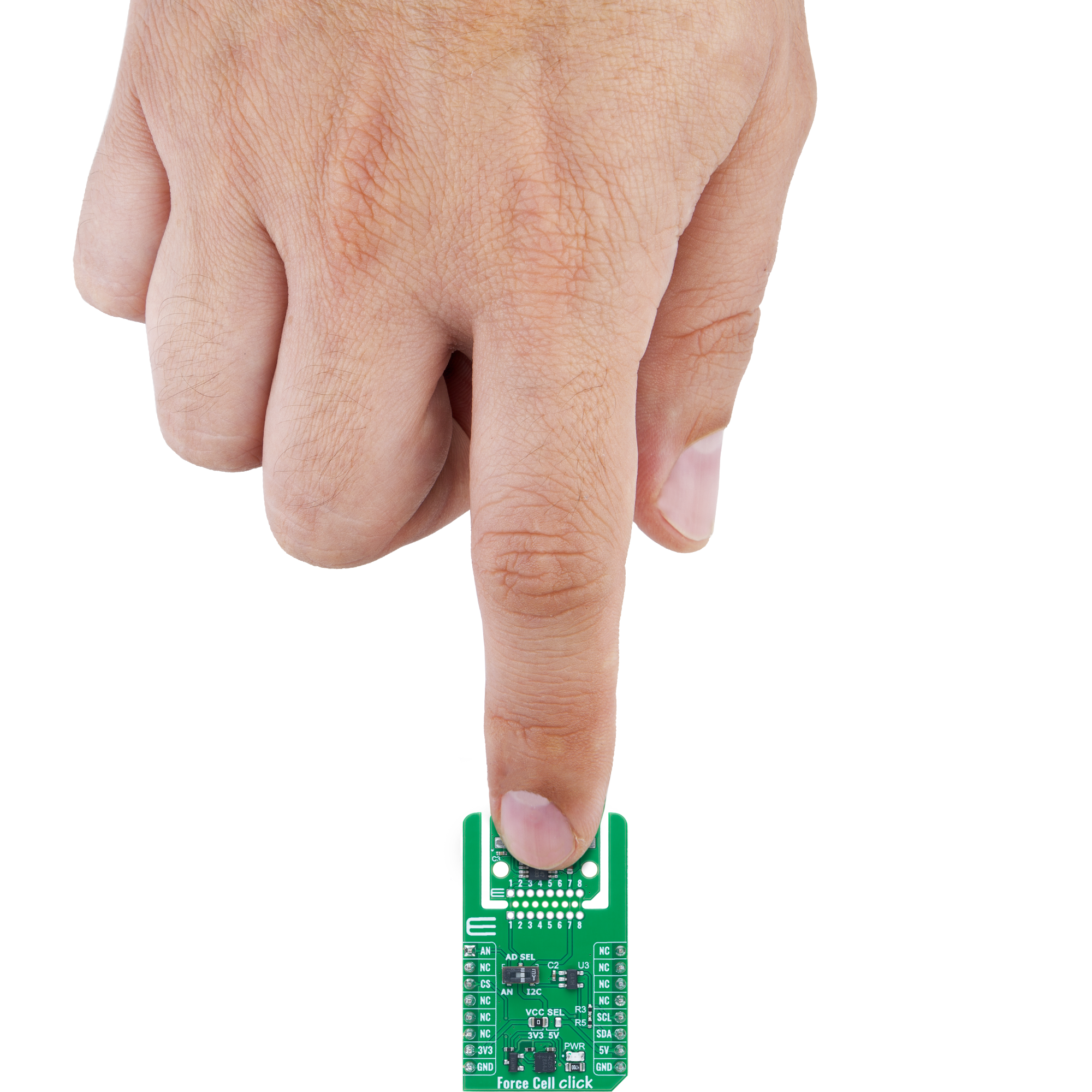

space constraints, accuracy, and durability are critical factors. This Click board™ is designed in a unique format supporting the newly introduced MIKROE feature called "Click Snap." Unlike the standardized version of Click boards, this feature allows the main sensor area to become movable by breaking the PCB, opening up many new possibilities for implementation. Thanks to the Snap feature, the FS102A-0000-3000-G can operate autonomously by accessing its signals directly on the pins marked 1-8. Additionally, the Snap part includes a specified and fixed screw hole position, enabling users to secure the Snap board in their desired location. The signal conditioning and amplification for the FS102A-0000-3000-G sensor are handled by the INA333, a high-performance rail-to-rail operational amplifier from Texas Instruments, ensuring precise and stable amplification of the sensor's low-level output signal. After amplification, the conditioned signal is routed to the AD SEL switch, providing the user with the flexibility to choose between analog and digital output modes depending on the specific requirements of their application. When analog output is selected, the amplified signal is made

available directly on the AN pin of the mikroBUS™ socket, allowing for straightforward integration with analog signal processing circuits. For digital signal acquisition, the board incorporates the MCP3221 from Microchip, a 12-bit resolution analog-to-digital converter that enables high-accuracy digital conversion and communicates via the standard 2-wire I2C interface, ensuring compatibility with a wide range of MCUs and digital systems. The output mode selection is easily configured through the onboard surface-mount device (SMD) switch labeled AD SEL, which allows users to toggle between the analog (AN) position and the digital (I2C) position to accommodate diverse application scenarios and design preferences. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

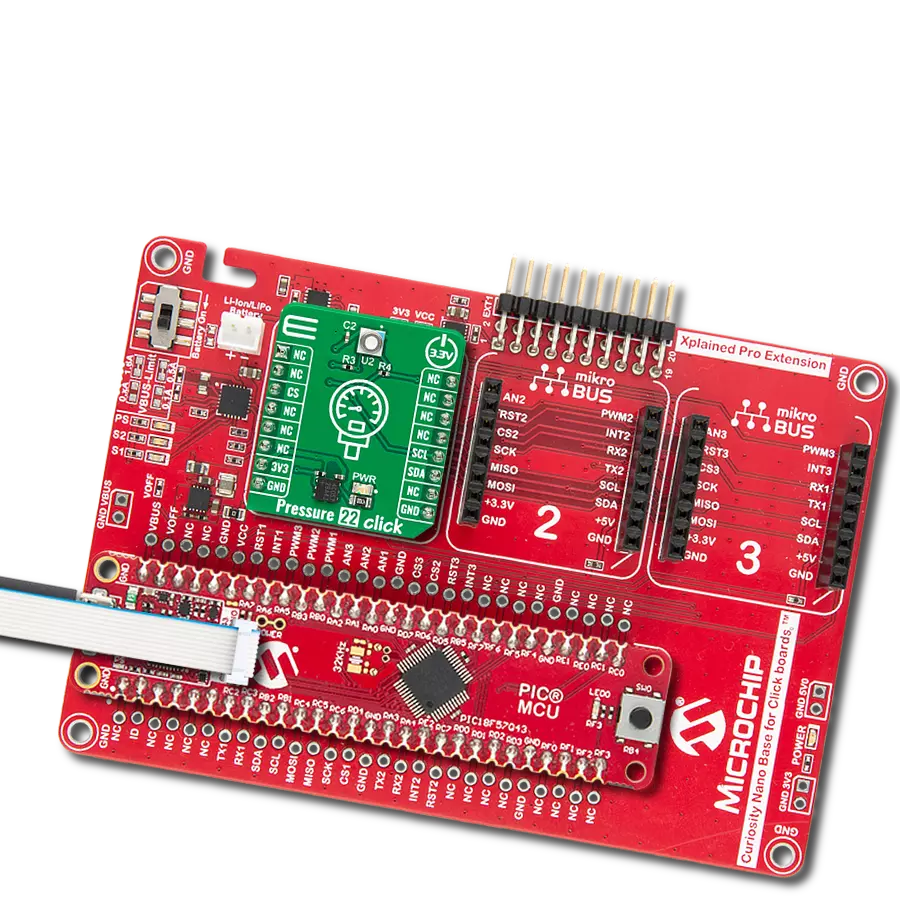

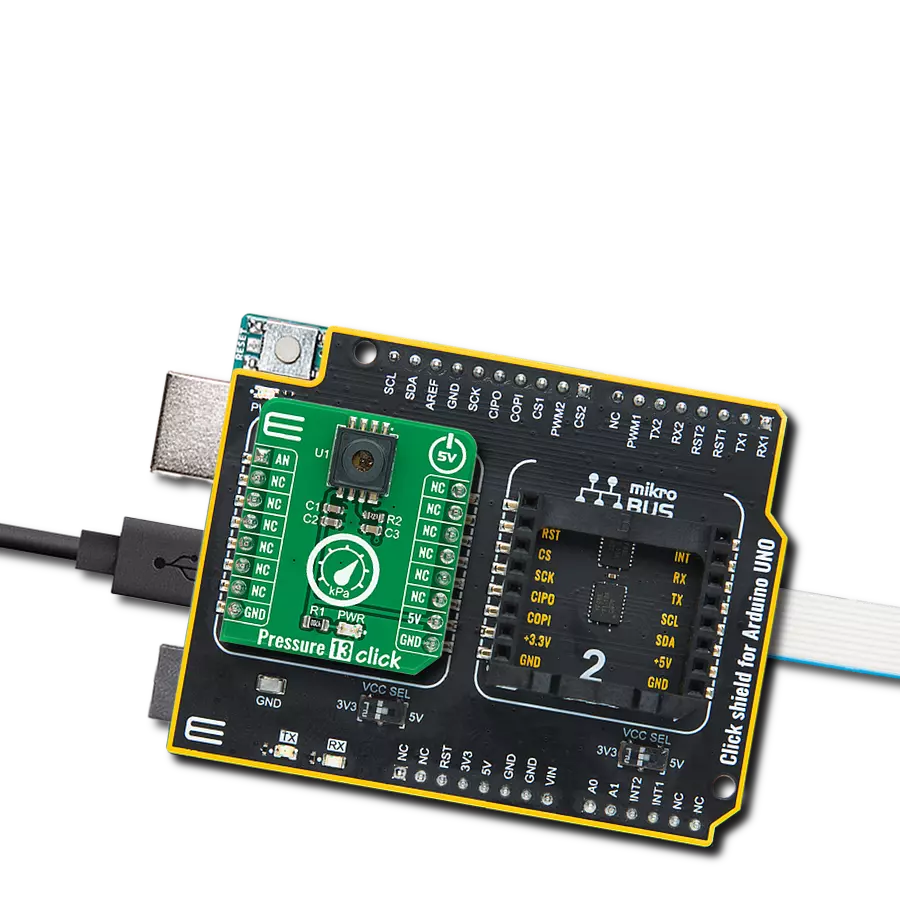

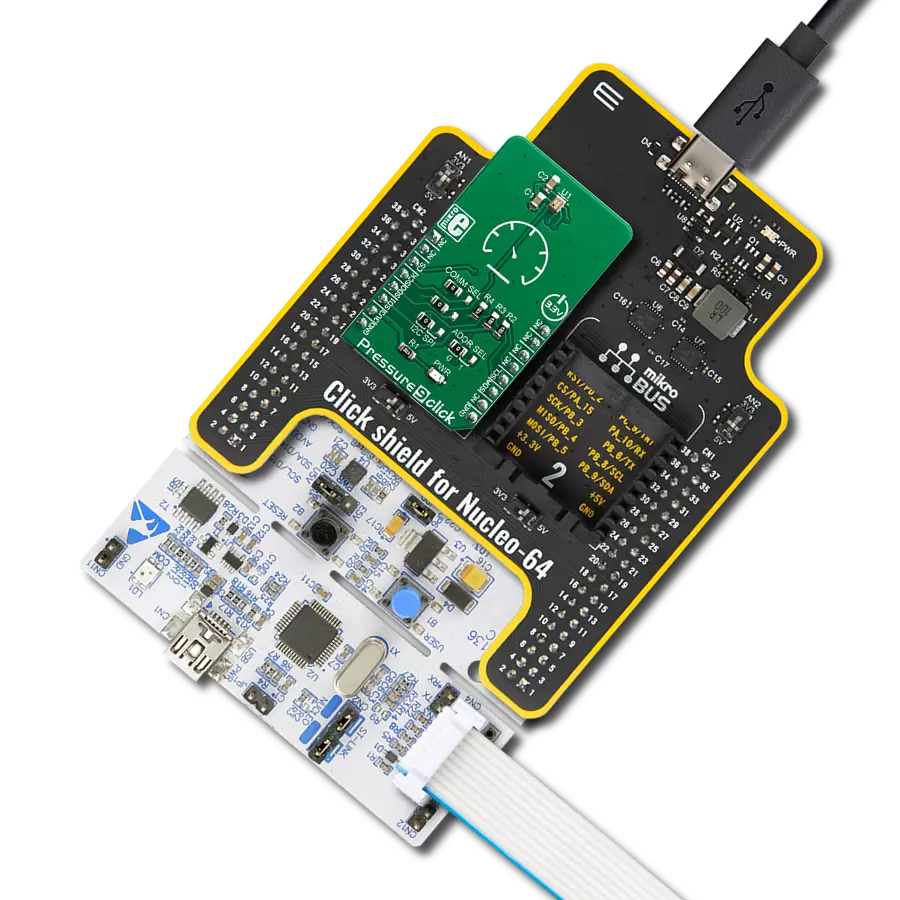

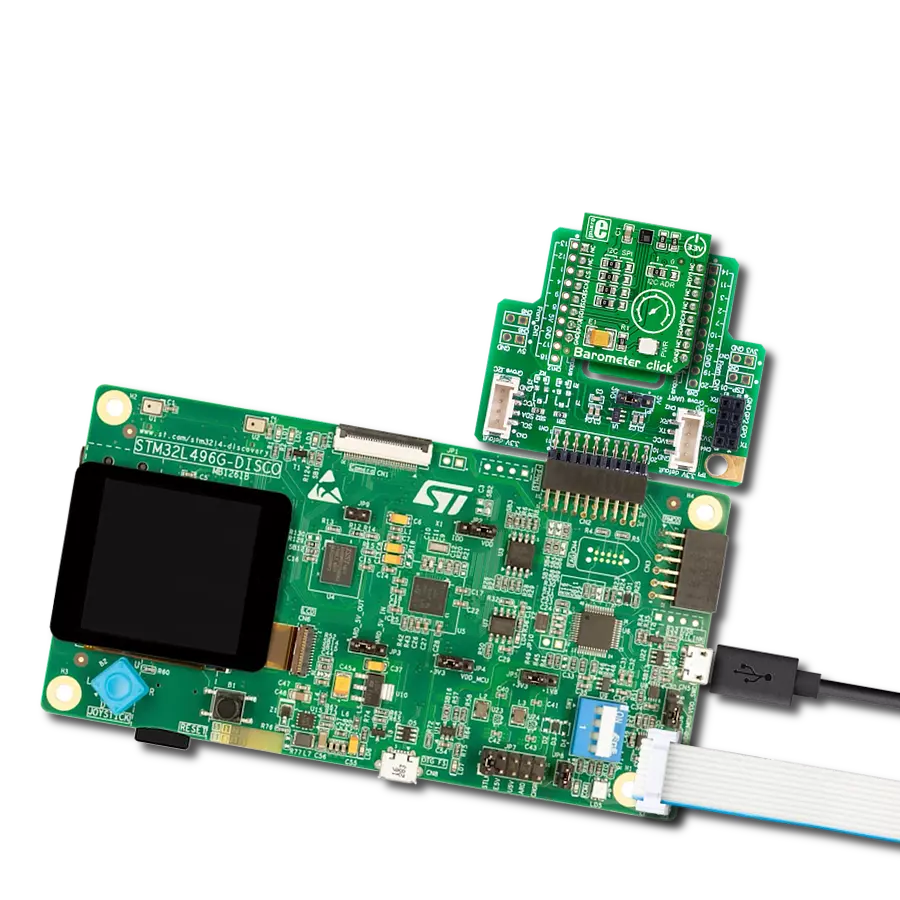

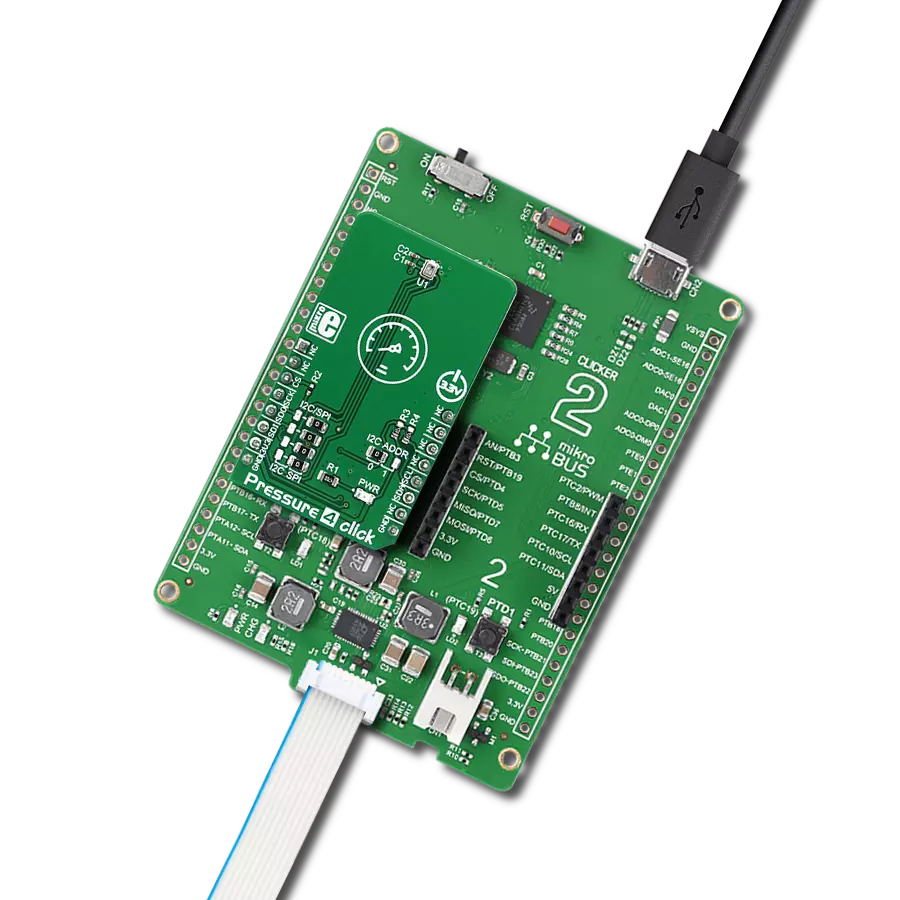

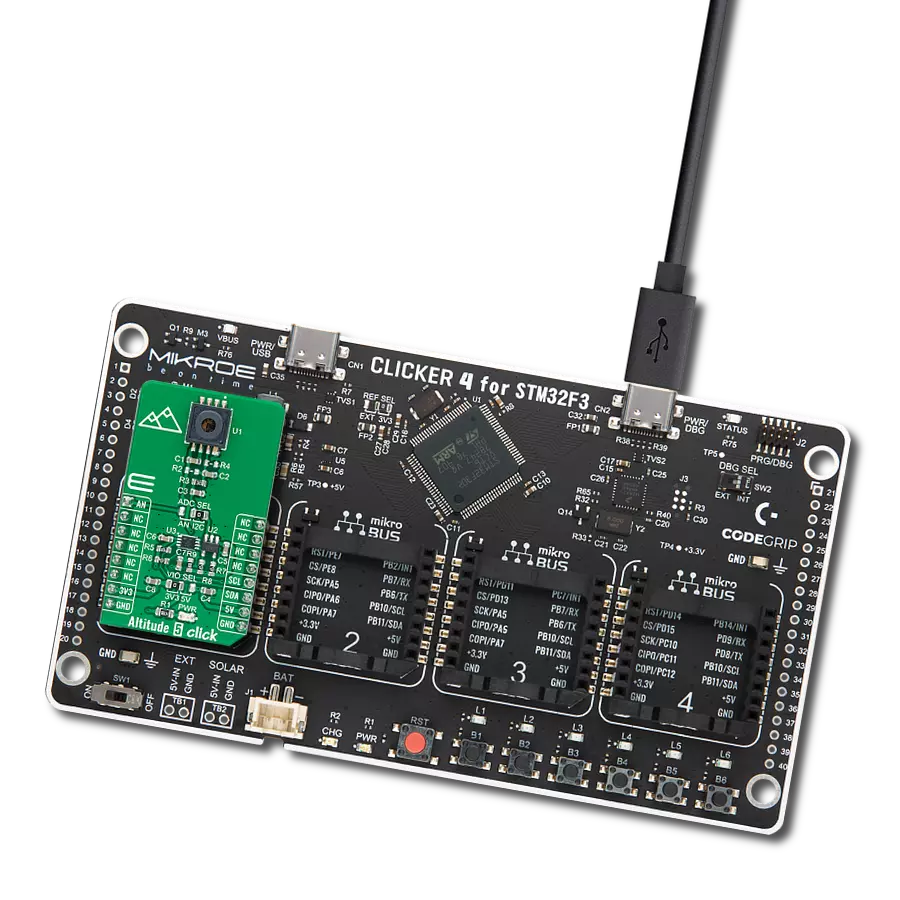

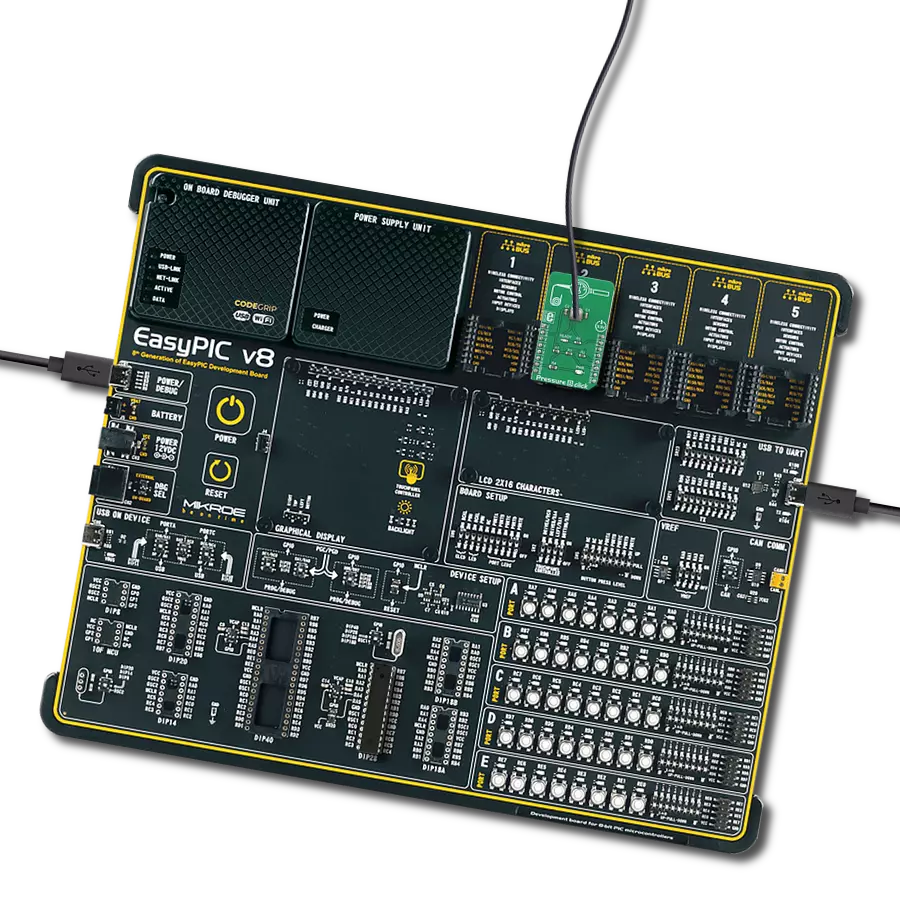

Development board

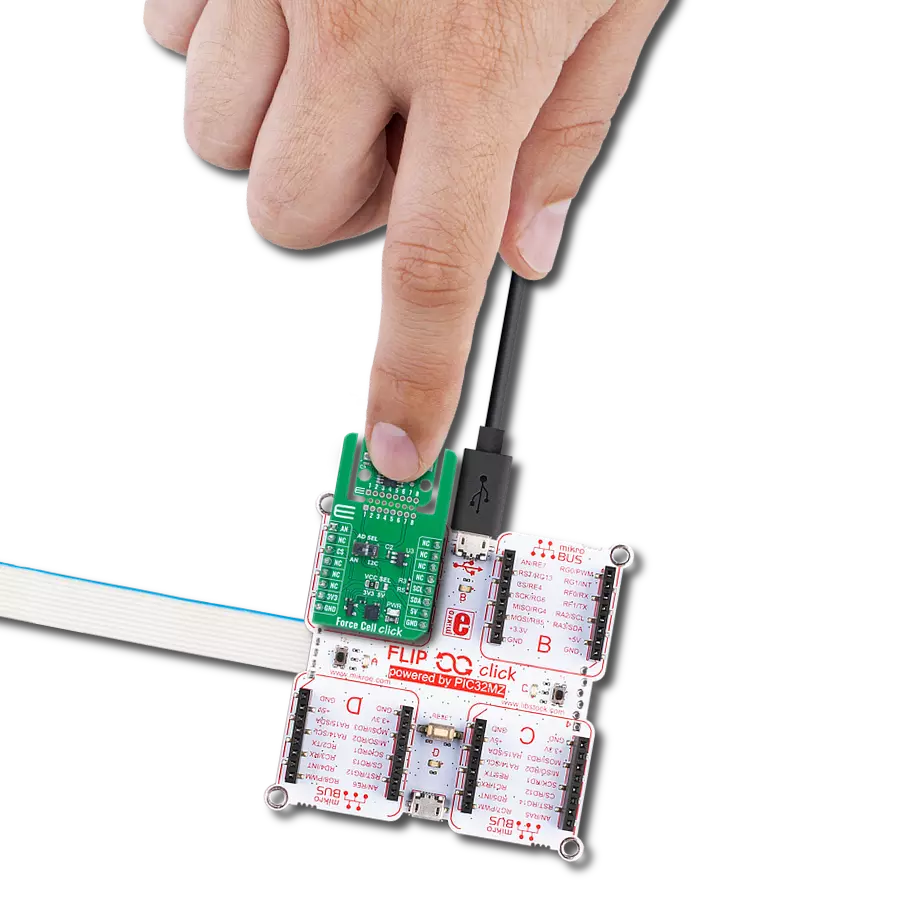

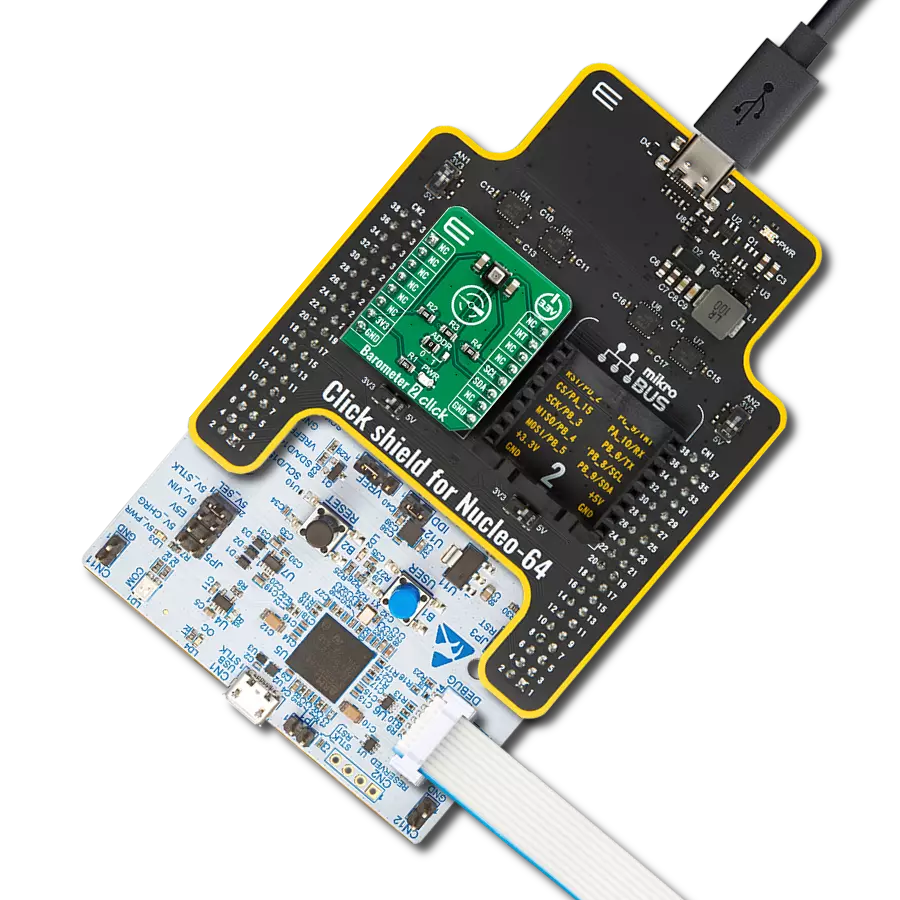

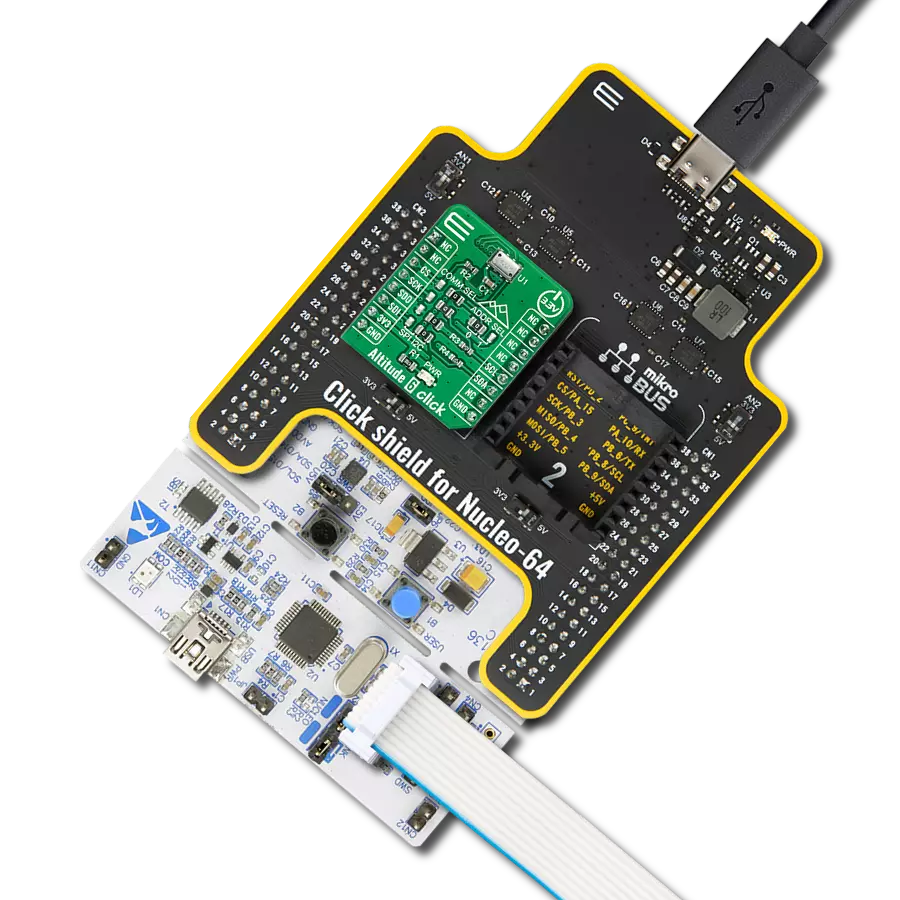

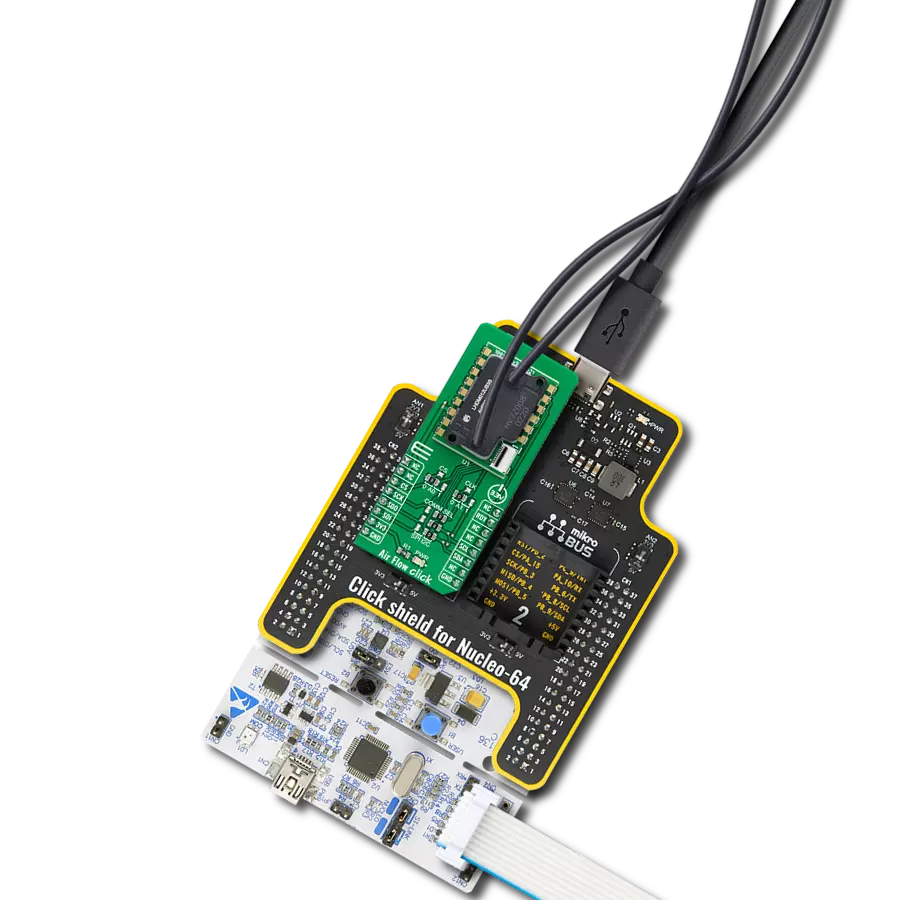

Flip&Click PIC32MZ is a compact development board designed as a complete solution that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit PIC32MZ microcontroller, the PIC32MZ2048EFH100 from Microchip, four mikroBUS™ sockets for Click board™ connectivity, two USB connectors, LED indicators, buttons, debugger/programmer connectors, and two headers compatible with Arduino-UNO pinout. Thanks to innovative manufacturing technology,

it allows you to build gadgets with unique functionalities and features quickly. Each part of the Flip&Click PIC32MZ development kit contains the components necessary for the most efficient operation of the same board. In addition, there is the possibility of choosing the Flip&Click PIC32MZ programming method, using the chipKIT bootloader (Arduino-style development environment) or our USB HID bootloader using mikroC, mikroBasic, and mikroPascal for PIC32. This kit includes a clean and regulated power supply block through the USB Type-C (USB-C) connector. All communication

methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, user-configurable buttons, and LED indicators. Flip&Click PIC32MZ development kit allows you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

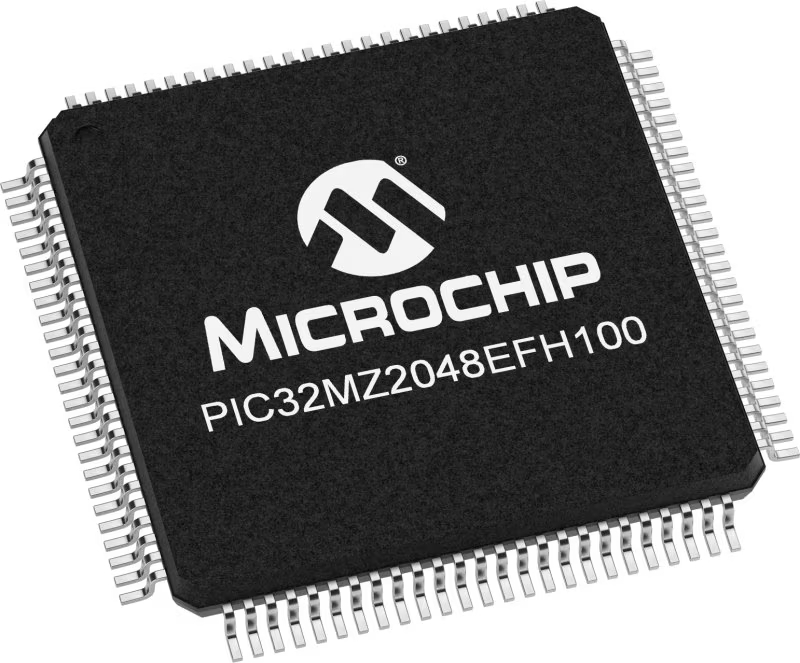

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

2048

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

Force Cell Click demo application is developed using the NECTO Studio, ensuring compatibility with mikroSDK's open-source libraries and tools. Designed for plug-and-play implementation and testing, the demo is fully compatible with all development, starter, and mikromedia boards featuring a mikroBUS™ socket.

Example Description

This example demonstrates the use of the Force Cell Click board by reading the applied force in newtons (N) from a load cell sensor. The application initializes the driver, calibrates the offset, and continuously measures and logs the force value to the USB UART terminal.

Key functions:

forcecell_cfg_setup- This function initializes Click configuration structure to initial values.forcecell_init- This function initializes all necessary pins and peripherals used for this Click board.forcecell_calib_offset- This function calibrates the zero force offset value.forcecell_read_force- This function reads the applied force level [N].

Application Init

Initializes the logger and the Click driver, performs offset calibration to null the load cell.

Application Task

Continuously reads and displays the current force value in newtons every 100ms.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief Force Cell Click Example.

*

* # Description

* This example demonstrates the use of the Force Cell Click board by reading the applied force

* in newtons (N) from a load cell sensor. The application initializes the driver, calibrates the

* offset, and continuously measures and logs the force value to the USB UART terminal.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the logger and the Click driver, performs offset calibration to null the load cell.

*

* ## Application Task

* Continuously reads and displays the current force value in newtons every 100ms.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "forcecell.h"

static forcecell_t forcecell; /**< Force Cell Click driver object. */

static log_t logger; /**< Logger object. */

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

forcecell_cfg_t forcecell_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

forcecell_cfg_setup( &forcecell_cfg );

FORCECELL_MAP_MIKROBUS( forcecell_cfg, MIKROBUS_1 );

err_t init_flag = forcecell_init( &forcecell, &forcecell_cfg );

if ( ( ADC_ERROR == init_flag ) || ( I2C_MASTER_ERROR == init_flag ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( FORCECELL_ERROR == forcecell_calib_offset ( &forcecell ) )

{

log_error( &logger, " Offset calibration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

float force = 0;

if ( FORCECELL_OK == forcecell_read_force ( &forcecell, &force ) )

{

log_printf( &logger, " Force : %.3f N\r\n\n", force );

Delay_ms ( 100 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Pressure