Whether you're in manufacturing or research, our digital pressure sensors deliver the edge you need to excel in a competitive world

A

A

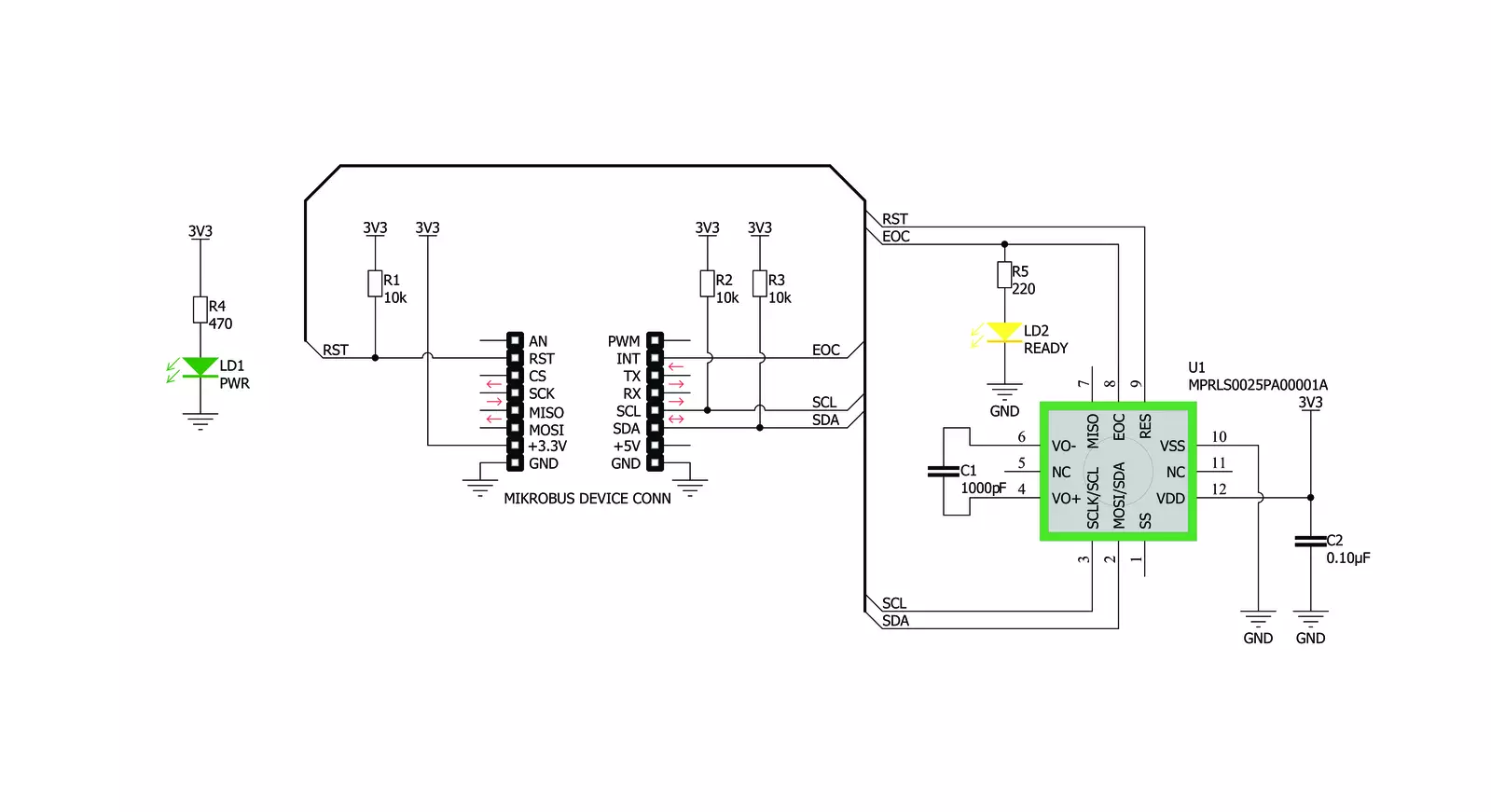

Hardware Overview

How does it work?

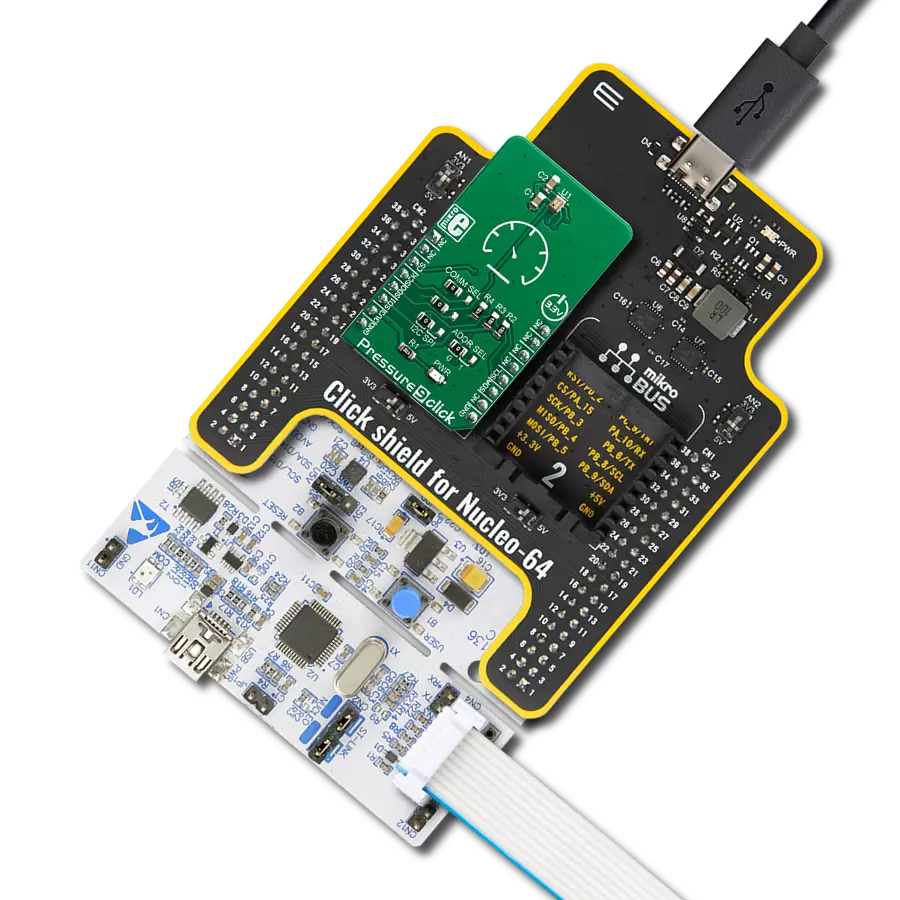

Pressure 8 Click is based on the MPRLS0025PA00001A, an accurate compensated absolute pressure sensor from Honeywell. This sensor offers a range of highly useful features. The most distinctive feature of this sensor is its high accuracy and ability to output compensated 24-bit values over the I2C interface. This MPR series sensor integrates an ASIC (Application Specific Integrated Circuit), along with the piezoresistive silicon pressure sensor. Thanks to the integrated ASIC, this sensor can output 24-bit compensated measurements within the range of 0 psi to 25 psi (0 to about 172kPa), and temperatures from 0 °C to 50 °C. Due to the silicone gel protection, it can be used with a variety of liquid media. The casing of the MPRLS0025PA00001A sensor is built of stainless steel, preventing the rust formation. All the electronic components within the sensor are protected by a silicone gel, allowing the sensor to be used with a wide variety of liquid media. It can be used to mesure absolute pressure values up to 25 psi, or about 172 kPa. However, the sensor can be exposed up to 60 psi (about 414 kPa) of overpressure, without causing permanent damage. The absolute maximum pressure allowed is 120 psi (about 825 kPa). Exposing the sensor to absolute maximum pressure will damage it

permanently, and it will not be functional anymore. Pressure beyond this point will physically destroy the sensor, resulting in possible leakage. There is a range of errors common to any sensor of this type, that affect its accuracy. The term "Total Error Band" (TEB) is used within the datasheet of the MPRLS0025PA00001A sensor to better illustrate its accuracy, considering all of the pressure measurement errors, combining them into a single parameter. The datasheet specifies the TBD of the sensor to be ±1.5. It also offers a transfer function, which can e used to calculate the output pressure value based on a 24-bit result, provided over the I2C interface. The first byte after the conversion command is sent over the I2C interface is the content of the status register. It contains a BUSY flag (bit 5) among other status bits. It indicates the end of conversion, so the software should poll the status byte and wait this bit to be reset. Another, much simpler method is to use the EOC (End of Conversion) pin, routed to the mikroBUS™ INT pin, labeled as EOC on this Click Board™. This pin allows much simpler software routine to be written, using the EOC pin to trigger an interrupt on the host microcontroller (MCU). A HIGH logic level on this pin indicates that the conversion is finished. Lastly, the user can

simply wait at least 5ms for the conversion to complete, before issuing another command. The RES pin of the sensor is used to perform a hardware reset. This pin is routed to the mikroBUS™ RST pin, and a logic LOW pulse on this pin will reset the sensor IC. It is pulled to a HIGH logic level by an onboard resistor preventing it to float and uncontrollably reset the sensor, if the corresponding pin is tri-stated on the host MCU. The EOC event is also signaled visually, by a LED labeled as READY. This LED provides visual feedback about the status of the conversion: when lit, it indicates that the conversion is ended, and the measurement conversion data can be retrieved over the I2C interface. Pressure 8 click is supported by the mikroSDK compatible library of functions that encapsulate all the necessary conversions and status checking, returning the measured value converted into physical units, directly. This vastly simplifies and speeds up the development process. This Click Board™ uses the I2C communication interface. It has pull-up resistors connected to the mikroBUS™ 3.3V rail. Proper conversion of logic voltage levels should be applied before the Click board™ is used with MCUs operated with 5V.

Features overview

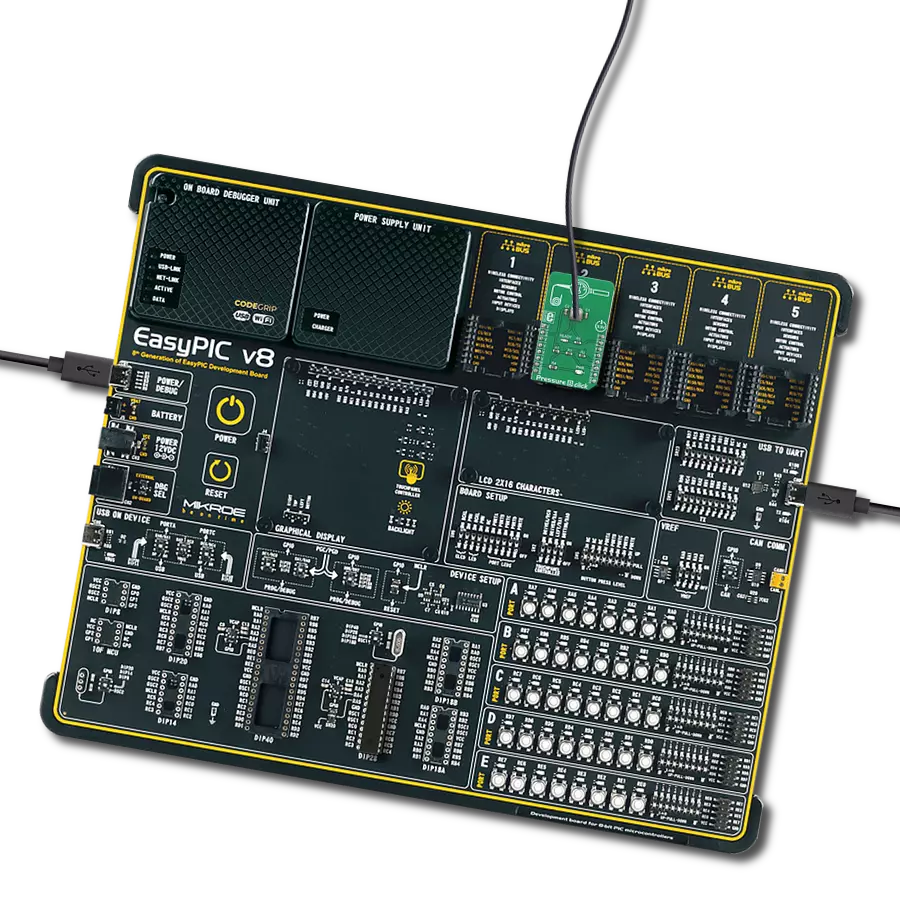

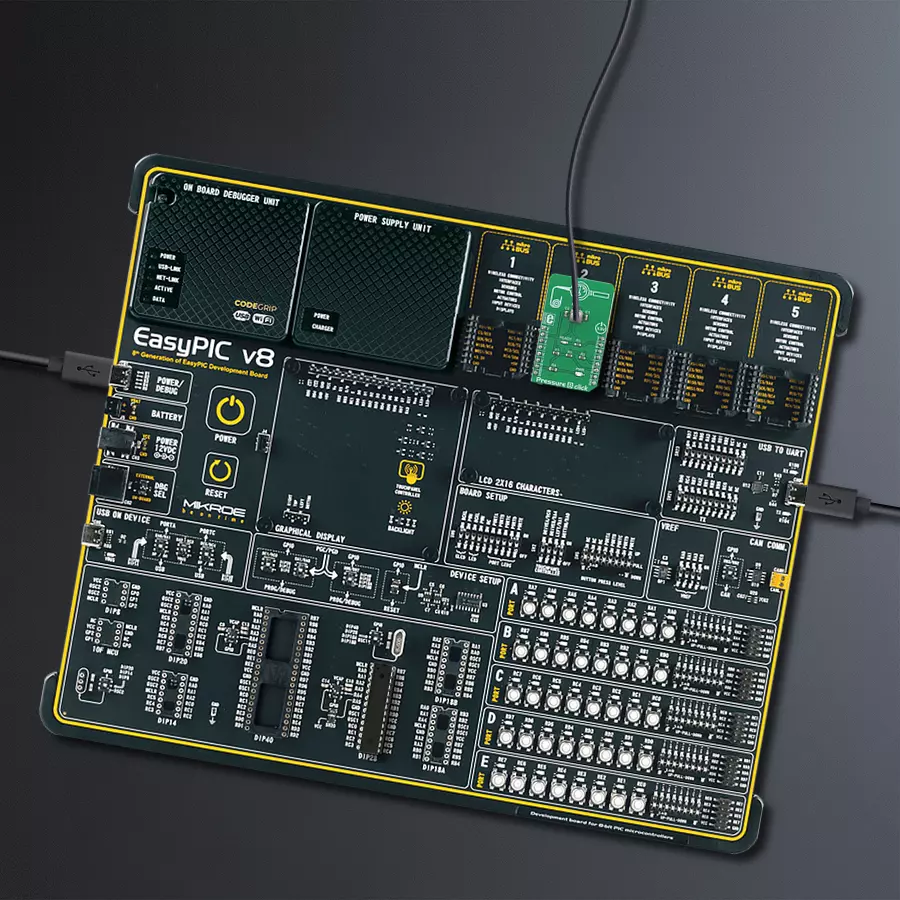

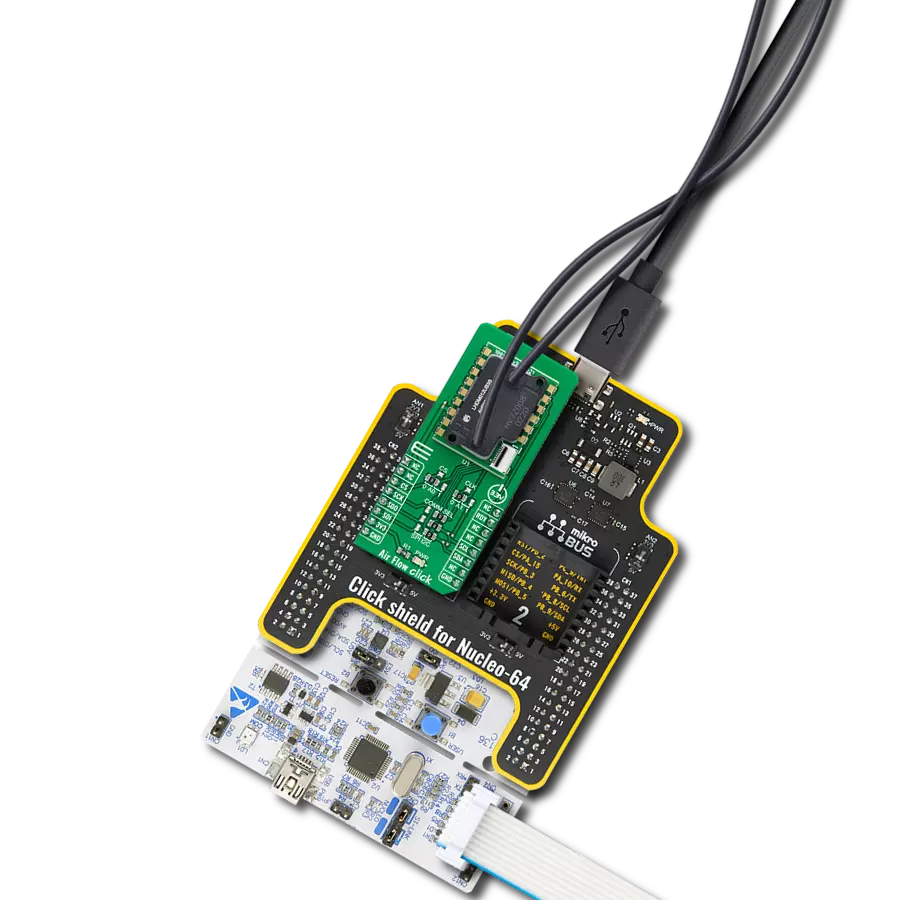

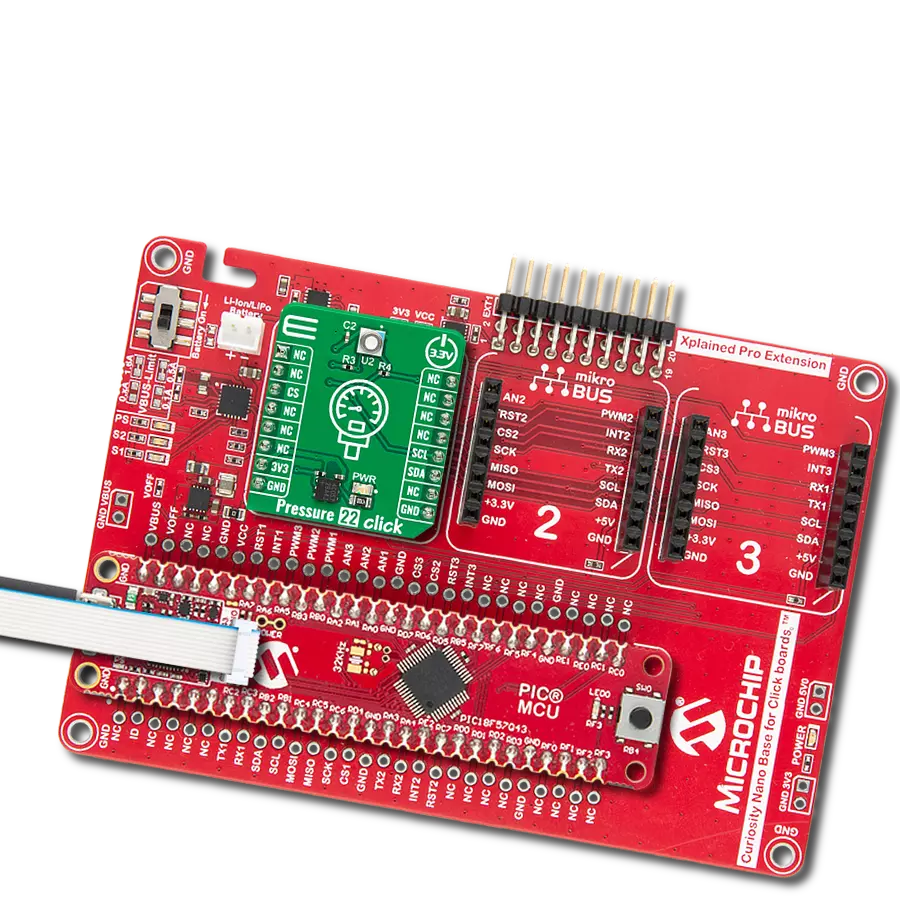

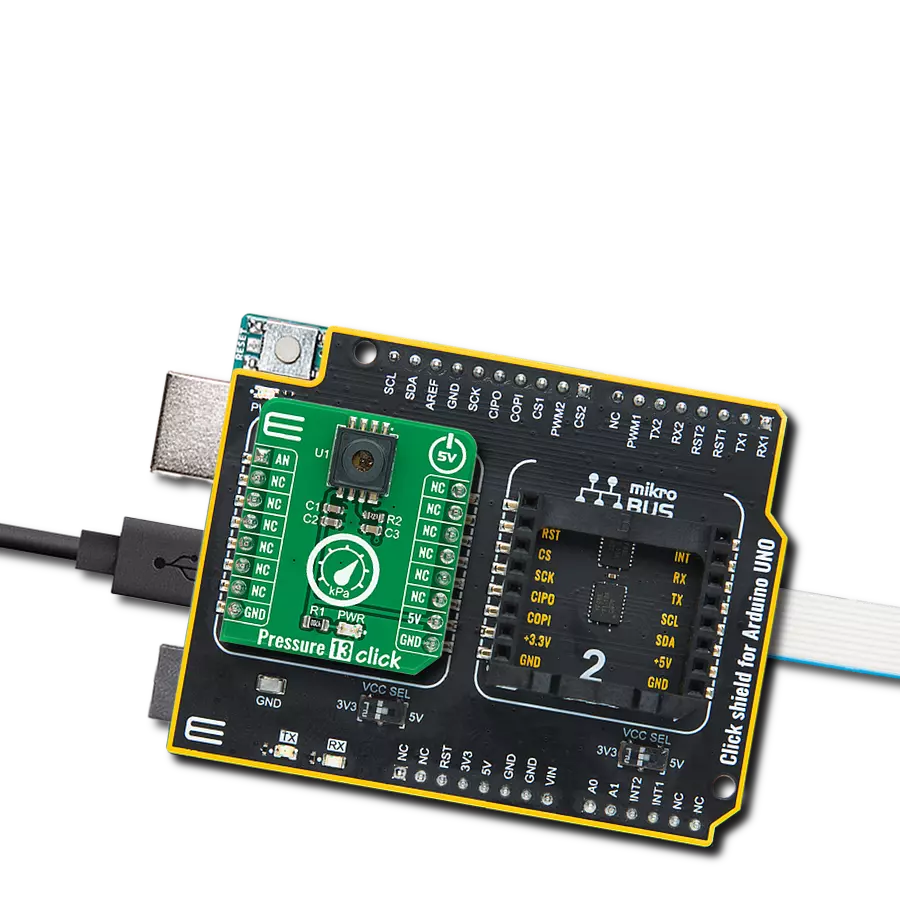

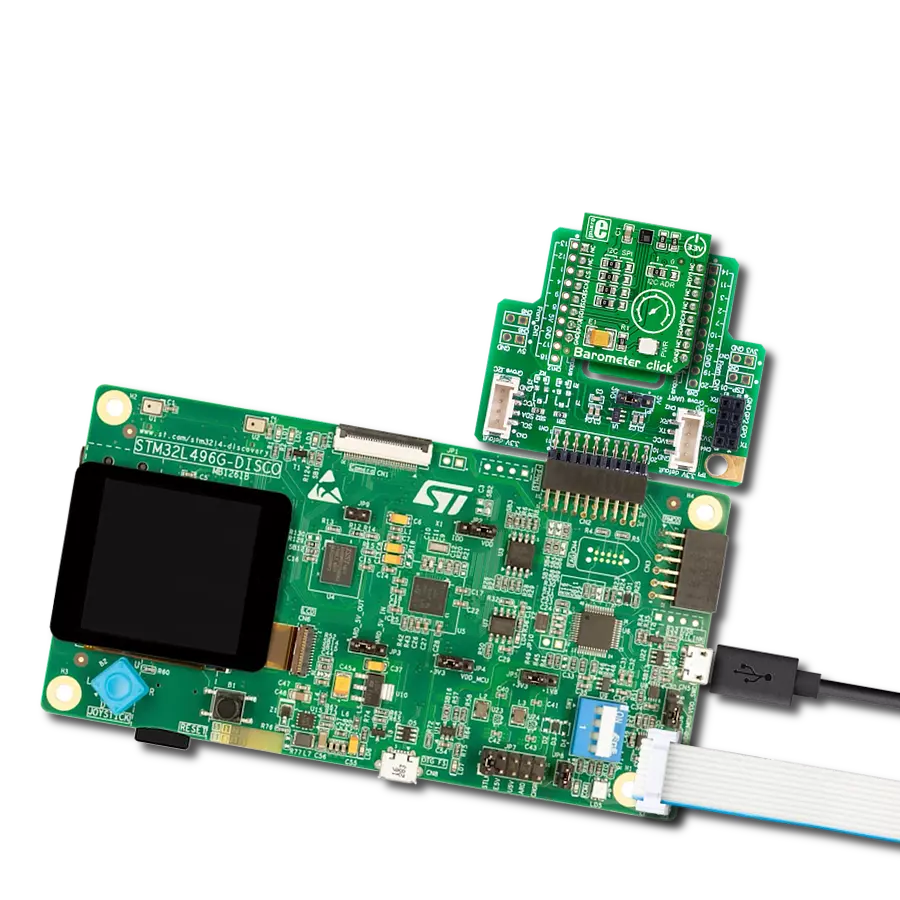

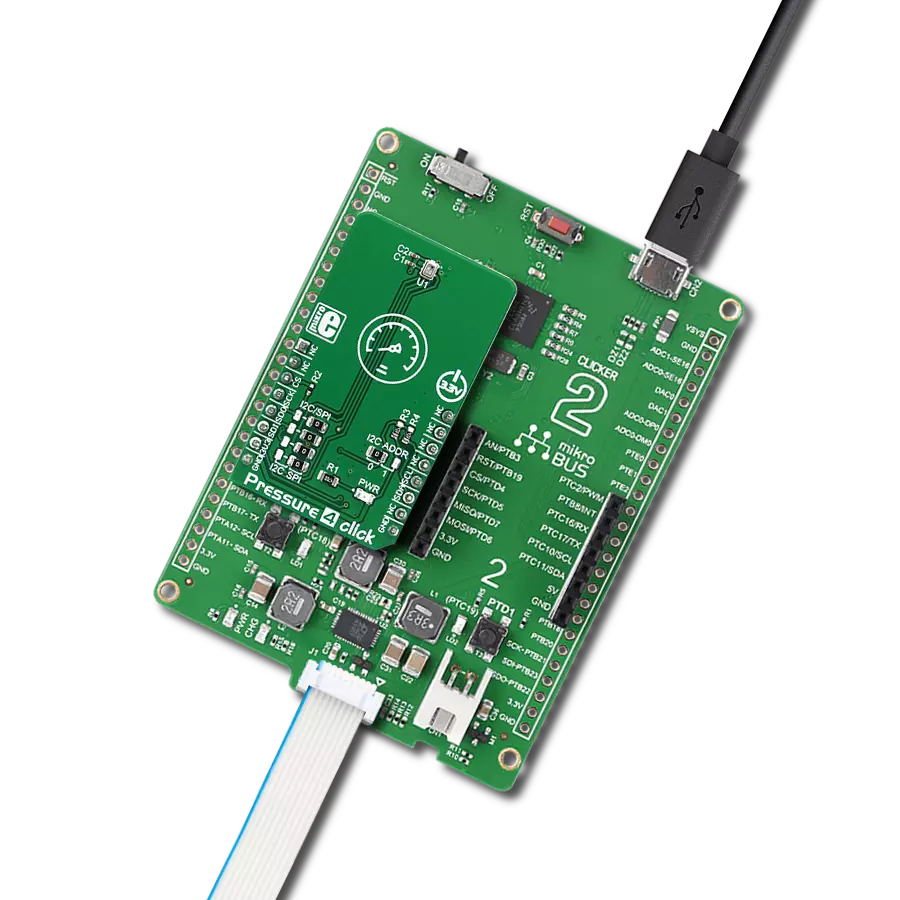

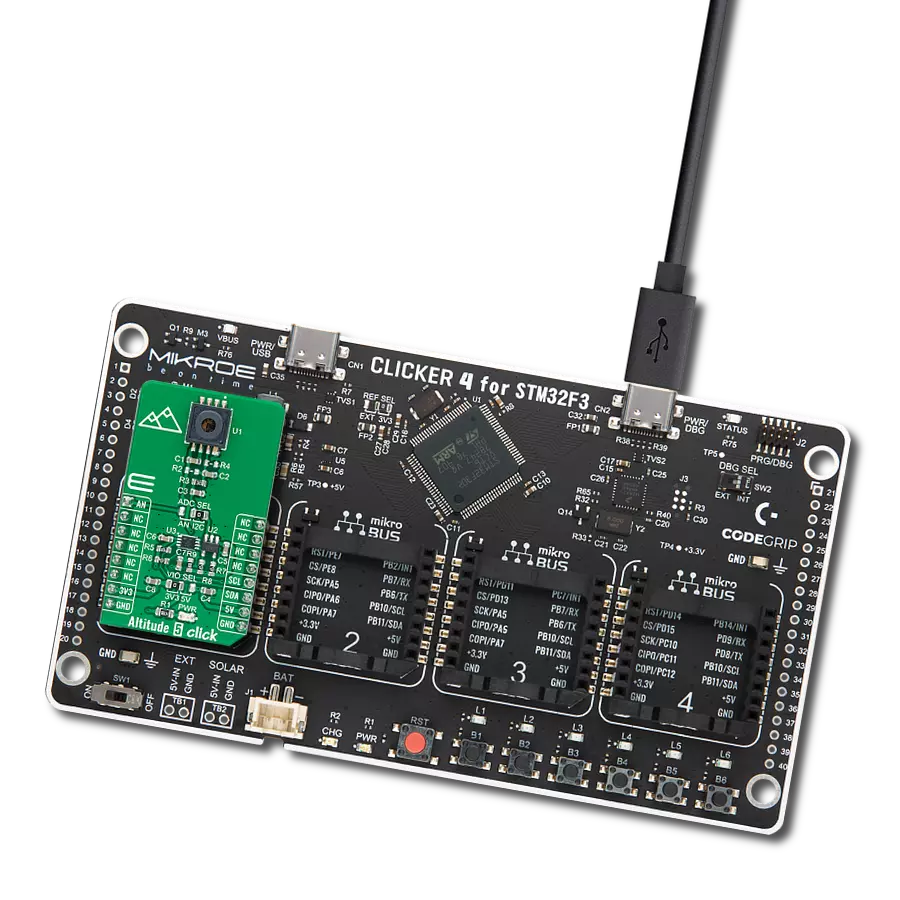

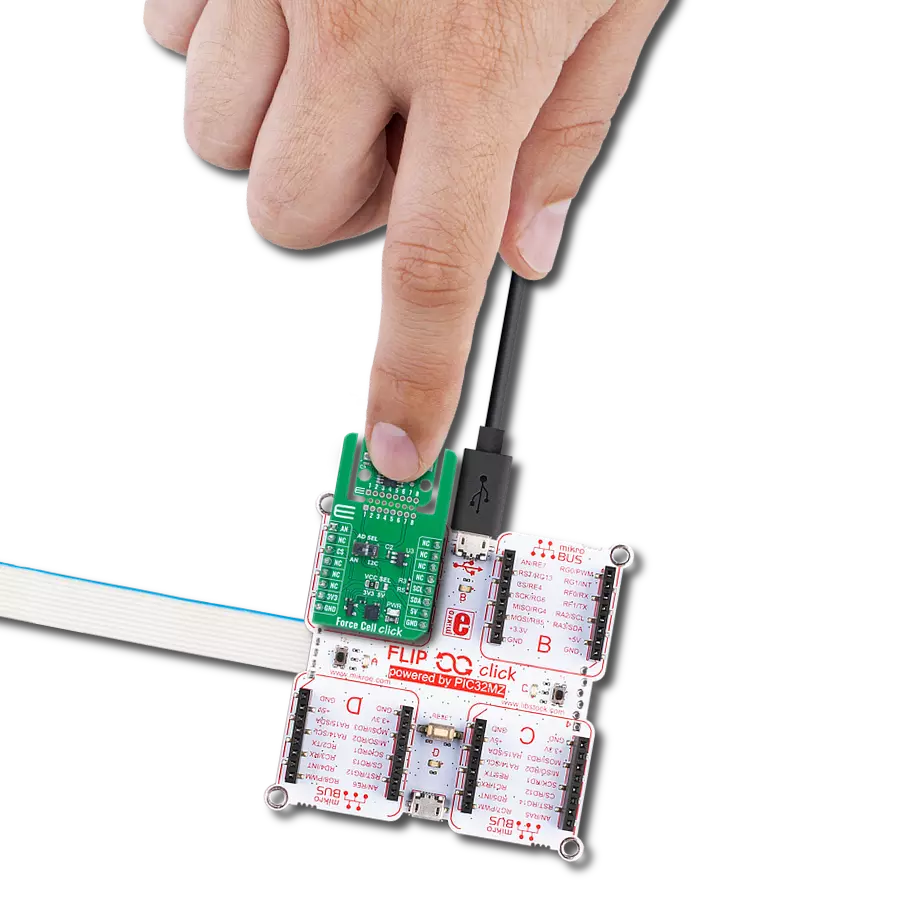

Development board

EasyPIC v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports many high pin count 8-bit PIC microcontrollers from Microchip, regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, EasyPIC v8 provides a fluid and immersive working experience, allowing access anywhere and under any

circumstances at any time. Each part of the EasyPIC v8 development board contains the components necessary for the most efficient operation of the same board. In addition to the advanced integrated CODEGRIP programmer/debugger module, which offers many valuable programming/debugging options and seamless integration with the Mikroe software environment, the board also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector.

Communication options such as USB-UART, USB DEVICE, and CAN are also included, including the well-established mikroBUS™ standard, two display options (graphical and character-based LCD), and several different DIP sockets. These sockets cover a wide range of 8-bit PIC MCUs, from the smallest PIC MCU devices with only eight up to forty pins. EasyPIC v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC

MCU Memory (KB)

64

Silicon Vendor

Microchip

Pin count

28

RAM (Bytes)

3728

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Pressure 8 Click driver.

Key functions:

pressure8_get_pressure- Functions for get Pressure datapressure8_get_device_status- Functions for get device statuspressure8_set_psi_range- Functions for set PSI range

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Pressure8 Click example

*

* # Description

* This application reads pressure data.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization device and logger module, reset device and set PSI range.

*

* ## Application Task

* Reads pressure data in mBar and logs it on the USB UART once per second.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "pressure8.h"

// ------------------------------------------------------------------ VARIABLES

static pressure8_t pressure8;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

pressure8_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

pressure8_cfg_setup( &cfg );

PRESSURE8_MAP_MIKROBUS( cfg, MIKROBUS_1 );

pressure8_init( &pressure8, &cfg );

pressure8_device_reset( &pressure8 );

pressure8_set_psi_range( &pressure8, 0, 25 );

Delay_ms ( 1000 );

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

float pressure = 0;

pressure = pressure8_get_pressure( &pressure8, PRESSURE8_DATA_IN_MBAR );

log_printf( &logger, " Pressure: %.1f mBar\r\n", pressure );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END