Create dynamic red LED matrix display perfect for indicators, animations, and real-time visual feedback

A

A

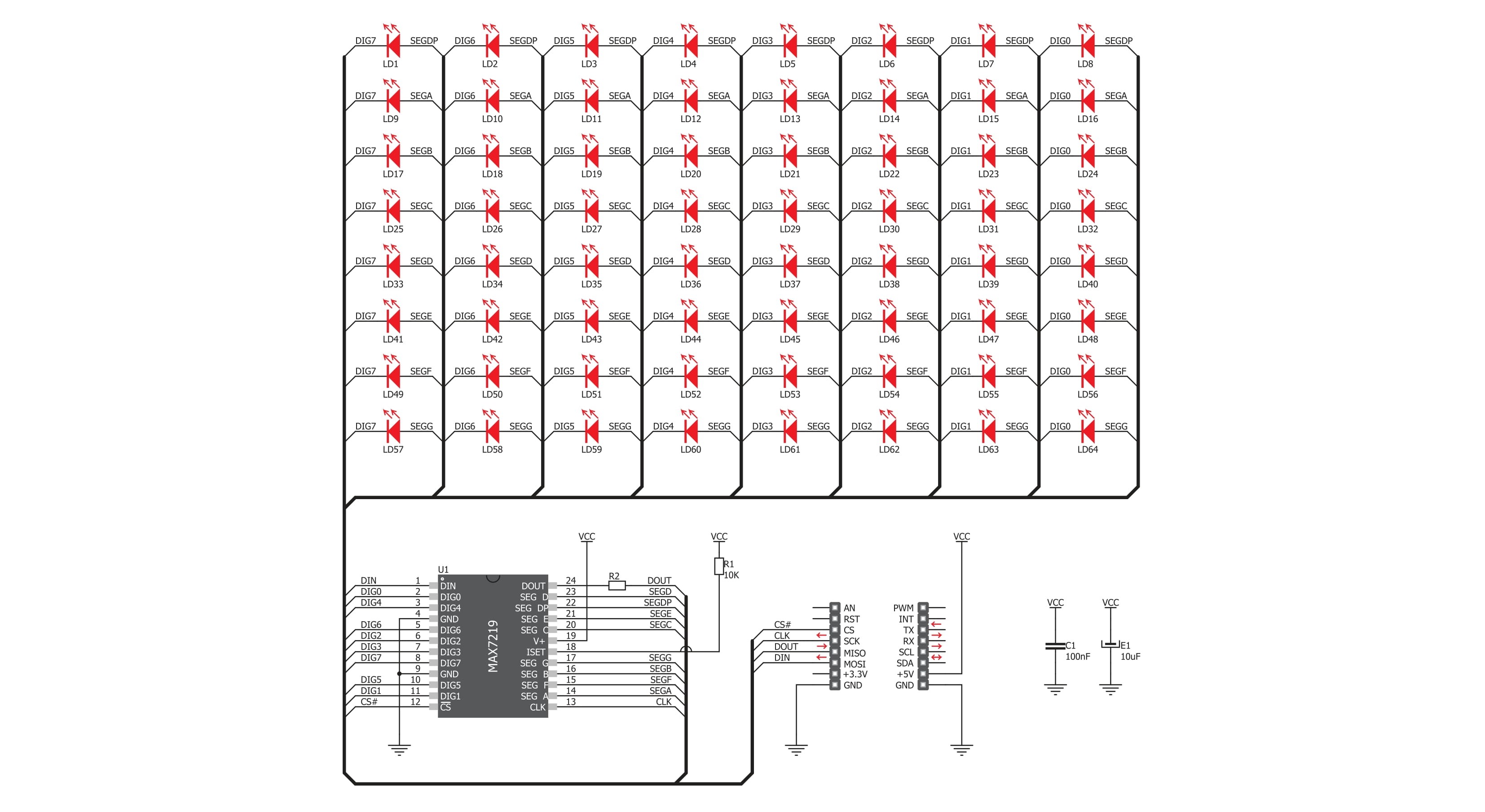

Hardware Overview

How does it work?

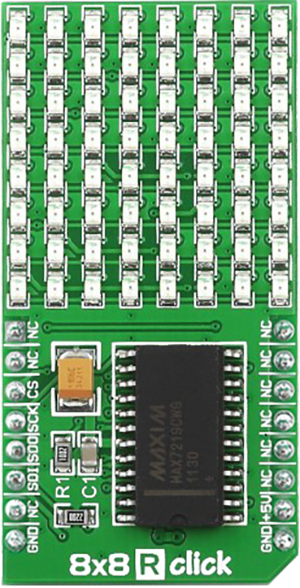

8x8 R Click is a compact 64 red LED matrix display Click board™, featuring a MAX7129 LED driver for precise control. It enables independent LED control, 16-step digital brightness adjustment, and glitch-free startup by blanking the display on power-up. With a fast SPI interface, 8x8 R Click ensures smooth data transmission and quick

response. The MAX7129 IC integrates 8x8 RAM storage, a 16-bit data shifter, a constant current source, and a PWM intensity control register, allowing efficient LED matrix operation. Designed for easy integration, the board requires only one external resistor for current control, simplifying the design. The 800Hz refresh rate ensures flicker-free

performance, while daisy-chaining support allows expansion with multiple modules. Ideal for LED matrix displays, bar graphs, and panel meters, 8x8 R Click provides a reliable solution for visual output in embedded applications.

Features overview

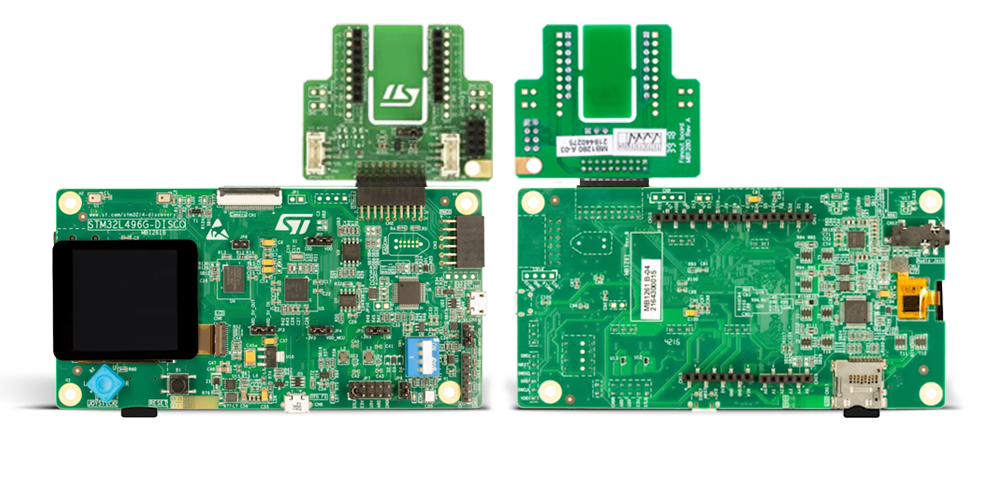

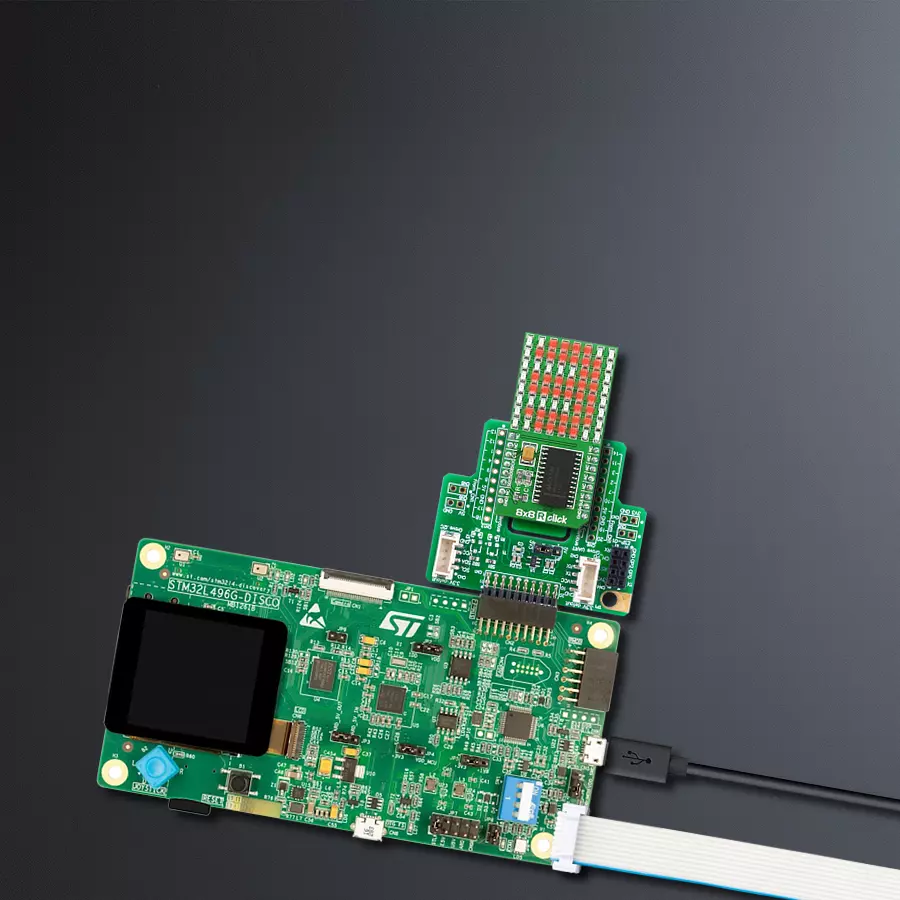

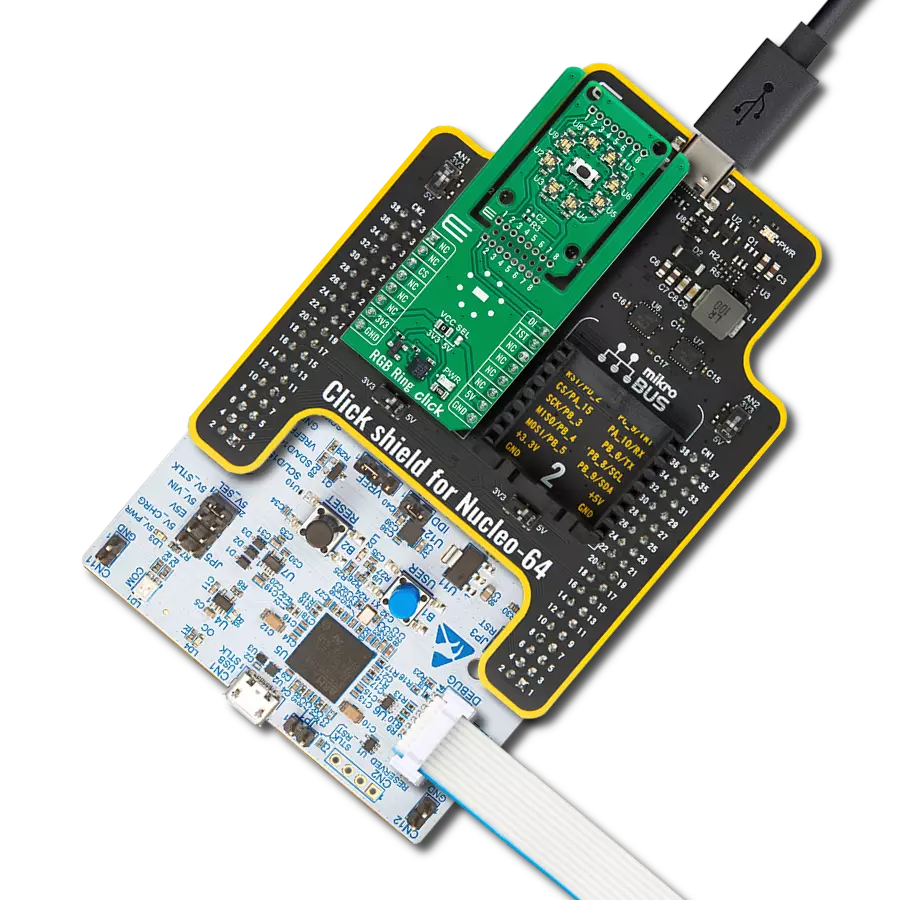

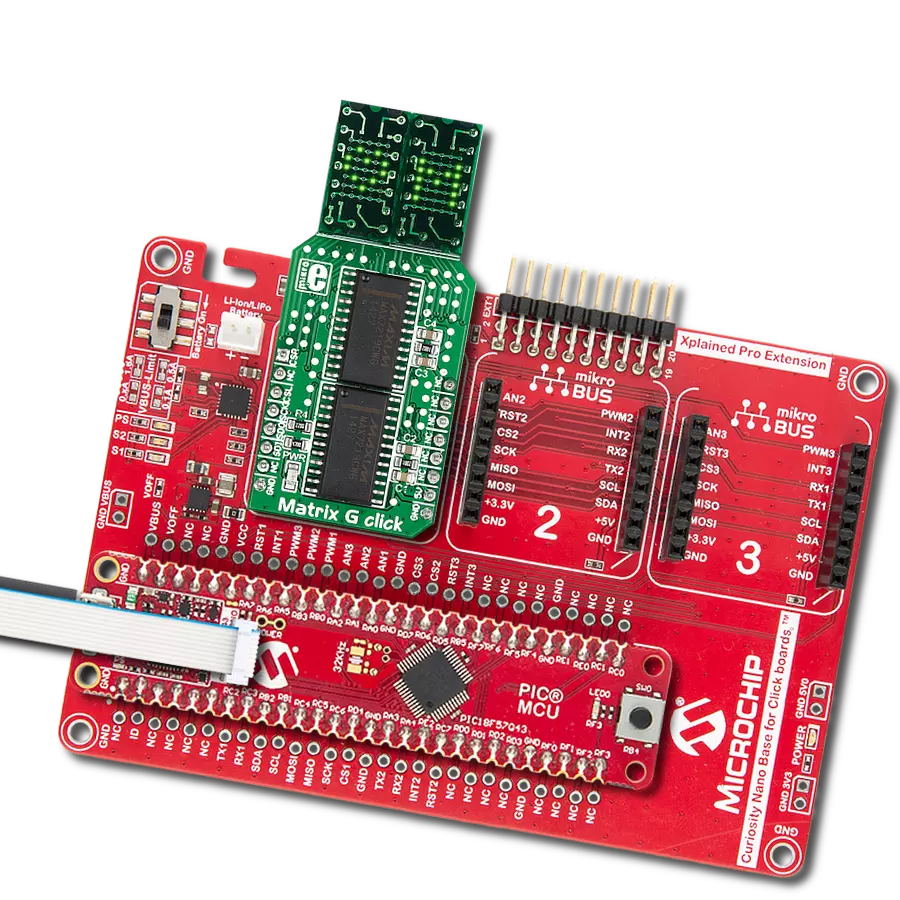

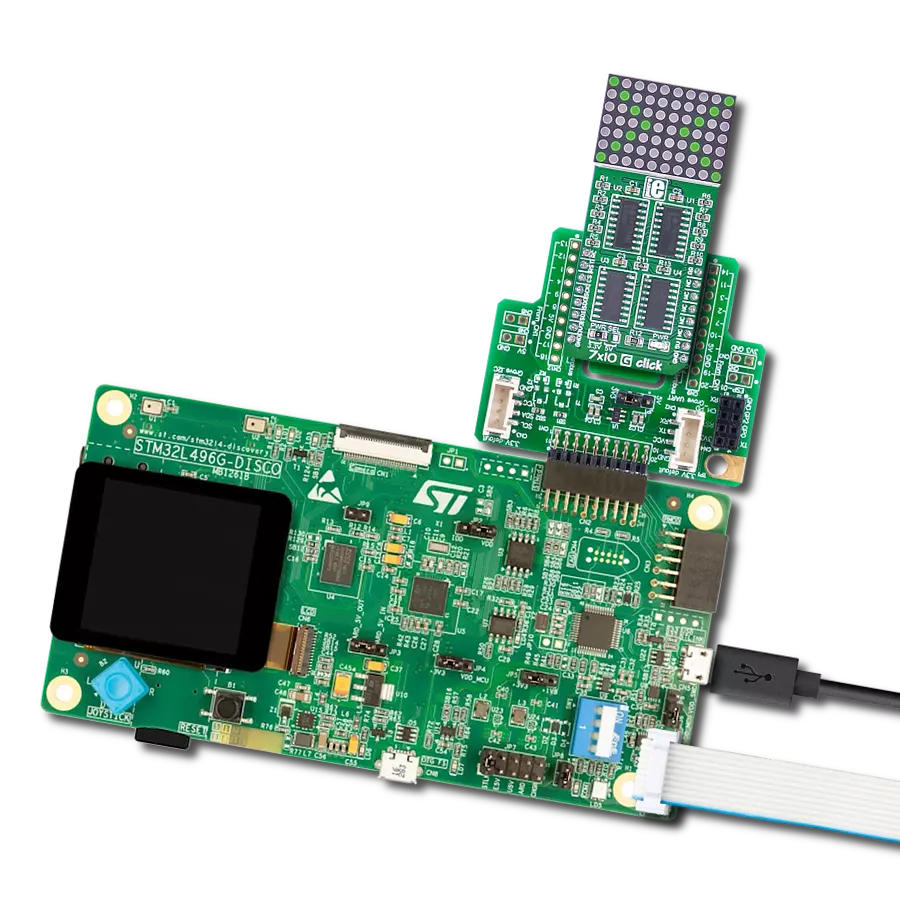

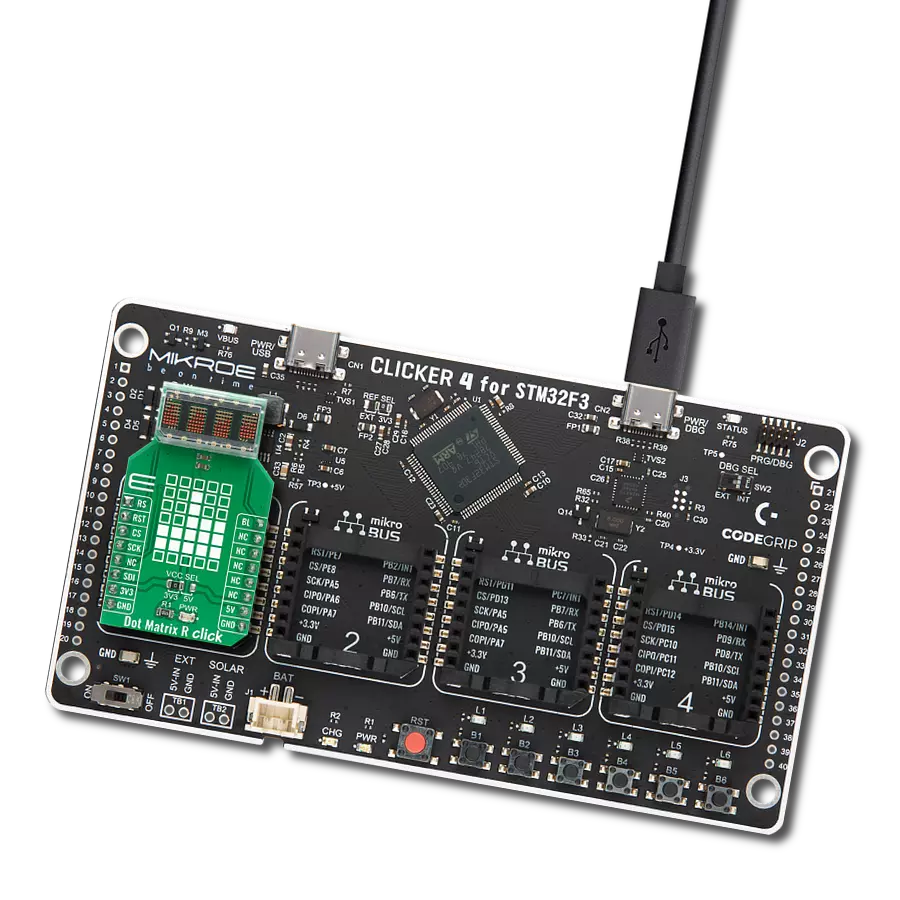

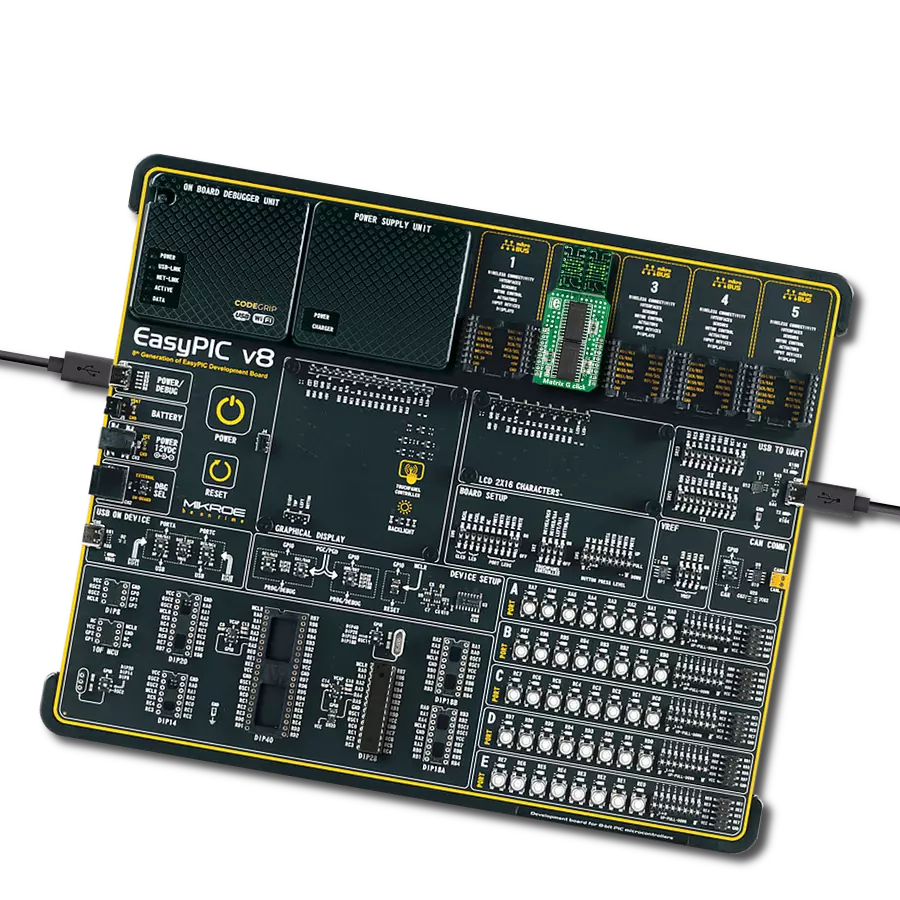

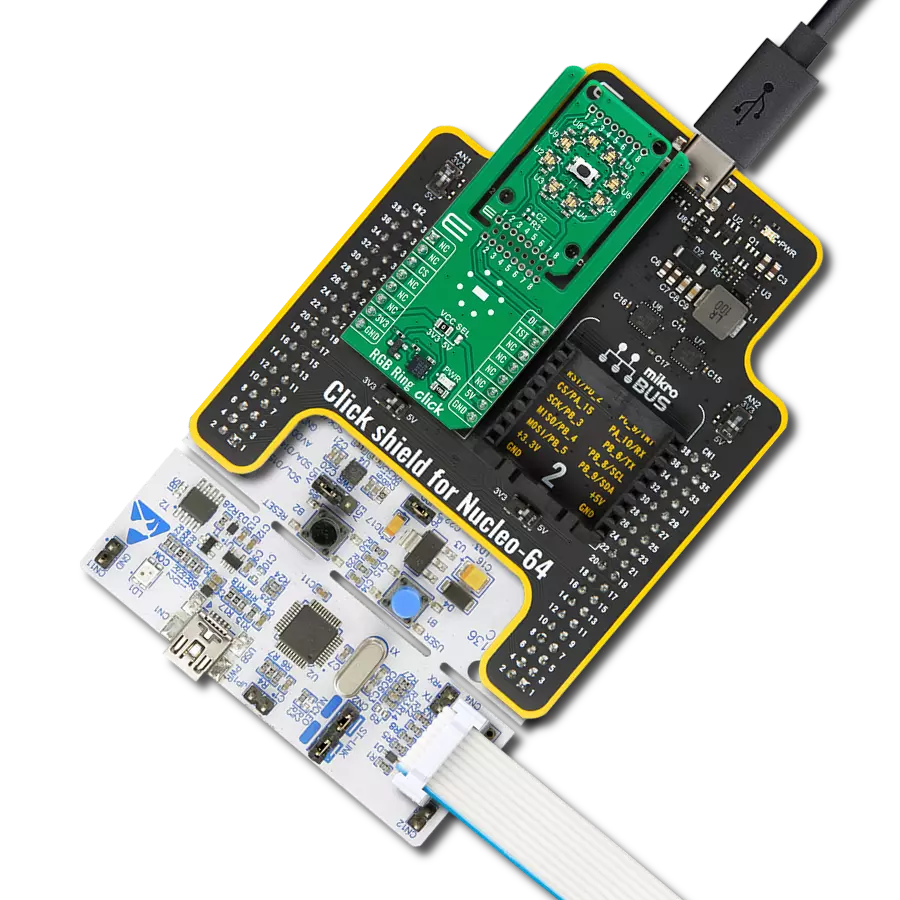

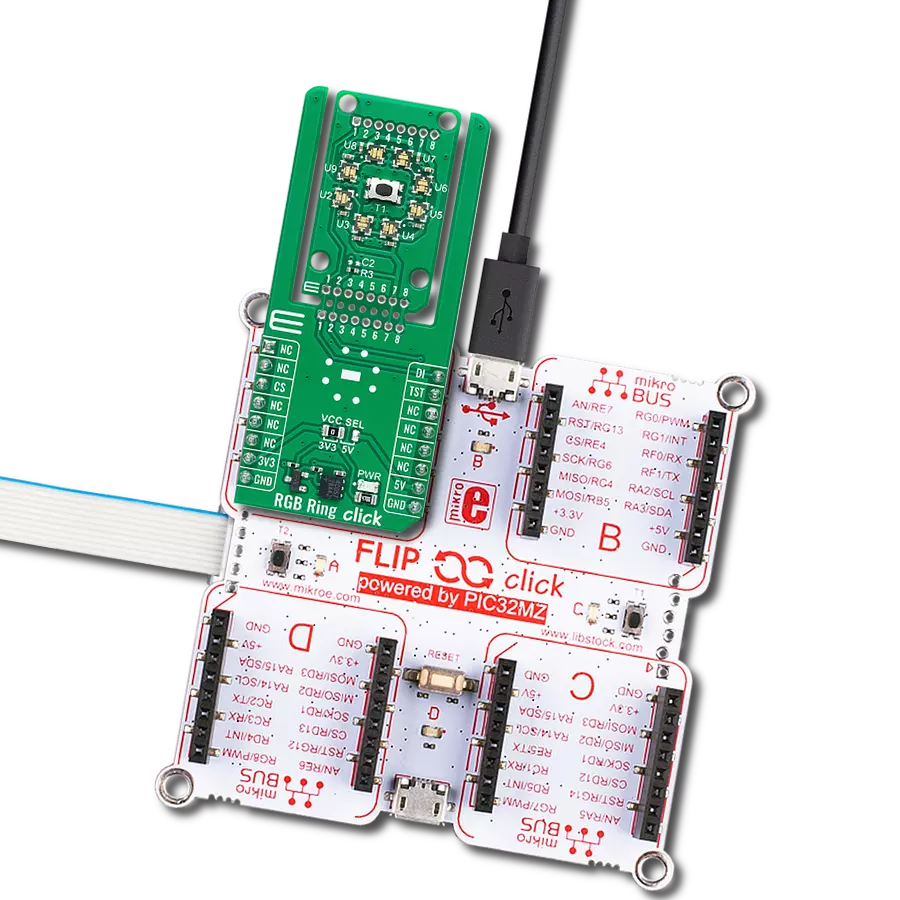

Development board

The 32L496GDISCOVERY Discovery kit serves as a comprehensive demonstration and development platform for the STM32L496AG microcontroller, featuring an Arm® Cortex®-M4 core. Designed for applications that demand a balance of high performance, advanced graphics, and ultra-low power consumption, this kit enables seamless prototyping for a wide range of embedded solutions. With its innovative energy-efficient

architecture, the STM32L496AG integrates extended RAM and the Chrom-ART Accelerator, enhancing graphics performance while maintaining low power consumption. This makes the kit particularly well-suited for applications involving audio processing, graphical user interfaces, and real-time data acquisition, where energy efficiency is a key requirement. For ease of development, the board includes an onboard ST-LINK/V2-1

debugger/programmer, providing a seamless out-of-the-box experience for loading, debugging, and testing applications without requiring additional hardware. The combination of low power features, enhanced memory capabilities, and built-in debugging tools makes the 32L496GDISCOVERY kit an ideal choice for prototyping advanced embedded systems with state-of-the-art energy efficiency.

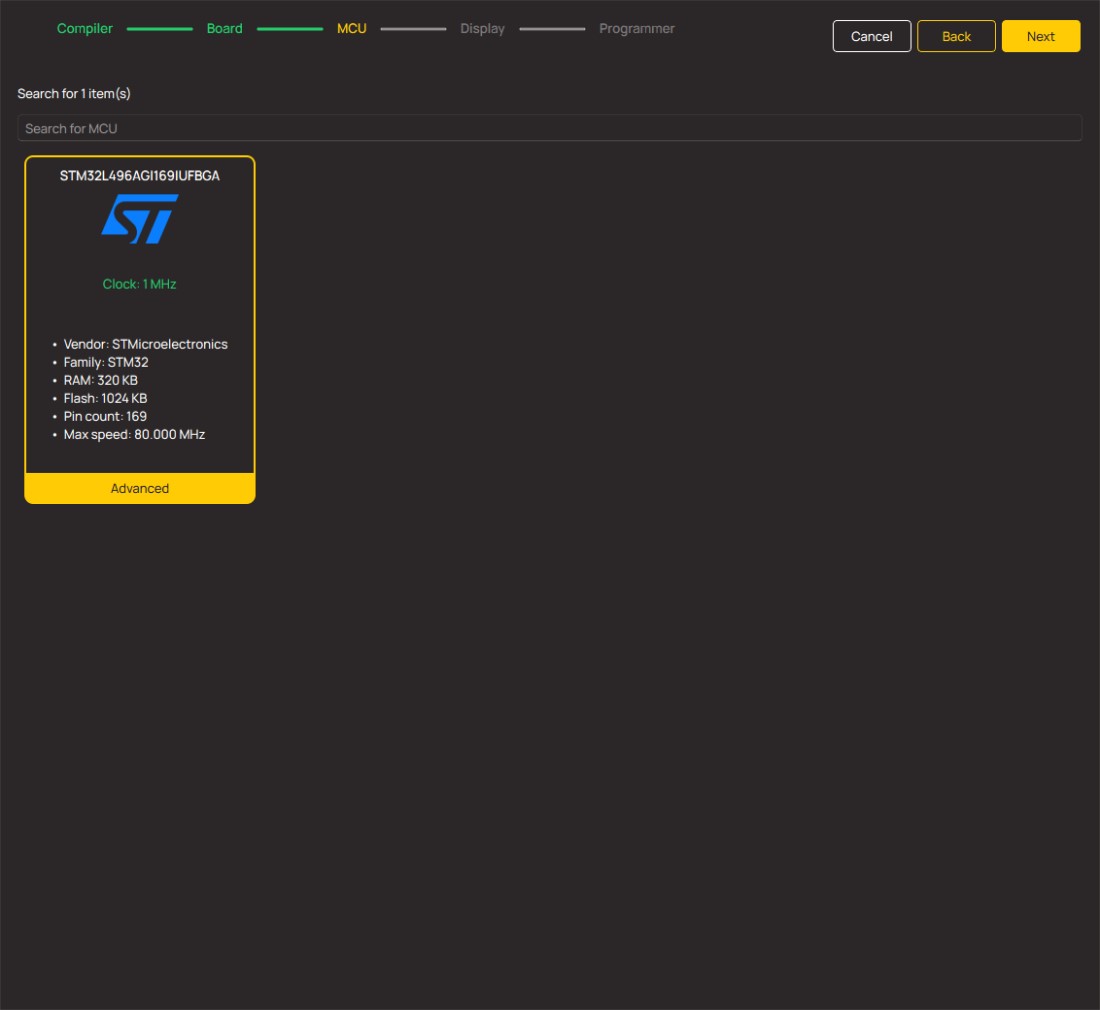

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

STMicroelectronics

Pin count

169

RAM (Bytes)

327680

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

8x8 R Click demo application is developed using the NECTO Studio, ensuring compatibility with mikroSDK's open-source libraries and tools. Designed for plug-and-play implementation and testing, the demo is fully compatible with all development, starter, and mikromedia boards featuring a mikroBUS™ socket.

Example Description

This demo example shows a drawing of Image, new create string and character on the screen.

Key functions:

c8x8r_cfg_setup- Config Object Initialization function.c8x8r_init- Initialization function.c8x8r_default_cfg- Click Default Configuration function.c8x8r_write_cmd- This function writes a desired number of data bytes starting from the selected register by using SPI serial interface.c8x8r_display_refresh- The function switches off all LEDs.c8x8r_display_byte- This function displayes one character to the display.

Application Init

Configuring Clicks and log objects. Settings the Click in the default configuration.

Application Task

Shows one byte, then scrolls the string and image, every 1 sec.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

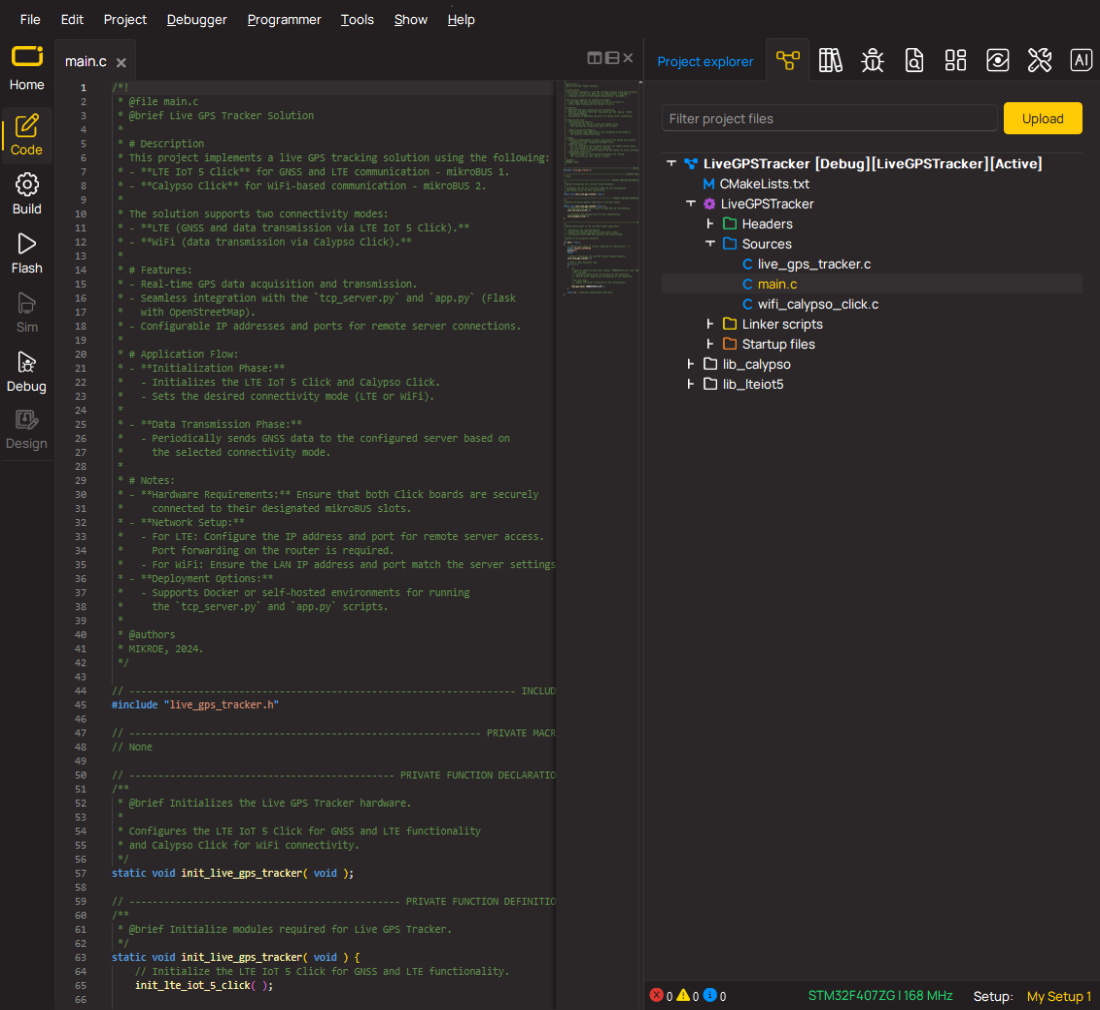

/*!

* @file main.c

* @brief 8x8 R Click example

*

* # Description

* This demo example shows a drawing of Image, new create string and character on the screen.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Configuring Clicks and log objects.

* Settings the Click in the default configuration.

*

* ## Application Task

* Shows one byte, then scrolls the string and image, every 1 sec.

*

* @author Stefan Ilic

*

*/

#include "board.h"

#include "log.h"

#include "c8x8r.h"

static c8x8r_t c8x8r;

static log_t logger;

uint8_t demo_string[ 11 ] = { ' ', '-', 'M', 'i', 'k', 'r', 'o', 'E', '-', ' ', 0 };

uint8_t demo_img_on[ 8 ] = { 0x08, 0x1c, 0x36, 0x22, 0x08, 0x1c, 0x36, 0x22 };

uint8_t demo_img_off[ 8 ] = { 0xf7, 0xe3, 0xc9, 0xdd, 0xf7, 0xe3, 0xc9, 0xdd };

char demo_char = 'A';

void application_init ( void ) {

log_cfg_t log_cfg; /**< Logger config object. */

c8x8r_cfg_t c8x8r_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

c8x8r_cfg_setup( &c8x8r_cfg );

C8X8R_MAP_MIKROBUS( c8x8r_cfg, MIKROBUS_1 );

err_t init_flag = c8x8r_init( &c8x8r, &c8x8r_cfg );

if ( init_flag == SPI_MASTER_ERROR ) {

log_info( &logger, " Application Init Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

c8x8r_default_cfg ( &c8x8r );

log_info( &logger, " Application Task " );

Delay_ms ( 1000 );

}

void application_task ( void ) {

c8x8r_display_byte( &c8x8r, demo_char );

Delay_ms ( 1000 );

c8x8r_display_string( &c8x8r, &demo_string[ 0 ] );

Delay_ms ( 1000 );

c8x8r_display_image( &c8x8r, &demo_img_on[ 0 ] );

Delay_ms ( 1000 );

c8x8r_display_image( &c8x8r, &demo_img_off[ 0 ] );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:LED Matrix