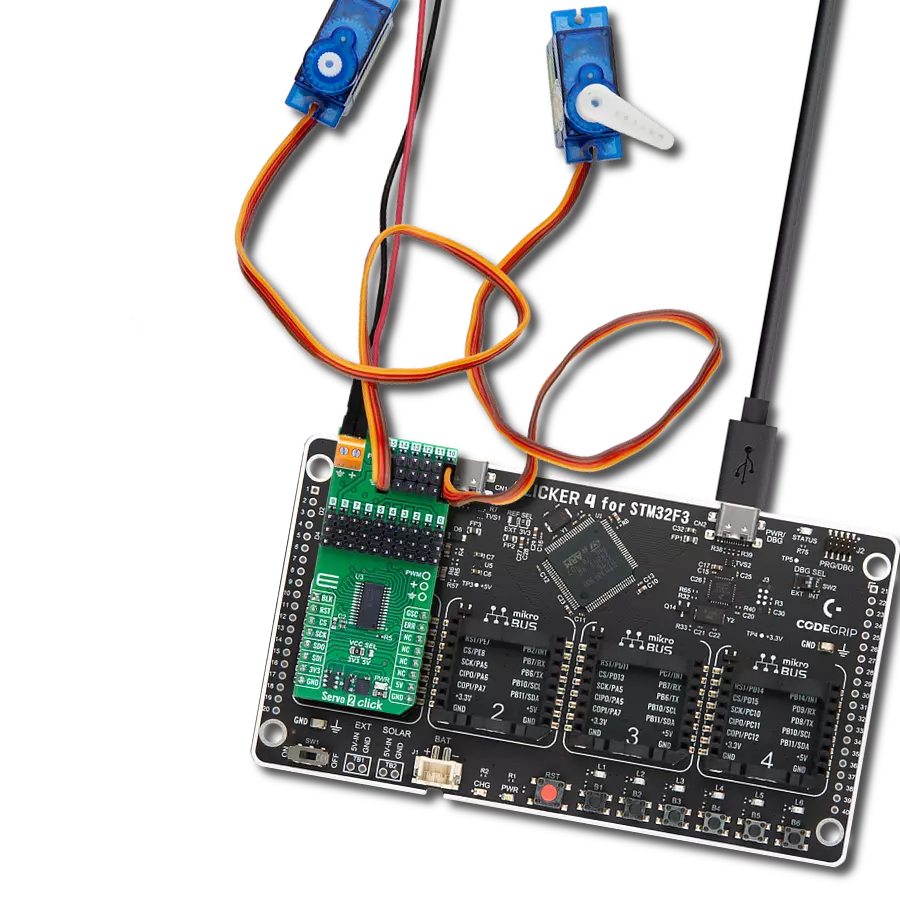

Control up to 16 servo motors with high-resolution PWM and robust safety features perfect for robotics and automation systems

A

A

Hardware Overview

How does it work?

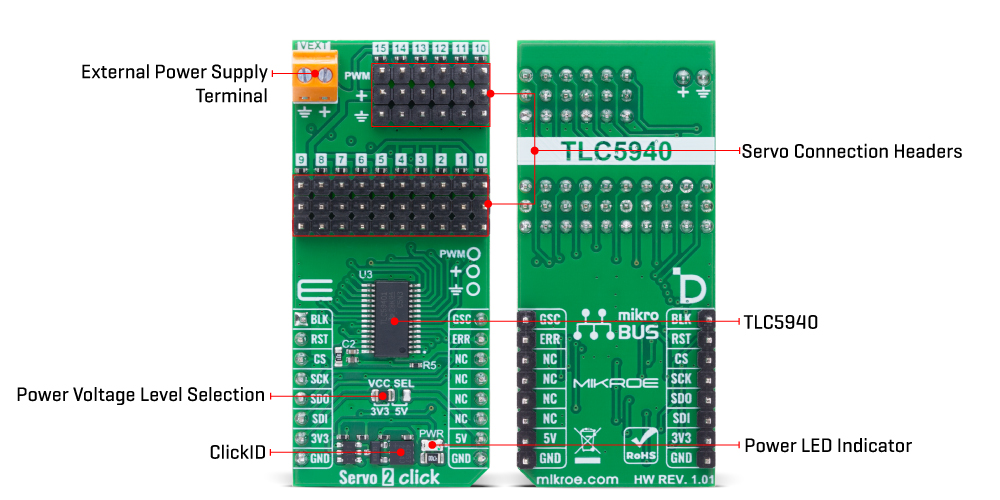

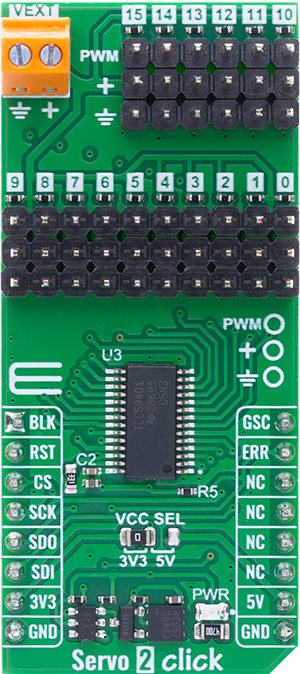

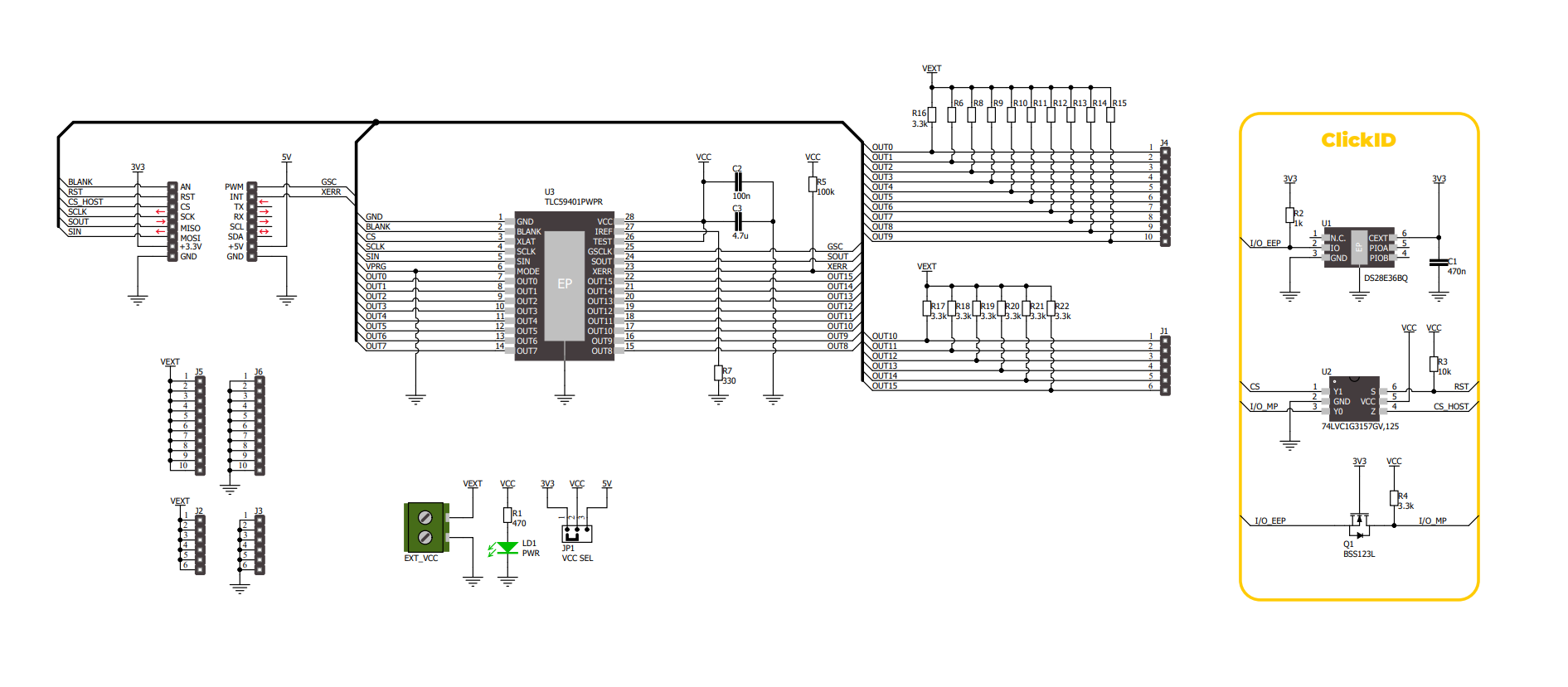

Servo 2 Click is based on the TLC59401, a 16-channel LED driver from Texas Instruments designed to control multiple outputs using a high-precision constant-current sink architecture. Each of the 16 channels features an individually programmable 12-bit grayscale PWM control, allowing for 4096 levels of pulse width adjustment per output. This level of control is accessible via a serial interface, ensuring flexible and accurate operation across all channels. The maximum output current for each channel is defined by a single external resistor, which simplifies configuration. On the Servo 2 Click, this resistor is set to 330Ω (R7), resulting in a maximum current of approximately 120mA per channel. This makes the board well-suited not only for precise servo motor control but also for driving high-current LEDs in secondary applications, including monocolor, multicolor, and

full-color LED displays, signboards, and back lighting systems where accurate brightness control and current regulation are essential. This Click board™ establishes communication with the host MCU via a 4-wire SPI interface with a maximum clock frequency of 30MHz, ensuring reliable and high-speed data transfer. Beyond the SPI pins, the board includes additional control and status lines that enhance its functionality. The BLK pin is used to blank all outputs simultaneously - when set HIGH, all output channels are disabled and the internal grayscale counter is reset. When driven LOW, the outputs resume operation under the control of the internal PWM grayscale engine. The design also supports the parallel configuration of multiple output channels to increase total current-driving capability. The supply voltage for the connected loads is provided through the VEXT

terminal, which distributes the same voltage to all output channels. This voltage can go up to a maximum of 17V, making the board compatible with a wide range of connected devices, including servo motors and LEDs. Additionally, the ERR pin provides essential fault indication through two integrated monitoring features: LED open detection (LOD), which flags disconnected or broken LEDs, and the thermal error flag (TEF), which signals an over-temperature condition. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

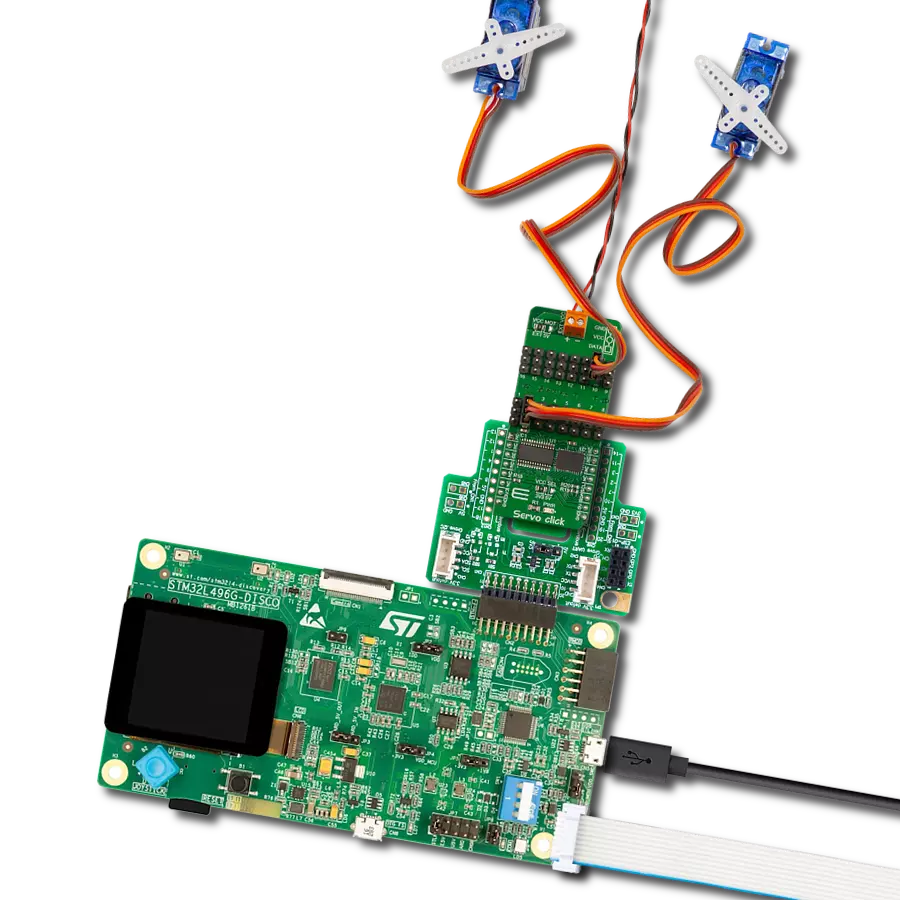

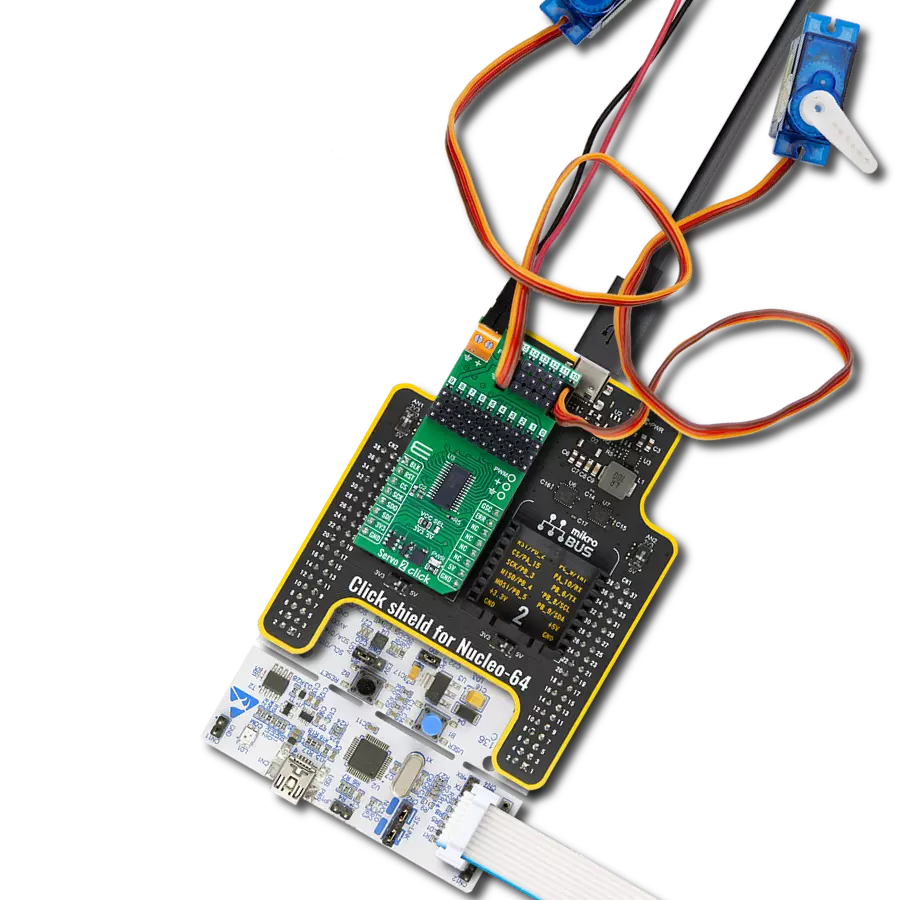

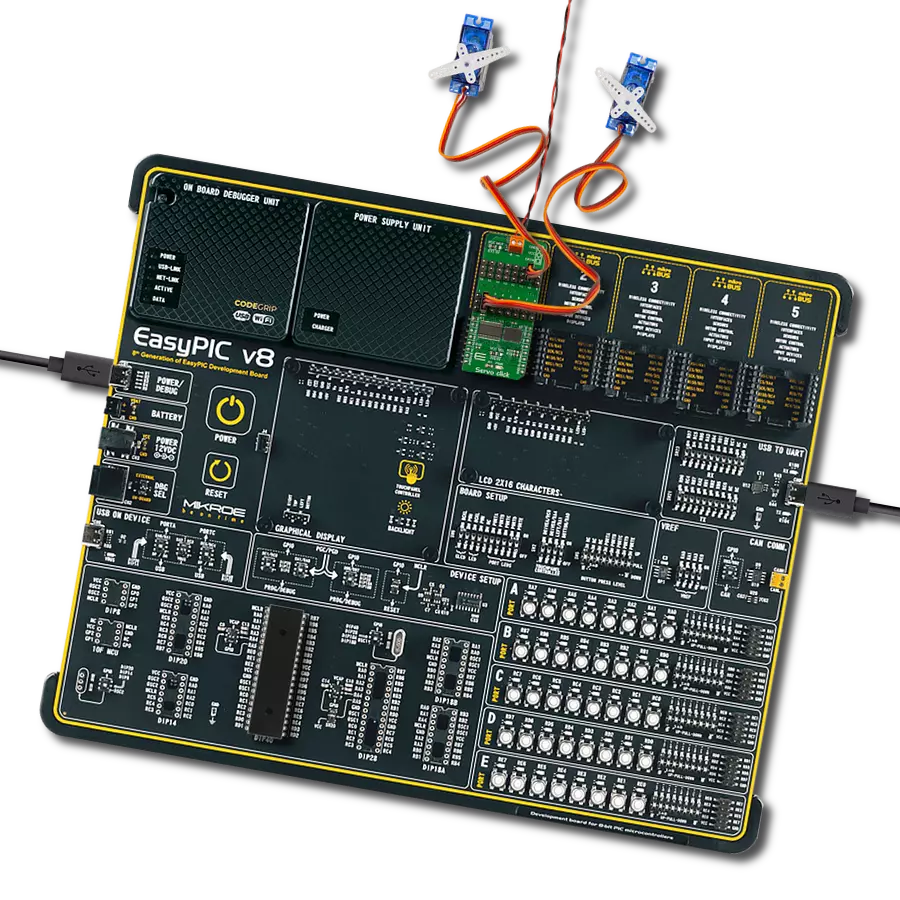

Development board

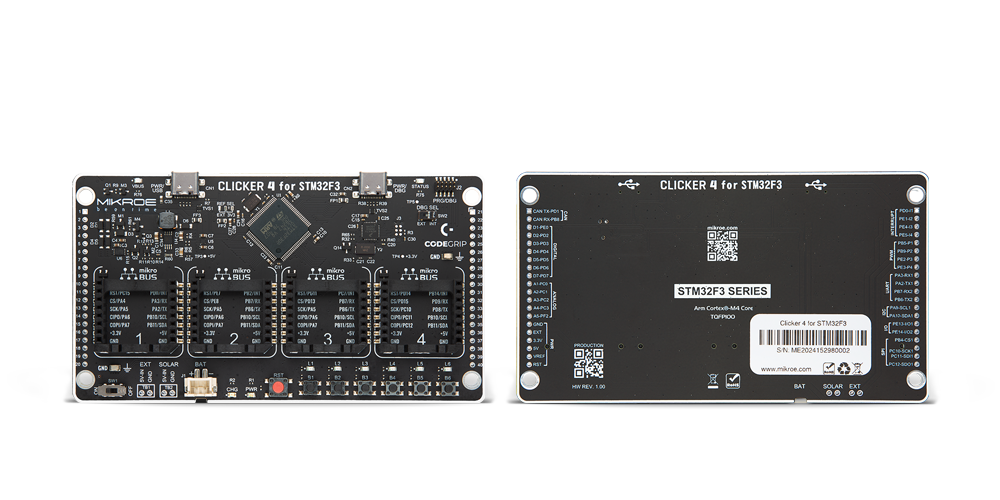

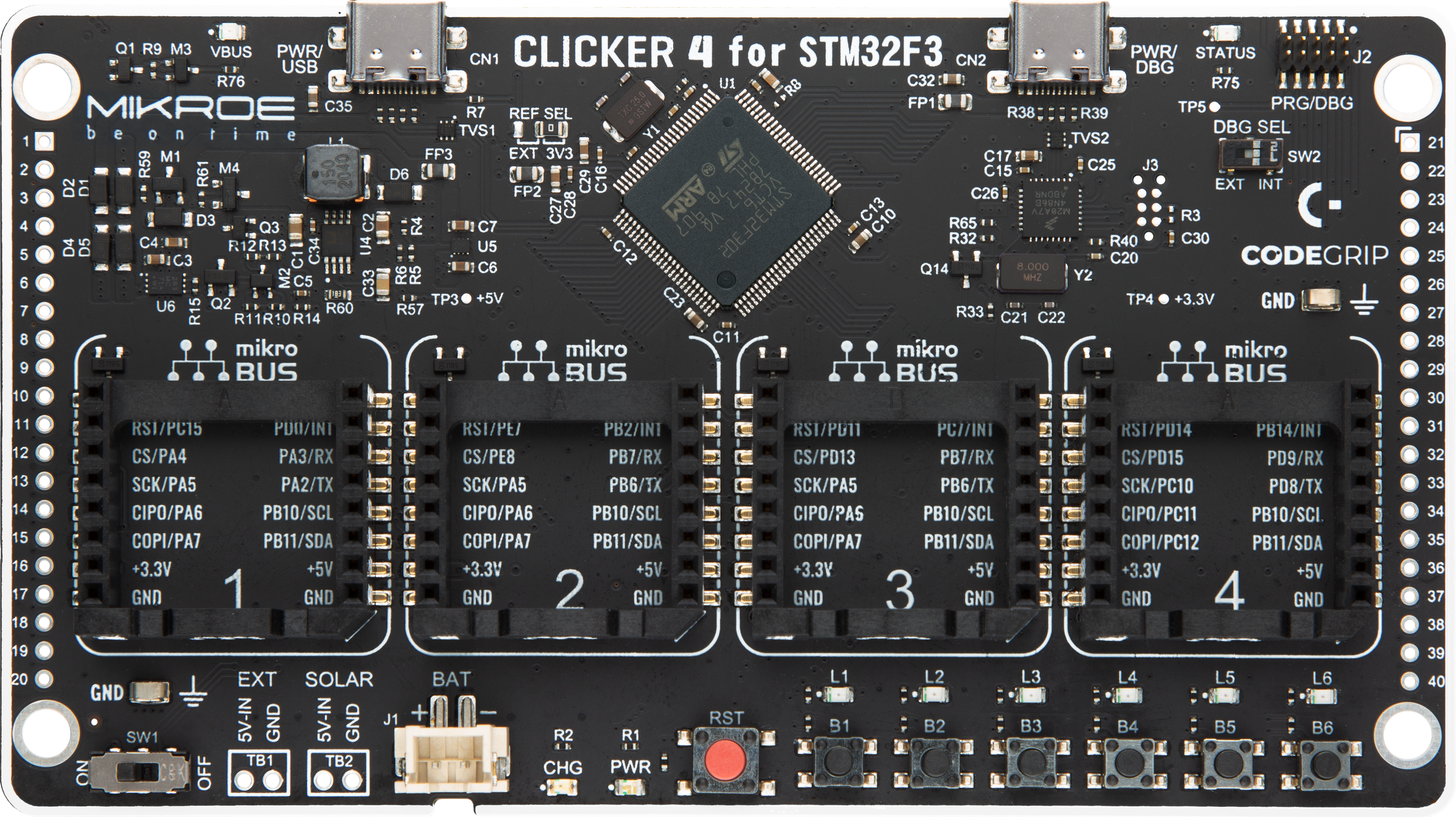

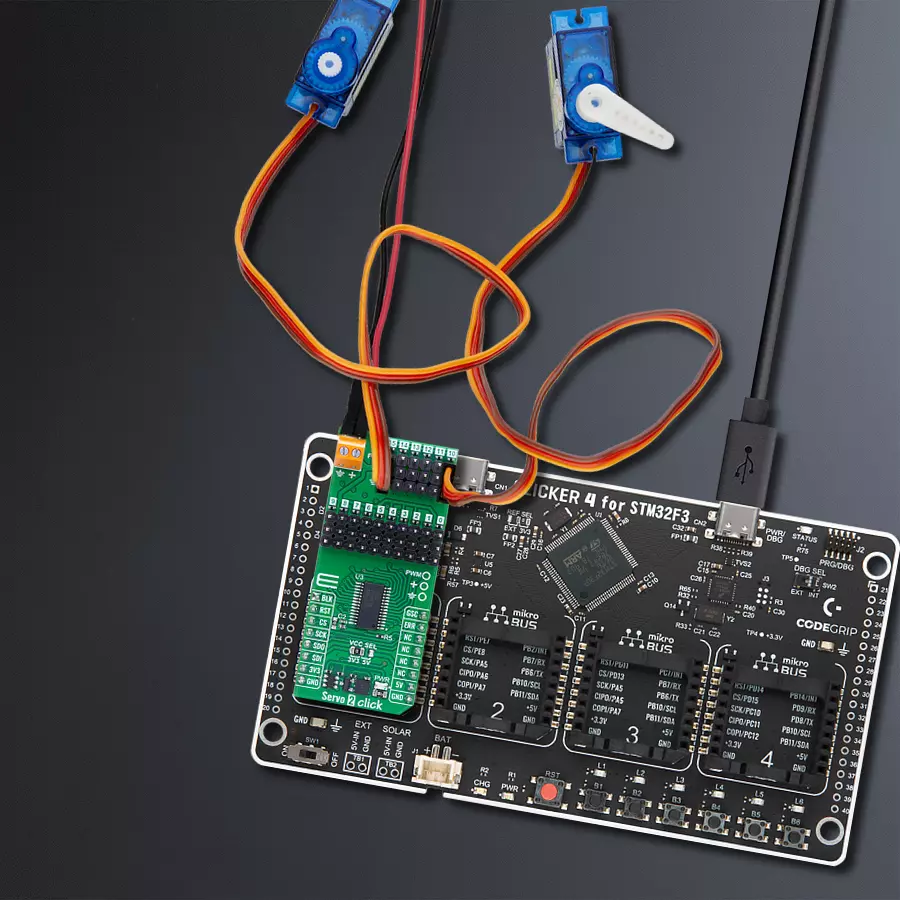

Clicker 4 for STM32F3 is a compact development board designed as a complete solution, you can use it to quickly build your own gadgets with unique functionalities. Featuring a STM32F302VCT6, four mikroBUS™ sockets for Click boards™ connectivity, power managment, and more, it represents a perfect solution for the rapid development of many different types of applications. At its core, there is a STM32F302VCT6 MCU, a powerful microcontroller by STMicroelectronics, based on the high-

performance Arm® Cortex®-M4 32-bit processor core operating at up to 168 MHz frequency. It provides sufficient processing power for the most demanding tasks, allowing Clicker 4 to adapt to any specific application requirements. Besides two 1x20 pin headers, four improved mikroBUS™ sockets represent the most distinctive connectivity feature, allowing access to a huge base of Click boards™, growing on a daily basis. Each section of Clicker 4 is clearly marked, offering an intuitive and clean interface. This makes working with the development

board much simpler and thus, faster. The usability of Clicker 4 doesn’t end with its ability to accelerate the prototyping and application development stages: it is designed as a complete solution which can be implemented directly into any project, with no additional hardware modifications required. Four mounting holes [4.2mm/0.165”] at all four corners allow simple installation by using mounting screws. For most applications, a nice stylish casing is all that is needed to turn the Clicker 4 development board into a fully functional, custom design.

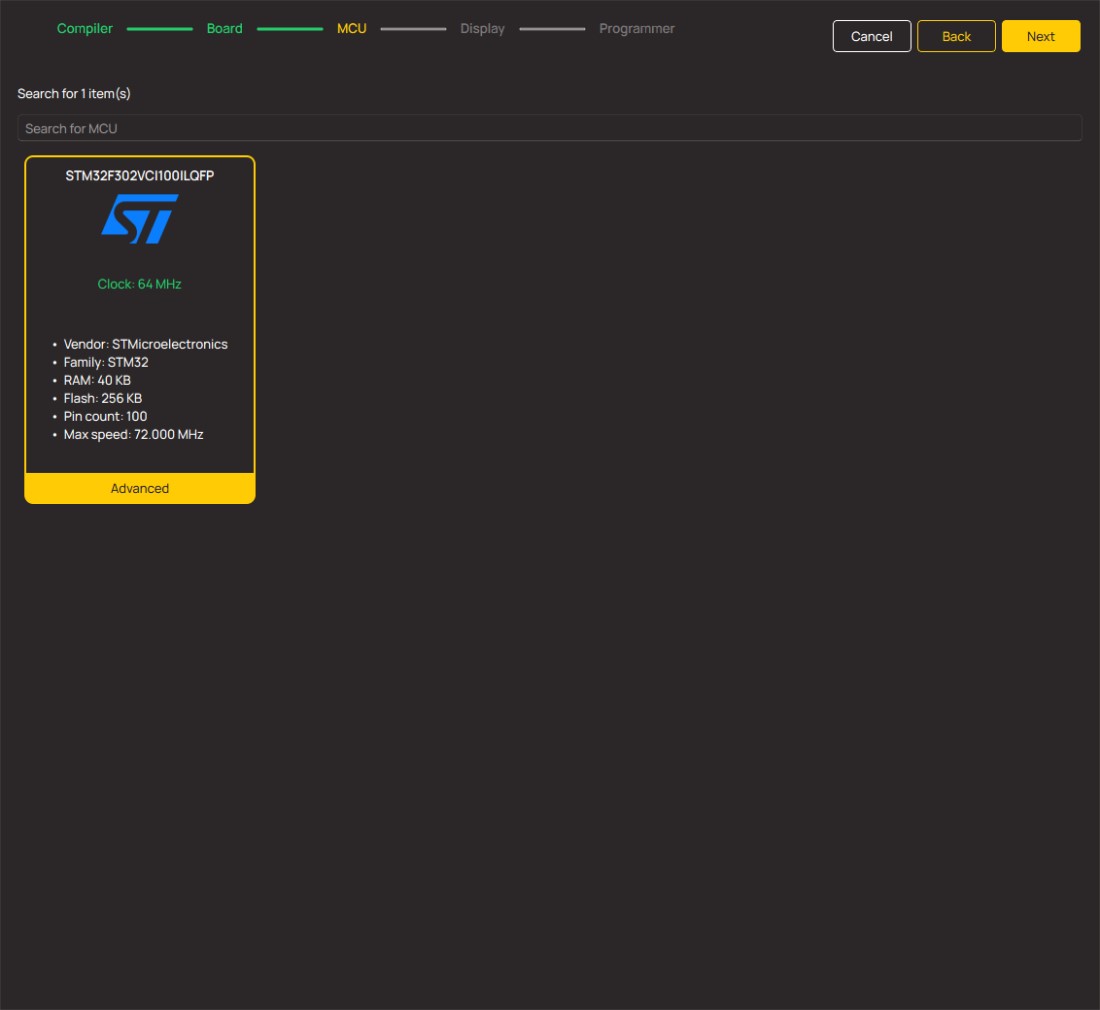

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

256

Silicon Vendor

STMicroelectronics

Pin count

100

RAM (Bytes)

40960

You complete me!

Accessories

SG90 Digital Servo Motor from TowerPro is a compact and lightweight 9g servo, widely recognized for its balance of performance, reliability, and affordability. As an enhanced digital version of the original analog SG90, this servo offers improved precision and response, making it a popular choice for hobbyists and professionals alike. With a stall torque of 1.8kg/cm at 4.8V and an impressive operating speed of 0.1 seconds per 60 degrees, the SG90 is well-suited for applications requiring fast and accurate motion control. It features a durable POM (polyoxymethylene) gear set that ensures smooth operation and extended lifespan under moderate loads. Operating at 4.8V, the SG90 covers a temperature range from 0°C to 55°C, allowing reliable performance in various indoor and semi-controlled environments. Its tight dead band width of just 1μs ensures high positional accuracy, which is essential for robotics, RC models, and small automation systems. The servo comes with a 25cm cable and a JR-type connector, making it compatible with most popular RC receivers and microcontroller platforms, including JR and Futaba systems. Its compact dimensions (23 × 12.2 × 29mm) make it easy to integrate into space-constrained designs.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

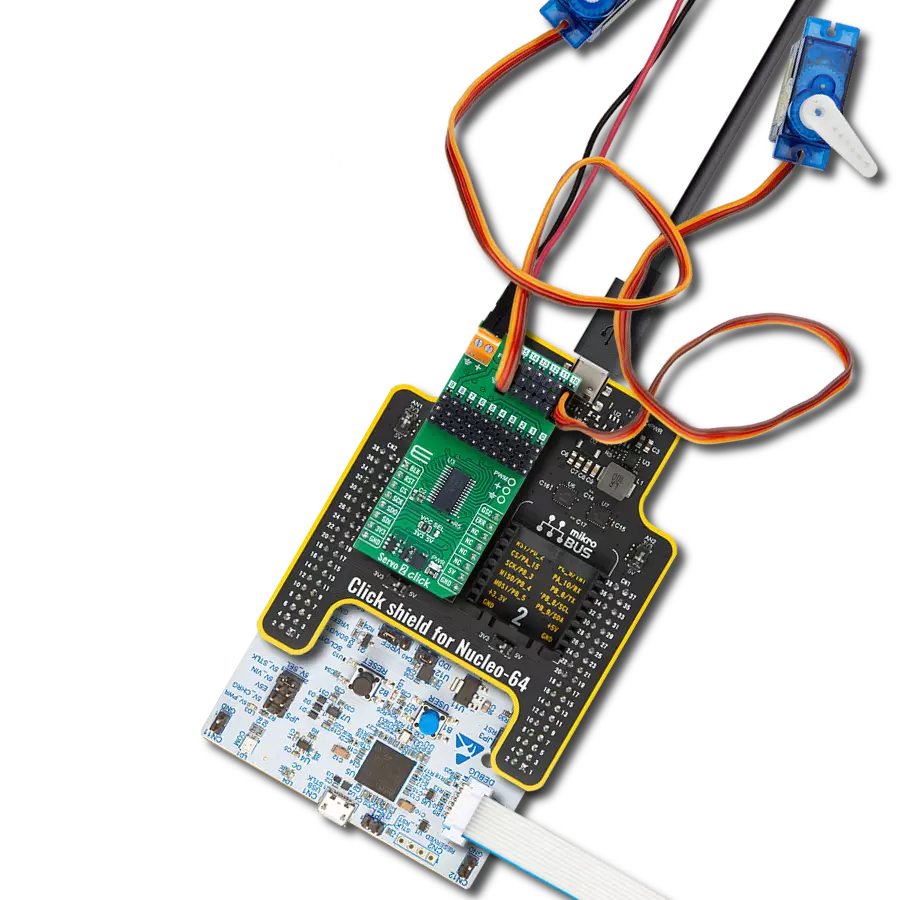

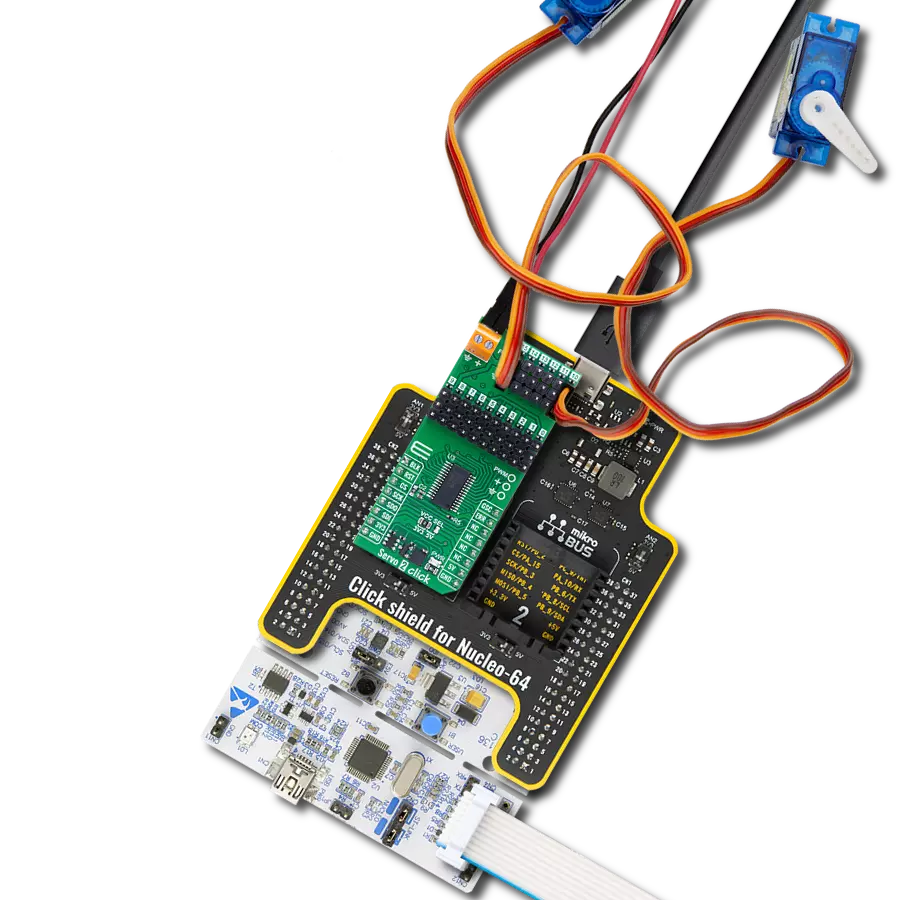

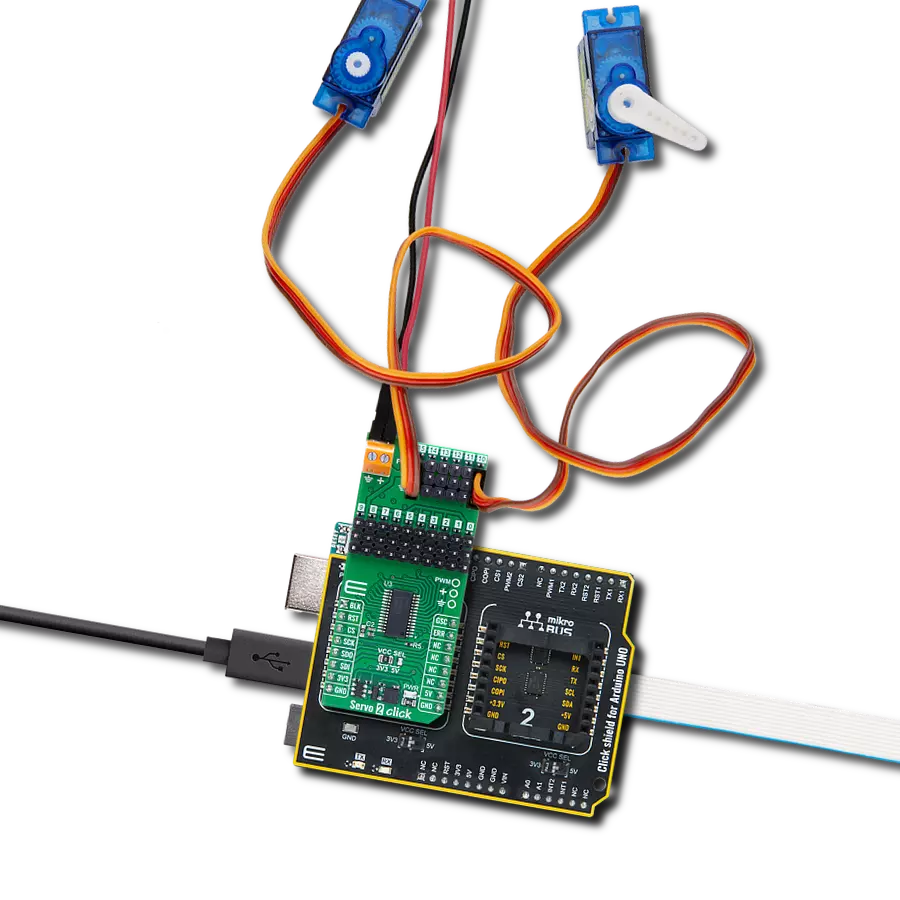

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

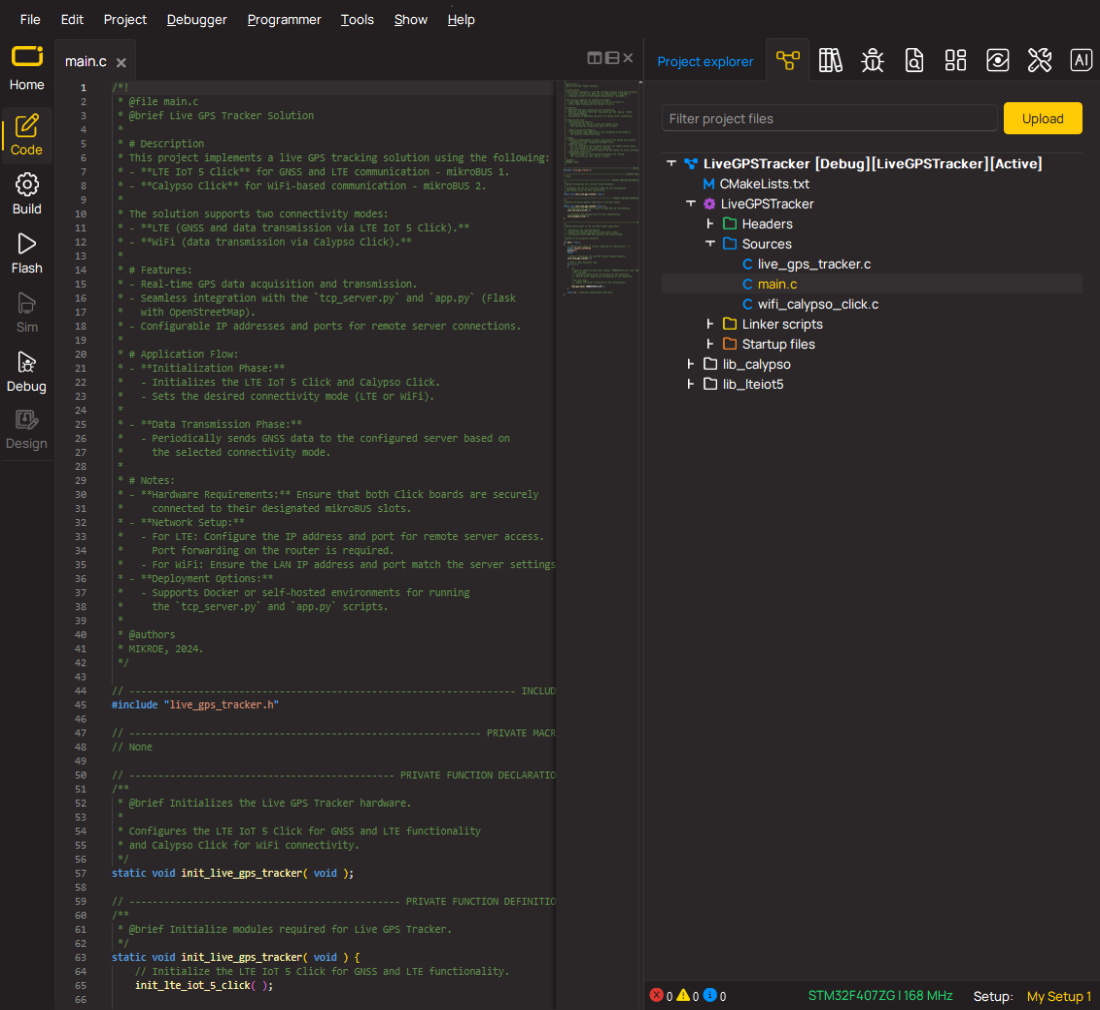

Servo 2 Click demo application is developed using the NECTO Studio, ensuring compatibility with mikroSDK's open-source libraries and tools. Designed for plug-and-play implementation and testing, the demo is fully compatible with all development, starter, and mikromedia boards featuring a mikroBUS™ socket.

Example Description

This example demonstrates the use of the Servo 2 Click board for controlling the angle of servo motors. The board is capable of driving multiple servos, and the example illustrates how to change the angle of all connected servos simultaneously within a defined range.

Key functions:

servo2_cfg_setup- Config Object Initialization function.servo2_init- Initialization function.servo2_set_angle- This function sets the servo angle for a specific channel or all channels.servo2_update_output- This function updates the PWM output values for all channels by writing them to the device.servo2_set_channel_pwm- This function sets the PWM output for a specific channel or all channels.

Application Init

Initializes the logger module and configures the Servo 2 Click board. The PWM communication is established, and the device is prepared for controlling the servos.

Application Task

Gradually changes the angle of all connected servo motors from a minimum to a maximum value, and then back to the minimum, creating a sweeping motion. The current angle is logged during each update.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief Servo 2 Click example

*

* # Description

* This example demonstrates the use of the Servo 2 Click board for controlling the angle of servo motors.

* The board is capable of driving multiple servos, and the example illustrates how to change the angle

* of all connected servos simultaneously within a defined range.

*

* The demo application is composed of two sections:

*

* ## Application Init

* Initializes the logger module and configures the Servo 2 Click board. The PWM communication is

* established, and the device is prepared for controlling the servos.

*

* ## Application Task

* Gradually changes the angle of all connected servo motors from a minimum to a maximum value, and

* then back to the minimum, creating a sweeping motion. The current angle is logged during each update.

*

* @note

* Ensure that the servo motors are properly connected to the Servo 2 Click board and are compatible

* with the specified angle range such as the SG90 Micro Servo motors.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "servo2.h"

static servo2_t servo2;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

servo2_cfg_t servo2_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

servo2_cfg_setup( &servo2_cfg );

SERVO2_MAP_MIKROBUS( servo2_cfg, MIKROBUS_1 );

if ( PWM_ERROR == servo2_init( &servo2, &servo2_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

static uint8_t angle = SERVO2_ANGLE_MIN;

static int8_t step = 1;

log_printf( &logger, "All channels angle: %u\r\n\n", angle );

servo2_set_angle ( &servo2, SERVO2_CHANNEL_ALL, angle );

servo2_update_output ( &servo2 );

angle += step;

if ( angle > SERVO2_ANGLE_MAX )

{

step = -step;

angle += step;

}

else if ( angle < SERVO2_ANGLE_MIN )

{

step = -step;

angle += step;

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Servo