Enhance your decision-making processes by integrating our innovative random number generator into your applications, ensuring selection fairness and eliminating biases

A

A

Hardware Overview

How does it work?

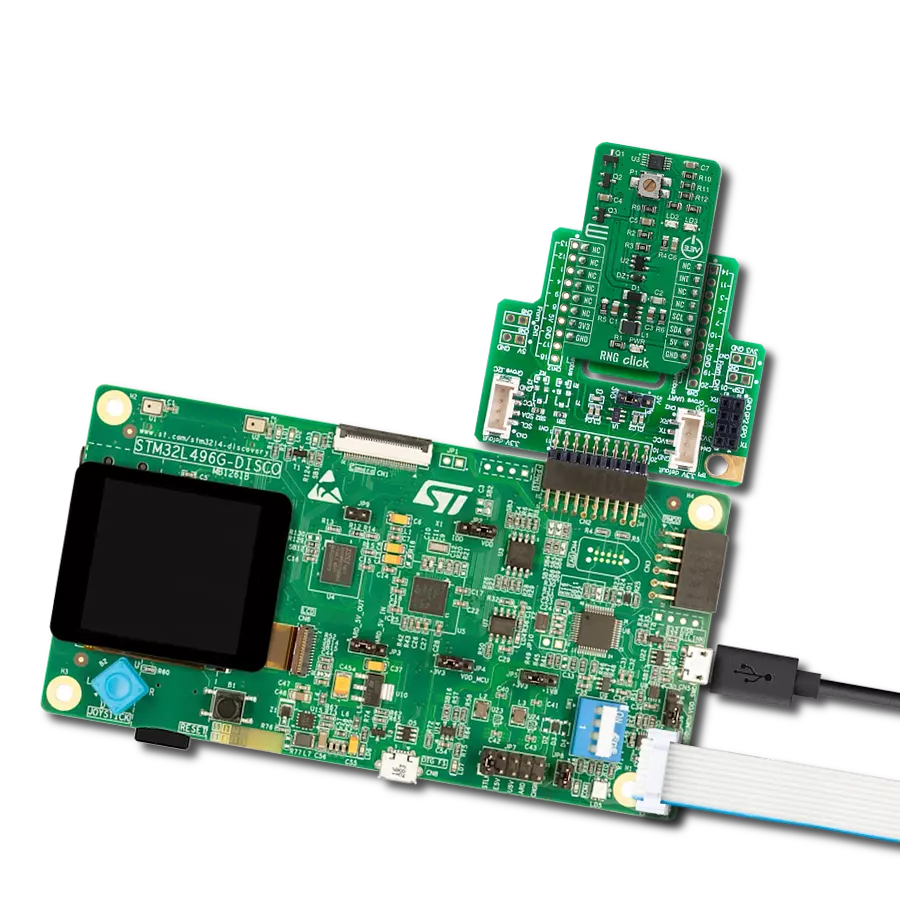

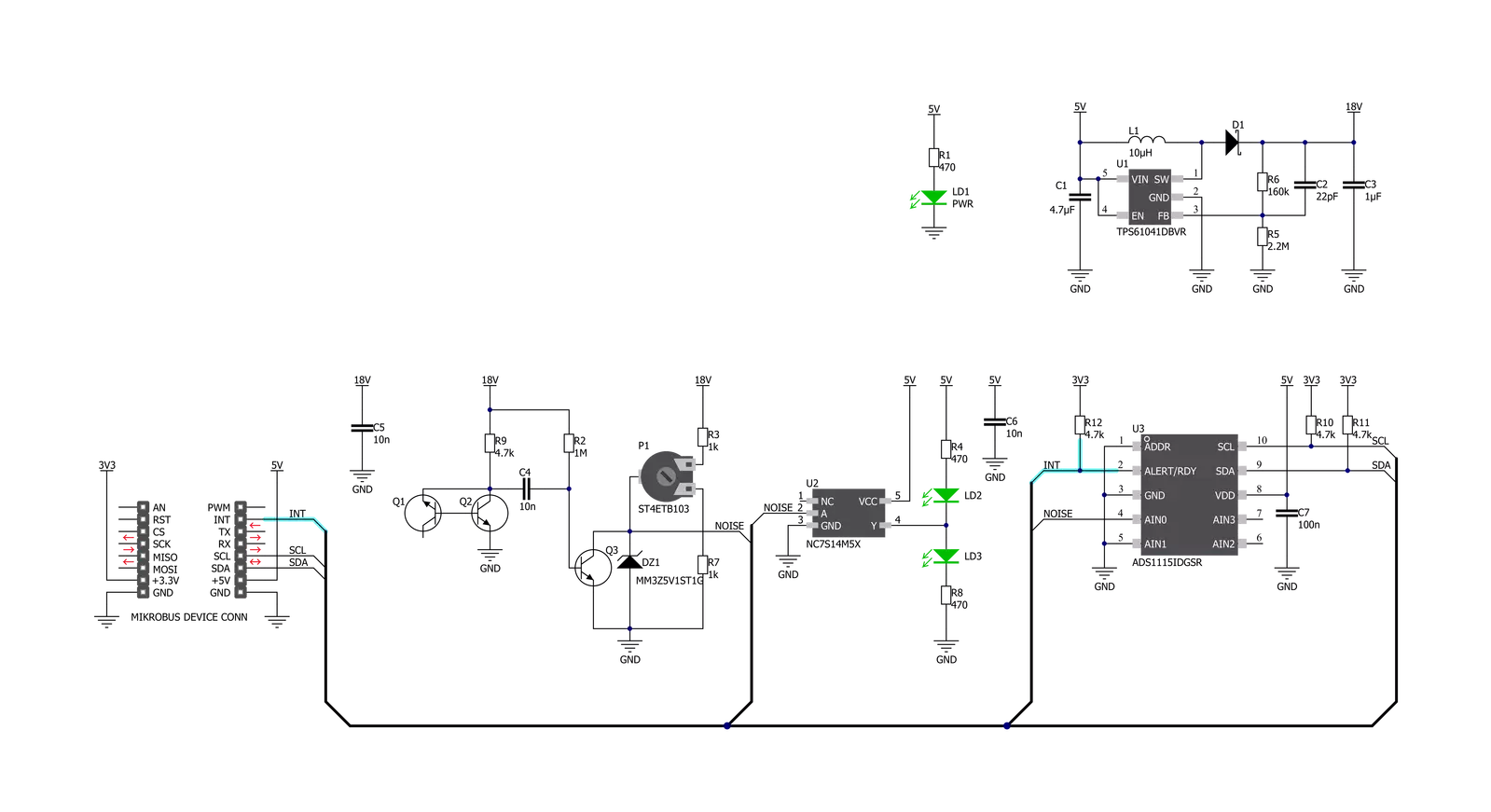

RNG Click is a random number generator (RNG) based on the ADS1115, 16-bit, I2C-compatible, analog-to-digital converter from Texas Instruments that generates a sequence of numbers or symbols that cannot be reasonably predicted better than by a random chance. In computing, a hardware random number generator (HRNG) or true random number generator (TRNG) is a device that generates random numbers from a physical process rather than using an algorithm. Such devices are often based on microscopic phenomena that generate low-level, statistically random "noise" signals, as in this Click board™. That process is, in theory, completely unpredictable, and the theory's assertions of unpredictability are subject to experimental tests. This is in contrast to the paradigm of pseudo-random number generation, which is commonly implemented by the

software. The heart of the RNG click is the avalanche noise generated from an internal diode of the transistor Q1 (BC846B). Avalanche breakdown is a phenomenon that can occur in both insulating and semiconducting materials. It is a form of electric current multiplication that can allow large currents within materials that are otherwise good insulators. The avalanche occurs when the electric field accelerates carriers in the transition region to energies sufficient to create mobile or free electron-hole pairs via collisions with bound electrons. To achieve that, RNG Click also has a boost converter onboard, based on TPS61041 from Texas Instruments, and creates the +18V power supply for the job. The noise signal, created by the transistors Q1 and Q2, is then amplified with Q3, voltage-limited using the Zener diode, and digitalized using the NC7S14M5X inverter. After that, the string of random ones and

zeros is achieved, which is brought to the ADS1115 - 16BIT sigma-delta ADC from Texas Instruments. The potentiometer P1 is used to set the distribution of ones and zeros as near as possible, which is indicated by the LD2 and LD3 LED diodes. The potentiometer P1 should be set to illuminate the LD2 and LD3 diodes equally. That way, when the single-shot measurement is performed using the ADS1115 over the I2C protocol, the true, 16-bit random number is obtained. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, it comes equipped with a library containing functions and an example code that can be used, as a reference, for further development.

Features overview

Development board

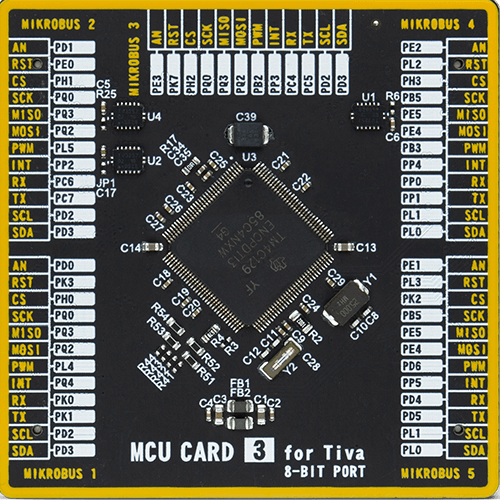

Fusion for TIVA v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports a wide range of microcontrollers, such as different 32-bit ARM® Cortex®-M based MCUs from Texas Instruments, regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer over a WiFi network. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, Fusion for TIVA v8 provides a fluid and immersive working experience, allowing access

anywhere and under any circumstances at any time. Each part of the Fusion for TIVA v8 development board contains the components necessary for the most efficient operation of the same board. An advanced integrated CODEGRIP programmer/debugger module offers many valuable programming/debugging options, including support for JTAG, SWD, and SWO Trace (Single Wire Output)), and seamless integration with the Mikroe software environment. Besides, it also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector.

Communication options such as USB-UART, USB HOST/DEVICE, CAN (on the MCU card, if supported), and Ethernet is also included. In addition, it also has the well-established mikroBUS™ standard, a standardized socket for the MCU card (SiBRAIN standard), and two display options for the TFT board line of products and character-based LCD. Fusion for TIVA v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

Texas Instruments

Pin count

128

RAM (Bytes)

262144

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for RNG Click driver.

Key functions:

rng_get_voltage- This function gets voltage in millivoltsrng_set_config- This function sets configurationrng_set_vref- This function sets desired vref.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Rng Click example

*

* # Description

* This Click is a random number generator. The device contain potentiometer which control voltage

* so it generates a sequence of numbers or symbols that cannot be reasonably predicted better

* by a random chance. Random number generators have applications in gambling, statistical sampling,

* computer simulation, cryptography, completely randomized design, and various other areas.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes driver, then sets configuration and voltage reference.

*

* ## Application Task

* It reads ADC value from AIN0 channel then converts it to voltage and

* displays the result on USB UART each second.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "rng.h"

// ------------------------------------------------------------------ VARIABLES

static rng_t rng;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

rng_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

rng_cfg_setup( &cfg );

RNG_MAP_MIKROBUS( cfg, MIKROBUS_1 );

rng_init( &rng, &cfg );

rng_default_cfg( &rng );

}

void application_task ( void )

{

float voltage;

voltage = rng_get_voltage( &rng );

log_printf( &logger, "Voltage from AIN0: %.2f mV\r\n", voltage );

log_printf( &logger, "-----------------------\r\n" );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END