Maximize the potential of your electronic circuits by unlocking unparalleled precision with our digital potentiometer – the key to achieving peak performance and efficiency in every application.

A

A

Hardware Overview

How does it work?

DIGI POT 12 Click is based on the AD5142A, a dual-channel, 256-position nonvolatile digital potentiometer from Analog Devices. The resistor wiper position is determined by the RDAC register contents, which act as a scratchpad register, allowing unlimited changes of resistance settings. The scratchpad register can be programmed with any position setting using the standard I2C interface by loading the 16-bit data word. The nominal resistance of the RDAC between terminals A and terminals B (RAB) is 10KΩ with 8-bit RDAC latch data decoded to select one of the 256 possible wiper settings. When a desired position is found, this value can be stored in the onboard EEPROM memory; thus, the wiper position is always restored for subsequent power-ups. The EEPROM data can be read back, written

independently, and protected by software. This Click board™ communicates with MCU through a standard 2-Wire I2C interface and operates at Standard (100KHz) and Fast (400KHz) data transfer modes. The I2C address can be selected via the ADDR SEL jumpers with 0 selected by default. There is an RST pin for resetting the digital potentiometers RDAC registers from EEPROM, with active LOW logic. In addition, this Click board™ comes with the INDEP SEL jumper that allows you to choose between the potentiometer and the linear gain setting mode, with the potentiometer mode set by default (0). The linear gain setting mode of operation can control the potentiometer as two independent rheostats connected at a single point. Once the jumper is set, it can not be turned off by software. In

addition, there is a burst mode in which multiple data bytes can be sent to the host MCU. The Shutdown mode places the RDAC in a zero power consumption while the data in EEPROM remains. There is no polarity constraint between the B, W, and A on both terminals, but they can not be higher than the VCC (5V maximum) nor lower than the VSS (0V). This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

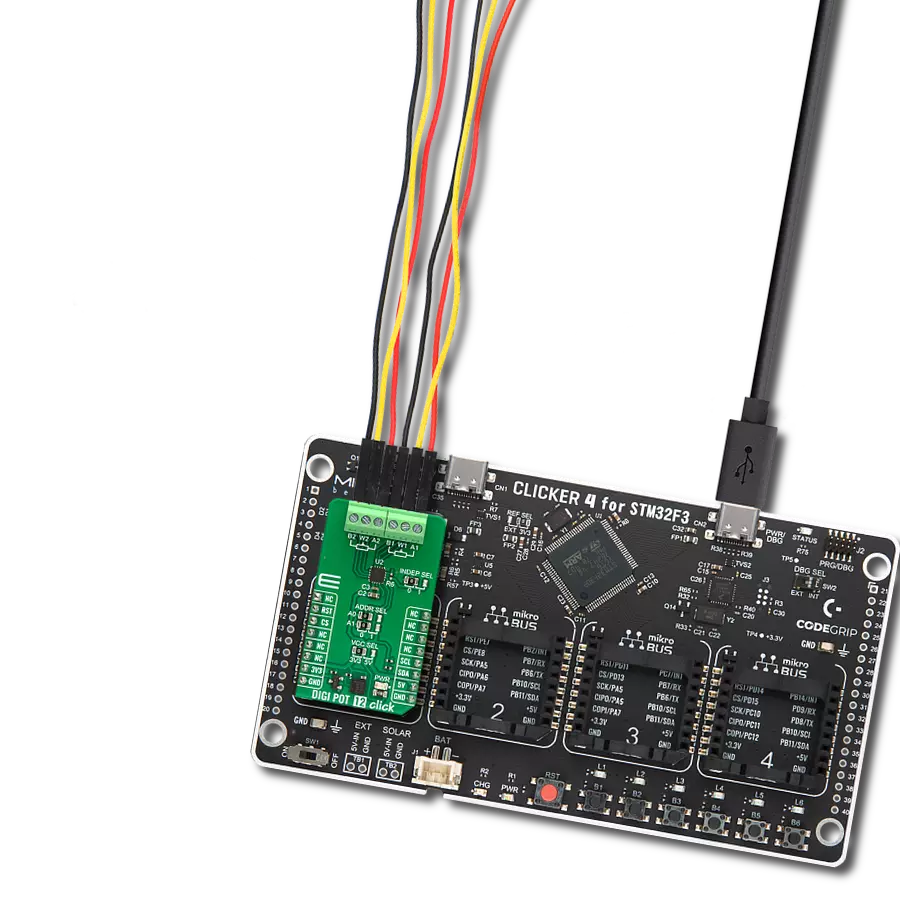

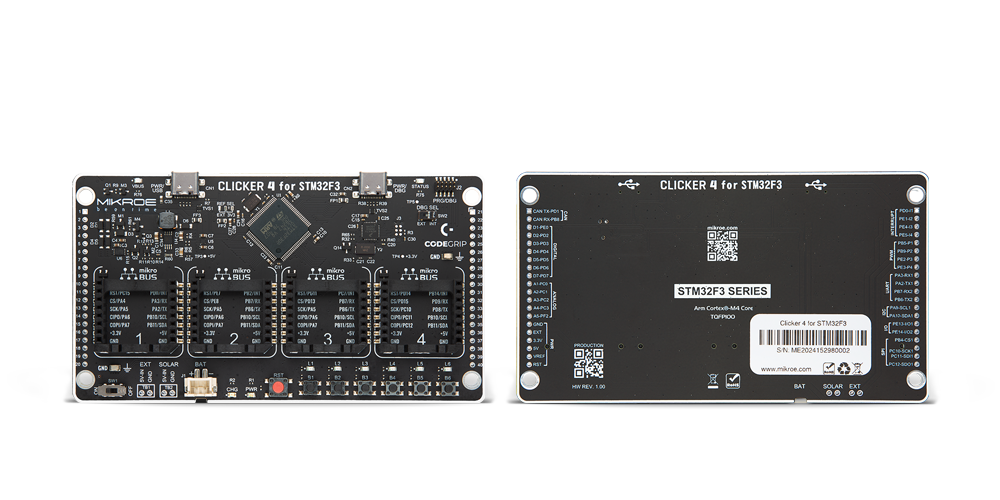

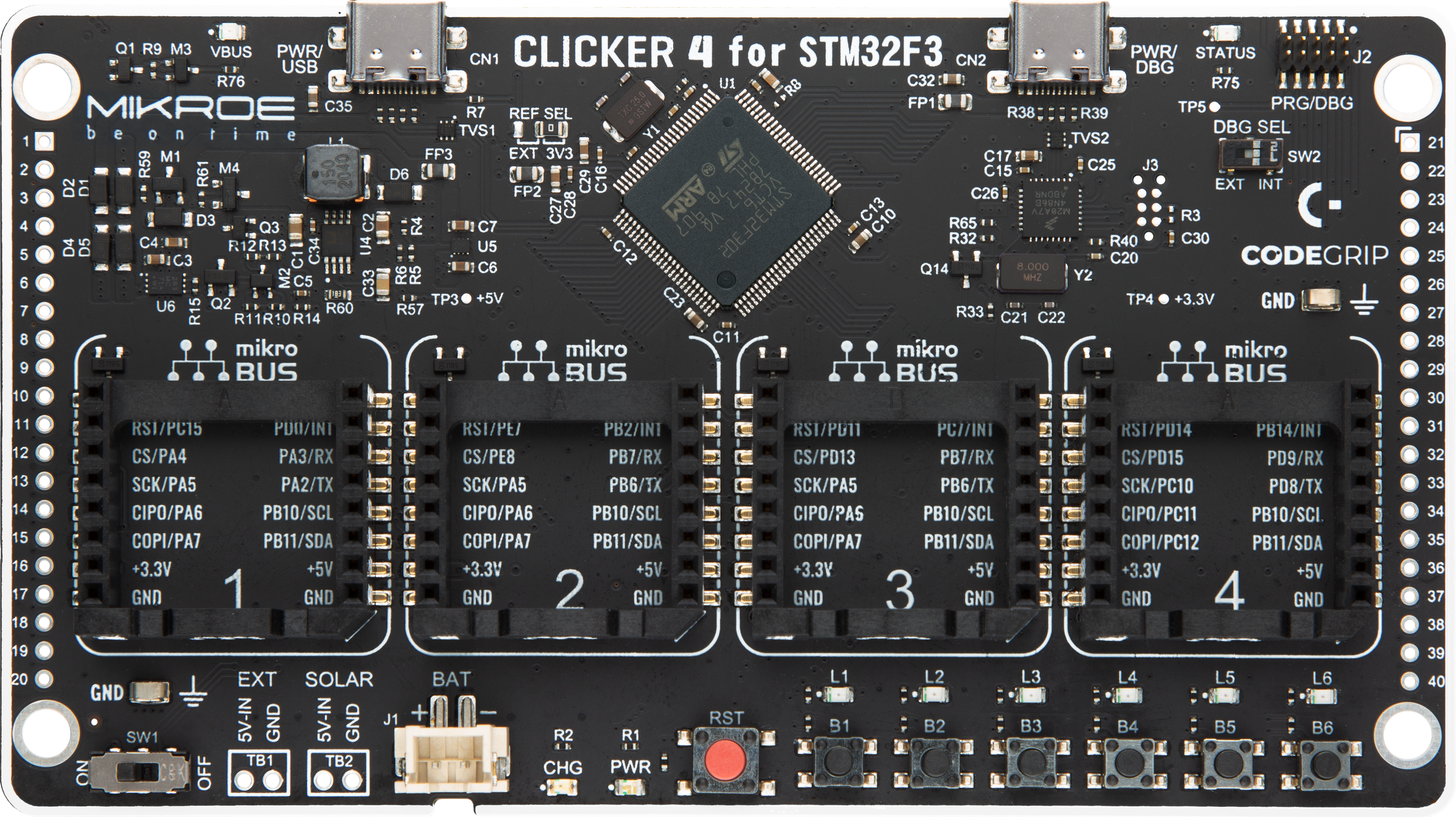

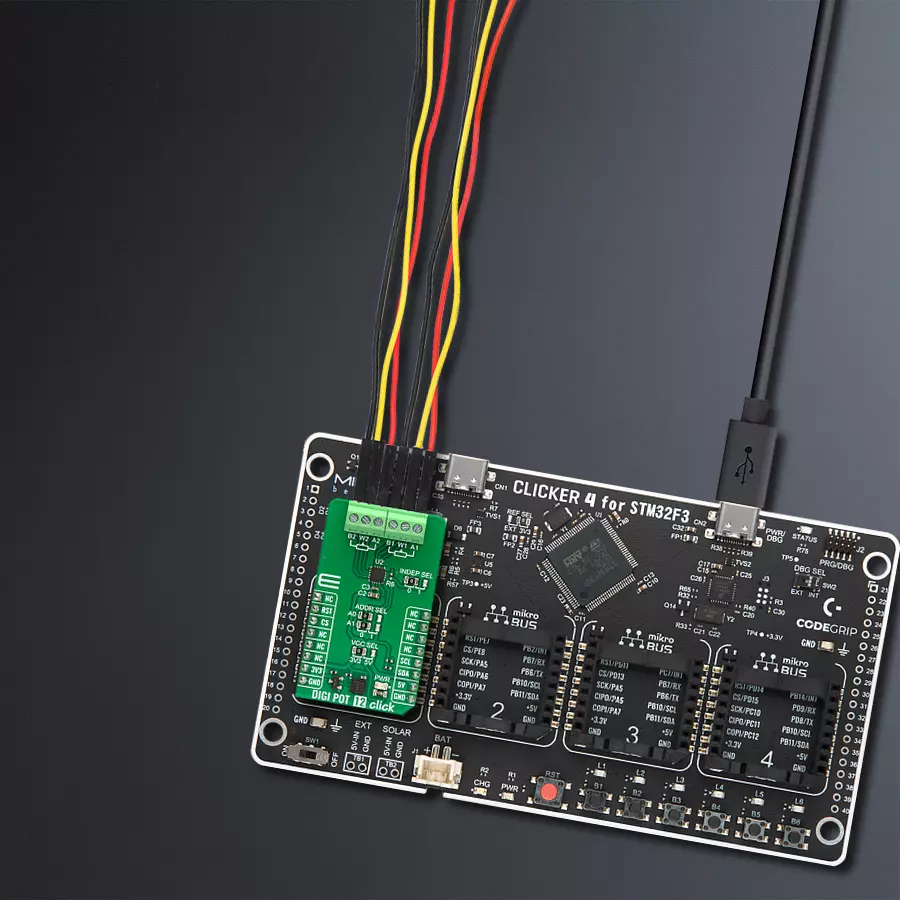

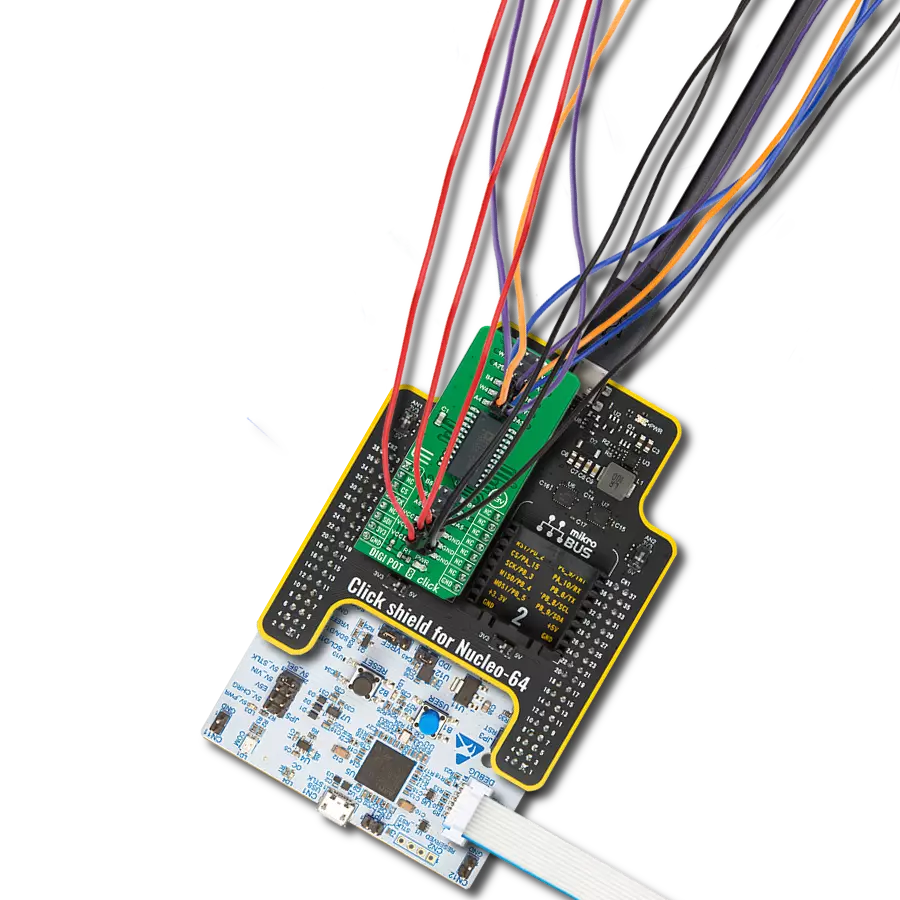

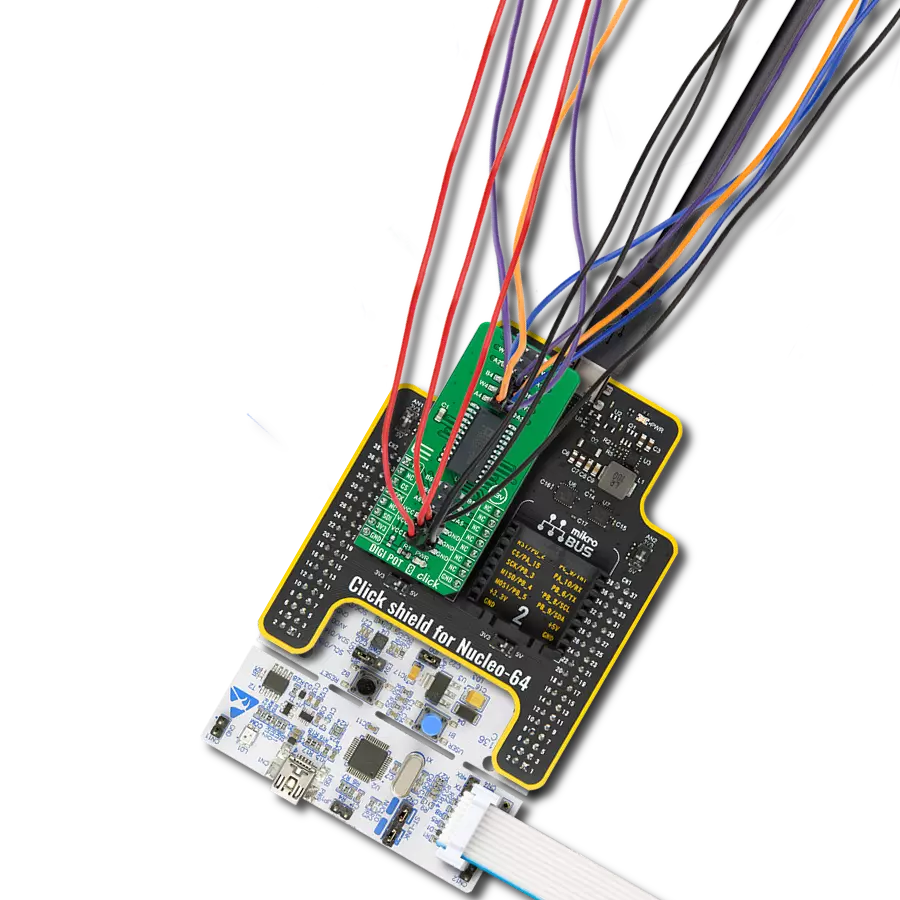

Development board

Clicker 4 for STM32F3 is a compact development board designed as a complete solution, you can use it to quickly build your own gadgets with unique functionalities. Featuring a STM32F302VCT6, four mikroBUS™ sockets for Click boards™ connectivity, power managment, and more, it represents a perfect solution for the rapid development of many different types of applications. At its core, there is a STM32F302VCT6 MCU, a powerful microcontroller by STMicroelectronics, based on the high-

performance Arm® Cortex®-M4 32-bit processor core operating at up to 168 MHz frequency. It provides sufficient processing power for the most demanding tasks, allowing Clicker 4 to adapt to any specific application requirements. Besides two 1x20 pin headers, four improved mikroBUS™ sockets represent the most distinctive connectivity feature, allowing access to a huge base of Click boards™, growing on a daily basis. Each section of Clicker 4 is clearly marked, offering an intuitive and clean interface. This makes working with the development

board much simpler and thus, faster. The usability of Clicker 4 doesn’t end with its ability to accelerate the prototyping and application development stages: it is designed as a complete solution which can be implemented directly into any project, with no additional hardware modifications required. Four mounting holes [4.2mm/0.165”] at all four corners allow simple installation by using mounting screws. For most applications, a nice stylish casing is all that is needed to turn the Clicker 4 development board into a fully functional, custom design.

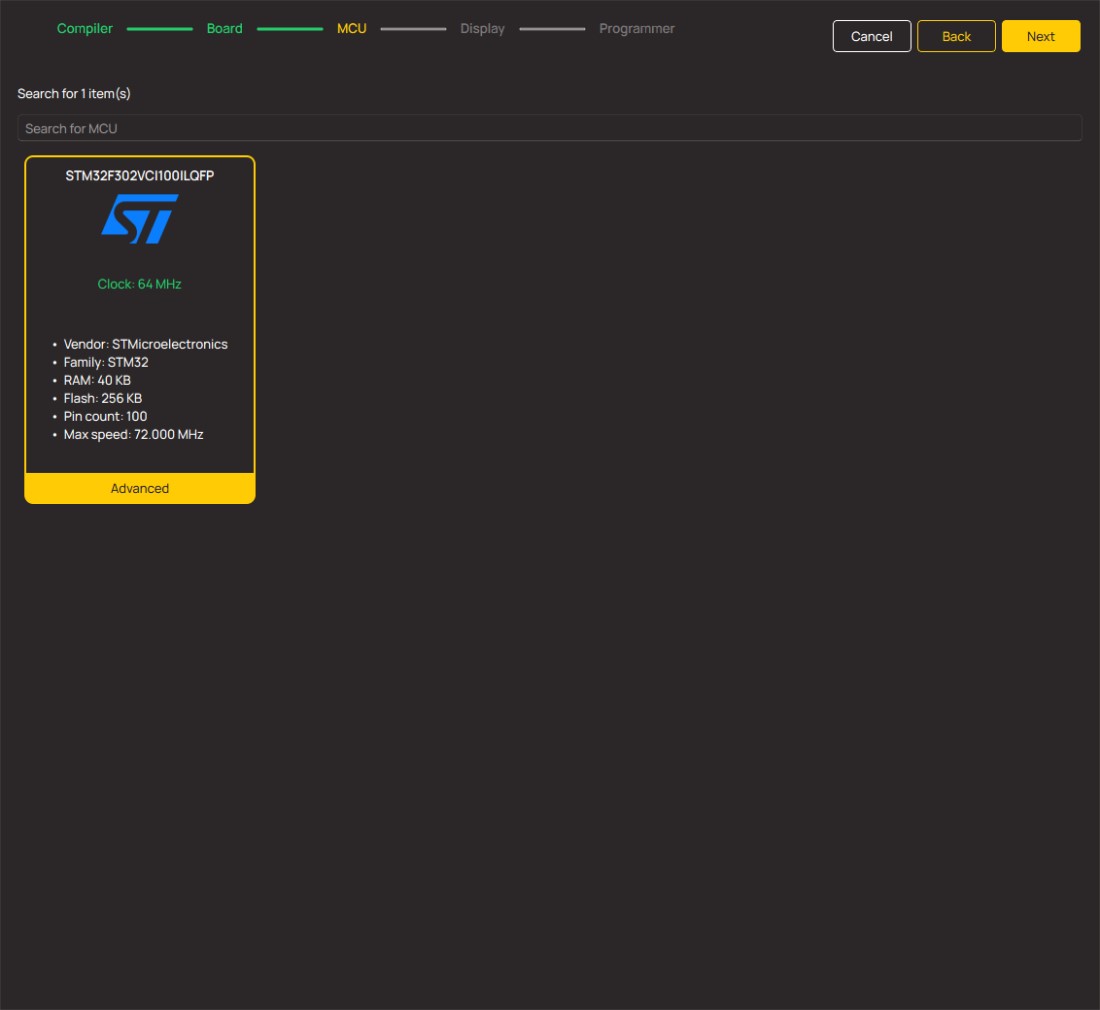

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

256

Silicon Vendor

STMicroelectronics

Pin count

100

RAM (Bytes)

40960

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

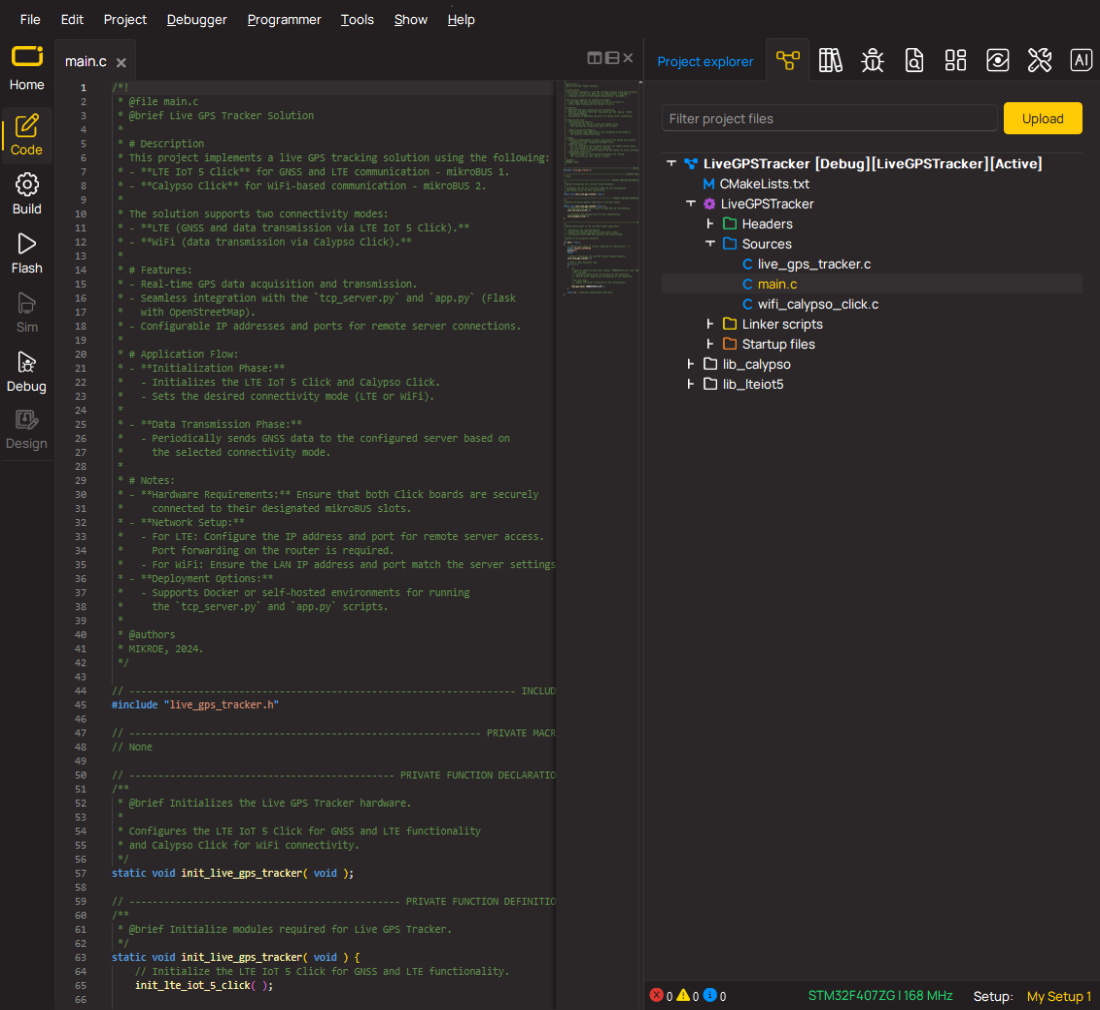

Software Support

Library Description

This library contains API for DIGI POT 12 Click driver.

Key functions:

digipot12_set_resistance- DIGI POT 12 set the resistance function.digipot12_get_resistance- DIGI POT 12 get the resistance function.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief DIGI POT 12 Click example

*

* # Description

* This library contains API for DIGI POT 12 Click driver.

* The demo application uses a digital potentiometer

* to change the resistance values of both channels.

*

* The demo application is composed of two sections :

*

* ## Application Init

* The initialization of I2C module, log UART, and additional pins.

* After the driver init, the app executes a default configuration.

*

* ## Application Task

* This example demonstrates the use of the DIGI POT 12 Click board™.

* The demo application iterates through the entire wiper range and

* sets the resistance of both channels in steps of approximately 1kOhm.

* Results are being sent to the UART Terminal, where you can track their changes.

*

* @author Nenad Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "digipot12.h"

static digipot12_t digipot12;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

digipot12_cfg_t digipot12_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

digipot12_cfg_setup( &digipot12_cfg );

DIGIPOT12_MAP_MIKROBUS( digipot12_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == digipot12_init( &digipot12, &digipot12_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( DIGIPOT12_ERROR == digipot12_default_cfg ( &digipot12 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

log_printf( &logger, " ----------------------------\r\n" );

Delay_ms ( 100 );

}

void application_task ( void )

{

static float res_kohm;

for ( uint8_t n_cnt = DIGIPOT12_RES_0_KOHM; n_cnt <= DIGIPOT12_RES_10_KOHM; n_cnt++ )

{

if ( DIGIPOT12_OK == digipot12_set_resistance( &digipot12, DIGIPOT12_WIPER_SEL_1, ( float ) n_cnt ) )

{

if ( DIGIPOT12_OK == digipot12_get_resistance( &digipot12, DIGIPOT12_WIPER_SEL_1, &res_kohm ) )

{

log_printf( &logger, " Rwb1 : %.2f kOhm\r\n", res_kohm );

Delay_ms ( 100 );

}

}

if ( DIGIPOT12_OK == digipot12_set_resistance( &digipot12, DIGIPOT12_WIPER_SEL_2, ( float ) ( DIGIPOT12_RES_10_KOHM - n_cnt ) ) )

{

if ( DIGIPOT12_OK == digipot12_get_resistance( &digipot12, DIGIPOT12_WIPER_SEL_2, &res_kohm ) )

{

log_printf( &logger, " Rwb2 : %.2f kOhm\r\n", res_kohm );

Delay_ms ( 100 );

}

}

log_printf( &logger, " ----------------------------\r\n" );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Digital potentiometer