Unifying speed and reliability, our high-speed CAN FD transceiver establishes unprecedented standards in automotive diagnostic applications

A

A

Hardware Overview

How does it work?

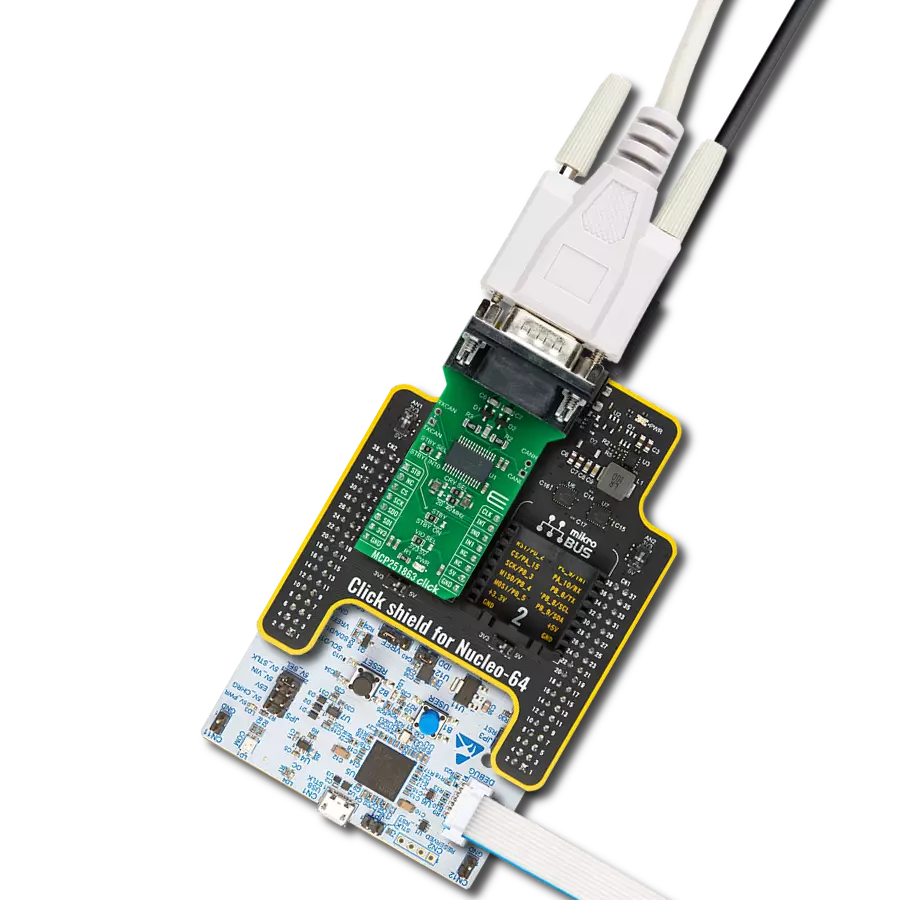

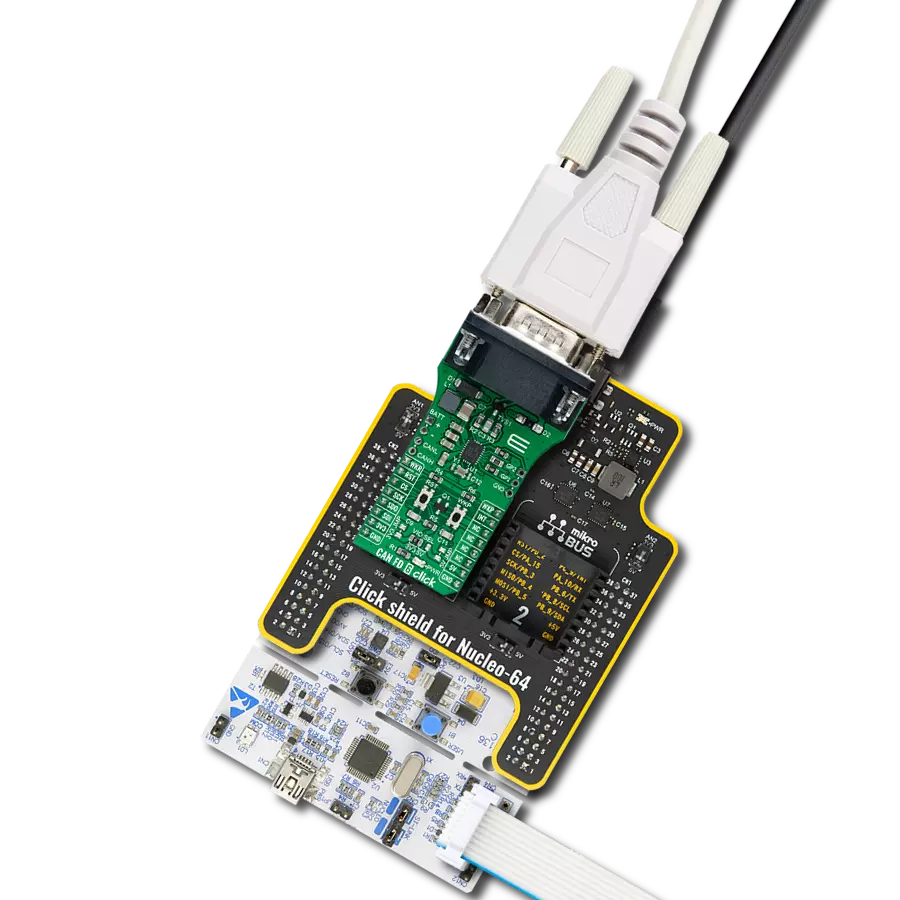

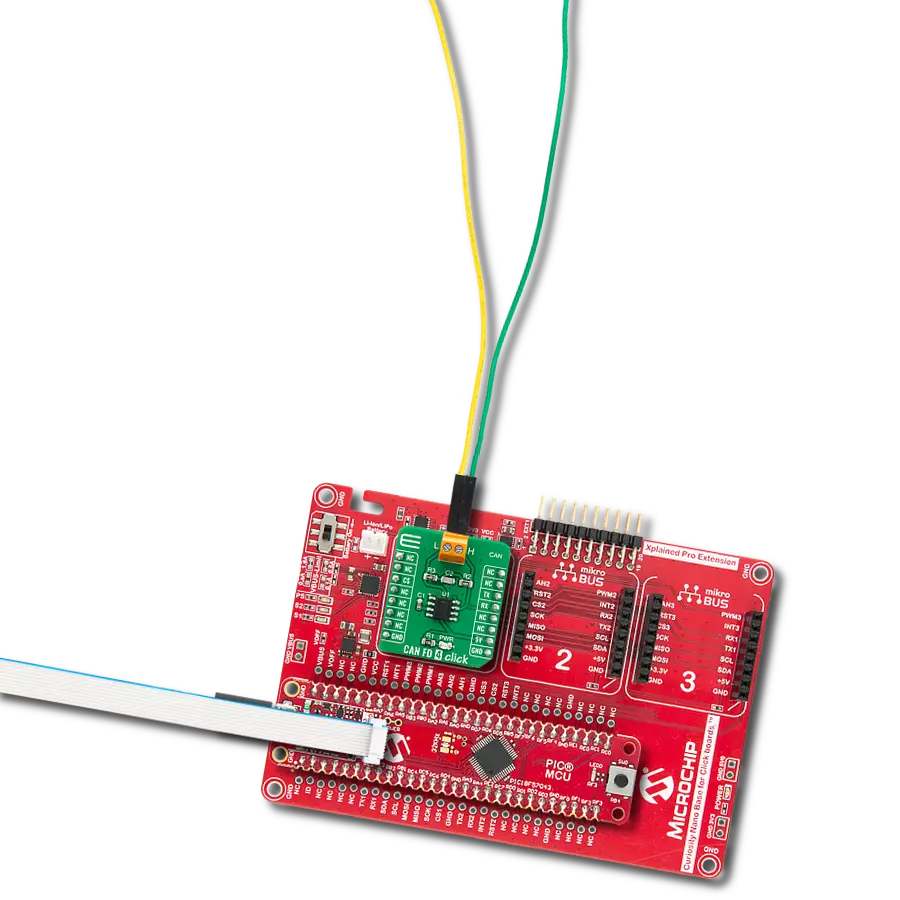

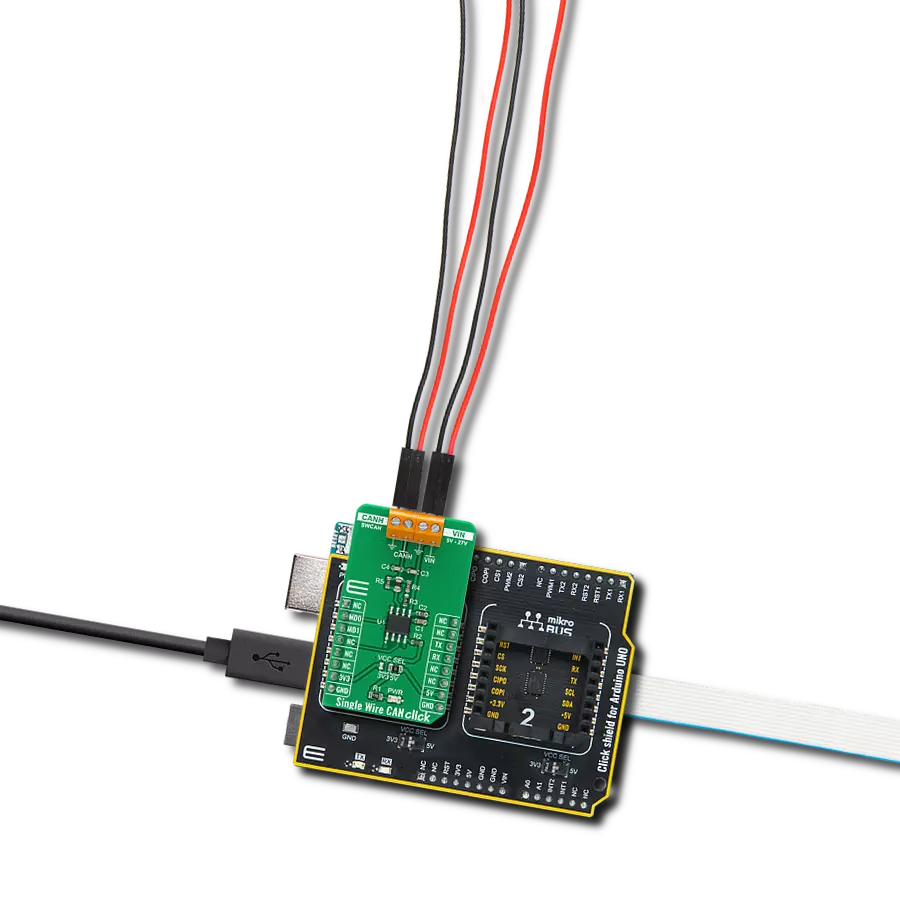

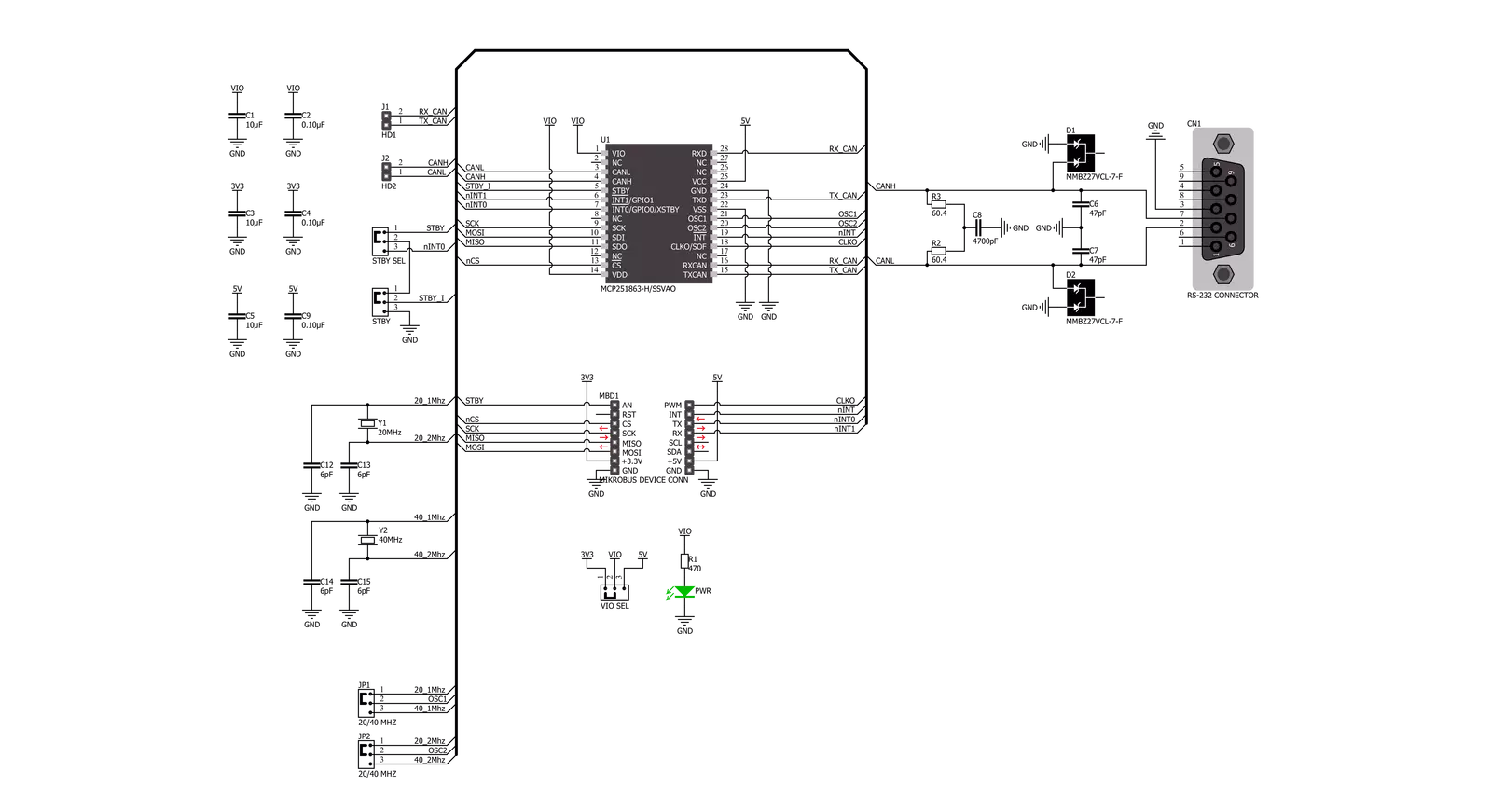

MCP251863 Click is based on the MCP251863, an IC representing a compact solution containing a CAN FD controller with an SPI interface and a high-speed CAN transceiver from Microchip. The high-speed CAN transceiver provides a physical connection with the CAN bus, while the CAN controller represents an interface between the MCU and the transceiver. The role of the CAN controller is to provide arbitration, message framing, message validation, error detection, message filtering, and more. Among all other tasks, it offers formatted CAN data for the application layer running on the host MCU. The MCP251863 communicates with MCU using the SPI interface, allowing communication speeds up to 5Mbps and supporting Normal and Standby operational modes. Normal mode is engaged when the STB pin, routed on the AN pin of the mikroBUS™ socket, is at the logic low level while its transmit pin is held to a high logic level. While in the Normal mode, the data can be sent and received via the CAN H/L bus lines. The mode

selection can be performed by positioning the SMD jumper labeled as STBY to an appropriate position marked as STBY or ON. In Standby mode, if the STBY jumper is set to the STBY position, the user has the option of activating the Standby mode in two ways, where the selection is made by positioning the SMD jumper labeled as STBY SEL to an appropriate position marked as STBY or INT0. This way, the Standby mode can be activated via the STB pin from the mikroBUS™ socket or by the MCP251863 interrupt signal IN0 routed to the TX pin of the mikroBUS™ socket (the IN0 pin can also be used to alert the MCU about the TX events). In addition, this Click board™ also uses several pins of the mikroBUS™ socket. The CLK pin from the MCP251863 routed to the PWM pin of the mikroBUS™ socket can provide the clock output for the host MCU or represent the start of the frame signal. It is derived from the input clock generated by the onboard chip oscillators, where the onboard SMD jumpers allow frequency selection between 20MHz and 40MHz.

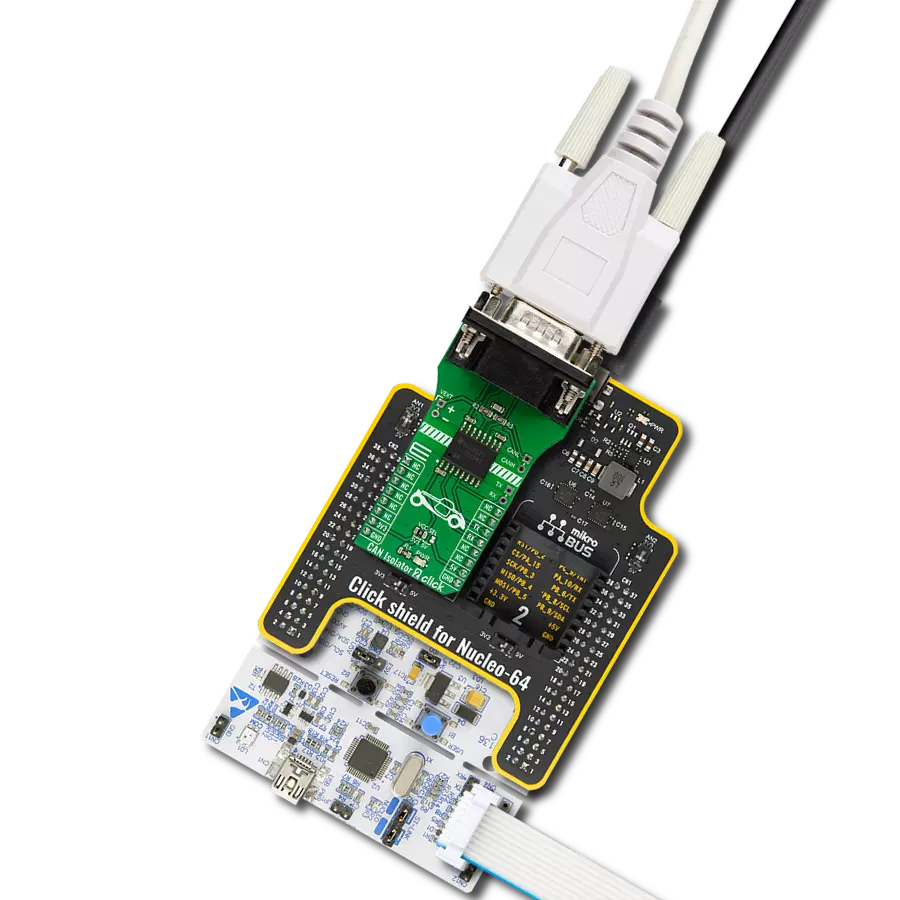

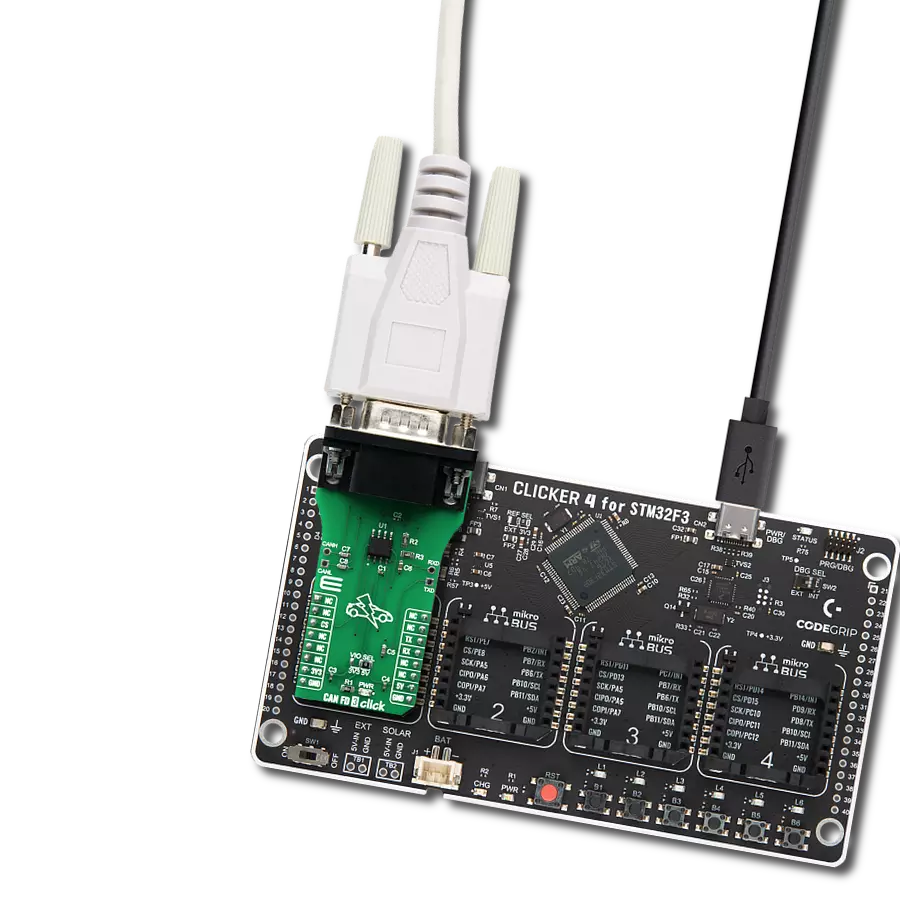

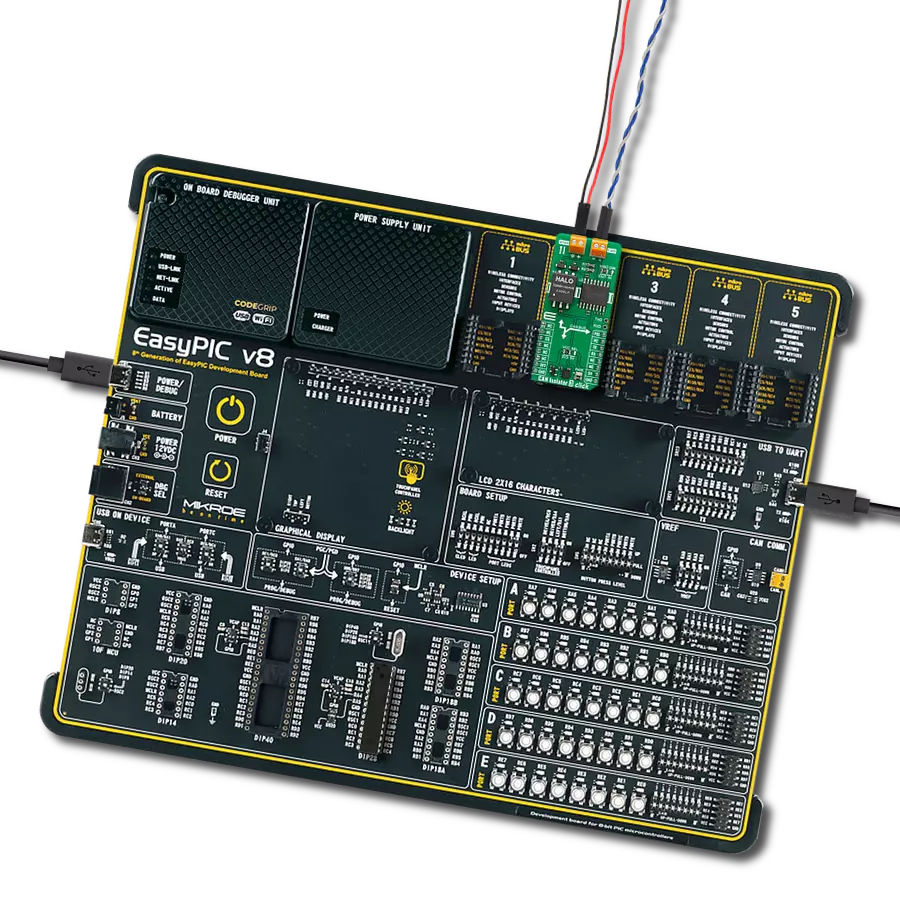

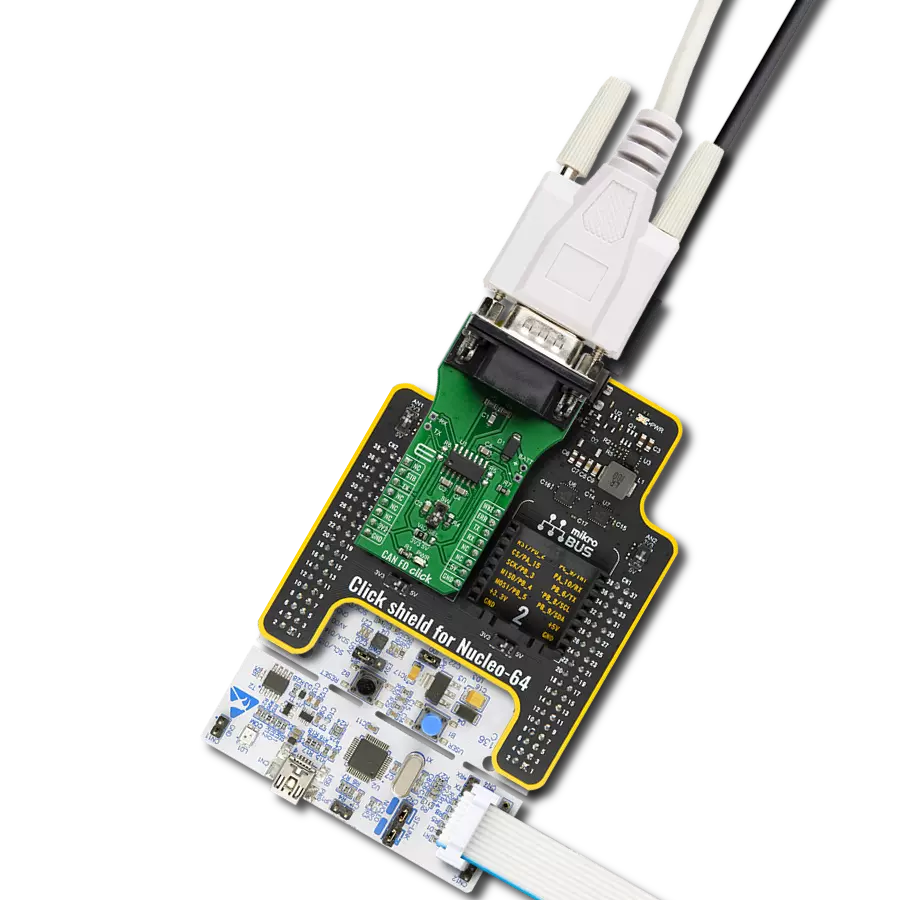

Besides, it also uses two interrupt pins, INT and INT1, routed to the INT and RX pins of the mikroBUS™ socket, respectively. While the INT pin is always an interrupt pin used to alert the MCU of the enabled interrupt event, the INT1 pin alerts the MCU about the RX events (if these interrupts are enabled). In addition, the user can connect the external TX/RX signals to the CAN FD transceiver and CAN bus signals directly through the onboard headers on the left and right sides of the board. This Click board™ comes equipped with the standard DB-9 connector, making interfacing with the CAN bus simple and easy. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VIO SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used, as a reference, for further development.

Features overview

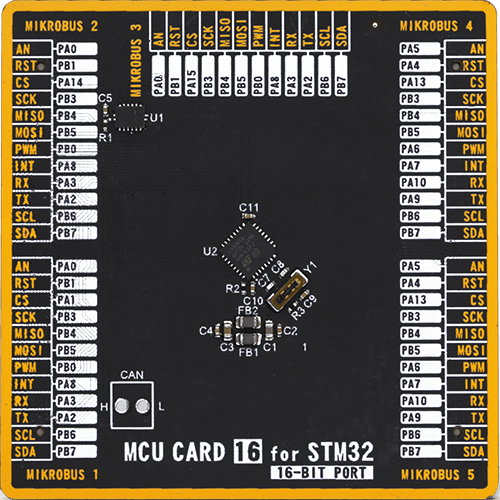

Development board

Fusion for ARM v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports a wide range of microcontrollers, such as different ARM® Cortex®-M based MCUs regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer over WiFi. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, Fusion for ARM v8 provides a fluid and immersive working experience, allowing access anywhere and under any

circumstances at any time. Each part of the Fusion for ARM v8 development board contains the components necessary for the most efficient operation of the same board. An advanced integrated CODEGRIP programmer/debugger module offers many valuable programming/debugging options, including support for JTAG, SWD, and SWO Trace (Single Wire Output)), and seamless integration with the Mikroe software environment. Besides, it also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector.

Communication options such as USB-UART, USB HOST/DEVICE, CAN (on the MCU card, if supported), and Ethernet is also included. In addition, it also has the well-established mikroBUS™ standard, a standardized socket for the MCU card (SiBRAIN standard), and two display options for the TFT board line of products and character-based LCD. Fusion for ARM v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

ARM Cortex-M4

MCU Memory (KB)

256

Silicon Vendor

STMicroelectronics

Pin count

32

RAM (Bytes)

65536

You complete me!

Accessories

DB9 Cable Female-to-Female (2m) cable is essential for establishing dependable serial data connections between devices. With its DB9 female connectors on both ends, this cable enables a seamless link between various equipment, such as computers, routers, switches, and other serial devices. Measuring 2 meters in length, it offers flexibility in arranging your setup without compromising data transmission quality. Crafted with precision, this cable ensures consistent and reliable data exchange, making it suitable for industrial applications, office environments, and home setups. Whether configuring networking equipment, accessing console ports, or utilizing serial peripherals, this cable's durable construction and robust connectors guarantee a stable connection. Simplify your data communication needs with the 2m DB9 female-to-female cable, an efficient solution designed to meet your serial connectivity requirements easily and efficiently.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for MCP251863 Click driver.

Key functions:

mcp251863_transmit_message- Transmits the desired message and checks is message successfully sentmcp251863_receive_message- Receives the message and checks is message successfully receivedmcp251863_operation_mode_select- Function for select operation mode

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief MCP251863 Click example

*

* # Description

* This example demonstrates the use of an MCP251863 Click board by showing

* the communication between the two Click boards configured as a receiver and transmitter.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and logger, performs the Click default configuration and

* displays the selected application mode.

*

* ## Application Task

* Depending on the selected mode, it sends a desired message using CAN protocol or

* reads all the received data and displays them on the USB UART.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "mcp251863.h"

// #define DEMO_APP_TRANSMITTER // Uncomment this line to switch to the transmitter mode

#define DEMO_TEXT_MESSAGE "MikroE"

static mcp251863_t mcp251863;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

mcp251863_cfg_t mcp251863_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

mcp251863_cfg_setup( &mcp251863_cfg );

MCP251863_MAP_MIKROBUS( mcp251863_cfg, MIKROBUS_1 );

if ( SPI_MASTER_ERROR == mcp251863_init( &mcp251863, &mcp251863_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( MCP251863_ERROR == mcp251863_default_cfg ( &mcp251863 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

#ifdef DEMO_APP_TRANSMITTER

log_printf( &logger, " Application Mode: Transmitter\r\n" );

#else

log_printf( &logger, " Application Mode: Receiver\r\n" );

#endif

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

#ifdef DEMO_APP_TRANSMITTER

if ( MCP251863_OK == mcp251863_transmit_message( &mcp251863, DEMO_TEXT_MESSAGE, strlen( DEMO_TEXT_MESSAGE ) ) )

{

log_printf( &logger, " The message \"%s\" has been sent!\r\n", ( char * ) DEMO_TEXT_MESSAGE );

}

Delay_ms ( 1000 );

Delay_ms ( 1000 );

#else

uint8_t data_buf[ 256 ] = { 0 };

uint16_t data_len = 0;

if ( MCP251863_OK == mcp251863_receive_message( &mcp251863, data_buf, &data_len ) )

{

log_printf( &logger, " A new message has received: \"" );

for ( uint16_t cnt = 0; cnt < data_len; cnt++ )

{

log_printf( &logger, "%c", data_buf[ cnt ] );

}

log_printf( &logger, "\"\r\n" );

}

#endif

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:CAN