This innovative product unlocks new possibilities in I2C connectivity, inspiring users to explore and unleash the full potential of 8-pin connections, fostering innovation and creativity in electronics projects.

A

A

Hardware Overview

How does it work?

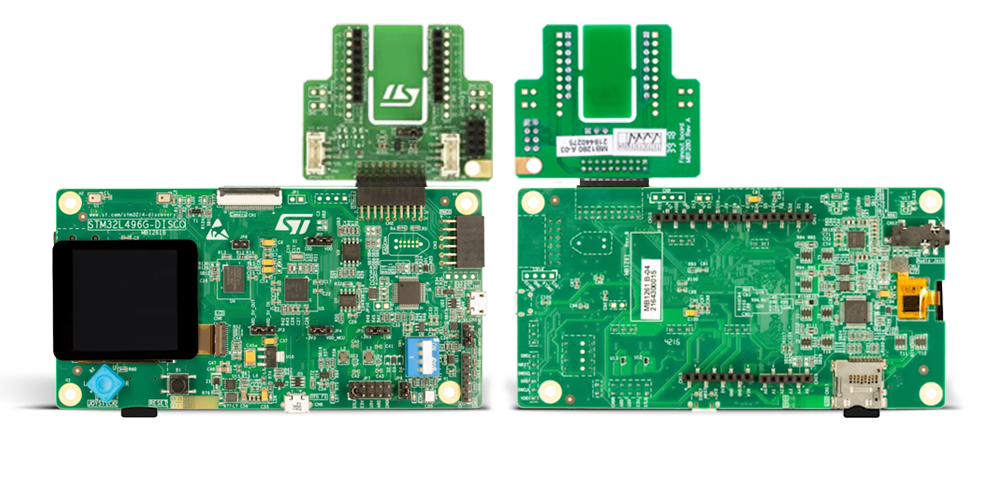

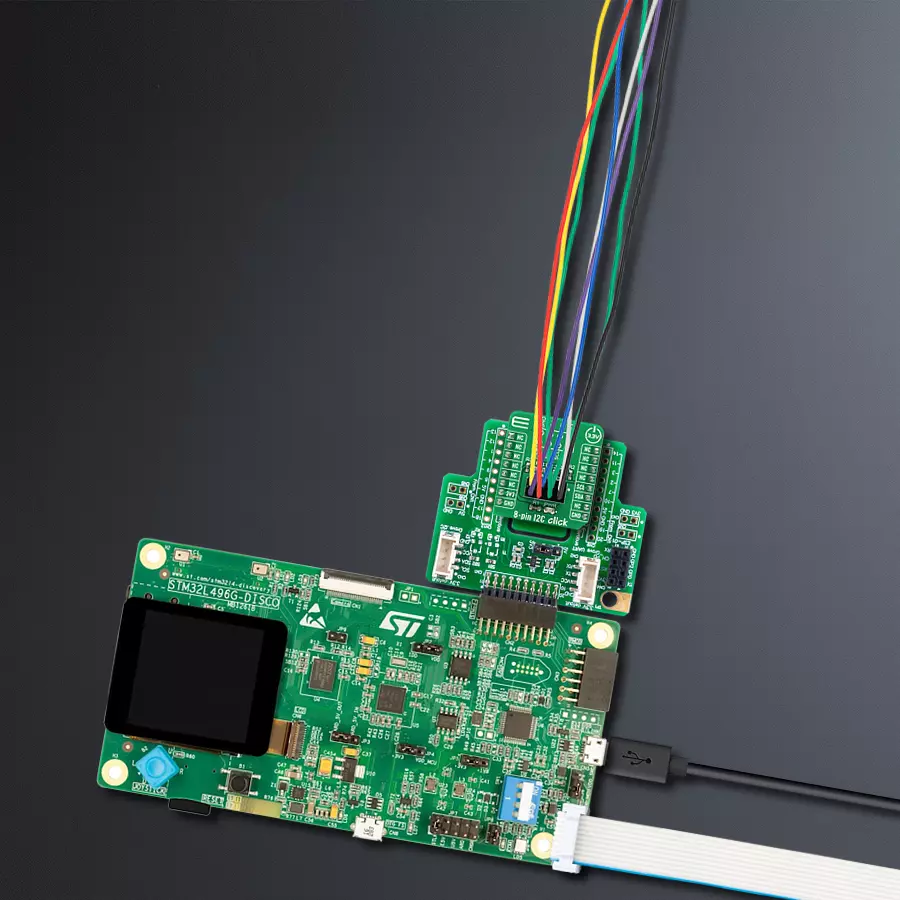

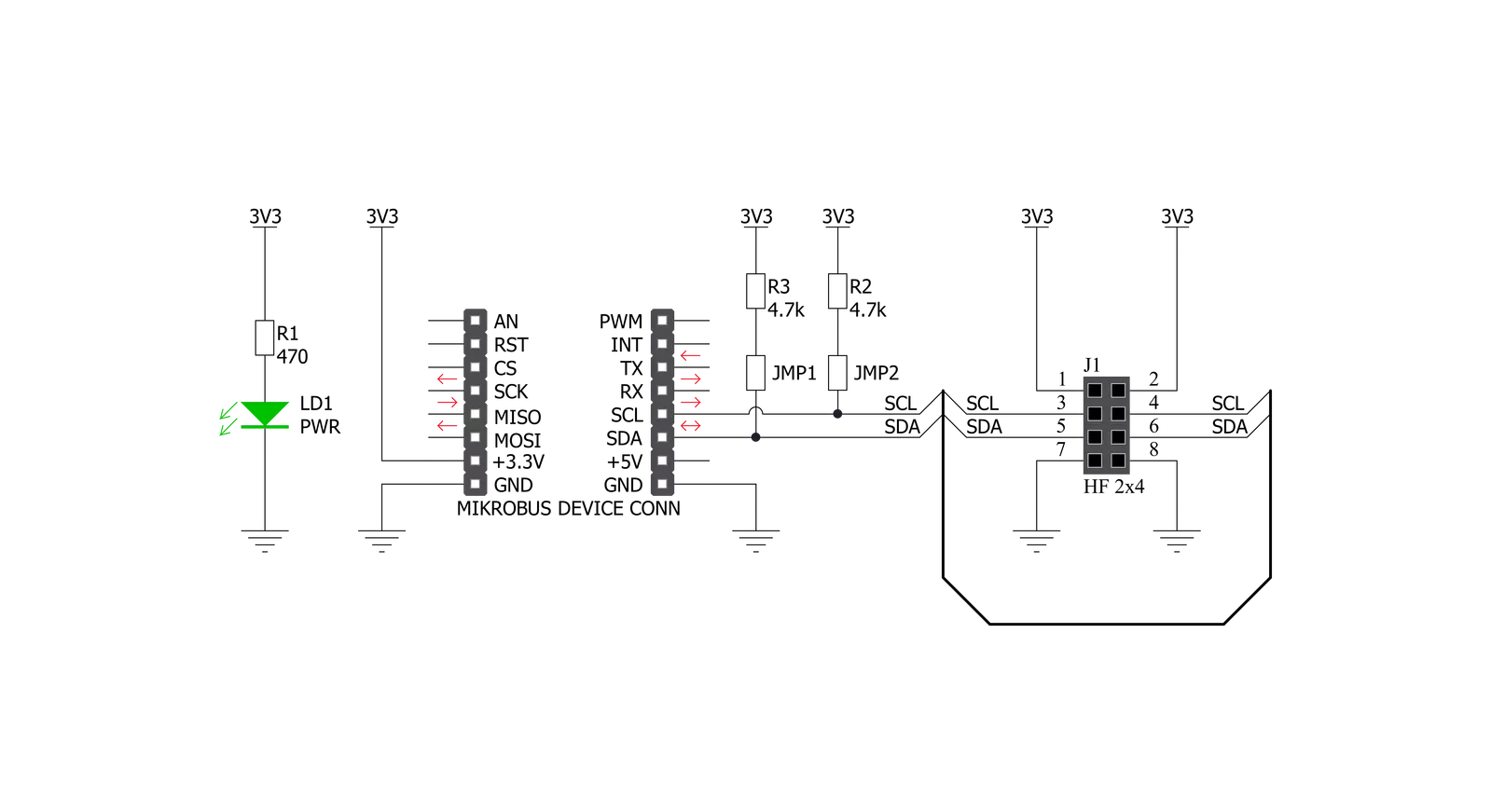

8-pin I2C Click is an adapter Click board™ that simplifies the connection of add-on boards to the mikroBUS™ socket. This Click board™ represents a small-size PCB that can be connected to the mikroBUS™ socket like any other Click board™, with a 2x4 female header placed on itself. Each header pin corresponds to a pin on the mikroBUS™ socket, such as I2C lines (SCL, SDA) with two jumpers for I2C lines pull-up function selection, 3V3 power supply, and ground. This Click board™ allows easy pin access and manipulation while always retaining a perfect connection

quality. Being compatible with Apple's MFI is the most important feature of the 8-pin I2C Click board™, which ensures its proper operation with additional Apple accessories. The name is a shortened version of the long-form Made for iPod, the original program that ultimately became MFI which refers to peripherals that work with Apple's iPod, iPad, and iPhone. 8-pin I2C Click communicates with MCU using the standard I2C 2-Wire interface. Lines of the mikroBUS™ to which this Click board™ is attached are shared through the top 8-pin female header, which mirrors

the pins of the connected mikroBUS™ socket. The 8-pin I2C Click also shares the 3V3 power rails, making it compatible with other power-compatible Click board™ and development systems. This Click board™ can only be operated with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. However, the Click board™ comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

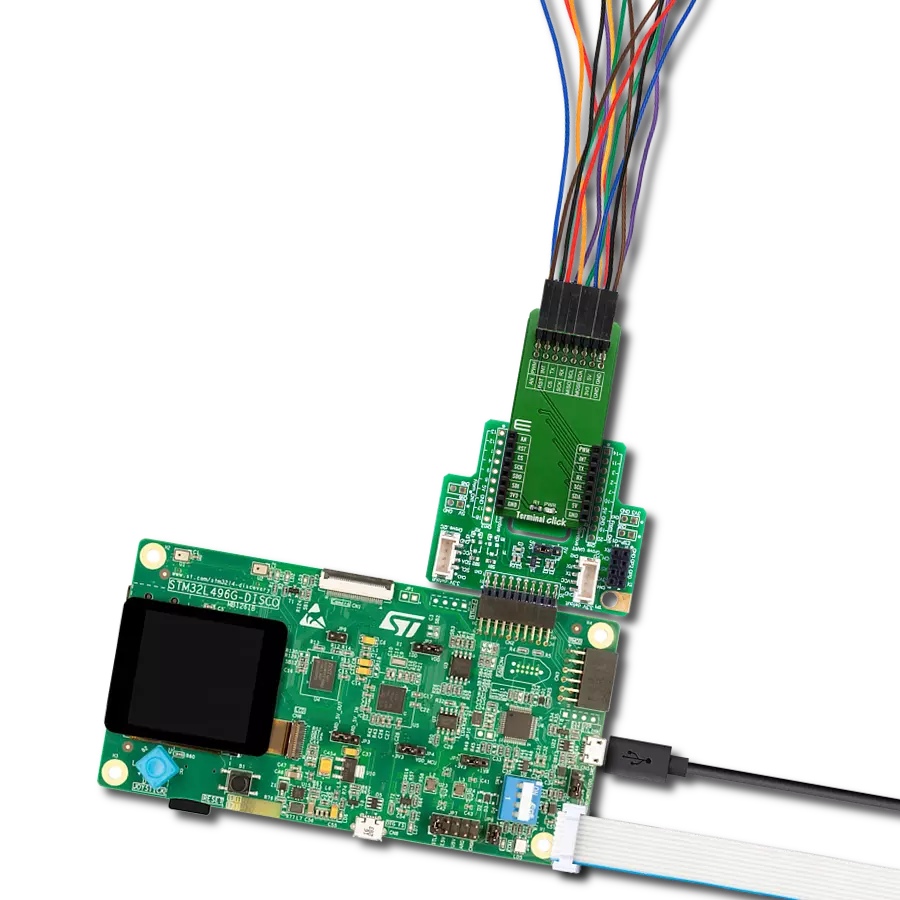

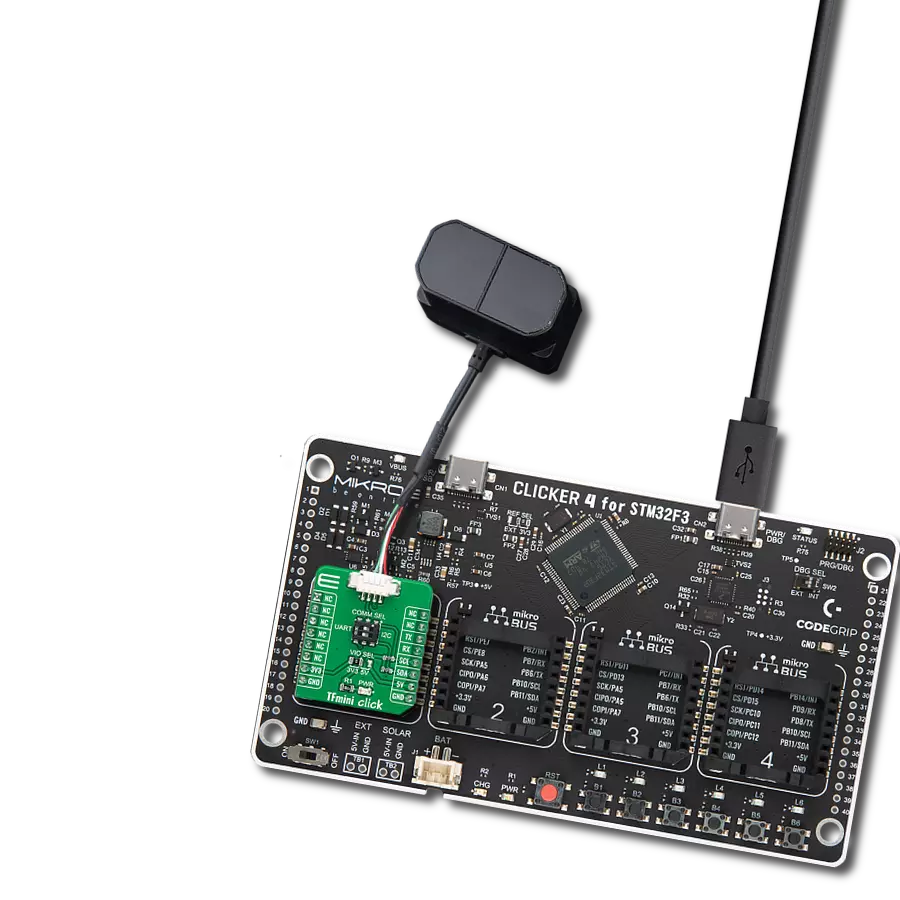

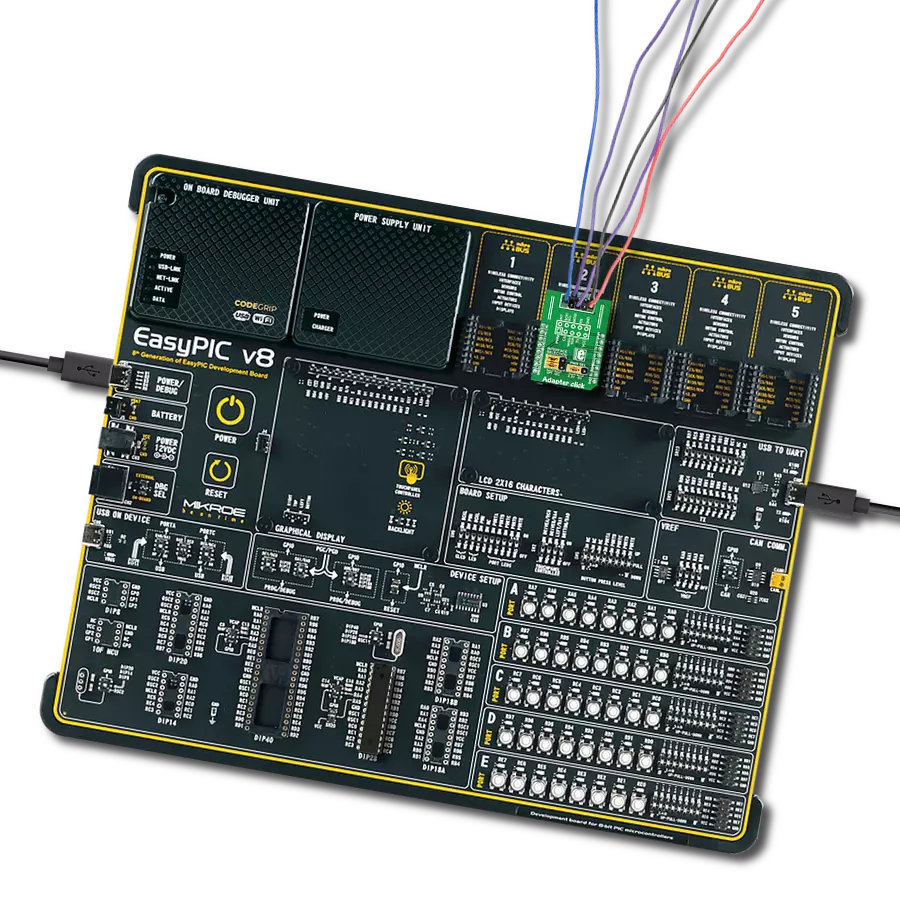

Development board

The 32L496GDISCOVERY Discovery kit serves as a comprehensive demonstration and development platform for the STM32L496AG microcontroller, featuring an Arm® Cortex®-M4 core. Designed for applications that demand a balance of high performance, advanced graphics, and ultra-low power consumption, this kit enables seamless prototyping for a wide range of embedded solutions. With its innovative energy-efficient

architecture, the STM32L496AG integrates extended RAM and the Chrom-ART Accelerator, enhancing graphics performance while maintaining low power consumption. This makes the kit particularly well-suited for applications involving audio processing, graphical user interfaces, and real-time data acquisition, where energy efficiency is a key requirement. For ease of development, the board includes an onboard ST-LINK/V2-1

debugger/programmer, providing a seamless out-of-the-box experience for loading, debugging, and testing applications without requiring additional hardware. The combination of low power features, enhanced memory capabilities, and built-in debugging tools makes the 32L496GDISCOVERY kit an ideal choice for prototyping advanced embedded systems with state-of-the-art energy efficiency.

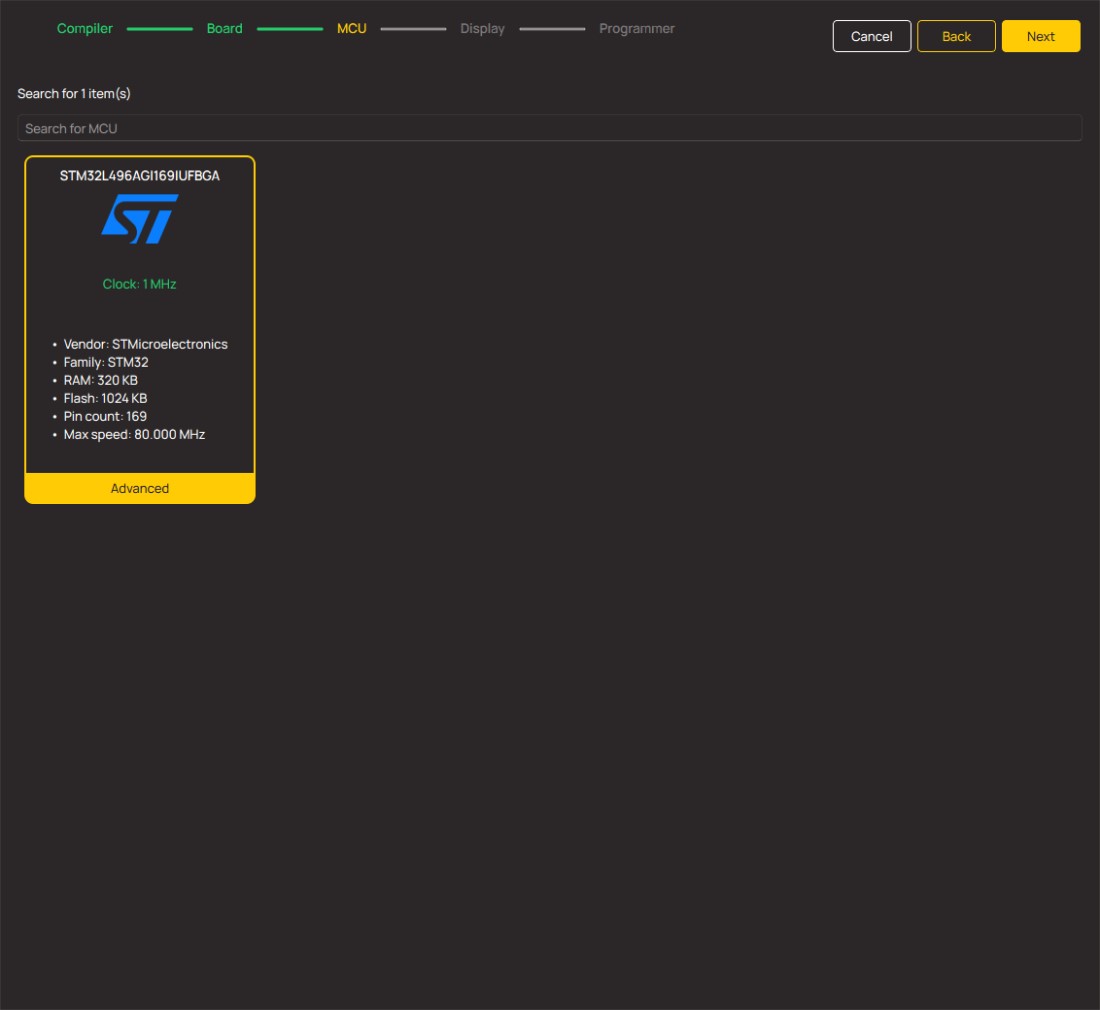

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

STMicroelectronics

Pin count

169

RAM (Bytes)

327680

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

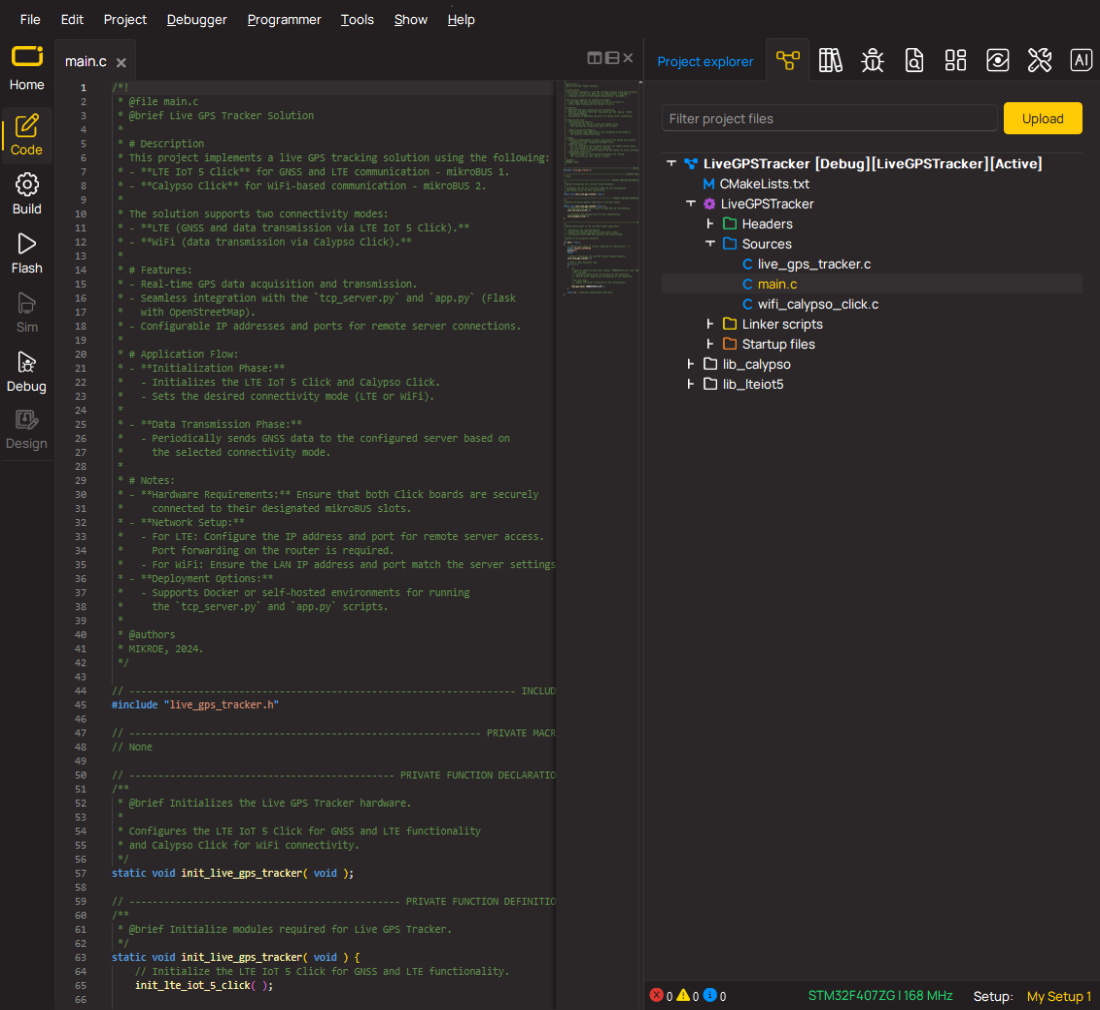

Software Support

Library Description

This library contains API for 8-pin I2C Click driver.

Key functions:

c8pini2c_generic_write- Generic write function.c8pini2c_generic_read- Generic read function.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief 8pinI2c Click example

*

* # Description

* This demo example reads temperature detected by Surface temp Click board.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and configures a Surface temp Click board.

*

* ## Application Task

* Reads the temperature detected by Surface temp Click board and

* logs it on the USB UART each second.

*

* @note

* In order to run this example successfully, a Surface temp Click board needs to be

* connected properly to an 8-pin I2C Click board.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "c8pini2c.h"

// ------------------------------------------------------------------ VARIABLES

static c8pini2c_t c8pini2c;

static log_t logger;

// Surface temp Click - example

#define SURFACE_TEMP_DEVICE_SLAVE_ADDRESS 0x48

#define SURFACE_TEMP_REG_SOFT_RESET 0x2F

#define SURFACE_TEMP_REG_ID 0x0B

#define SURFACE_TEMP_REG_CONFIG 0x03

#define SURFACE_TEMP_REG_TEMP_MSB 0x00

// ------------------------------------------------------- ADDITIONAL FUNCTIONS

void surfacetemp_soft_reset ( )

{

uint8_t tx_data;

tx_data = SURFACE_TEMP_REG_SOFT_RESET;

c8pini2c_generic_write ( &c8pini2c, SURFACE_TEMP_DEVICE_SLAVE_ADDRESS,

0, &tx_data, 1 );

}

uint8_t surfacetemp_setup ( )

{

uint8_t tmp;

surfacetemp_soft_reset( );

Delay_100ms( );

c8pini2c_generic_read( &c8pini2c, SURFACE_TEMP_DEVICE_SLAVE_ADDRESS,

SURFACE_TEMP_REG_ID, &tmp, 1 );

if ( tmp != 0xCB )

{

return 1;

}

tmp = 0x93;

c8pini2c_generic_write( &c8pini2c, SURFACE_TEMP_DEVICE_SLAVE_ADDRESS,

SURFACE_TEMP_REG_CONFIG, &tmp, 1 );

return 0;

}

float surfacetemp_get_temperature ( )

{

uint8_t rx_buff[ 2 ];

int16_t temp;

float temperature;

c8pini2c_generic_read( &c8pini2c, SURFACE_TEMP_DEVICE_SLAVE_ADDRESS,

SURFACE_TEMP_REG_TEMP_MSB, &rx_buff[ 0 ], 2 );

temp = rx_buff[ 0 ];

temp <<= 8;

temp |= rx_buff[ 1 ];

temp &= 0xFFF8;

temperature = (float)(temp);

temperature *= 0.0078;

return temperature;

}

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

c8pini2c_cfg_t cfg;

uint8_t status;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

c8pini2c_cfg_setup( &cfg );

C8PINI2C_MAP_MIKROBUS( cfg, MIKROBUS_1 );

c8pini2c_init( &c8pini2c, &cfg );

status = surfacetemp_setup( );

if ( status == 0 )

{

log_printf( &logger, "--- INIT DONE --- \r\n" );

}

else

{

log_printf( &logger, "--- INIT ERROR --- \r\n" );

for( ; ; );

}

}

void application_task ( void )

{

float temperature;

temperature = surfacetemp_get_temperature( );

log_printf( &logger, "> Temperature : %.2f Celsius\r\n", temperature );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Adapter