See how our OLED solution empowers you to push the boundaries of design, functionality, and energy efficiency, making your products stand out in the market

A

A

Hardware Overview

How does it work?

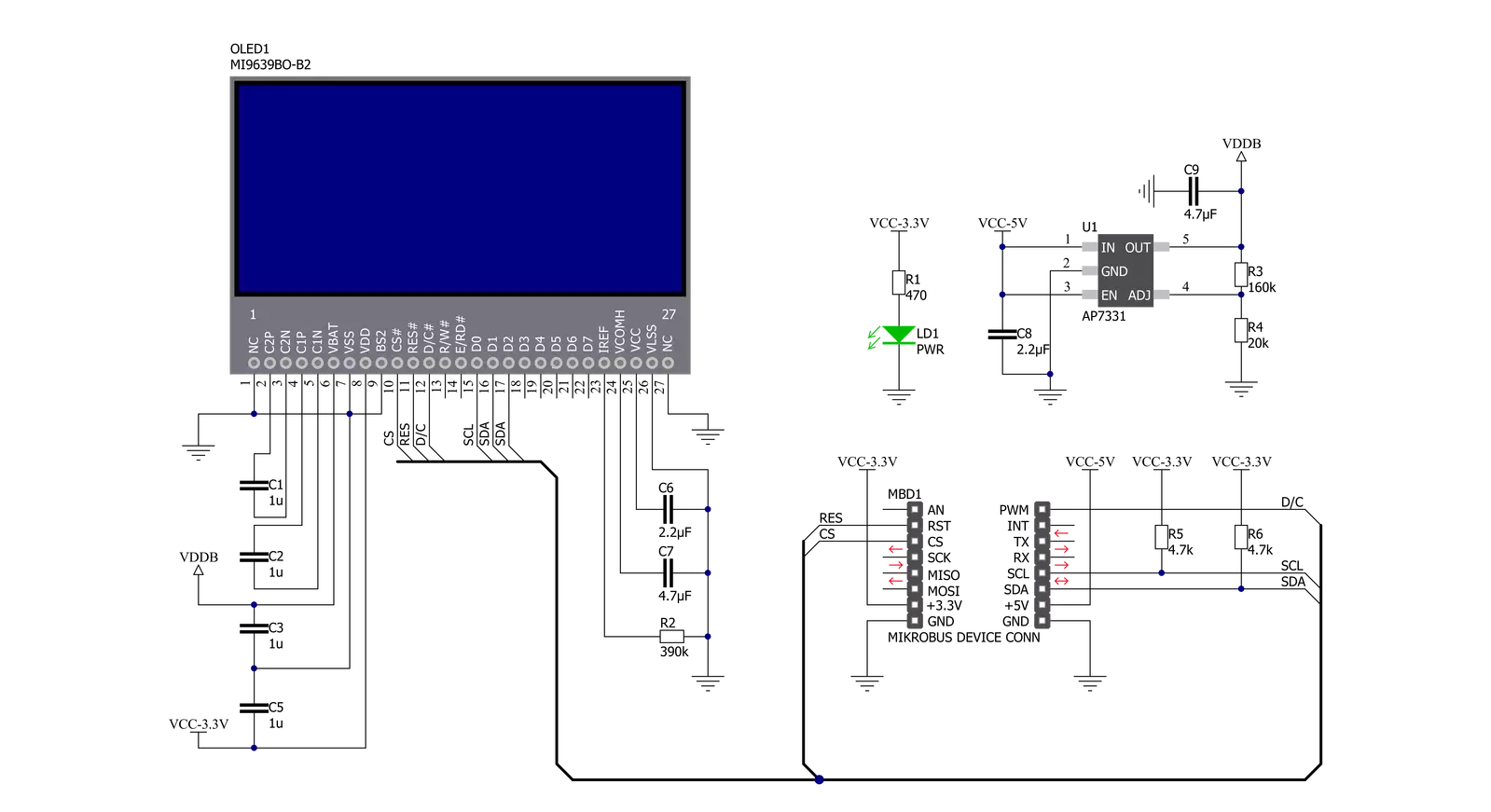

OLED B Click is based on the MI9639BO-B2, a 19.3x7.8mm 96x39px light blue monochrome passive matrix OLED display from Multi-Inno Technology. The MI9639BO-B2 display features an SSD1306, a 128x64 dot-matrix OLED/PLED segment/common driver with a controller. The controller has built-in functionalities like contrast control (256-step brightness control), normal or inverse image display, vertical and horizontal scrolling functions, and much more accessible through the I2C serial interface. OLEDs are emissive and don't require a separate backlight as LCD technology does, reducing the OLED display's overall power consumption compared to LCDs. It also does not suffer from loss of contrast due to bleed-through of the backlight in the "off" pixels. OLEDs, being emissive, have a consistent contrast ratio greater than 100:1 with no limitation in viewing angle. In addition, they don't suffer from temperature-related response time delays and

contrast changes. Like any OLED display, the MI9639BO-B2 is made from a thin film of an organic compound that emits light when exposed to a current. A small monochrome display like this represents an ideal solution for displaying text or icons. The MI9639BO-B2 display is bright, has a wide viewing angle, and has low power consumption. In addition to the display's main power supply, taken from the +3.3V microBUS™ power rail, the MI9639BO-B2 has another power pin, more precisely, the power supply for the DC/DC converter circuit. This pin is the power supply pin for the internal buffer of the DC/DC voltage converter. Therefore, for this pin, the Click board™ uses a low dropout linear regulator AP7331 from Diodes Incorporated, providing a 3.6V power supply out of 5V mikroBUS™ rail. OLED B Click communicates with MCU using the standard I2C 2-Wire interface to read data and configure settings. It allows the communication-enable

feature to be routed to the CS pin of the mikroBUS™ socket, enabling the OLED B Click for MCU communication only when the CS pin is pulled to a low logic state. In addition, it has two more pins. The first is related to the reset function, routed to the RST pin on the mikroBUS™ socket (when the pin is in a low logic state, the initialization of the chip is executed), and the second is labeled as D/C and routed to the PWM pin on the mikroBUS™ socket is I2C slave address selection pin. This Click board™ is designed to be operated only with a 3.3V logic voltage level, while 5V is used as a supply voltage of the AP7331 LDO. The board must perform appropriate logic voltage level conversion before use with MCUs with different logic levels. However, the Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

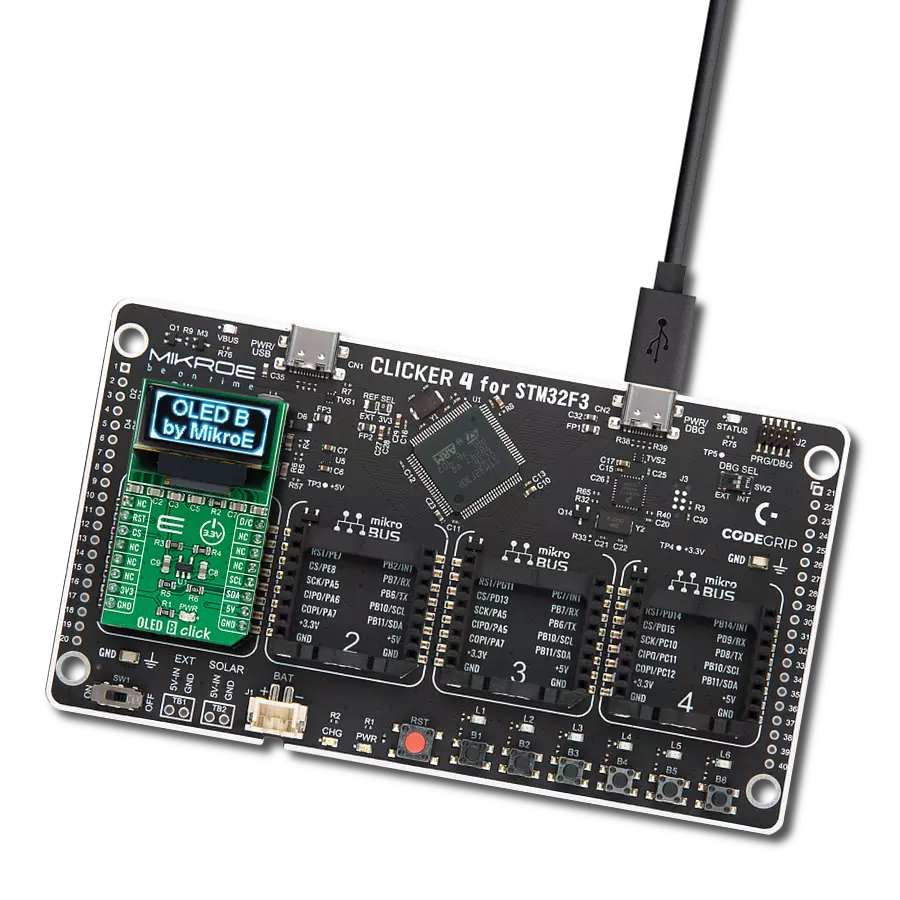

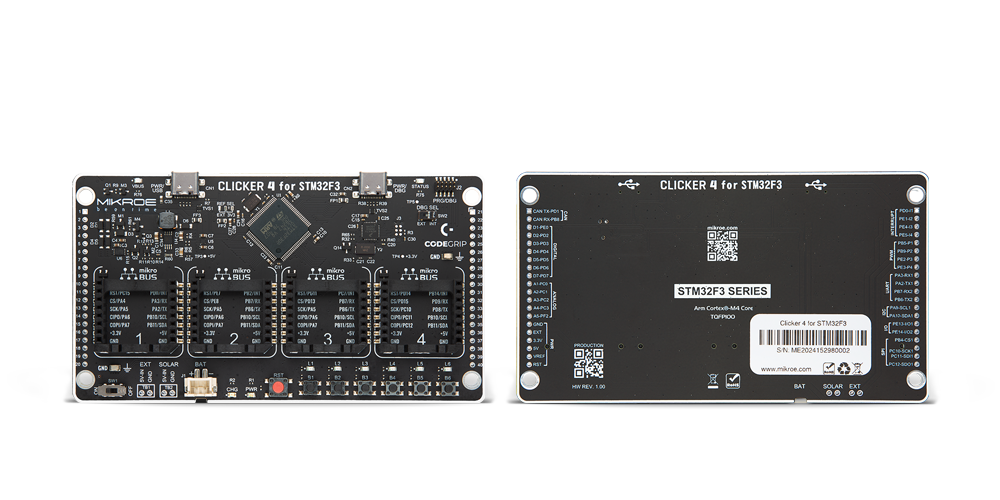

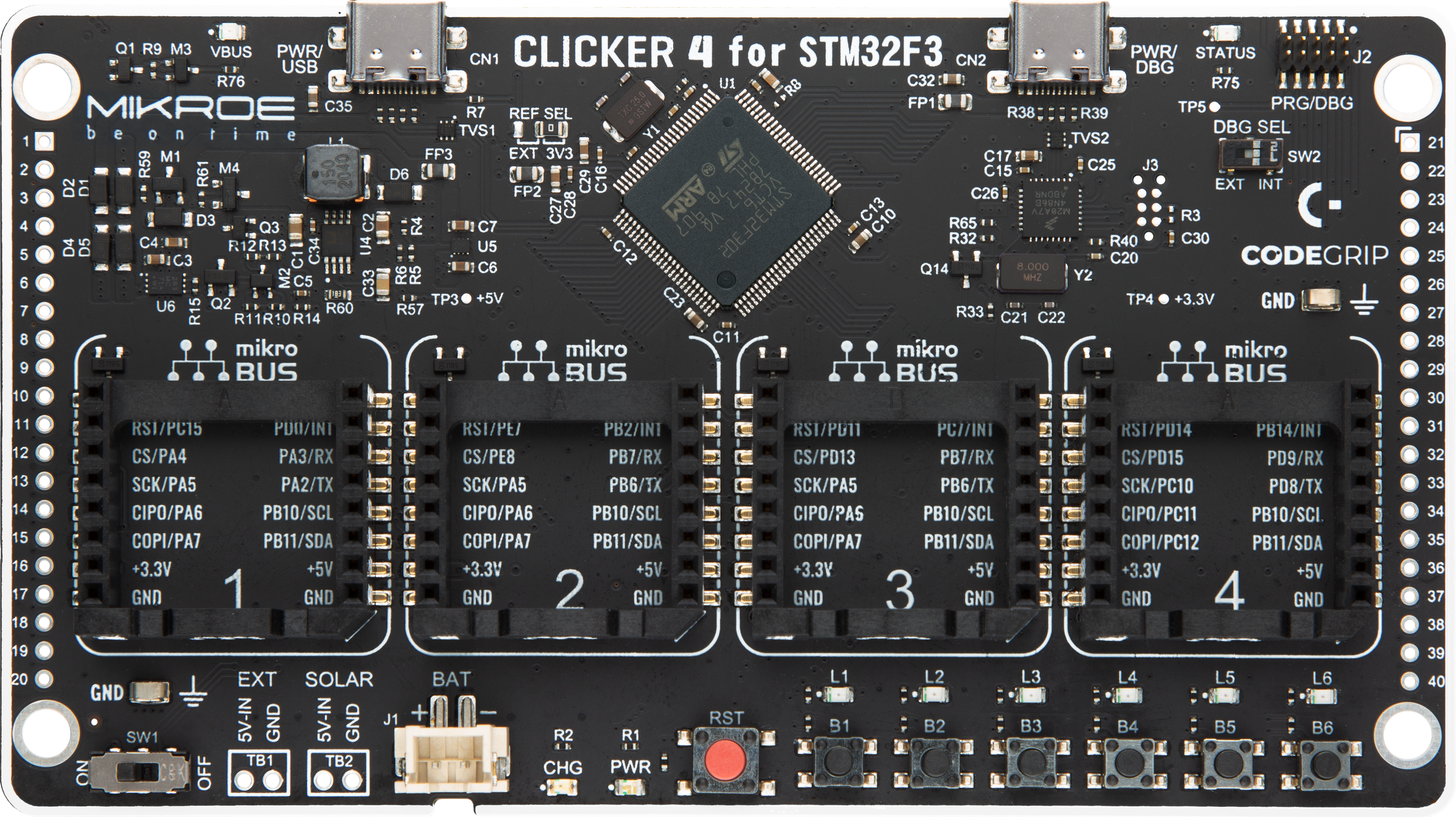

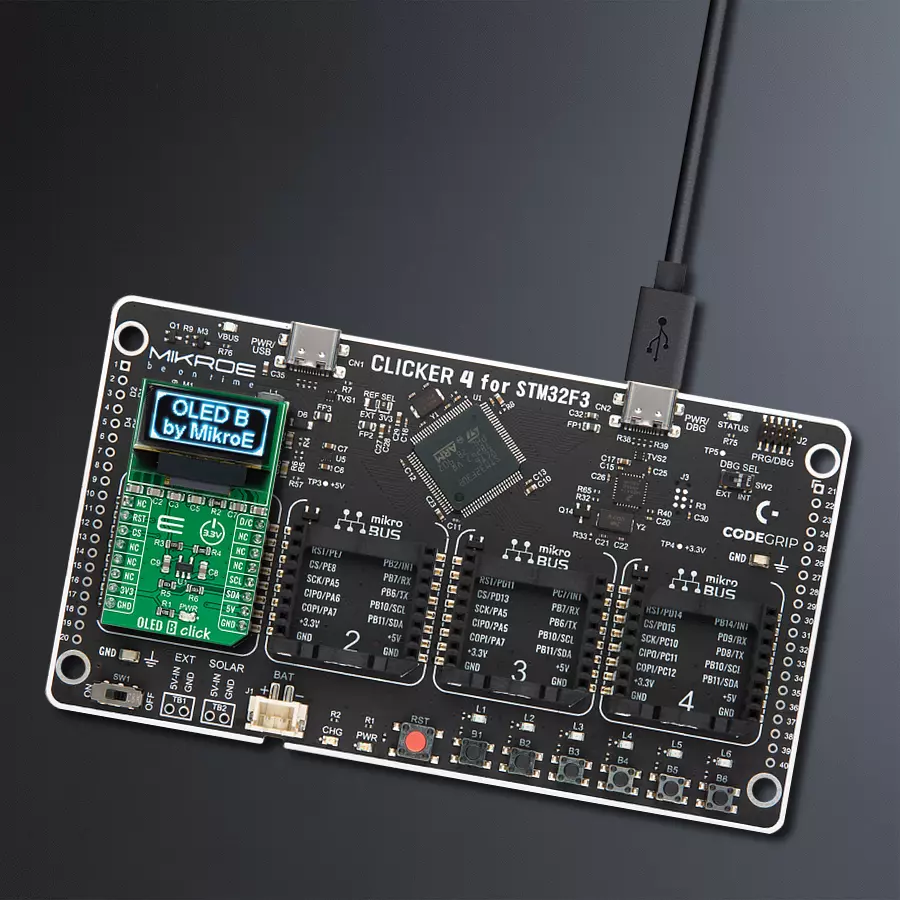

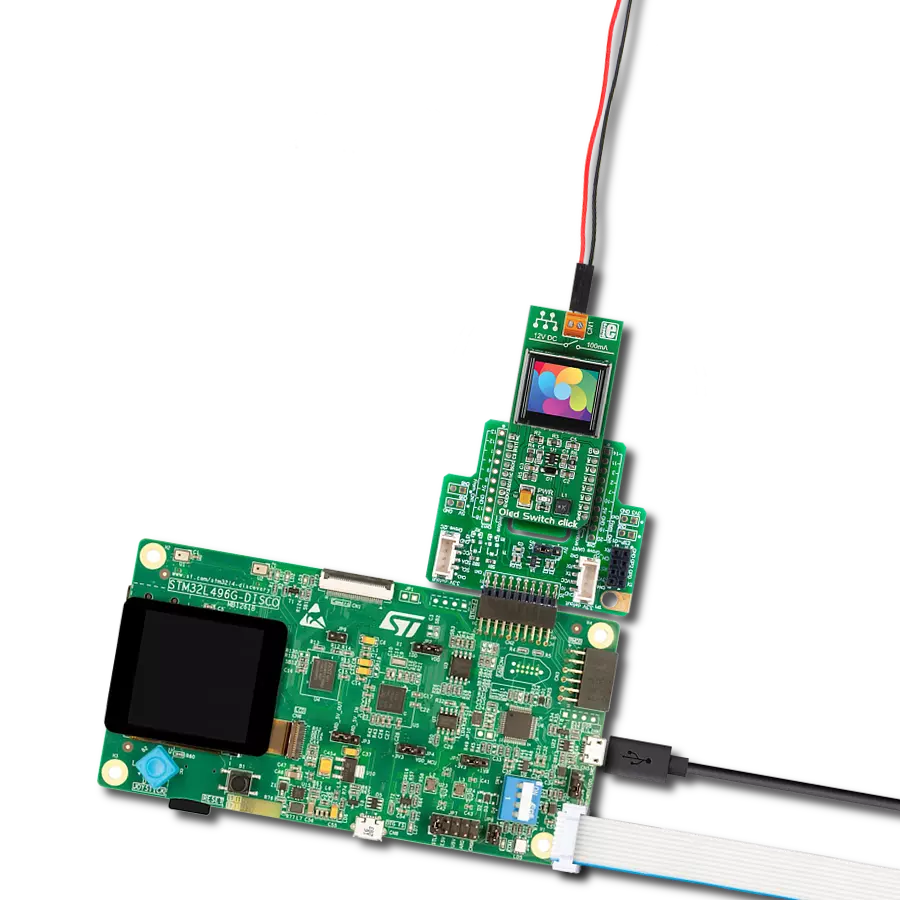

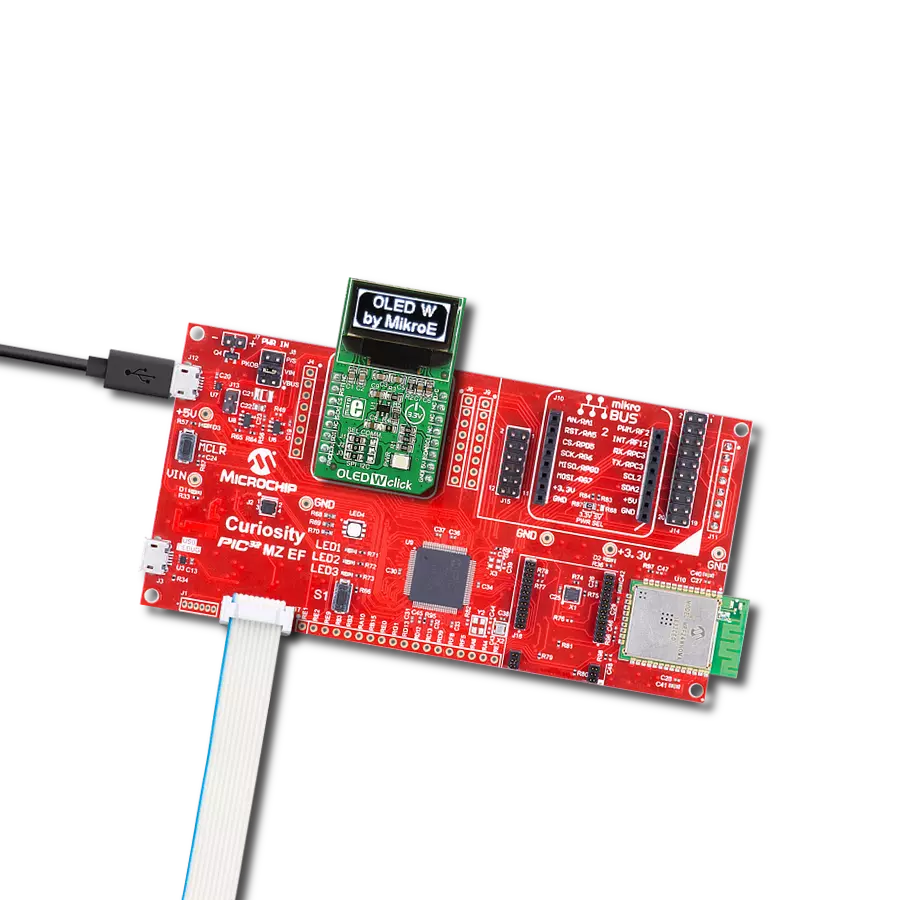

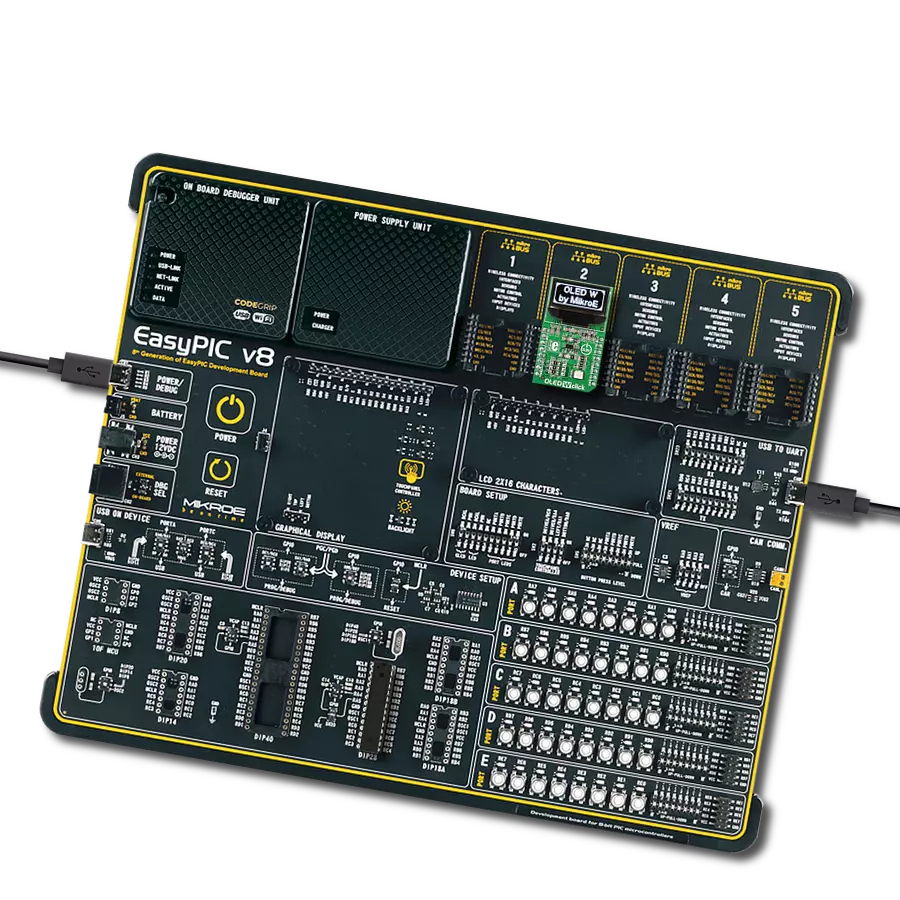

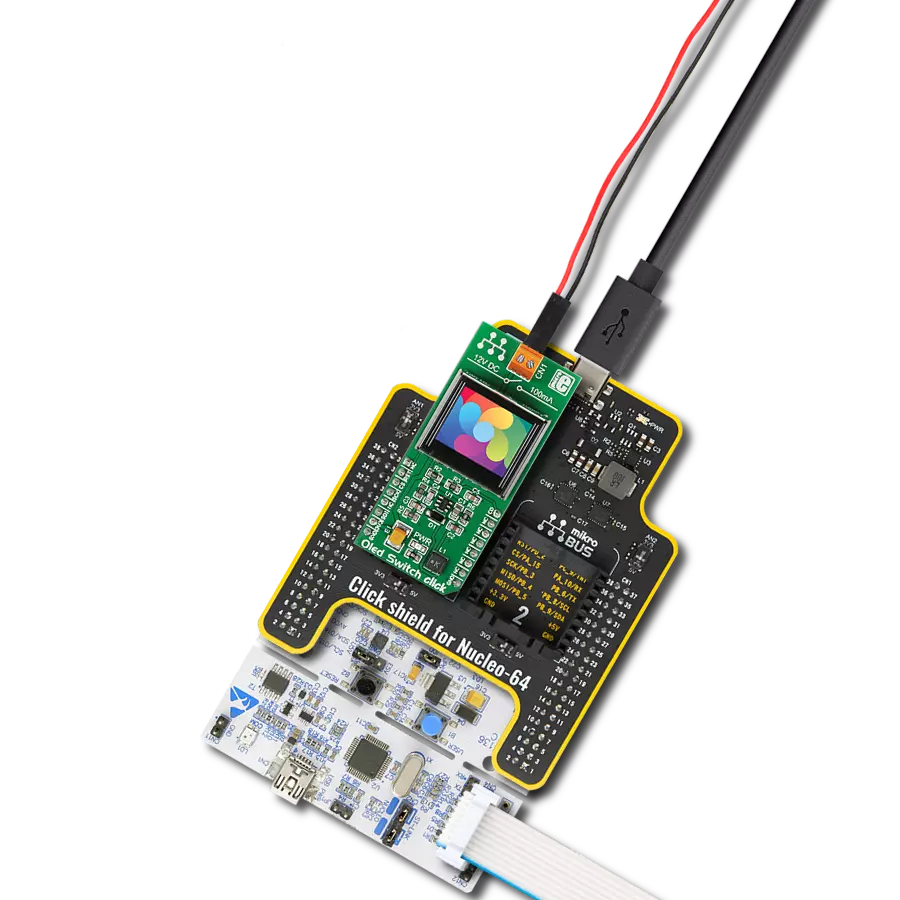

Development board

Clicker 4 for STM32F3 is a compact development board designed as a complete solution, you can use it to quickly build your own gadgets with unique functionalities. Featuring a STM32F302VCT6, four mikroBUS™ sockets for Click boards™ connectivity, power managment, and more, it represents a perfect solution for the rapid development of many different types of applications. At its core, there is a STM32F302VCT6 MCU, a powerful microcontroller by STMicroelectronics, based on the high-

performance Arm® Cortex®-M4 32-bit processor core operating at up to 168 MHz frequency. It provides sufficient processing power for the most demanding tasks, allowing Clicker 4 to adapt to any specific application requirements. Besides two 1x20 pin headers, four improved mikroBUS™ sockets represent the most distinctive connectivity feature, allowing access to a huge base of Click boards™, growing on a daily basis. Each section of Clicker 4 is clearly marked, offering an intuitive and clean interface. This makes working with the development

board much simpler and thus, faster. The usability of Clicker 4 doesn’t end with its ability to accelerate the prototyping and application development stages: it is designed as a complete solution which can be implemented directly into any project, with no additional hardware modifications required. Four mounting holes [4.2mm/0.165”] at all four corners allow simple installation by using mounting screws. For most applications, a nice stylish casing is all that is needed to turn the Clicker 4 development board into a fully functional, custom design.

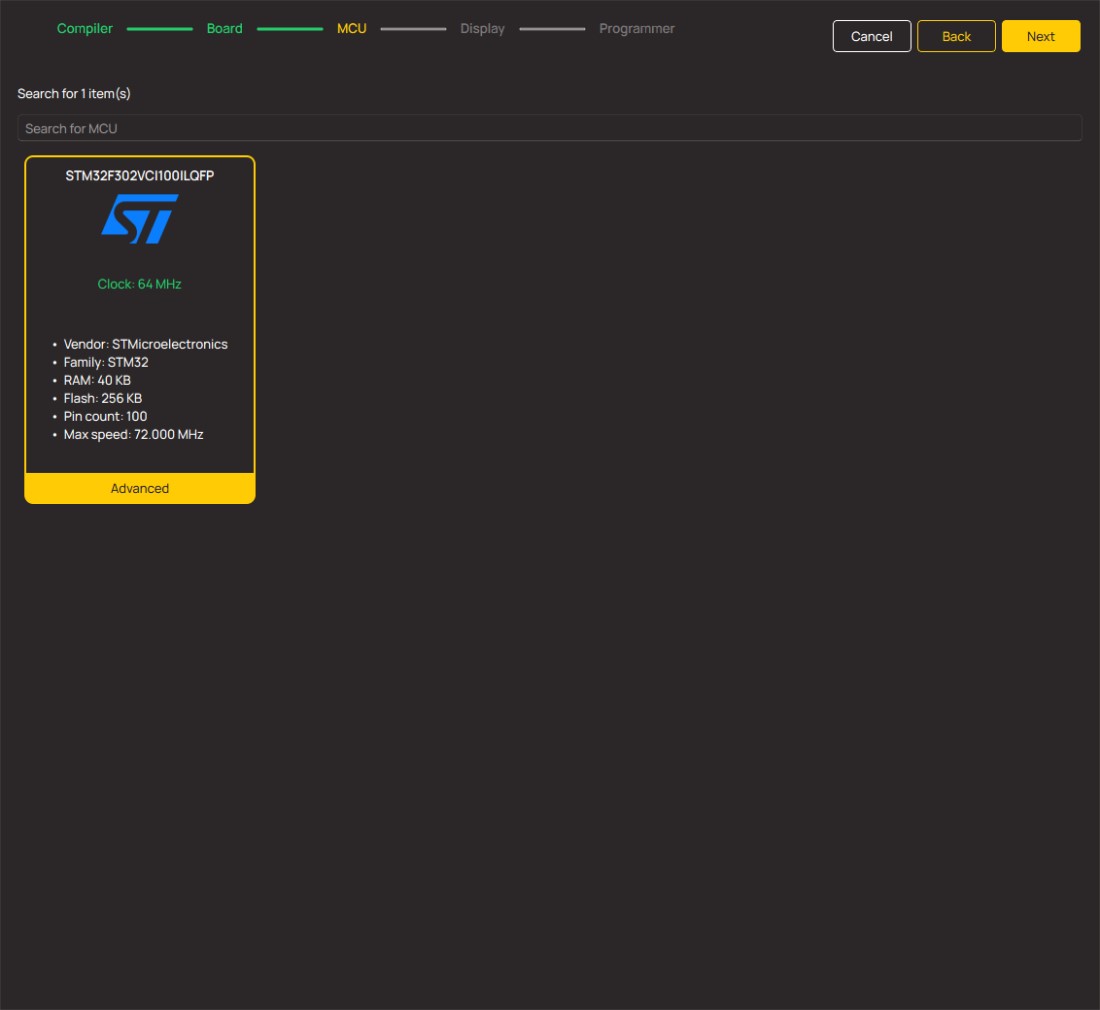

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

256

Silicon Vendor

STMicroelectronics

Pin count

100

RAM (Bytes)

40960

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

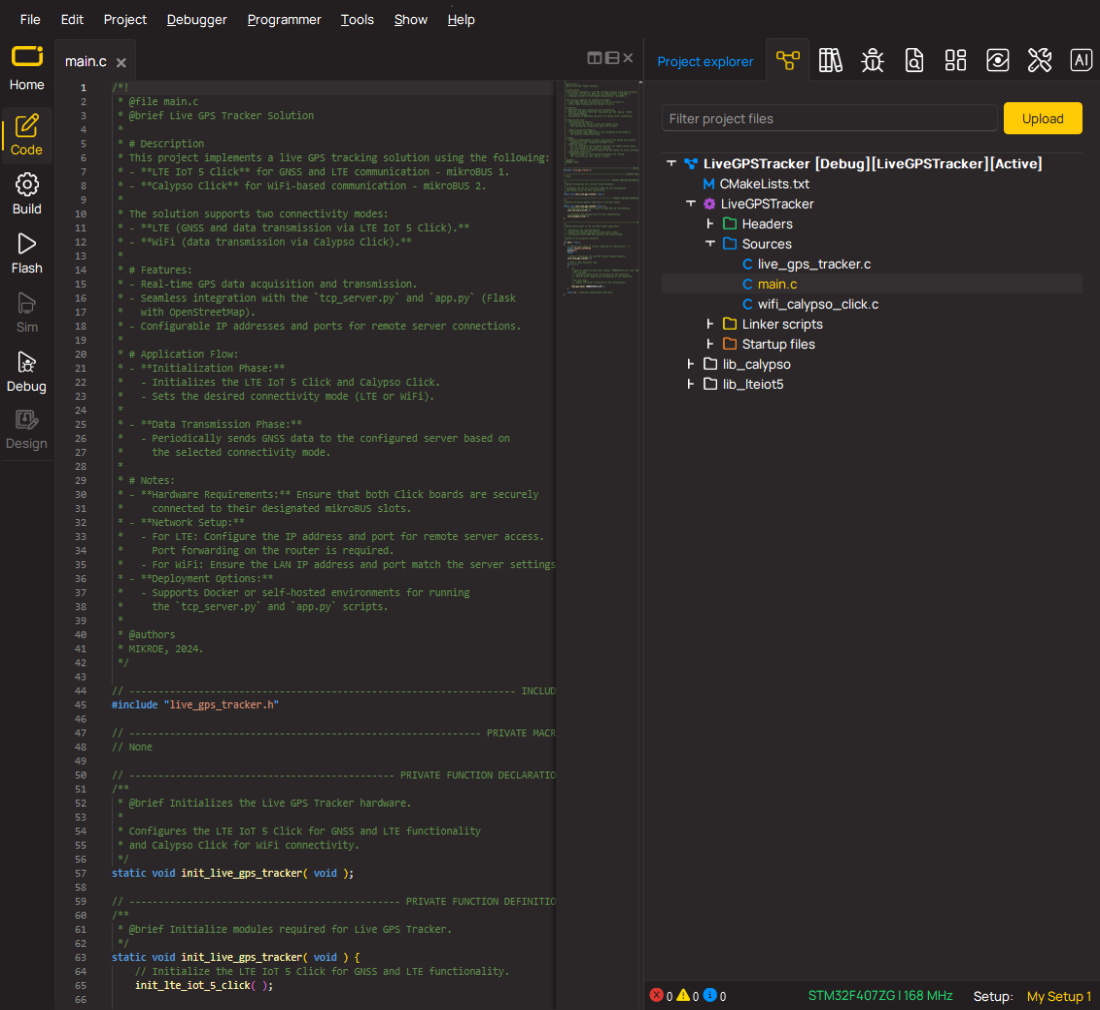

Software Support

Library Description

This library contains API for OLED B Click driver.

Key functions:

oledb_display_picture- This function allows user to display picture for on the screenoledb_clear_display- This function clears SSD1306 controller displayoledb_write_string- This function writes a text string from the selected position in a 5x7 or 6x8 font size

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief OLEDB Click example

*

# Description

* This example demonstrates the use (control) of the OLED B display.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Configures the microcontroller for communication and initializes the Click

* board to default state.

*

* ## Application Task

* This section contains the main program that is executed showing a practical

* example on how to use the implemented functions.

*

* @author MikroE Team

*

*/

#include "board.h"

#include "log.h"

#include "oledb.h"

static oledb_t oledb;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

oledb_cfg_t oledb_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

oledb_cfg_setup( &oledb_cfg );

OLEDB_MAP_MIKROBUS( oledb_cfg, MIKROBUS_1 );

err_t init_flag = oledb_init( &oledb, &oledb_cfg );

if ( ( I2C_MASTER_ERROR == init_flag ) || ( SPI_MASTER_ERROR == init_flag ) )

{

log_error( &logger, " Application Init Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

oledb_default_cfg ( &oledb );

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

oledb_clear_display( &oledb );

Delay_ms ( 100 );

oledb_write_string( &oledb, OLEDB_FONT_6X8, 0, 0, " MIKROE " );

oledb_write_string( &oledb, OLEDB_FONT_6X8, 1, 0, " OLED B Click " );

oledb_write_string( &oledb, OLEDB_FONT_6X8, 2, 0, " with SSD1306 " );

oledb_write_string( &oledb, OLEDB_FONT_6X8, 3, 0, " controller " );

oledb_write_string( &oledb, OLEDB_FONT_6X8, 4, 0, " TEST EXAMPLE " );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

oledb_write_string( &oledb, OLEDB_FONT_6X8, 0, 0, " TEXT SCROLL EXAMPLE " );

oledb_write_string( &oledb, OLEDB_FONT_6X8, 4, 0, " TEXT SCROLL EXAMPLE " );

Delay_ms ( 1000 );

oledb_scroll_right( &oledb, 4, 0 );

// 6 seconds delay

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

oledb_stop_scroll( &oledb );

oledb_clear_display( &oledb );

Delay_ms ( 100 );

oledb_display_picture( &oledb, oledb_img_mikroe );

Delay_ms ( 500 );

oledb_send_cmd( &oledb, OLEDB_INVERTDISPLAY );

Delay_ms ( 500 );

oledb_send_cmd( &oledb, OLEDB_NORMALDISPLAY );

Delay_ms ( 500 );

oledb_send_cmd( &oledb, OLEDB_INVERTDISPLAY );

Delay_ms ( 500 );

oledb_send_cmd( &oledb, OLEDB_NORMALDISPLAY );

Delay_ms ( 300 );

for ( uint8_t contrast = 0xAF; contrast > 0x00; contrast-- )

{

oledb_set_contrast( &oledb, contrast );

Delay_ms ( 5 );

}

for ( uint8_t contrast = 0x00; contrast < 0xAF; contrast++ )

{

oledb_set_contrast( &oledb, contrast );

Delay_ms ( 5 );

}

oledb_scroll_left( &oledb, 0, 4 );

Delay_ms ( 1000 );

oledb_stop_scroll( &oledb );

oledb_scroll_right( &oledb, 0, 4 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

oledb_stop_scroll( &oledb );

oledb_scroll_left( &oledb, 0, 4 );

Delay_ms ( 1000 );

oledb_stop_scroll( &oledb );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:OLED