Unlock new dimensions in distance measurement with our ToF solution, designed to enhance object detection, navigation, and spatial mapping in an array of fields

A

A

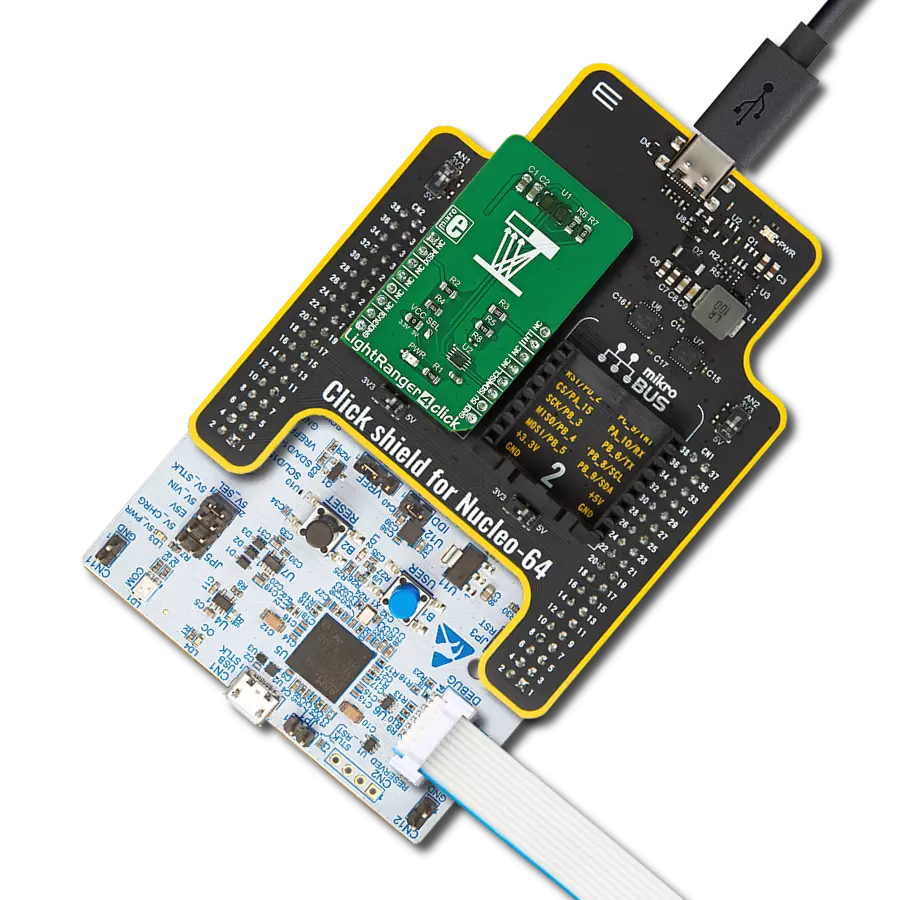

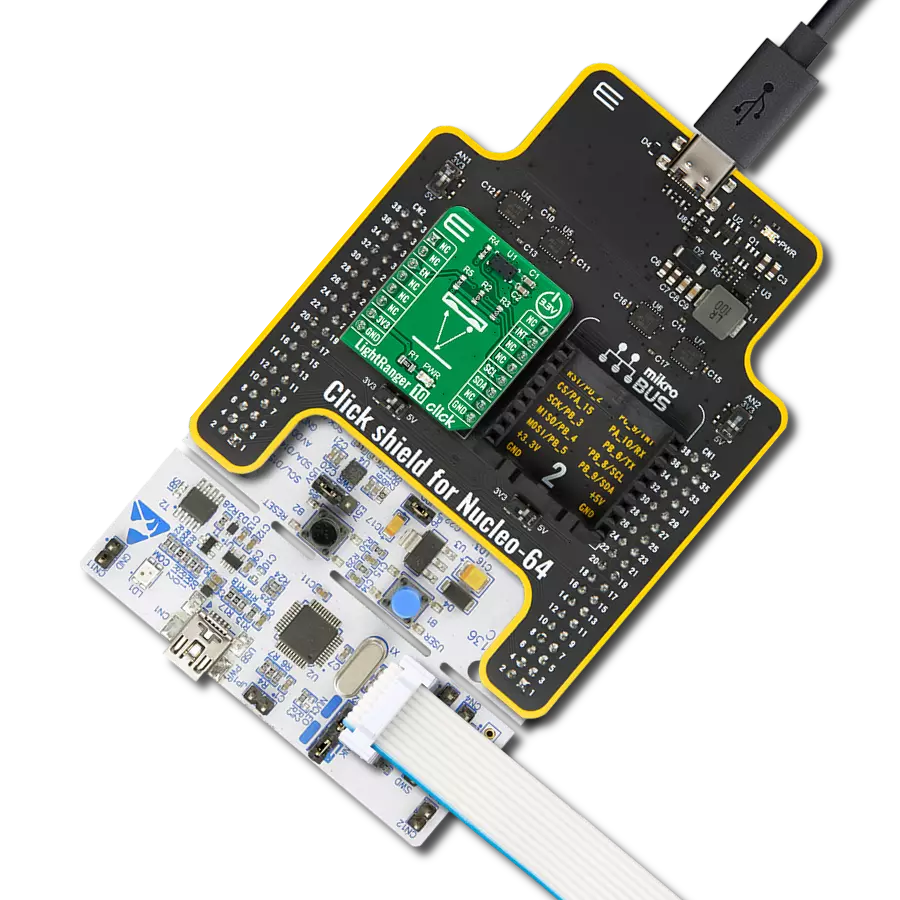

Hardware Overview

How does it work?

LightRanger 3 Click is based on the RFD77402, a ToF sensor module from RF Digital. This sensor uses the VCSE (Vertical Cavity Surface Emitting) narrowband LASER, which emits light in the range of 850 nm. The light emission is in the IR range of the spectrum and it is not visible by a human eye. It is received by the IR sensor and processed by the integrated sections of the RFD77402, giving an 11-bit result on the output register, available via the standard I2C interface. The device is rated as Class 1 LASER product, and it does not cause harmful eye injuries. However, it should not be pointed towards the eyes. The highly integrated RFD77402 ToF sensor encompasses several integrated sections. It has an embedded MCU, OTP memory, RAM area, ranging processing unit and the VCSEL driver. It exposes a simple I2C interface for the communication with the host MCU, offering a range of registers, used for configuring and status reporting. In addition, it offers an interrupt pin (INT) routed to the INT pin of the mikroBUS™.

Highly configurable interrupt engine allows this pin to be configured to generate interrupt signals for various events, alerting the host MCU about some important status changes, such as the Data Ready event, for example. It can be set to work in both open-drain configurations, as well as in the push-pull mode. The Click board™ is equipped with the 10K pull-up resistor, so it is advised to configure the INT pin in open-drain mode. The measurement is done by comparing the modulation shift of the light in the reflected beam. Therefore, the range and the accuracy depend on the material of the measured object, as well as the photo - pollution of the IR spectrum. The module is designed to suppress the noise and interference. The narrow Field of Illumination (29°) allows focused measurement and prevents beam scattering. The receiver has a bit wider Field of View (55°), allowing it to catch the reflected beam. The measurement is naturally affected by the IR reflectance of an object, so best results are

achieved when measuring the distance of the objects that have high IR reflectance. The maximum range that can be measured is 2000mm, while the minimum operational range is 100mm. The measurement error is linear, and it grows with the distance. It stays within 10% of the distance The Click board™ uses only 3.3V power rail from the mikroBUS™. No additional jumpers or selectors exist on the Click board™ since the RFD77402 ToF sensor module is highly integrated and requires a minimum number of external components to work. The RFD77402 module datasheet offers an extensive information about internal registers and how to configure them. However, the click comes with the library of functions that provide simplified operation and measurement. The use of these functions is demonstrated in the example, which can be used as the reference for custom design.

Features overview

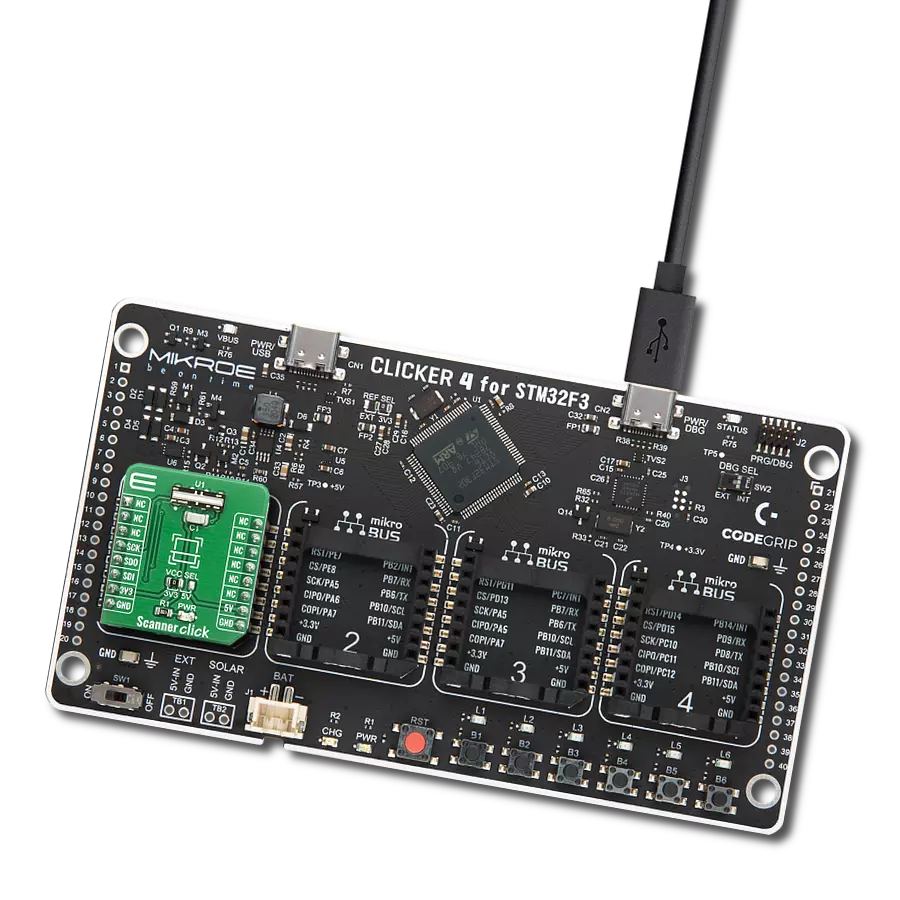

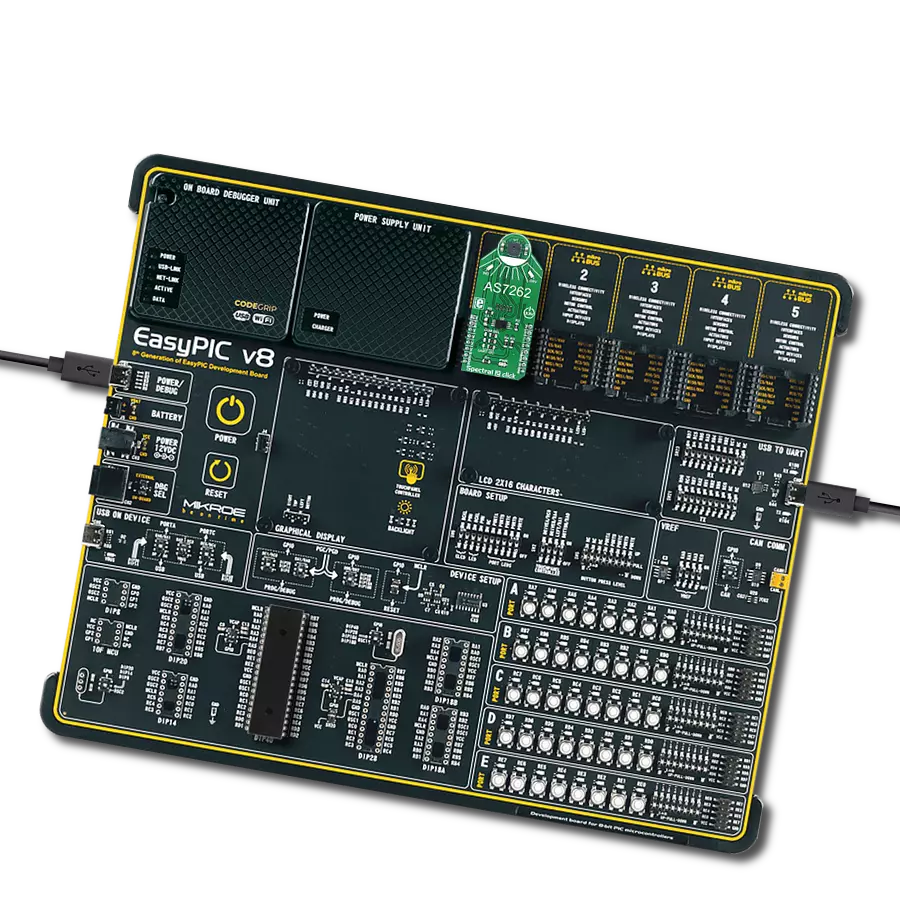

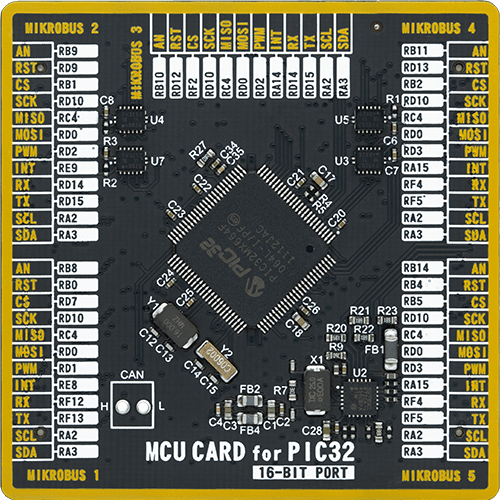

Development board

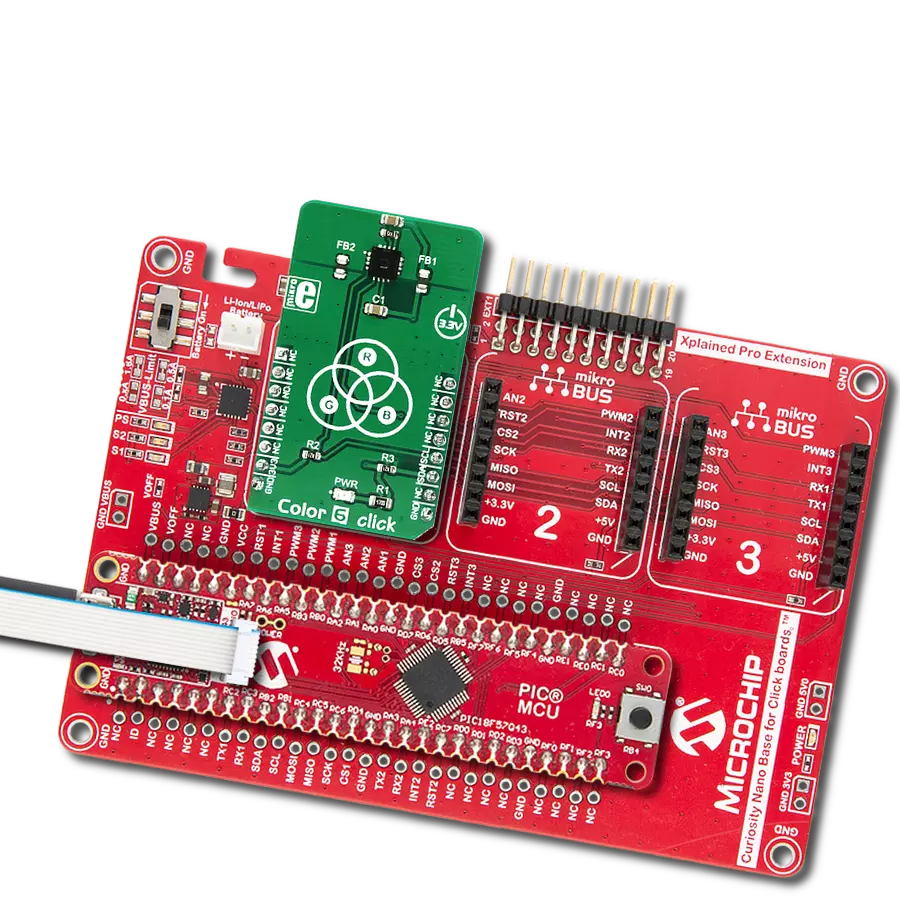

UNI-DS v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports a wide range of microcontrollers, such as different STM32, Kinetis, TIVA, CEC, MSP, PIC, dsPIC, PIC32, and AVR MCUs regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer over WiFi. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, UNI-DS v8 provides a fluid and immersive working experience, allowing access anywhere and under any

circumstances at any time. Each part of the UNI-DS v8 development board contains the components necessary for the most efficient operation of the same board. An advanced integrated CODEGRIP programmer/debugger module offers many valuable programming/debugging options, including support for JTAG, SWD, and SWO Trace (Single Wire Output)), and seamless integration with the Mikroe software environment. Besides, it also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector. Communication options such as USB-UART, USB

HOST/DEVICE, CAN (on the MCU card, if supported), and Ethernet is also included. In addition, it also has the well-established mikroBUS™ standard, a standardized socket for the MCU card (SiBRAIN standard), and two display options for the TFT board line of products and character-based LCD. UNI-DS v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

PIC32

MCU Memory (KB)

64

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

32768

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for LightRanger 3 Click driver.

Key functions:

lightranger3_set_measurement_mode- This function go to measurement modelightranger3_get_distance- This function reads distancelightranger3_get_confidence_value- This function reads confidence value.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief LightRanger3 Click example

*

* # Description

* This app precisely measure distance without making actual contact.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes driver init and configuration chip.

*

* ## Application Task

* Includes measurements, reads distance, and logs distance to USBUART for every 300 ms.

* Distance measurement at distances ranging from 100 mm to 2000 mm.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "lightranger3.h"

// ------------------------------------------------------------------ VARIABLES

static lightranger3_t lightranger3;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

lightranger3_cfg_t cfg;

uint8_t init_status;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

lightranger3_cfg_setup( &cfg );

LIGHTRANGER3_MAP_MIKROBUS( cfg, MIKROBUS_1 );

lightranger3_init( &lightranger3, &cfg );

init_status = lightranger3_device_init( &lightranger3 );

if ( init_status == 0 )

{

log_printf( &logger, " --- Device init successfully --- \r\n " );

}

else

{

log_printf( &logger, " --- Device init error --- \r\n " );

}

}

void application_task ( void )

{

uint16_t distance;

lightranger3_take_single_measurement( &lightranger3 );

distance = lightranger3_get_distance( &lightranger3 );

log_printf( &logger, "Distance = %u mm \r\n ", distance );

Delay_ms ( 300 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END