Translate physical POT adjustments into precise voltage reference outputs suitable for sensitive projects in industrial and hobbyist settings, where ease of use and reliability are paramount

A

A

Hardware Overview

How does it work?

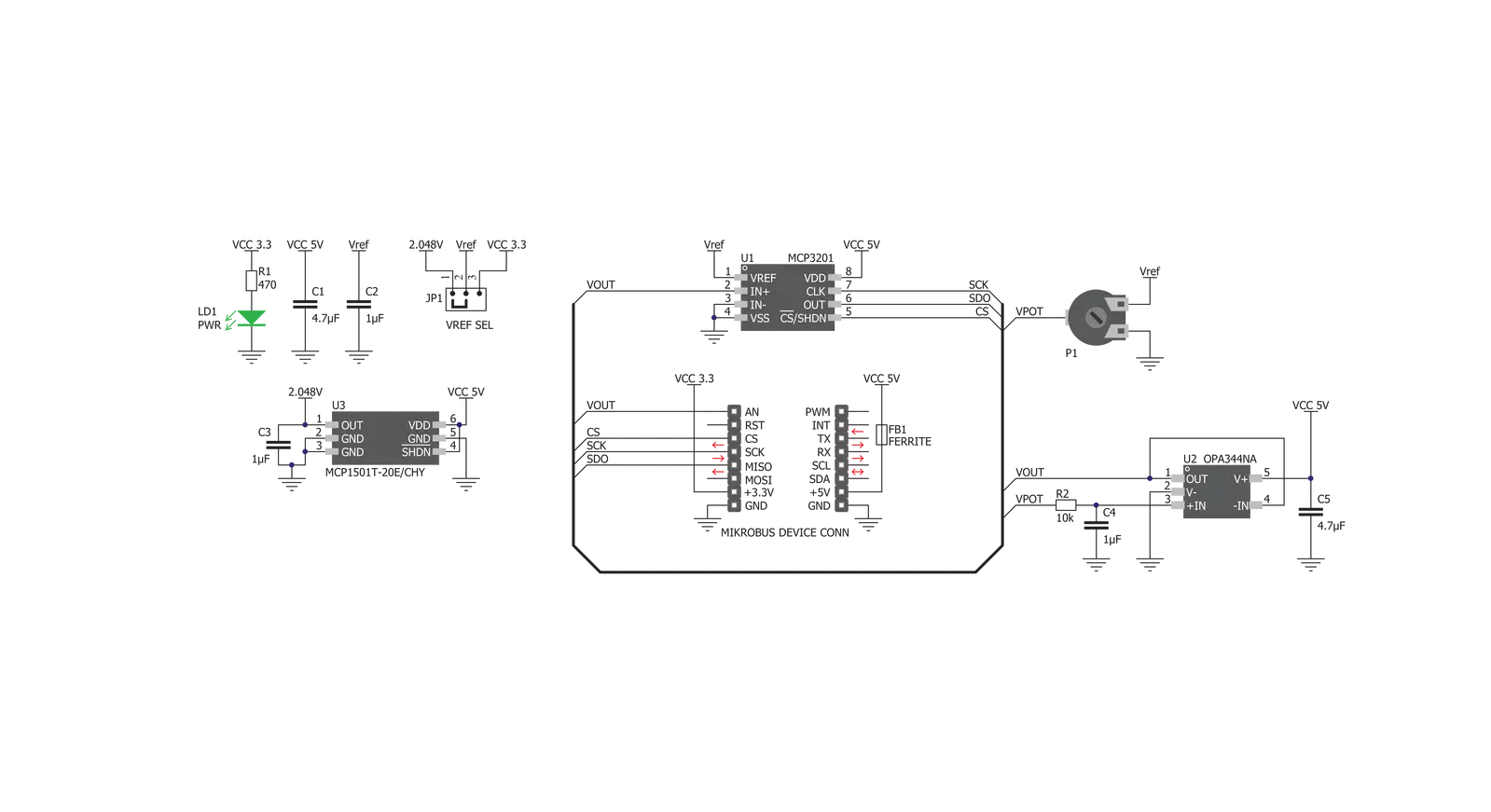

POT 3 Click is based on the MCP1501, a precision voltage reference IC from Microchip is used to provide the voltage of 2.048V. This voltage is routed to the small SMD jumper labeled as VREF SEL. By moving the jumper to the 2V position, 2.048V will be applied to one end of the potentiometer. Otherwise, the potentiometer will be connected to the 3.3V rail of the mikroBUS™. The other end of the potentiometer is tied to GND, allowing to select voltage from 0V to VREF (from 0 to 2.048V or from 0 to 3.3V ranges). The adjustable voltage is available on both AN pin of the mikroBUS™ and to the + input pin of the MCP3201. The potentiometer itself is labeled as RK1191110001. It is a high-quality potentiometer from Alps Alpine. This company is otherwise known for their high-quality electromechanical

components, used in many industries. The potentiometer has a carbon-based resistive surface with the resistance of 10 kΩ. It is a single-turn linear potentiometer, with 50% of resistance achieved when in the middle position. Its turning knob is not fixed: the potentiometer has 15mm shaft and a turning knob with the matching shape is delivered in the package with the Click board™. The output of the potentiometer is fed to the non-inverting input of the OPA344, a rail-to-rail single supply operational amplifier, from Texas Instruments. This operational amplifier is a perfect choice for this design, as it allows rail-to-rail operation, uses a single power supply of 5V, and has a stable unity gain. The OPA344 is used as a buffer, providing a constant input and output impedance. Without buffer, variable impedance

would affect the reference voltage. The reference voltage IC can provide less than 10 mA, with the significant voltage drop for output currents exceeding 2 mA. Therefore, the OPA344 ensures good stability of the circuit. The second section of this click board™ consists of the MCP3201 IC, a well known 12-bit ADC from Microchip. The potentiometer end terminals are connected between GND and the VREF, while the buffered voltage from the wiper is connected to the IN+ pin of the MCP3201. VREF is also connected to the reference voltage input pin of the MCP3201. That way, the whole range of the ADC is always used, regardless the chosen VREF voltage. The MCP3201 has its SPI lines routed to the mikroBUS™ so that the values can be read easily by the MCU.

Features overview

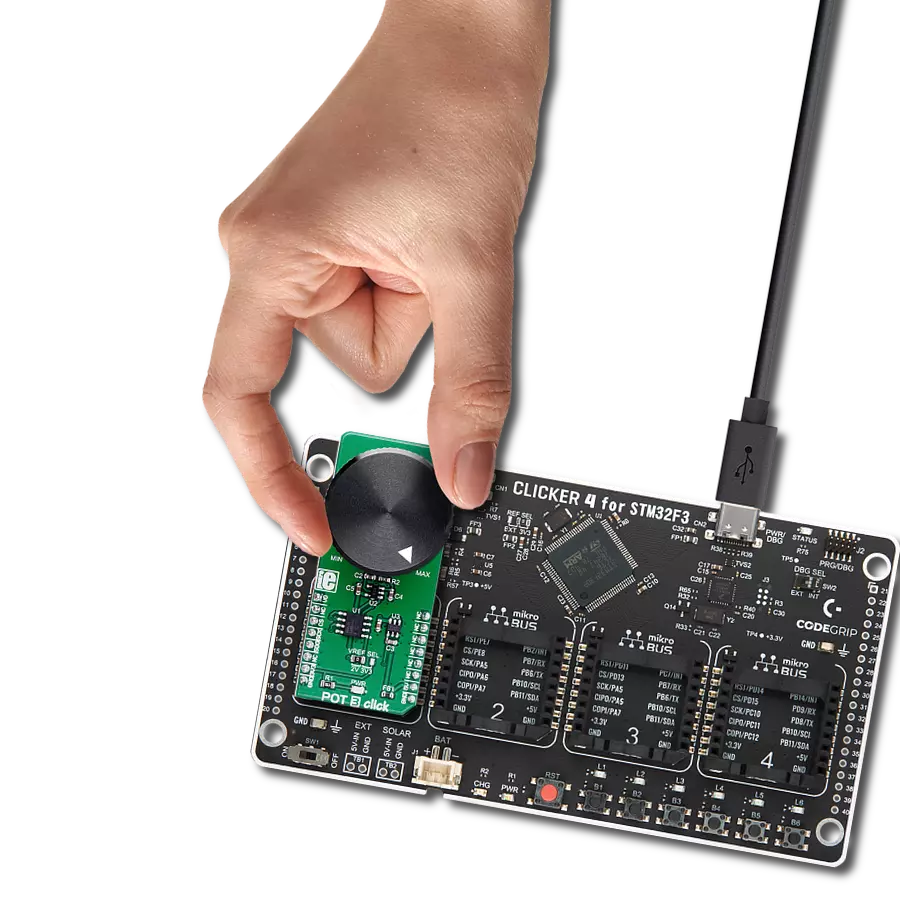

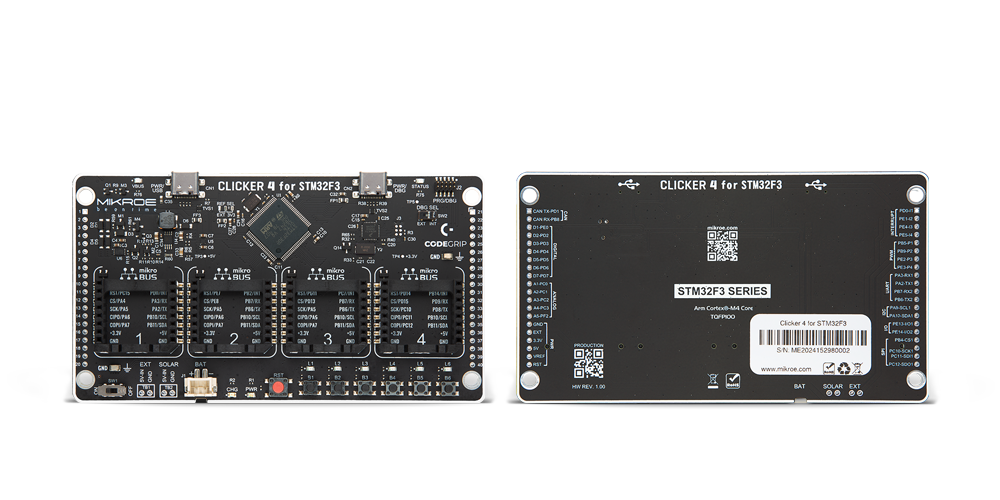

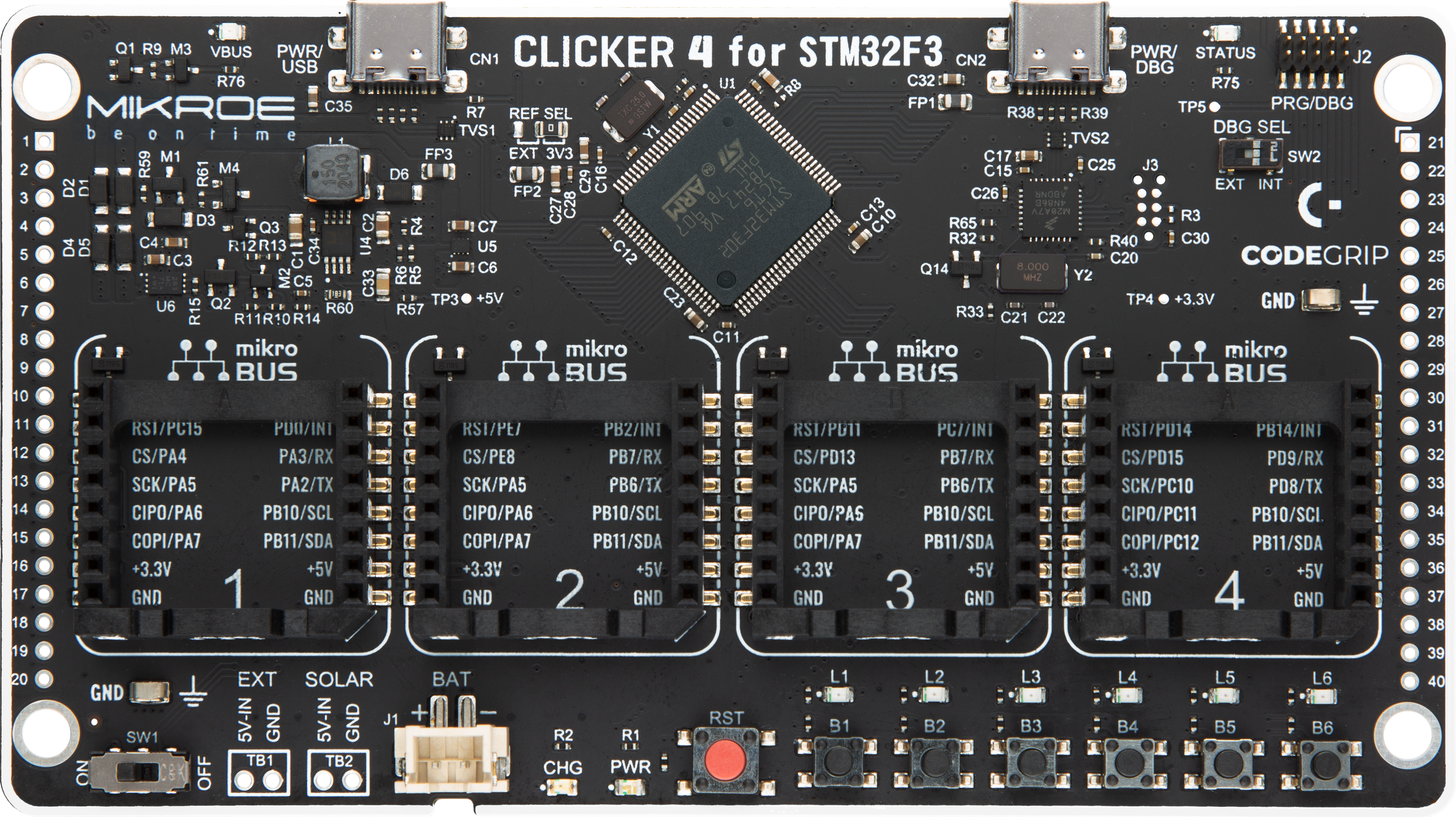

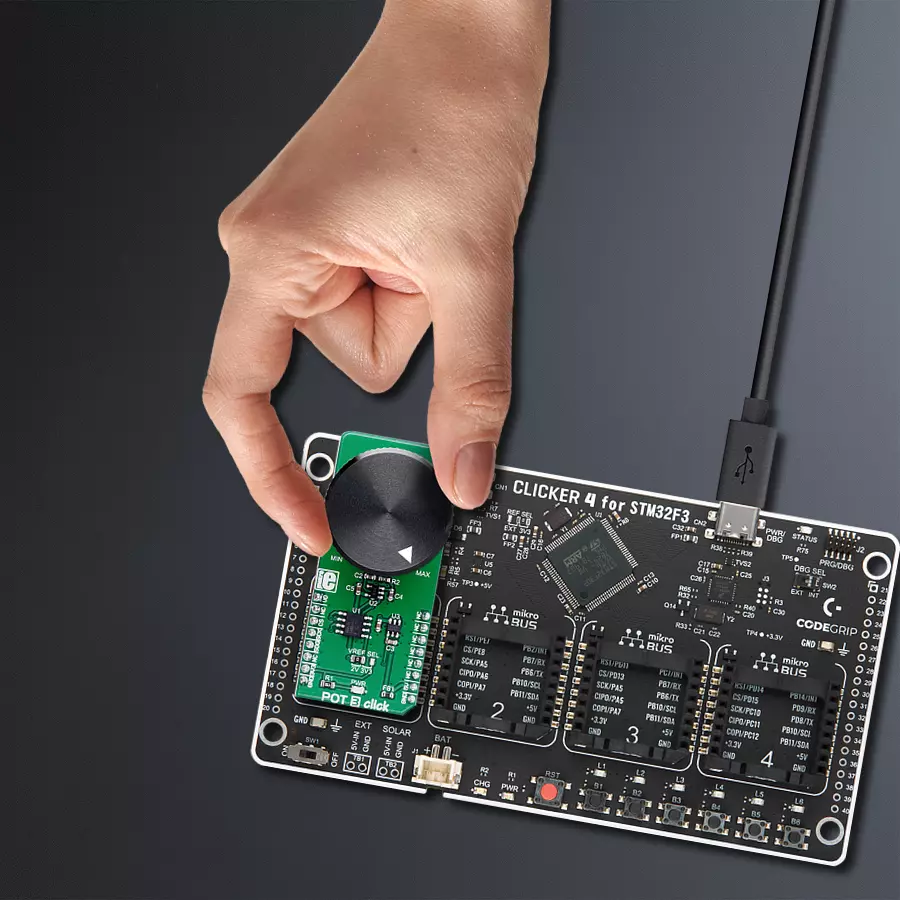

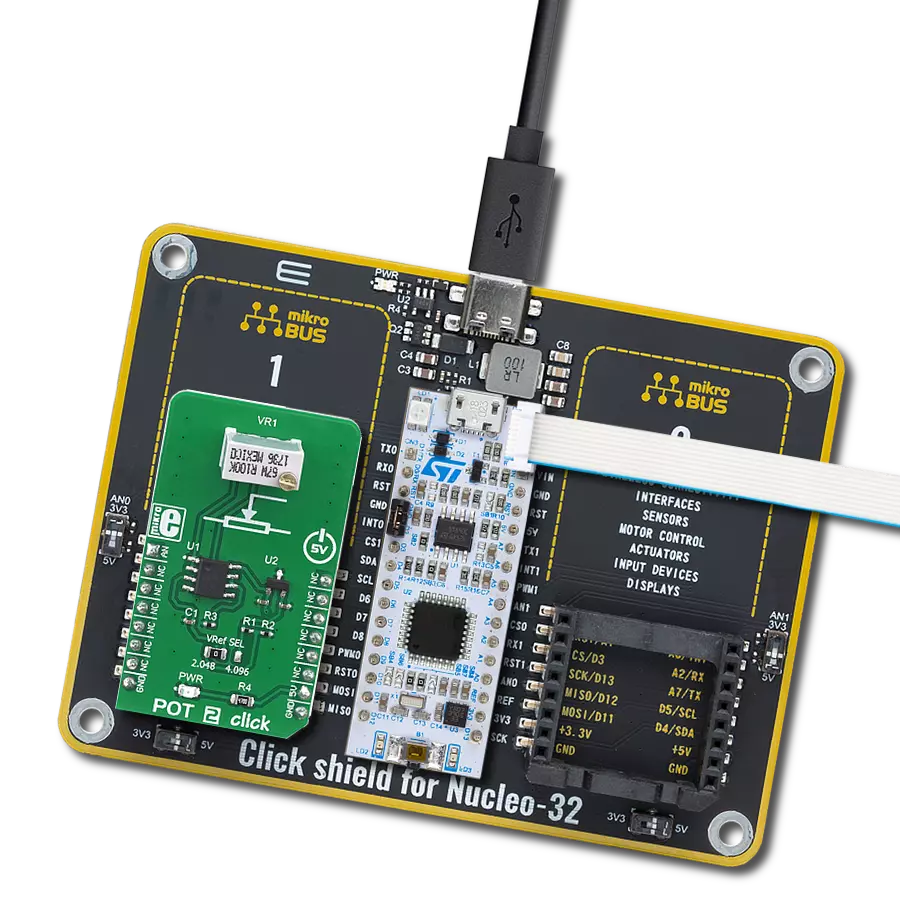

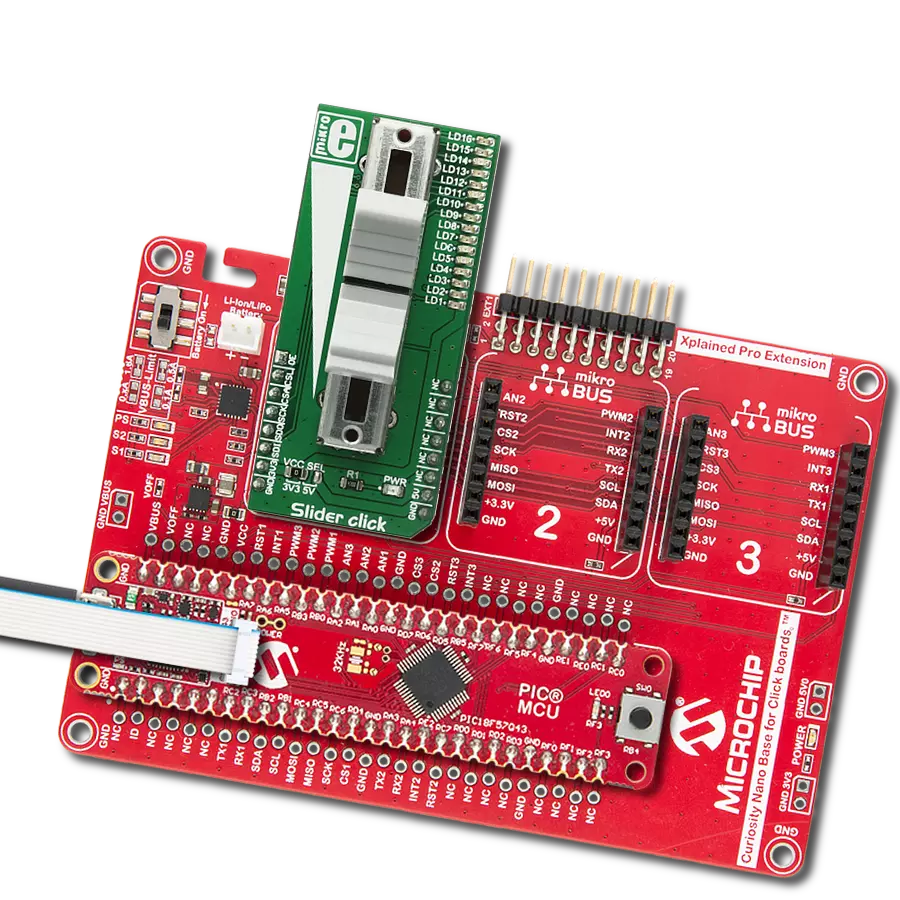

Development board

Clicker 4 for STM32F3 is a compact development board designed as a complete solution, you can use it to quickly build your own gadgets with unique functionalities. Featuring a STM32F302VCT6, four mikroBUS™ sockets for Click boards™ connectivity, power managment, and more, it represents a perfect solution for the rapid development of many different types of applications. At its core, there is a STM32F302VCT6 MCU, a powerful microcontroller by STMicroelectronics, based on the high-

performance Arm® Cortex®-M4 32-bit processor core operating at up to 168 MHz frequency. It provides sufficient processing power for the most demanding tasks, allowing Clicker 4 to adapt to any specific application requirements. Besides two 1x20 pin headers, four improved mikroBUS™ sockets represent the most distinctive connectivity feature, allowing access to a huge base of Click boards™, growing on a daily basis. Each section of Clicker 4 is clearly marked, offering an intuitive and clean interface. This makes working with the development

board much simpler and thus, faster. The usability of Clicker 4 doesn’t end with its ability to accelerate the prototyping and application development stages: it is designed as a complete solution which can be implemented directly into any project, with no additional hardware modifications required. Four mounting holes [4.2mm/0.165”] at all four corners allow simple installation by using mounting screws. For most applications, a nice stylish casing is all that is needed to turn the Clicker 4 development board into a fully functional, custom design.

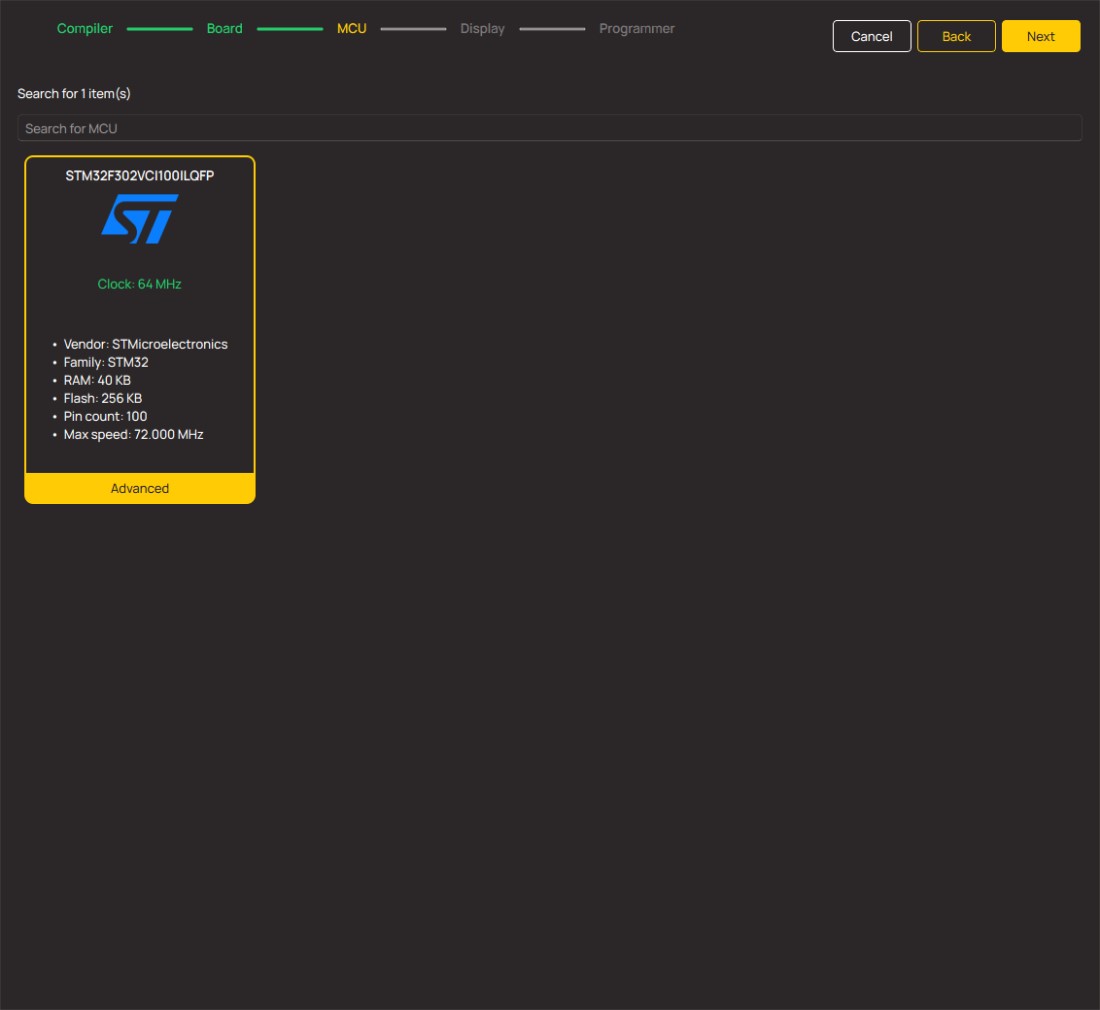

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

256

Silicon Vendor

STMicroelectronics

Pin count

100

RAM (Bytes)

40960

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

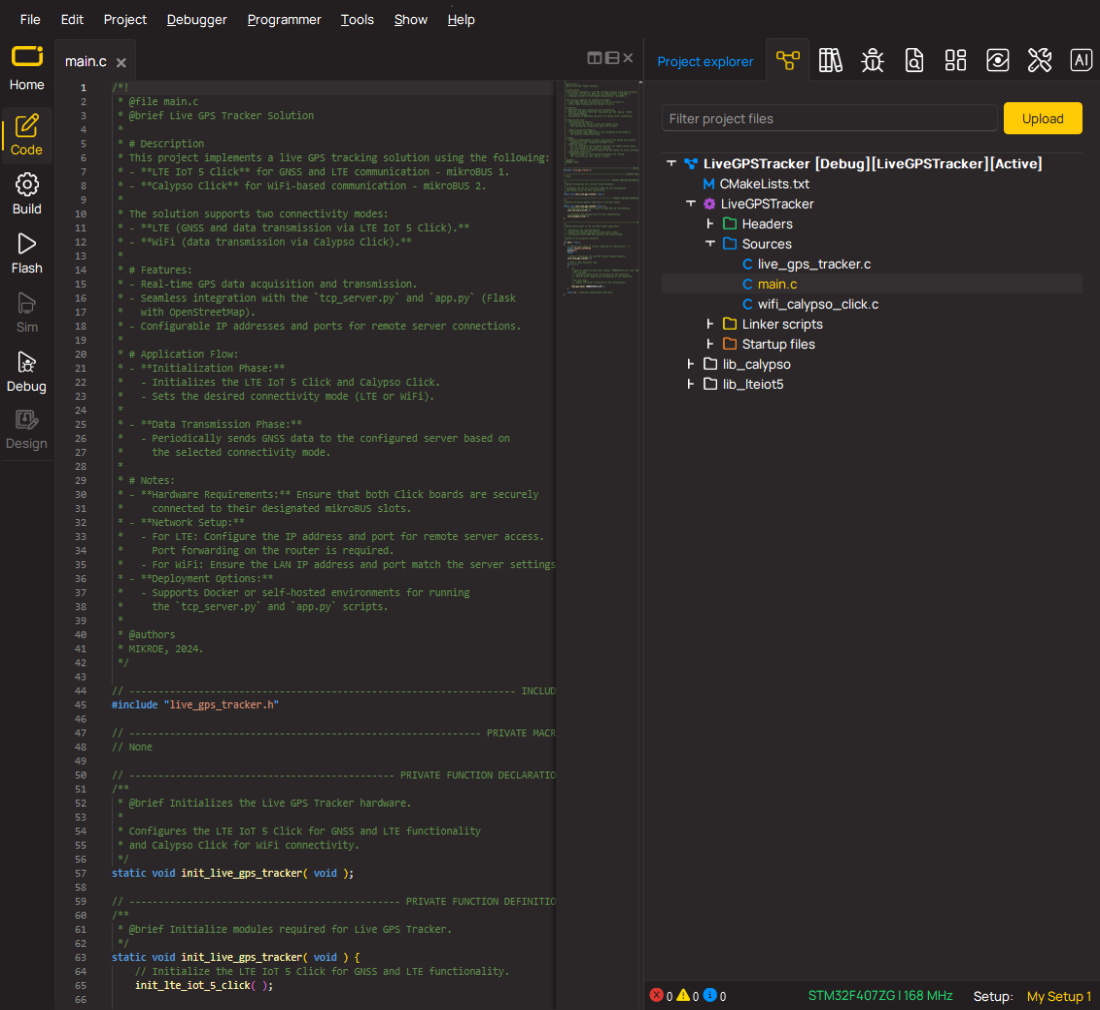

Software Support

Library Description

This library contains API for POT 3 Click driver.

Key functions:

pot3_read_adc- This function reads the result of AD conversionpot3_read_avg_adc- This function reads the averaged result of AD conversionspot3_get_vout- This function returns VOUT value calculated to millivolts

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Pot3 Click example

*

* # Description

* This application reads voltage value, calculates it to millivolts and then

* logs it to the uart terminal.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes devices module.

*

* ## Application Task

* Reads VOUT value calculated to millivolts with 2000 conversions

* included in one measurement cycle.

*

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "pot3.h"

// ------------------------------------------------------------------ VARIABLES

static pot3_t pot3;

static log_t logger;

static uint16_t voltage_mv;

static uint16_t voltage_old;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

pot3_cfg_t pot3_cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

pot3_cfg_setup( &pot3_cfg );

POT3_MAP_MIKROBUS( pot3_cfg, MIKROBUS_1 );

pot3_init( &pot3, &pot3_cfg );

voltage_old = 0;

}

void application_task ( void )

{

voltage_mv = pot3_get_vout( &pot3, POT3_VREF_2V, 2000);

if (voltage_mv != voltage_old)

{

log_printf(&logger, " VOUT : %d mV\r\n", voltage_mv);

}

voltage_old = voltage_mv;

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Potentiometers