Experience the magic of proximity sensing, a gateway to a world where convenience and innovation coexist

A

A

Hardware Overview

How does it work?

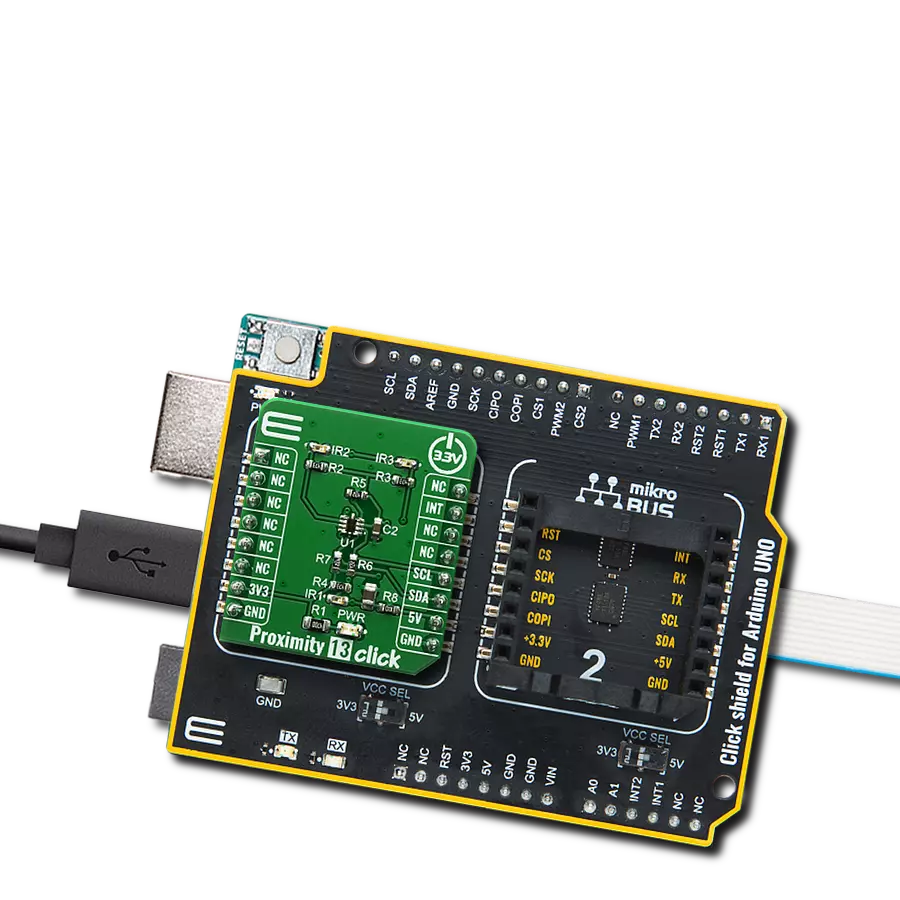

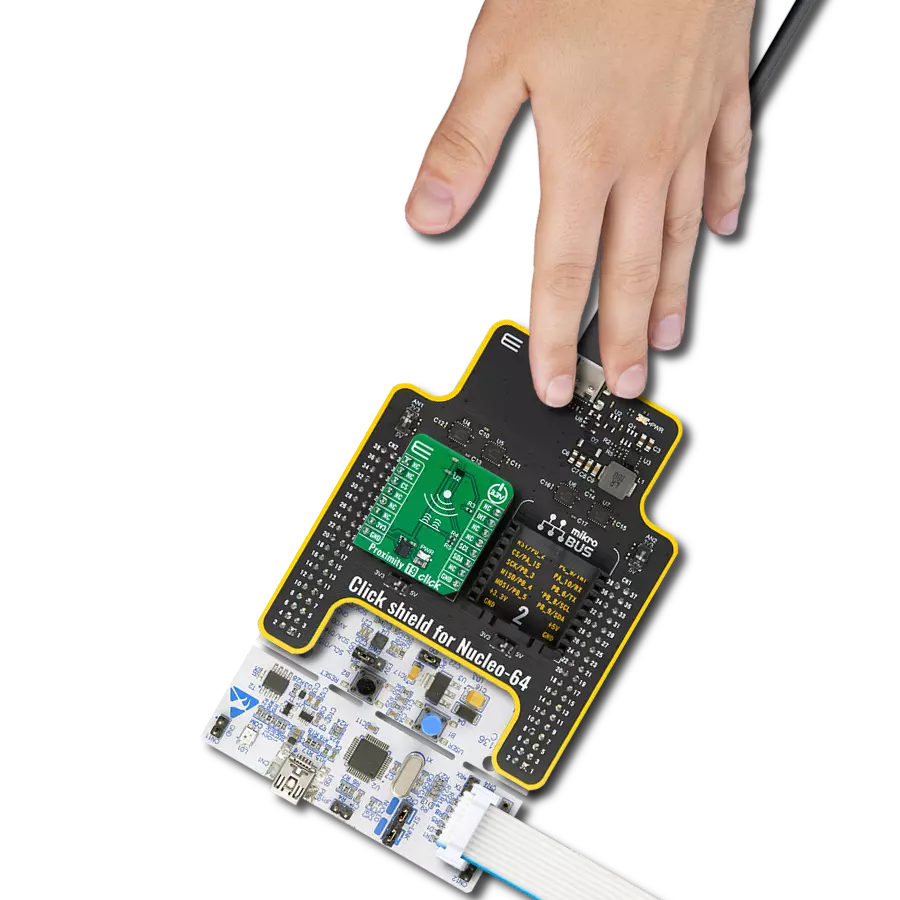

Proximity 13 Click is based on the Si1153, a touchless sensor IC from Silicon Labs that includes dual 23-bit analog-to-digital converters, an integrated high-sensitivity array of visible and infrared photodiodes, a digital signal processor, and three integrated LED drivers with programmable drive levels. The photodiode response and associated digital conversion circuitry provide excellent immunity to artificial light flicker noise and natural light flutter noise. By default, the measurement parameters are optimized for indoor ambient light levels, where it is possible to detect low light levels. For operation under direct sunlight, the ADC can be programmed to operate in a high signal operation so that it is possible to measure direct sunlight without overflowing. The Proximity 13 click is capable of measuring visible and infrared light. However, the visible photodiode is also influenced by infrared light. The measurement of illuminance requires the same spectral response as the human

eye. If an accurate lux measurement is desired, the extra IR response of the visible-light photodiode must be compensated. Therefore, to allow the host to make corrections to the infrared light’s influence, SI1153-AB09-GMR reports the infrared light measurement on a separate channel. The separate visible and IR photodiodes lend themselves to a variety of algorithmic solutions. The host can then take these two measurements and run an algorithm to derive an equivalent lux level as perceived by a human eye. Having the IR correction algorithm running in the host allows for the most flexibility in adjusting for system-dependent variables. For example, if the glass used in the system blocks visible light more than infrared light, the IR correction needs to be adjusted. Over distances of less than 50 cm, the dual-port active reflection proximity detector has significant advantages over single-port, motion-based infrared systems, which are only good for triggered events. Motion-based infrared detectors

identify objects within proximity, but only if they are moving. Single-port motion-based infrared systems are ambiguous about stationary objects even if they are within the proximity field. The Proximity 13 click can reliably detect an object entering or exiting a specified proximity field, even if the object is not moving or is moving very slowly. However, beyond about 30–50 cm, even with good optical isolation, single-port signal processing may be required due to static reflections from nearby objects, such as tables, walls, etc. If motion detection is acceptable, the SI1153-AB09-GMR can achieve ranges of up to 50 cm, through a single product window. Since the three infrared LEDs are placed in an L-shaped configuration, it is possible to triangulate an object within the three-dimensional proximity field. Thus, a touchless user interface can be implemented with the aid of host software.

Features overview

Development board

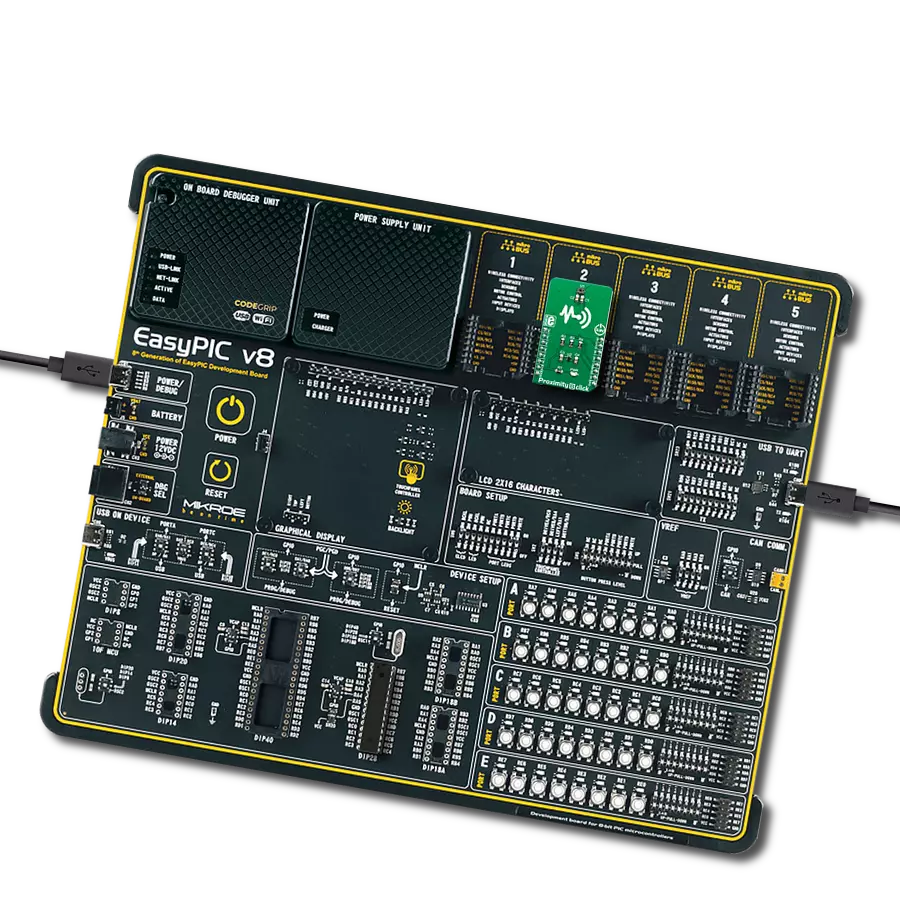

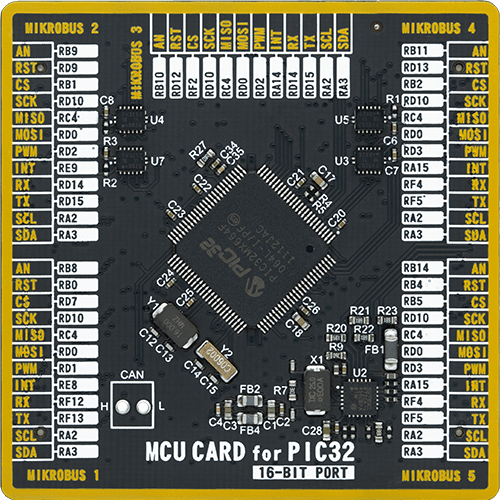

Fusion for PIC32 v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports a wide range of Microchip's PIC32 microcontrollers regardless of their number of pins and a broad set of unique functions, such as the first-ever embedded debugger/programmer over WiFi. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, Fusion for PIC32 v8 provides a fluid and immersive working experience, allowing access anywhere and under any circumstances at any time. Each part of the

Fusion for PIC32 v8 development board contains the components necessary for the most efficient operation of the same board. In addition to the advanced integrated CODEGRIP programmer/debugger module, which offers many valuable programming/debugging options and seamless integration with the Mikroe software environment, the board also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector. Communication options such as USB-UART, USB HOST/DEVICE, CAN (on the MCU card, if

supported), and Ethernet is also included. In addition, it also has the well-established mikroBUS™ standard, a standardized socket for the MCU card (SiBRAIN standard), and two display options for the TFT board line of products and character-based LCD. Fusion for PIC32 v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

PIC32

MCU Memory (KB)

64

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

32768

Used MCU Pins

mikroBUS™ mapper

Take a closer look

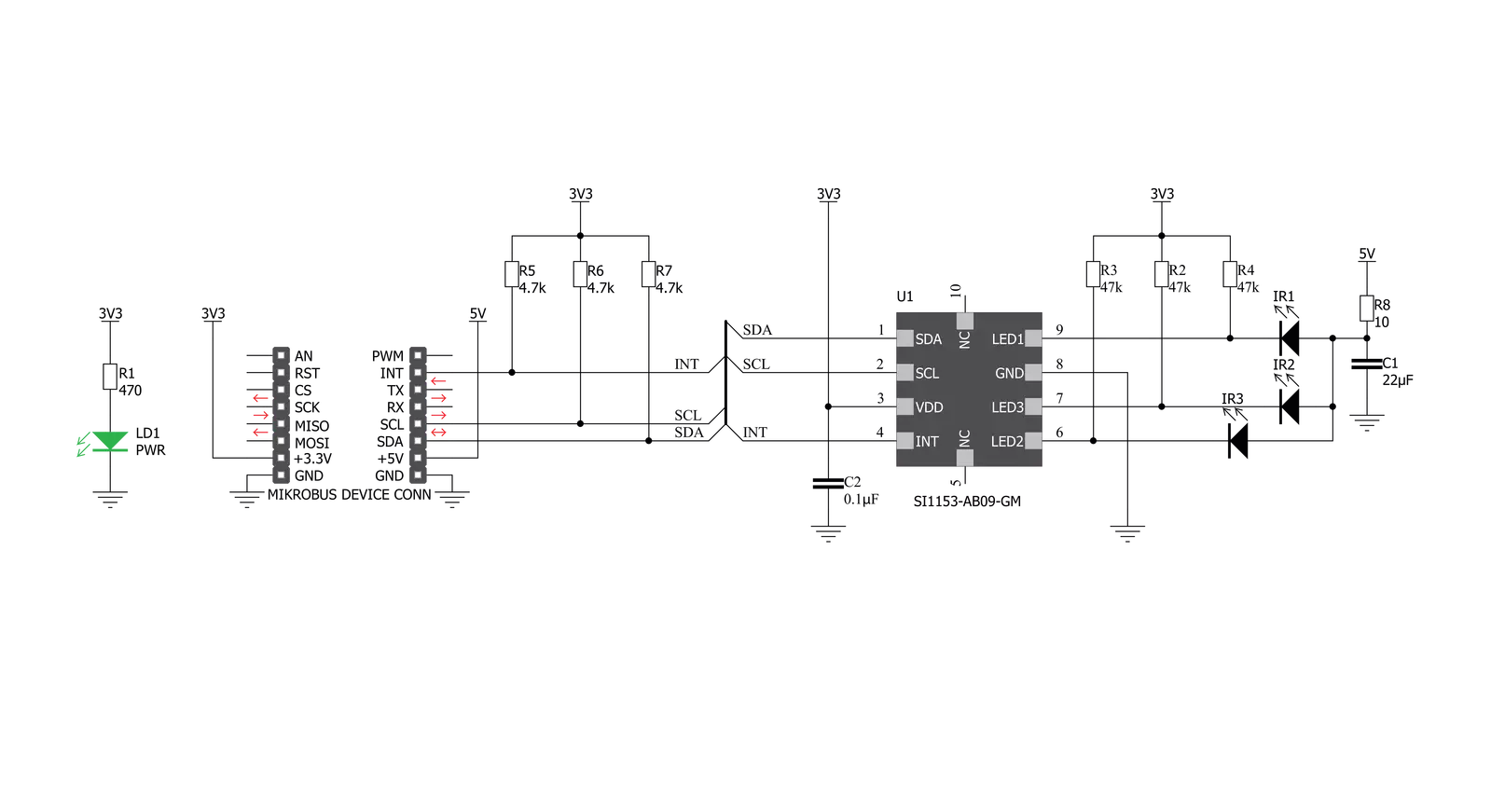

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Proximity 13 Click driver.

Key functions:

proximity13_generic_write- This function writes data to the desired register.proximity13_generic_read- This function reads data from the desired register.proximity13_read_channels- This function reads all enabled channels.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Proximity13 Click example

*

* # Description

* This demo application shows example for measuring close distance

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization of I2C module and additional pin, checks id of device,

* configurates device for measuring 1. channel,

* and then sends command to start measuring

*

* ## Application Task

* Appliction measures values every 100ms and logs result

*

* \author Luka Filipovic

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "proximity13.h"

// ------------------------------------------------------------------ VARIABLES

static proximity13_t proximity13;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

proximity13_cfg_t cfg;

uint8_t status;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

proximity13_cfg_setup( &cfg );

PROXIMITY13_MAP_MIKROBUS( cfg, MIKROBUS_1 );

proximity13_init( &proximity13, &cfg );

status = proximity13_get_int_pin_status( &proximity13 );

while ( status != PROXIMITY13_PIN_HIGH );

status = porximity13_check_id( &proximity13 );

if ( status == PROXIMITY13_OK )

{

log_info( &logger, " Device OK" );

}

else

{

log_info( &logger, " Device Error" );

for ( ; ; );

}

log_info( &logger, " Setting default configuration" );

proximity13_default_cfg ( &proximity13 );

proximity13_send_command( &proximity13, PROXIMITY13_CMD_START );

log_info( &logger, " Starting measurement" );

}

void application_task ( void )

{

proximity13_chn_val_t chn_val;

proximity13_read_channels( &proximity13, &chn_val );

log_printf( &logger, " Data : %lu\r\n", chn_val.channel_1 );

Delay_ms ( 100 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Proximity