Safeguard delicate signals from potential harm, such as electrical noise or voltage fluctuations, ensuring they reach their destination intact and unaltered.

A

A

Hardware Overview

How does it work?

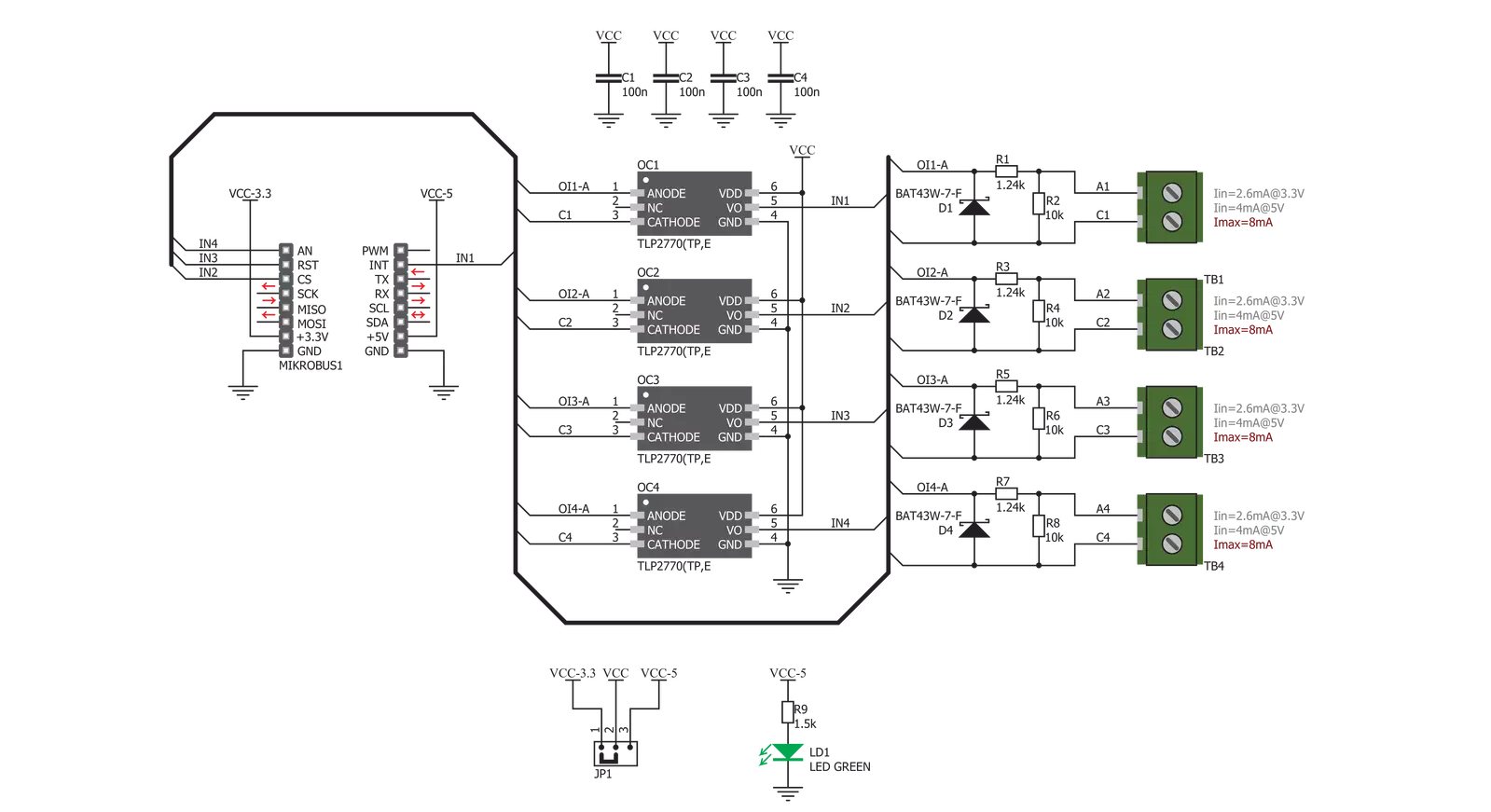

Opto 2 Click is based on four TLP2770, 20Mbps low-power optocouplers from Toshiba Semiconductor. These are fast optocouplers, with their output stages shielded against EMI, allowing them to work on higher speeds, providing common-mode transient immunity of ±20 kV/μs. The internal LED elements are driven with 4mA for 5V operation or 2.6mA for 3.3V operation. The input stages are also equipped with (Schottky) diodes, which prevents inverse polarization of the LED elements and thus, a permanent damage that might occur in that case. The working principle of the optocouplers is quite simple: A photo-emitting element - usually a LED, is encapsulated inside the die along with the photo-sensitive element, which can be a photo-sensitive transistor or a photo-diode. LEDs and photo-sensing elements are galvanically isolated, making the input and output electrical networks completely independent of each other. When the LED is biased, it emits light which in return causes the current to flow through

the photo-sensitive element. In these particular optocouplers, the output stage is additionally conditioned by a Schmitt trigger and it drives the output transistors which form a totem pole output stage. Having a totem pole output configuration allows the output stage to both sink and source current. The optocoupler inputs - the anodes (labeled as A) and cathodes (labeled as C) of the internal optocoupler LEDs, are routed to the screw terminals, which allow connection the external electrical circuit, used to trigger an event on the isolated MCU. The electrical potential between the anode and the cathode input of each optocoupler element should stay within the range between 3.3V and 5V. The optocoupler outputs are routed to the mikroBUS™ The mikroBUS™ pins INT, CS, RST, and AN, are routed to the optocoupler outputs 1, 2, 3, and 4, respectively, and are labeled as IN1, IN2, IN3, and IN4. As already mentioned, the output stages are conditioned with the Schmitt trigger circuit, reducing the input noise sensitivity

and false triggering. The Faraday shield protects the output stages against EMI and provides common-mode transient immunity of ±20 kV/μs. Although these mikroBUS™ pins are labeled as IN1 to IN4, they are actually outputs from the optocouplers, and it is highly recommended to use them as the INPUT pins on the host MCU. The Click board™ is equipped with an SMD jumper labeled as LOGIC, which allows selection of the voltage, applied to the optocoupler output stage. This voltage effectively determines the logic voltage level for the MCU pins. It can be selected between 3.3V and 5V, allowing this Click board™ to be interfaced with both 3.3V and 5V MCUs. The provided library offers functions that simplify and speed up the application development. The included example application demonstrates their use. This application can be used as a reference for custom projects.

Features overview

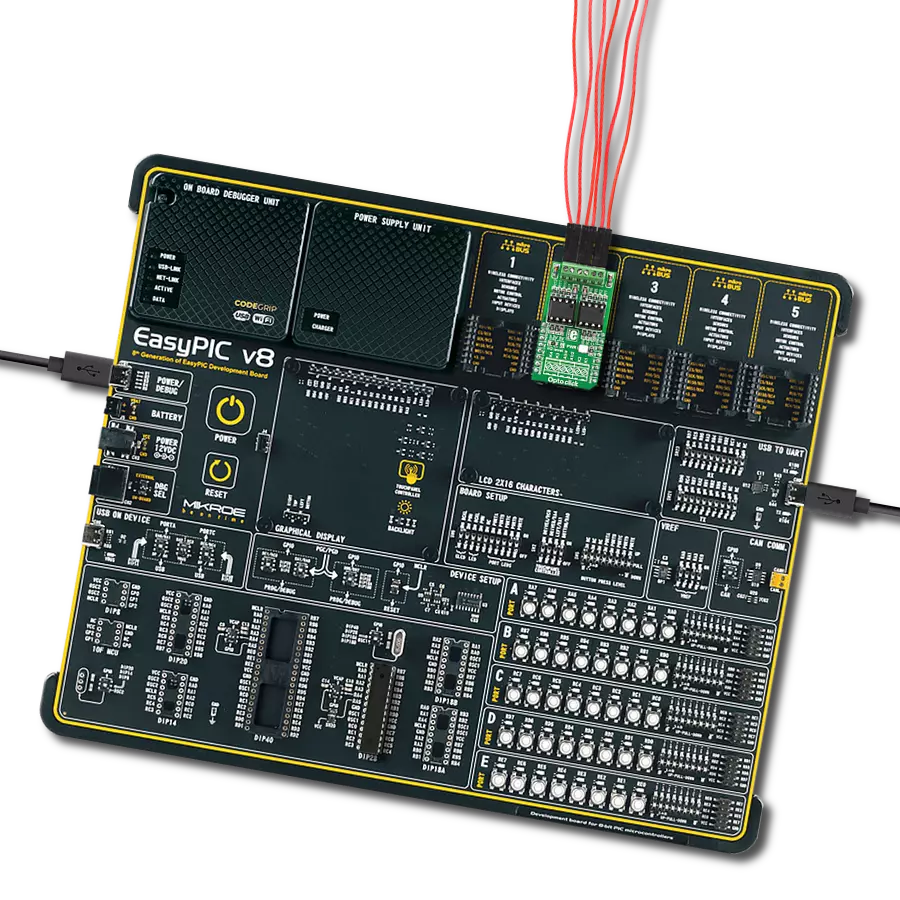

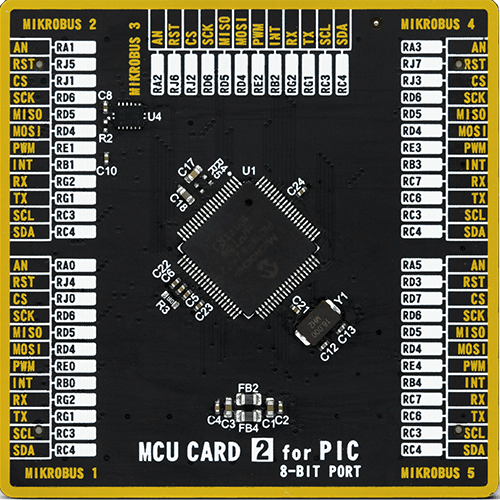

Development board

Fusion for PIC v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports a wide range of microcontrollers, such as different PIC, dsPIC, PIC24, and PIC32 MCUs regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer over WiFi. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, Fusion for PIC v8 provides a fluid and immersive working experience, allowing access anywhere and under any

circumstances at any time. Each part of the Fusion for PIC v8 development board contains the components necessary for the most efficient operation of the same board. In addition to the advanced integrated CODEGRIP programmer/debugger module, which offers many valuable programming/debugging options and seamless integration with the Mikroe software environment, the board also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector. Communication options such as USB-UART, USB

HOST/DEVICE, CAN (on the MCU card, if supported), and Ethernet are also included, including the well-established mikroBUS™ standard, a standardized socket for the MCU card (SiBRAIN standard), and two display options (graphical and character-based LCD). Fusion for PIC v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

PIC

MCU Memory (KB)

128

Silicon Vendor

Microchip

Pin count

80

RAM (Bytes)

3904

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Opto 2 Click driver.

Key functions:

opto2_check_out1- OUT1 Check functionopto2_check_out2- OUT2 Check functionopto2_check_out3- OUT3 Check function

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Opto 2 Click example

*

* # Description

* This application used to provide an optical isolation of sensitive microcontroller.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes device selects the outputs (OUT1 - OUT4) which state be checked.

*

* ## Application Task

* Performs the check procedure for selected outputs and logs the states from that

outputs on USB UART. Repeat the check procedure every 2 seconds.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "opto2.h"

// ------------------------------------------------------------------ VARIABLES

static opto2_t opto2;

static log_t logger;

static uint8_t sel_output;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void opto2_set_logger ( uint8_t sel_out1, uint8_t sel_out2, uint8_t sel_out3, uint8_t sel_out4 )

{

if ( sel_out1 > 1 )

{

sel_out1 = 1;

}

if ( sel_out2 > 1 )

{

sel_out2 = 1;

}

if ( sel_out3 > 1 )

{

sel_out3 = 1;

}

if ( sel_out4 > 1 )

{

sel_out4 = 1;

}

sel_output = 0;

sel_output |= sel_out1;

sel_output |= sel_out2 << 1;

sel_output |= sel_out3 << 2;

sel_output |= sel_out4 << 3;

}

void application_init ( void )

{

log_cfg_t log_cfg;

opto2_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

opto2_cfg_setup( &cfg );

OPTO2_MAP_MIKROBUS( cfg, MIKROBUS_1 );

opto2_init( &opto2, &cfg );

log_info( &logger, "---- Application Init ----" );

opto2_set_logger( 1, 1, 0, 0 );

log_printf( &logger, "OPTO 2 is initialized \r\n" );

log_printf( &logger, "" );

Delay_ms ( 200 );

}

void application_task ( void )

{

uint8_t check_output;

uint8_t cnt;

uint8_t tmp;

tmp = 1;

for ( cnt = 0; cnt < 4; cnt++ )

{

switch ( sel_output & tmp )

{

case 0x01 :

{

check_output = opto2_check_out1( &opto2 );

if ( check_output == 0 )

{

log_printf( &logger, "OUT1 is low\r\n" );

}

else

{

log_printf( &logger, "OUT1 is high\r\n" );

}

break;

}

case 0x02 :

{

check_output = opto2_check_out2( &opto2 );

if ( check_output == 0 )

{

log_printf( &logger, "OUT2 is low\r\n" );

}

else

{

log_printf( &logger, "OUT2 is high\r\n" );

}

break;

}

case 0x04 :

{

check_output = opto2_check_out3( &opto2 );

if ( check_output == 0 )

{

log_printf( &logger, "OUT3 is low\r\n" );

}

else

{

log_printf( &logger, "OUT3 is high\r\n" );

}

break;

}

case 0x08 :

{

check_output = opto2_check_out4( &opto2 );

if ( check_output == 0 )

{

log_printf( &logger, "OUT4 is low\r\n" );

}

else

{

log_printf( &logger, "OUT4 is high\r\n" );

}

break;

}

default :

{

break;

}

}

tmp <<= 1;

}

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END